Académique Documents

Professionnel Documents

Culture Documents

Dehumidification Application: Ehumidification in The Arine Ndustry

Transféré par

pothirajkalyanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Dehumidification Application: Ehumidification in The Arine Ndustry

Transféré par

pothirajkalyanDroits d'auteur :

Formats disponibles

Dehumidification Application

The choice for

desiccant dehumidification®

® Reg. TM Bry-Air (Asia) Pvt. Ltd.

Dehumidification

in the Marine

Industry

Bry-Air environmental control

systems allow for consistent

control to efficiently prevent the

effects of moisture damage in the

marine industry.

Photo Courtesy of MCT Direct Photos

H

umidity problems in the exporters. The time lag between avoid humidity related delays,

marine industry are a a ship arriving at the port with a contamination and loss of business.

constant battle. Moisture particular cargo and leaving with

causes damage during new another is getting shorter and Ocean going vessels such as oil rigs

construction, attacks vulnerable shorter. At the same time there and oil tankers are often stored for

interior surfaces during is also a demand that the ships long periods of time during which

sandblasting, damages engine parts holds are clean and dry before they frequently become damaged

and causes millions of dollars worth a new cargo is loaded. These due to corrosion. Dehumidification

of damage to moisture sensitive concerns, coupled with the fact can effectively eliminate corrosion

cargo. that weather conditions are rarely and prevent millions of dollars in

perfect for efficient and quick drying maintenance and refurbishing costs.

Better quality and faster shipping of tanks and holds, means that

periods are being demanded today today’s shipping companies must All sandblasting and coating/painting

as more and more new markets are consider desiccant dehumidification operations must utilize 100% fresh

being tapped by manufacturers and as the most efficient option to air for safety reasons. The presence

of moisture in the air can cause

rusting (blushing) and adhesion

problems in the application of the

coating. Again, dehumidification

eliminates these problems and

speeds up the process. Controlled

dry air maintains a clean surface,

free from condensation, for optimal

corrosion prevention.

Another humidity concern is the fact

that cargo has a tendency to “sweat”

when it is colder than the humid

air in the cargo hold. As a result it

can condense moisture from the

air resulting in rust spots, stained

Photo Courtesy of MCT Direct Photos

labels, dull finish and soggy cartons. Whether in storage, dry-dock, or at

This is particularly true of moisture sea, Bry-Air dehumidifiers reduce

sensitive cargoes such as tobacco, humidity levels inside the ship

fine chemicals, coils, aluminum and resulting in:

steel sheet, furniture, canned goods,

cocoa, coffee beans, etc.. The use • Prevention of damage to

of a Bry-Air desiccant dehumidifier sensitive mechanical and

to dry the cargo hold will completely electronic equipment.

eliminate these problems and allow • Elimination of corrosion of

the ship to arrive in port with the stored components and machine

cargo dry and intact. parts in shaft galleys and pipe

galleries.

It is recommended that the following • Reduction in drying time of ship

areas of the ship utilize dry air from holds.

the dehumidification process: • Prevention of cargo damage due

to excessive humidity.

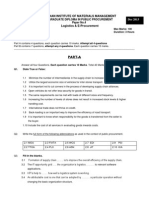

1. Cargo Holds/Tanks

2. Machinery/Engine Room Bry-Air has supplied many

3. Living Quarters dehumidifiers to the marine industry

4. Midship Deck House and military for ship mothballing,

5. Pump Room equipment storage, sandblasting,

6. Steering Room/Bridge coating, and cargo hold drying.

Normally one air change every five

hours is recommended in the design

conditions of 40% RH. A rule of

thumb calculation is:

Total Cubic Feet = Dehumidifier CFM

300 Required

Using the above formula, the

dehumidifier will take about three

weeks to dry the ship to design

conditions after which the unit only

has to run 2-3 hours per day to

maintain conditions.

For more information on Bry-Air’s products and services please visit www.bry-air.com

Bry-Air, Inc. - 10793 St. Rt. 37 W. Sunbury, Ohio 43074 - P: 740.965.2974 - F: 740.965.5470 - E: bryair1@bry-air.com

Vous aimerez peut-être aussi

- Dehumidification During Coating Operations: Art Pedroza, JR., James D. Graham, and Richard W. DriskoDocument6 pagesDehumidification During Coating Operations: Art Pedroza, JR., James D. Graham, and Richard W. DriskoNgô Trung NghĩaPas encore d'évaluation

- Dehumidifiers: Take Control of Humidity and Condensation With Our Leading Range of DehumidifiersDocument8 pagesDehumidifiers: Take Control of Humidity and Condensation With Our Leading Range of Dehumidifiersmustafa elfatihPas encore d'évaluation

- April 2015-Vacuum Drying Chem Eng PDFDocument9 pagesApril 2015-Vacuum Drying Chem Eng PDFAlvaro BarbozaPas encore d'évaluation

- Brochure - E - Manufacturing - Power - TDSDocument3 pagesBrochure - E - Manufacturing - Power - TDSGaurav GoyalPas encore d'évaluation

- Masterclass 52 - DemudificationDocument7 pagesMasterclass 52 - DemudificationsofyangunawanPas encore d'évaluation

- Solid Desiccant Dehumidification and Regeneration Techniques: September 2017Document6 pagesSolid Desiccant Dehumidification and Regeneration Techniques: September 2017VeekhThorPas encore d'évaluation

- DryingDocument9 pagesDryingrushi777Pas encore d'évaluation

- Fis AirDocument4 pagesFis AirAmir ZeidabadiPas encore d'évaluation

- Pure Performance: Dehumidification and Drying For Industrial and Commercial ApplicationsDocument24 pagesPure Performance: Dehumidification and Drying For Industrial and Commercial ApplicationsipraoPas encore d'évaluation

- Ventilation of Cargo HoldsDocument3 pagesVentilation of Cargo HoldsHarman SandhuPas encore d'évaluation

- Calorex DehumidifiersDocument8 pagesCalorex DehumidifiersrogerchetcutiPas encore d'évaluation

- Temp 1 PDFDocument15 pagesTemp 1 PDFmaddukuri jagadeesh babuPas encore d'évaluation

- Corrosion of Aircrafts - A Case Study in Mauritius: Kunal Boodhun, and B.Y.R. SurnamDocument6 pagesCorrosion of Aircrafts - A Case Study in Mauritius: Kunal Boodhun, and B.Y.R. SurnamAyin AhuninPas encore d'évaluation

- Terjemahan PLBDocument154 pagesTerjemahan PLBshindy sekendari br sembiringPas encore d'évaluation

- Chapter 20Document19 pagesChapter 20Shujaat Hussain KharmangiPas encore d'évaluation

- Dehumidification Equipment Advance ASHRAE Journal PDFDocument6 pagesDehumidification Equipment Advance ASHRAE Journal PDFThomás ArévaloPas encore d'évaluation

- TDS 202 Dura ProofDocument2 pagesTDS 202 Dura ProofGhulam WaheedPas encore d'évaluation

- Dehumidification Application: S G C MDocument1 pageDehumidification Application: S G C MYolanda PerezPas encore d'évaluation

- A New Drying Application For Garment LeatherDocument7 pagesA New Drying Application For Garment LeatherandryeazanzPas encore d'évaluation

- Dehumidification: Desiccant Based Definitions Options Technologies Equipment ApplicationsDocument7 pagesDehumidification: Desiccant Based Definitions Options Technologies Equipment ApplicationsBogdanBPas encore d'évaluation

- Des Case Evolution Breathers WhitePaperDocument10 pagesDes Case Evolution Breathers WhitePaperdiegogsouzzaPas encore d'évaluation

- Application Meat Processing HaccpDocument2 pagesApplication Meat Processing HaccpbjaabdouPas encore d'évaluation

- ApplyingDHEquipment Rev1610-03Document2 pagesApplyingDHEquipment Rev1610-03Thein Tun AungPas encore d'évaluation

- Dehumidifier Studies PDFDocument18 pagesDehumidifier Studies PDFabhinav prPas encore d'évaluation

- Transportation of CementDocument13 pagesTransportation of CementKaustubh Joshi100% (1)

- How To Choose Refrig or Desiccant DryersDocument4 pagesHow To Choose Refrig or Desiccant Dryersian007papagPas encore d'évaluation

- Preventing Moisture PBE March2017Document5 pagesPreventing Moisture PBE March2017tonPas encore d'évaluation

- Silicones para Manutenção em Isoladores OutdoorDocument4 pagesSilicones para Manutenção em Isoladores OutdoorSergio SachtPas encore d'évaluation

- Moisture in ElectronicsDocument4 pagesMoisture in ElectronicsSolehah JasmeePas encore d'évaluation

- High Velocity Air Filtration System For Marine LM2500 Gas TurbineDocument9 pagesHigh Velocity Air Filtration System For Marine LM2500 Gas TurbineZakaria ZelmatPas encore d'évaluation

- FMT2021 01Document41 pagesFMT2021 01dabuserPas encore d'évaluation

- Molecular Sieve 13XDocument2 pagesMolecular Sieve 13Xkanu PatelPas encore d'évaluation

- IPPTA 104-49-59 Innovative Steam ShowerDocument11 pagesIPPTA 104-49-59 Innovative Steam ShowerAmri ZalPas encore d'évaluation

- Container Sweat and Condensation CargoDocument31 pagesContainer Sweat and Condensation Cargobuddhansamrat100% (1)

- Drying Technology Trends and ApplicationDocument10 pagesDrying Technology Trends and ApplicationvodounnouPas encore d'évaluation

- Buren in 2007Document5 pagesBuren in 2007MoqaPas encore d'évaluation

- CGDF en 20 0Document4 pagesCGDF en 20 0shakaw shaPas encore d'évaluation

- Carpet Cleaning - Wikipedia, The Free EncyclopediaDocument6 pagesCarpet Cleaning - Wikipedia, The Free EncyclopediaviahulPas encore d'évaluation

- Factory Dehydrating, Charging, and TestingDocument7 pagesFactory Dehydrating, Charging, and TestingLuis Carlos PardoPas encore d'évaluation

- Breathable GarmentsDocument7 pagesBreathable Garmentsmarikaki12Pas encore d'évaluation

- Preservation ProcedureDocument61 pagesPreservation Procedureshetty259641Pas encore d'évaluation

- Corrosion 3L T Apr 07 PDFDocument4 pagesCorrosion 3L T Apr 07 PDFBarathPas encore d'évaluation

- Soft Gelatin Capsule ManufacturingDocument1 pageSoft Gelatin Capsule Manufacturingmelimaulani-1Pas encore d'évaluation

- Gardner Denver - GDX Modular Adsorption DryersDocument16 pagesGardner Denver - GDX Modular Adsorption DryerskuraimundPas encore d'évaluation

- Hull Performance Management and Biosecurity by Cleaning: Shipbuilding & EquipmentDocument3 pagesHull Performance Management and Biosecurity by Cleaning: Shipbuilding & Equipmentargentum19619692Pas encore d'évaluation

- Performance Comparison of New and Conventional Water RepellentsDocument6 pagesPerformance Comparison of New and Conventional Water RepellentsQuyen Tran Thi AnhPas encore d'évaluation

- Air DryerDocument21 pagesAir DryerGeorgiPas encore d'évaluation

- Dryer DesignDocument39 pagesDryer DesignPrashanth Chidambaram75% (4)

- The Misconceptions of Silica GelDocument6 pagesThe Misconceptions of Silica GelShofi MuktianaPas encore d'évaluation

- Cargo Ventilation and Precautions To Minimise Sweat West of England P&I ClubDocument4 pagesCargo Ventilation and Precautions To Minimise Sweat West of England P&I ClubEmma100% (1)

- Handout 4.4-Common Drying MethodsDocument4 pagesHandout 4.4-Common Drying MethodsWilli De Barros GonçalvesPas encore d'évaluation

- D-Fog System Description - Donaldson PDFDocument8 pagesD-Fog System Description - Donaldson PDFUdhayakumar VenkataramanPas encore d'évaluation

- Conditioning of Steam & Air NotesDocument22 pagesConditioning of Steam & Air Notesbonginkosi mathunjwaPas encore d'évaluation

- Trojosky2019 PDFDocument21 pagesTrojosky2019 PDFHector CabezasPas encore d'évaluation

- HVACDocument3 pagesHVACDavid MartinPas encore d'évaluation

- TDS CP 1 CapaStuccoDocument3 pagesTDS CP 1 CapaStuccoMearg NgussePas encore d'évaluation

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceD'EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssurancePas encore d'évaluation

- The Fabrication of Materials: Materials TechnologyD'EverandThe Fabrication of Materials: Materials TechnologyÉvaluation : 5 sur 5 étoiles5/5 (1)

- Corrosion and Fouling Control in Desalination IndustryD'EverandCorrosion and Fouling Control in Desalination IndustryPas encore d'évaluation

- New Welding Technologies in The ShipbuildingDocument2 pagesNew Welding Technologies in The ShipbuildingpothirajkalyanPas encore d'évaluation

- Ship Hydrodynamics Lecture Notes Part 7 Propeller DesignDocument11 pagesShip Hydrodynamics Lecture Notes Part 7 Propeller Designmst405622Pas encore d'évaluation

- Homework M1: Bring Paper Copy of You Results To ClassDocument1 pageHomework M1: Bring Paper Copy of You Results To ClasspothirajkalyanPas encore d'évaluation

- Quality Planning and AnalysisDocument649 pagesQuality Planning and AnalysispothirajkalyanPas encore d'évaluation

- Welding Technology - NPTELDocument145 pagesWelding Technology - NPTELpothirajkalyan100% (1)

- ME2029 Jig and Fixtues NOTESDocument47 pagesME2029 Jig and Fixtues NOTESpothirajkalyanPas encore d'évaluation

- 09-Hl47 Trim Optimisation - Sustainable SavingsDocument2 pages09-Hl47 Trim Optimisation - Sustainable SavingspothirajkalyanPas encore d'évaluation

- Loads On ShipsDocument6 pagesLoads On ShipspothirajkalyanPas encore d'évaluation

- 2.2 StabilityDocument24 pages2.2 StabilitypothirajkalyanPas encore d'évaluation

- Rationally-Based Structural Design: Owen HughesDocument46 pagesRationally-Based Structural Design: Owen HughespothirajkalyanPas encore d'évaluation

- Unit 16 LP01PS - Intro Hydrocarbons and AlkanesDocument21 pagesUnit 16 LP01PS - Intro Hydrocarbons and AlkanespothirajkalyanPas encore d'évaluation

- Internal Examinar External Examinar Internal Examinar External ExaminarDocument1 pageInternal Examinar External Examinar Internal Examinar External ExaminarpothirajkalyanPas encore d'évaluation

- Introduction of Naval ArchitectureDocument5 pagesIntroduction of Naval ArchitecturepothirajkalyanPas encore d'évaluation

- PGM-199 R1Document5 pagesPGM-199 R1Faraz Ali Khan0% (1)

- Customs Memorandum Order No. 4 - 2010: Administrative ProvisionsDocument8 pagesCustoms Memorandum Order No. 4 - 2010: Administrative ProvisionsOtis MelbournPas encore d'évaluation

- 15 Obieiuri Pentru Imbunatatirea VederiiDocument1 page15 Obieiuri Pentru Imbunatatirea VederiiMi BratosinPas encore d'évaluation

- C11 - Packaging and Materials Handling - SVDocument13 pagesC11 - Packaging and Materials Handling - SVNguyen MyPas encore d'évaluation

- Loading LPG CalculationsDocument12 pagesLoading LPG CalculationsJohn Green67% (3)

- PL BrassFittingsDocument76 pagesPL BrassFittingskhan4luvPas encore d'évaluation

- Solution Manual For Horngrens Financial Managerial Accounting 6th EditionDocument36 pagesSolution Manual For Horngrens Financial Managerial Accounting 6th Editioncupric.diaphane1xmf100% (44)

- Certification Course in Foreign ExchangeDocument16 pagesCertification Course in Foreign ExchangeVishav Mahajan100% (6)

- Boeing Current Market Outlook 2009 To 2028Document30 pagesBoeing Current Market Outlook 2009 To 2028Jijoo Jacob VarghesePas encore d'évaluation

- Gati LogisticDocument12 pagesGati LogisticNaveen MootaPas encore d'évaluation

- Supplier Guide BookDocument33 pagesSupplier Guide BookfgmarquePas encore d'évaluation

- AircapDocument8 pagesAircapigor6995Pas encore d'évaluation

- Container ShipDocument46 pagesContainer ShipdozajPas encore d'évaluation

- Logistics e ProcurementDocument3 pagesLogistics e Procurementshivamdubey12100% (1)

- Chap 13 Inventory ManagementDocument32 pagesChap 13 Inventory Managementrogean gullem33% (3)

- How Can We ExportDocument94 pagesHow Can We ExportUdit PradeepPas encore d'évaluation

- Financial Accounting Libby Short 7th Edition Test BankDocument36 pagesFinancial Accounting Libby Short 7th Edition Test Bankwalerfluster9egfh3100% (35)

- Beyond Type Certification A400m CQCDocument20 pagesBeyond Type Certification A400m CQCJDee DeskPas encore d'évaluation

- Container Parts Catalogue AU WebDocument105 pagesContainer Parts Catalogue AU WebTeguh MedanLand Property100% (2)

- Phil First Insurance vs. Wallem First ShippingDocument2 pagesPhil First Insurance vs. Wallem First ShippingGlenn Francis GacalPas encore d'évaluation

- Oracle Work in Process - : Component Pick ReleaseDocument50 pagesOracle Work in Process - : Component Pick Release1lvlup100% (4)

- Airport Cities & The Aerotropolis:: New Planning ModelsDocument4 pagesAirport Cities & The Aerotropolis:: New Planning ModelsariesPas encore d'évaluation

- AbreviationsDocument161 pagesAbreviationsBogdan PopaPas encore d'évaluation

- Vận Tải Bảo HiểmDocument6 pagesVận Tải Bảo HiểmMinh ThưPas encore d'évaluation

- Jobar IntlDocument1 pageJobar IntlstephanieperrottaPas encore d'évaluation

- Accounting Treatment of Import PurchaseDocument3 pagesAccounting Treatment of Import PurchasePallavi ChawlaPas encore d'évaluation

- 149063-1956-General Foods Corp. v. National Coconut Corp.20160920-3445-1wj08zuDocument5 pages149063-1956-General Foods Corp. v. National Coconut Corp.20160920-3445-1wj08zu123abc456defPas encore d'évaluation

- 2007 APQP Program MGMT ClassroomDocument95 pages2007 APQP Program MGMT ClassroomMartin BoianiPas encore d'évaluation

- AAA Chairmans Address On LOHDocument10 pagesAAA Chairmans Address On LOHrajasekharboPas encore d'évaluation

- Handout 7 - Communication in Cargo OperationDocument7 pagesHandout 7 - Communication in Cargo OperationEfraim Gil Maristela100% (3)