Académique Documents

Professionnel Documents

Culture Documents

Diesel Progress Article Kohler - Mitsubishi

Transféré par

sowabarCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Diesel Progress Article Kohler - Mitsubishi

Transféré par

sowabarDroits d'auteur :

Formats disponibles

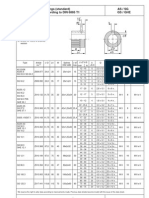

POWER GENERATION

CK Power supplied a pair of Kohler standby diesel generator sets rated 2000 kW each to provide backup power for a new neonatal intensive

care unit at SSM Health St. Mary’s Hospital in Richmond Heights, Mo. The gen-sets were housed within a custom-designed Chillicothe Metal

sound-attenuated enclosure.

BACKING UP THE BABIES

St. Louis hospital installs Kohler generator set system to support neonatal intensive care unit

E

veryone knows that waking a sleeping baby is a bad had to be installed in a very limited footprint in the middle

idea. But when that baby is fighting for its life in a of a fully operational hospital.”

neonatal intensive care unit (NICU), it’s way beyond CK Power supplied a pair of 2000 kW Kohler 2000REOZMD

just being a bad idea — it’s unthinkable. Thus, with modern gen-sets for the project. Each unit is powered by a

neonatal care reliant on an uninterrupted supply of electric- 16-cylinder, 65.4 L Mitsubishi S16R-Y2PTAW2-1 turbo-

ity, standby diesel generator sets have to be ready to pick charged diesel engine rated 2923 bhp. The engine is cooled

up the load within seconds of any service interruption. by a 97 gal. radiator system with an 81 in. diameter fan.

Meeting both demands was just part of the challenge fac- The engine drives a four-pole, rotating-field Marathon

ing CK Power in St. Louis, Mo., when the company won the permanent magnet brushless alternator that delivers

contract to supply a pair of 2000 kW standby diesel gen-sets 1988 kW and is designed to provide both short-circuit pro-

as part of the addition of a neonatal intensive care unit at tection and strong load response. The alternator can accept

SSM Health St. Mary’s Hospital in Richmond Heights, Mo. 100% loads in one step, has an unbalanced load capability

“The project manager explained that these gen-sets of 100% of rated standby current and can sustain short-

replaced three existing units and the paralleling gear which circuit current up to 300% of its rated current for 10 seconds,

added considerably to the overall complexity of the proj- providing ample time for downstream circuit breakers to trip

ect,” said Clayton Costello, vice president of Marketing & without collapsing the alternator field, CK said.

Strategic Planning at CK. “In addition, all of the equipment A Kohler Decision-Maker 550 controller completes the

had to meet IBC seismic certification and FMG approval system, designed to provide advanced control, system mon-

requirements, include fire suppression systems and meet itoring and system diagnostics, as well as remote monitoring

a noise specification of 57 dB(A) at 23 ft. Then everything capabilities. A digital display and keypad facilitate local data

12 DIESEL PROGRESS NORTH AMERICAN EDITION April 2018

POWER GENERATION

access and the unit can communicate via a PC network

or modem. The controller is also designed to support the

Modbus protocol and provides integrated ±0.25% voltage

regulation and alternator thermal overload protection.

The gen-sets are UL 2200 listed at 60 Hz and meet

NFPA 110, Level 1 requirements when properly equipped

and installed, CK Power said. They are EPA Tier 2 certified

for stationary emergency power applications.

The systems supplied by CK Power were mounted on a

1400 gal. subbase tank housed within a Chillicothe Metal

custom-designed, sound-attenuated enclosure. Each gen-

erator was shipped in three pieces and the trucks had to

back down a residential street and avoid overhead wires.

“Because of the strict acoustic requirements we had Along with the gen-sets, CK also supplied switchgear and Kohler’s

to put the gen-sets inside a second enclosure to further Decision-Maker 550 controller designed to provide advanced con-

attenuate the sound,” Costello said. “The ‘penthouse’ was trol, system monitoring and system diagnostics, as well as remote

fabricated for us by Chillicothe Metal. It contains a second monitoring capabilities.

silencer as well as additional fans, baffles and insulation

needed to meet the 57 dB(A) requirement. four months. “Everyone went above and beyond to make

“Everything was assembled and tested at Chillicothe this project successful,” Costello said. “They all knew we

and then loaded on seven trucks and shipped to the jobsite had to get it done and meet stringent requirements for

where they were reassembled.” sound levels, limited footprints and minimal disruptions to

CK Power also supplied the Kohler paralleling gear pack- the community and on time for the new NICU opening in

age and that was installed prior to the generators. That January 2018 — which we did.” dp

enclosure also included a fire suppression system.

From start to finish, CK Power was able to install and

commission the backup power system in approximately www.ckpower.com

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Mending Plates: - Place A Wood Block Over The Mending Plate and Hammer The Wood Block To Embed The ProngsDocument1 pageMending Plates: - Place A Wood Block Over The Mending Plate and Hammer The Wood Block To Embed The ProngssowabarPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Engine Technology International - Hot Vee - June 2017Document128 pagesEngine Technology International - Hot Vee - June 2017Junior Augusto100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- 2017 09Document164 pages2017 09sowabar100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 2017 03Document88 pages2017 03sowabarPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- 2017 01Document104 pages2017 01sowabarPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Determining Pollutants Accurately: Stack TestingDocument8 pagesDetermining Pollutants Accurately: Stack TestingsowabarPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- 1502298L Craftsman 917.20403 Garden Tractor User ManualDocument80 pages1502298L Craftsman 917.20403 Garden Tractor User ManualsowabarPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Governors - Gas & Diesel: Application and Installation GuideDocument25 pagesGovernors - Gas & Diesel: Application and Installation GuideQld_99Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)AmriteshbhaskarPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Mohit Soni ReportDocument104 pagesMohit Soni ReportMohitPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Analysis of Business EnvironmentDocument10 pagesAnalysis of Business Environmentrashmi123vaish50% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Six Tsakalis Pedal ManualDocument1 pageSix Tsakalis Pedal ManualAdedejinfoPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Macmillan English Grammar in Context Advanced PDFDocument3 pagesMacmillan English Grammar in Context Advanced PDFAnonymous l1MDLhBFXPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- As / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1Document1 pageAs / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1hadePas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Practice Test 3Document13 pagesPractice Test 3Ngân Hà NguyễnPas encore d'évaluation

- Code PICDocument6 pagesCode PICsongbao527Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Chapter 3 - Bending MembersDocument41 pagesChapter 3 - Bending MembersSuhailah SuhaimiPas encore d'évaluation

- DepEd Learner Information System (LIS) PDFDocument36 pagesDepEd Learner Information System (LIS) PDFshasagailPas encore d'évaluation

- Pds Maestro Alkyd Primer 12070 En-GbDocument2 pagesPds Maestro Alkyd Primer 12070 En-GbKhyle Laurenz DuroPas encore d'évaluation

- Presentation 1Document12 pagesPresentation 1Varun MaheshwariPas encore d'évaluation

- Fundamentals of ElectronicsDocument2 pagesFundamentals of ElectronicsatulzendePas encore d'évaluation

- Claa150xp Shenzhen HBDocument22 pagesClaa150xp Shenzhen HBSatya NarayanPas encore d'évaluation

- ReadMe PDFDocument31 pagesReadMe PDForaleculero117Pas encore d'évaluation

- Mca Voice Morphing ReportDocument4 pagesMca Voice Morphing Reportmango sravanreddyPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Eamcet2010 Notification Part2Document1 pageEamcet2010 Notification Part2Lokesh KumarPas encore d'évaluation

- Facility Details On DataCenterDocument26 pagesFacility Details On DataCenterishtiaqkhurshid470Pas encore d'évaluation

- Ethods For Mitigation of Voltage Fluctuation Effects: Publication No Cu0208 Issue Date: November 2014Document5 pagesEthods For Mitigation of Voltage Fluctuation Effects: Publication No Cu0208 Issue Date: November 2014Camilo CortesPas encore d'évaluation

- Smis PPT FinalDocument18 pagesSmis PPT FinalSwastika KunduPas encore d'évaluation

- 4-2.0L Gasoline EngineDocument187 pages4-2.0L Gasoline EngineMarco Antonio Tomaylla Huamani100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Technical Service Bulletin 6.7L - Illuminated Mil With Dtcs P1291, P1292, P0191 And/Or P06A6 - Engine Harness Chafe 19-2231Document4 pagesTechnical Service Bulletin 6.7L - Illuminated Mil With Dtcs P1291, P1292, P0191 And/Or P06A6 - Engine Harness Chafe 19-2231Yaniss AlgeriaPas encore d'évaluation

- Kota StationDocument5 pagesKota StationshashankjeePas encore d'évaluation

- Atm MachineDocument7 pagesAtm MachineNguyen TungPas encore d'évaluation

- Hyperloop 170201003657Document29 pagesHyperloop 170201003657RafaelLazoPomaPas encore d'évaluation

- Service Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsDocument30 pagesService Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsHenry Javier RíosPas encore d'évaluation

- kp-57-65wv600 SONYDocument33 pageskp-57-65wv600 SONYdjcamdtvPas encore d'évaluation

- Void Acoustics 2017 BrochureDocument28 pagesVoid Acoustics 2017 BrochureCraig ConnollyPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Bangkok-Singapore CDM JournalDocument20 pagesBangkok-Singapore CDM JournalvasidhartaPas encore d'évaluation

- How02 - Z11 - Mec503 - C01 - Oss Piping Matr Class SpecDocument31 pagesHow02 - Z11 - Mec503 - C01 - Oss Piping Matr Class Speckristian100% (1)