Académique Documents

Professionnel Documents

Culture Documents

First

Transféré par

vg_vvgDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

First

Transféré par

vg_vvgDroits d'auteur :

Formats disponibles

[Company Name]

[Company Group, Division, Location]

Document Title: First Article Inspection

Document Number: [Document Number]

Document Filename: [Document Filename]

CONTROLLED COPY/ MASTER COPY

STAMP HERE

OTHER

STAMP HERE

Revision Revision DCO/ECO Revision

Level Date Number Description of Revision Author

DRAFT DD/MM/Y YY-00000 Draft Author Name

Y

1.00 DD/MM/Y YY-00000 Initial Release Author Name

Y

COMPANY PROPRIETARY AND CONFIDENTIAL

[Company Name] First Article Inspection

[Company Group, Division, Location] [Document Number]

Rev x.xx DD/MM/YY

Table of Contents

1.0 Purpose..........................................................................................................................................................2

2.0 Scope.............................................................................................................................................................2

3.0 Definition Of Terms......................................................................................................................................2

3.1 First Article Inspection.......................................................................................................................2

4.0 Responsibilities.............................................................................................................................................3

4.1 Quality Assurance..............................................................................................................................3

4.2 Engineering........................................................................................................................................3

4.3 Manufacturing Engineering...............................................................................................................3

4.4 Purchasing..........................................................................................................................................3

5.0 References.....................................................................................................................................................3

6.0 First Article Inspection Procedure................................................................................................................3

6.1 Criteria For Performing First Article Inspection...............................................................................3

6.2 Who May Perform First Article Inspection.......................................................................................3

6.3 Performing First Article Inspection...................................................................................................4

6.3.1 First Article inspection Performed by [Company Name]....................................................4

6.3.2 First Article inspection Performed by Vendor or Third Party.............................................4

6.4 Review of First Article Inspection Results, Pass/Fail Criteria..........................................................4

6.5 Disposition, Fail First Article............................................................................................................4

6.5.1 Change the Item to Conform to the Design........................................................................4

6.5.2 Change the Design to Conform to the Item........................................................................5

6.6 Disposition, Pass First Article............................................................................................................5

6.7 Trial Assembly....................................................................................................................................5

7.0 Flow Chart....................................................................................................................................................6

7.1 First Article Inspection.......................................................................................................................6

[Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 1 of 5

[Company Name] First Article Inspection

[Company Group, Division, Location] [Document Number]

Rev x.xx DD/MM/YY

1.0 Purpose

To establish a system and documentation requirements for first article inspection.

2.0 Scope

This procedure applies to first article inspections performed to support activities at the facilities of

[Company Name].

3.0 Definition Of Terms

3.1 First Article Inspection

An inspection performed on the first article or lot from a vendor or process to assure compliance

with all design requirements.

4.0 Responsibilities

4.1 Quality Assurance

Quality Assurance is responsible for performing, overseeing, and/or reviewing first article

inspections. Quality Assurance is responsible for coordinating when, where, and by whom first

article inspection is performed. Quality Assurance is responsible for participating in the

resolution of any nonconformity found during first article inspection.

4.2 Engineering

Engineering is responsible for evaluating the impact on design of nonconformities found during

first article inspection, for recommending ways to resolve nonconformities, and for reviewing and

approving any changes to design documentation resulting from resolution of nonconformities.

4.3 Manufacturing Engineering

Manufacturing Engineering is responsible for evaluating the impact on manufacturing of

nonconformities found during first article inspection, and for recommending ways to resolve

nonconformities. For items made in-house, Manufacturing Engineering is responsible for the

modification of tooling and/or process so that items conform to design documentation.

4.4 Purchasing

Purchasing is responsible for communicating the requirement for first article inspection and the

results of first article inspection to the vendor, and for coordinating with the vendor resolution of

any nonconformities found during first article inspection.

5.0 References

First Article Inspection Data Sheet

6.0 First Article Inspection Procedure

6.1 Criteria For Performing First Article Inspection

First article inspection is recommended when any of the following occur:

An item is supplied by a vendor for the first time;

A new revision of an item is supplied;

A change occurs in the processing of an item;

A change occurs in the tooling for an item.

When the criteria for performing first article inspection is met, Quality Assurance, Engineering,

Manufacturing Engineering, and Purchasing are notified. These four functions jointly decide to

[Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 2 of 5

[Company Name] First Article Inspection

[Company Group, Division, Location] [Document Number]

Rev x.xx DD/MM/YY

perform or waive first article inspection and/or trial assembly. If first article inspection and trial

assembly are waived by all four functions, this procedure terminates. Otherwise, first article

inspection and/or trial assembly is performed according to this procedure.

6.2 Who May Perform First Article Inspection

Coordinated by [Company Name] Quality Assurance, first article inspection may be performed by

any of the following:

[Company Name] Quality Assurance Representative, performed at the vendor or [Company

Name];

Vendor personnel, either witnessed by a [Company Name] Quality Assurance Representative,

or vendor certified measurements sent to [Company Name];

Third party inspector, at a location agreeable to all parties, with results sent to [Company

Name].

6.3 Performing First Article Inspection

The goal of first article inspection is to verify all design features or attributes of an item.

Typically, first article inspection is performed on one article or article. If more than one article is

submitted or available for first article inspection, [Company Name] Quality Assurance will

choose the number of articles to be measured. If certain design features are very difficult or

expensive to measure, their measurement may be waived jointly by Quality Assurance,

Engineering, and Manufacturing Engineering. The waiver must be communicated to the party

performing first article inspection. Material composition of the first article should be verified

unless a Material Certificate is supplied, as required.

6.3.1 First Article inspection Performed by [Company Name]

Measure all or selected attributes and record the measurements on a First Article

Inspection Data Sheet form and/or on engineering documentation (i.e. drawings or

component specifications). "First Article Inspection" must be indicated on the inspection

documentation.

6.3.2 First Article inspection Performed by Vendor or Third Party

Typically, the vendor or third party will perform first article inspection and send the first

article inspection item(s) and the inspection results to [Company Name] Inspection.

Results should be recorded in a format agreed to by [Company Name] Quality

Assurance. [Company Name] Quality Assurance will decide whether or not to

independently verify some or all of the vendor or third party measurements. Quality

Assurance will normally retain the first article items.

6.4 Review of First Article Inspection Results, Pass/Fail Criteria

[Company Name] Quality Assurance reviews the results of first article inspection.

First article inspection is passed if all inspected attributes are within design tolerance limits for

those attributes.

First article inspection is failed if any inspected attribute is outside of design tolerance limits for

that attribute.

6.5 Disposition, Fail First Article

Convene a MRB meeting of Quality, Engineering, Manufacturing Engineering, and Purchasing,

to determine appropriate action to resolve failure. For each nonconforming attribute, there are

essentially two choices: change the item to conform to the design (use-as-is N/A), or change the

[Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 3 of 5

[Company Name] First Article Inspection

[Company Group, Division, Location] [Document Number]

Rev x.xx DD/MM/YY

design to conform to the item (use-as-is). For an item with multiple nonconforming attributes,

one or both of these methods may be used to bring the entire item into conformance with the

design.

An NCMR form must be completed upon failure of a first article inspection.

6.5.1 Change the Item to Conform to the Design

Modify the tooling or process so the item now conforms to the design.

Fabricate new items and perform another first article inspection per "Performing First

Article Inspection," above.

6.5.2 Change the Design to Conform to the Item

Modify the design documentation to conform to the item. Design documentation may be

permanently changed by an Engineering Change Order (ECO).

Compare revised design documentation to the first article inspection results to assure

that the item now passes first article inspection per "Review of First Article Inspection

Results, Pass/Fail Criteria," above.

6.6 Disposition, Pass First Article

Complete and file the documentation for first article inspection, and notify Engineering,

Manufacturing Engineering, and Purchasing of the results.

6.7 Trial Assembly

In addition to measurement of a first article item for conformance to engineering requirements,

Quality Assurance, Engineering, Manufacturing Engineering, and Purchasing may choose to

perform trial assembly of the first article item. If trial assembly is not chosen, this procedure is

complete.

If trial assembly is selected, Quality Assurance coordinates trial assembly and records results. If

problems are not encountered during trial assembly, Quality Assurance notifies Engineering,

Manufacturing Engineering, and Purchasing of the results, and this procedure is complete.

If problems are encountered during trial assembly, Engineering will lead the effort to resolve

those problems. Design changes will be made as necessary, new parts will be fabricated, and first

article inspection and trial assembly will be performed using the new parts to assure problems

have been resolved.

[Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 4 of 5

[Company Name] First Article Inspection

[Company Group, Division, Location] [Document Number]

Rev x.xx DD/MM/YY

7.0 Flow Chart

7.1 First Article Inspection

A Purchased or Manufactured

Item meets the Criteria for First

Article Inspection

Quality Assurance,

Engineering, Manufacturing

Engineering, and Purchasing

are Notified

Waive First Article

Inspection?

Yes

No Change Tooling or Process,

Make New Parts

Quality Assurance Coordinates

First Article Inspection,

Reviews Results

Change Parts

Quality Assurance,

Change Part

Engineering, Manufacturing

to Match Design, or

Pass? No Engineering, and Purchasing

Change Design to

Meet in MRB to Decide

Match Part?

Appropriate Action

Yes

Change Design

Quality Notifies Appropriate Change Design, Make New

Functions, Files Inspection Parts, Perform First Article

Report Inspection Change Design Documentation

to Match Part, Quality

No Compares New Design to

Inspection Results

Trial Assembly

Waive Trial Assembly? No

Performed. Pass?

Yes Yes

Quality Assurance Documents

-End-

and Distributes Results

[Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 5 of 5

Vous aimerez peut-être aussi

- EngineeringDocument1 pageEngineeringvg_vvgPas encore d'évaluation

- 7492 - Agile Test Summary Report TemplateDocument9 pages7492 - Agile Test Summary Report TemplateDaniel JosiahPas encore d'évaluation

- SAT Plan & Procedure VMSDocument47 pagesSAT Plan & Procedure VMSMGHIRBI HAYKELPas encore d'évaluation

- Corrective and Preventative Action ReportDocument2 pagesCorrective and Preventative Action ReportGerardo Gómez SalasPas encore d'évaluation

- Safety Precautions of Electronics LaboratoryDocument3 pagesSafety Precautions of Electronics LaboratoryrosePas encore d'évaluation

- DLL 1st 2018-2019 ETECHDocument4 pagesDLL 1st 2018-2019 ETECHROMARIE QUIJANO100% (2)

- Ziimart Business PlanDocument18 pagesZiimart Business PlanNsereko Ssekamatte100% (1)

- Canadair CL-44 (CC-106 Yukon) - Specifications - Technical Data - Description (English)Document1 pageCanadair CL-44 (CC-106 Yukon) - Specifications - Technical Data - Description (English)calinnicolaeadrianPas encore d'évaluation

- CorrectiveDocument8 pagesCorrectivevg_vvgPas encore d'évaluation

- ASMI-OSHMS-PR-14 - Control of Documents and Record Retention ProcedureDocument10 pagesASMI-OSHMS-PR-14 - Control of Documents and Record Retention ProcedureJHUPEL ABARIALPas encore d'évaluation

- Form 400-3-1439 - Notification of Escape (NOE)Document3 pagesForm 400-3-1439 - Notification of Escape (NOE)Michel DisderoPas encore d'évaluation

- 022 - Leak Test FormDocument1 page022 - Leak Test FormAngela YumangPas encore d'évaluation

- Spec. Number Suffixes: US Based On US Codes, ON For Onshore Projects, M&U Units Used: SI Metric and US Customary UnitsDocument30 pagesSpec. Number Suffixes: US Based On US Codes, ON For Onshore Projects, M&U Units Used: SI Metric and US Customary Unitsrahul100% (1)

- Business Management System: Orrective Ction EportDocument2 pagesBusiness Management System: Orrective Ction EportBự BụngPas encore d'évaluation

- Test Plan ForDocument17 pagesTest Plan ForAli HamzaPas encore d'évaluation

- Process StructuresDocument38 pagesProcess StructuresPayalmba19Pas encore d'évaluation

- KSC de 512 SM - Interim - M PDFDocument101 pagesKSC de 512 SM - Interim - M PDFramalingamPas encore d'évaluation

- Escc Component Qualification - BrochureDocument11 pagesEscc Component Qualification - BrochurejsadachiPas encore d'évaluation

- Workmanship Manual: Revision RecordDocument20 pagesWorkmanship Manual: Revision Recordfrancisco lopez moyaPas encore d'évaluation

- Mil STD 810C: Prepared By: Muhammad Abdullah Roll No: BAEM-F17-003Document6 pagesMil STD 810C: Prepared By: Muhammad Abdullah Roll No: BAEM-F17-003Muhammad Abdullah100% (1)

- Test Summary Report: Yes YesDocument2 pagesTest Summary Report: Yes YesNilotpal Shankar MitraPas encore d'évaluation

- Sensor Catalog 2018Document20 pagesSensor Catalog 2018Aníbal RodriguezPas encore d'évaluation

- (Project Name) Test Plan: (Document Version Number) Project Team: (Date)Document3 pages(Project Name) Test Plan: (Document Version Number) Project Team: (Date)periwinkle_radcliffePas encore d'évaluation

- Quality ControlDocument51 pagesQuality ControlOprisor CostinPas encore d'évaluation

- QMS Form TemplateDocument2 pagesQMS Form Templatebdumeng665Pas encore d'évaluation

- F-05 Corrective Action FormDocument1 pageF-05 Corrective Action Formsuhara hussainPas encore d'évaluation

- Environmental Assessment ReportDocument6 pagesEnvironmental Assessment ReportTichaona KwazvichasvikaPas encore d'évaluation

- Format 4 Test PlansDocument2 pagesFormat 4 Test Plansapi-3710677Pas encore d'évaluation

- Contoh Form RMADocument1 pageContoh Form RMAAgung NurfadillahPas encore d'évaluation

- KON 8.2 QA PRO 0024 C1 Certification ProcedureDocument8 pagesKON 8.2 QA PRO 0024 C1 Certification ProcedureAlizamin SalmanovPas encore d'évaluation

- AIS-038 Rev 2Document110 pagesAIS-038 Rev 2tripathi prashant100% (1)

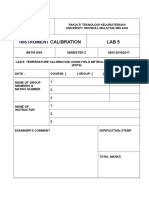

- Lab 5 - Thermocouple Temperature Calibration (PRTS)Document7 pagesLab 5 - Thermocouple Temperature Calibration (PRTS)Slim ShaddysPas encore d'évaluation

- Sem 1 Brazing With Oxyacetylene WeldingDocument3 pagesSem 1 Brazing With Oxyacetylene WeldingKamarul Nizam100% (1)

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityPas encore d'évaluation

- Quality Record Control ProcedureDocument6 pagesQuality Record Control ProcedurePrime CapPas encore d'évaluation

- GA-SRC-0002 Cosmetic Inspection Guidelines For Mechanical Components (Rev 1.0)Document26 pagesGA-SRC-0002 Cosmetic Inspection Guidelines For Mechanical Components (Rev 1.0)Manoj Pai D100% (1)

- Agilent Temperature PDFDocument36 pagesAgilent Temperature PDFcnrk777Pas encore d'évaluation

- ECSS Q ST 60 13C (21october2013)Document100 pagesECSS Q ST 60 13C (21october2013)jsadachiPas encore d'évaluation

- QSV 2 Product Release Procedure EN 01Document6 pagesQSV 2 Product Release Procedure EN 01prashanthPas encore d'évaluation

- QP7 Purchasing Control & Suppilers EvaluationDocument4 pagesQP7 Purchasing Control & Suppilers EvaluationMuhammad Shiraz KhalidPas encore d'évaluation

- 001 Form NCR - FormDocument2 pages001 Form NCR - FormMike Eugene CollinsPas encore d'évaluation

- Control of Monitoring & Measuring DevicesDocument10 pagesControl of Monitoring & Measuring DevicesRamesh mudunuriPas encore d'évaluation

- Qam 3Document35 pagesQam 3Arunachalam AvanashiPas encore d'évaluation

- Control of Documents: Organization Details JustificationDocument1 pageControl of Documents: Organization Details JustificationaezacsPas encore d'évaluation

- Samples ITPDocument4 pagesSamples ITPHassan SajidPas encore d'évaluation

- Sop 7.4.4 Counterfeit Parts PreventionDocument6 pagesSop 7.4.4 Counterfeit Parts PreventionEDGAR GONZALEZPas encore d'évaluation

- QAP K-HouseDocument4 pagesQAP K-HouseAbhinash TamangPas encore d'évaluation

- 8D Report TemplateDocument1 page8D Report TemplateAmit YadavPas encore d'évaluation

- QP-QA-03-Final InspectionDocument2 pagesQP-QA-03-Final InspectionDebkanta Das100% (1)

- ISO 90012015 Documents & Records ListDocument10 pagesISO 90012015 Documents & Records ListKhaja Shanawaz UddinPas encore d'évaluation

- Supplier Deviataion Request Form RevBDocument2 pagesSupplier Deviataion Request Form RevBwdavid81100% (1)

- Daily Receiving Log PDFDocument2 pagesDaily Receiving Log PDFandyjonson007Pas encore d'évaluation

- Form - Scar LogDocument18 pagesForm - Scar LogHarie BongkyPas encore d'évaluation

- 10 FORGING TECHNOLOGY New 1Document43 pages10 FORGING TECHNOLOGY New 1Alfred KuwodzaPas encore d'évaluation

- VAL 005 Validation Concept and Procedure SampleDocument4 pagesVAL 005 Validation Concept and Procedure SampleSameh MostafaPas encore d'évaluation

- AS9100 Quality Manual: Advanced CompaniesDocument36 pagesAS9100 Quality Manual: Advanced Companiesdhir.ankurPas encore d'évaluation

- Job DescriptionsDocument3 pagesJob DescriptionsVaspeoPas encore d'évaluation

- Quality Assurance Manual: Preventive Action Section 8 Rev: E 0 Date: 15/08/09 Page 1 of 2Document2 pagesQuality Assurance Manual: Preventive Action Section 8 Rev: E 0 Date: 15/08/09 Page 1 of 2Ngonidzashe ZvarevashePas encore d'évaluation

- Contrat Jesa 4582K/12: Annex N Quality RequirementsDocument33 pagesContrat Jesa 4582K/12: Annex N Quality RequirementsoundilahmedPas encore d'évaluation

- Acceptance Test PlanDocument8 pagesAcceptance Test PlanKirischPas encore d'évaluation

- IncomingDocument8 pagesIncomingvg_vvgPas encore d'évaluation

- In Coming InspectionDocument8 pagesIn Coming InspectionSaker KhanPas encore d'évaluation

- Optimize Peak Detection & Integration With ApexTrackProcessing TheoryDocument59 pagesOptimize Peak Detection & Integration With ApexTrackProcessing Theorysaldanhalopes666Pas encore d'évaluation

- Empower 3 Software ApexTrack Integration AlgorithmDocument2 pagesEmpower 3 Software ApexTrack Integration Algorithmvg_vvgPas encore d'évaluation

- ECA USP Lifecycle Approach Analytical Procedures PDFDocument6 pagesECA USP Lifecycle Approach Analytical Procedures PDFvg_vvgPas encore d'évaluation

- Who Training GMPDocument144 pagesWho Training GMPboddarambabu100% (3)

- Pe 011 1 Pics GDP GuideDocument27 pagesPe 011 1 Pics GDP GuideBlank SermPas encore d'évaluation

- Empower 3 Electronic Data ReviewDocument34 pagesEmpower 3 Electronic Data Reviewvg_vvgPas encore d'évaluation

- Processing Tips and TricksDocument75 pagesProcessing Tips and Tricksvg_vvgPas encore d'évaluation

- Life Cycle Assessment (Lca) Approach To Analytical Method Development: A ReviewDocument31 pagesLife Cycle Assessment (Lca) Approach To Analytical Method Development: A Reviewvg_vvg100% (1)

- FunctionalDocument4 pagesFunctionalvg_vvgPas encore d'évaluation

- HumanDocument3 pagesHumanvg_vvgPas encore d'évaluation

- ODIAC Template EasyMedicalDeviceDocument4 pagesODIAC Template EasyMedicalDevicevg_vvgPas encore d'évaluation

- InternalDocument1 pageInternalvg_vvgPas encore d'évaluation

- In ProcessDocument5 pagesIn Processvg_vvgPas encore d'évaluation

- InspectionDocument1 pageInspectionvg_vvgPas encore d'évaluation

- EmployeeDocument4 pagesEmployeevg_vvgPas encore d'évaluation

- HazardDocument6 pagesHazardvg_vvgPas encore d'évaluation

- FirstDocument6 pagesFirstvg_vvgPas encore d'évaluation

- IncomingDocument8 pagesIncomingvg_vvgPas encore d'évaluation

- ExperimentationDocument4 pagesExperimentationvg_vvgPas encore d'évaluation

- InternalDocument1 pageInternalvg_vvgPas encore d'évaluation

- FunctionalDocument5 pagesFunctionalvg_vvgPas encore d'évaluation

- EquipmentDocument1 pageEquipmentvg_vvgPas encore d'évaluation

- FinalDocument5 pagesFinalvg_vvgPas encore d'évaluation

- FinalDocument1 pageFinalvg_vvgPas encore d'évaluation

- FacilitiesDocument3 pagesFacilitiesvg_vvgPas encore d'évaluation

- DevelopmentDocument8 pagesDevelopmentvg_vvgPas encore d'évaluation

- FieldDocument4 pagesFieldvg_vvgPas encore d'évaluation

- EngineeringDocument1 pageEngineeringvg_vvgPas encore d'évaluation

- DesignDocument8 pagesDesignvg_vvgPas encore d'évaluation

- Mfs Report Sample - enDocument21 pagesMfs Report Sample - enbassant_hegaziPas encore d'évaluation

- Multiply Across Zero Lesson PlanDocument3 pagesMultiply Across Zero Lesson Planapi-339651962Pas encore d'évaluation

- Crown Castle Roosevelt Island Wireless Infrastructure ProposalDocument44 pagesCrown Castle Roosevelt Island Wireless Infrastructure ProposalrooseveltislanderPas encore d'évaluation

- Firearms Training AssociatesDocument4 pagesFirearms Training Associatesdominique babisPas encore d'évaluation

- Frisbee AssessmentDocument1 pageFrisbee Assessmentapi-430993294Pas encore d'évaluation

- Student Development Theory Autobiography FinalDocument10 pagesStudent Development Theory Autobiography Finalapi-541684468Pas encore d'évaluation

- HNDBK Finaldraft2005 PDFDocument181 pagesHNDBK Finaldraft2005 PDFSejal AmbetkarPas encore d'évaluation

- Nestle Premium Chocolate Market StrategyDocument2 pagesNestle Premium Chocolate Market Strategyjmisra71Pas encore d'évaluation

- The Moorings Newsletter June 2016 - Final DraftDocument4 pagesThe Moorings Newsletter June 2016 - Final DraftViolintsarPas encore d'évaluation

- Guide To Pre-Week PlanningDocument3 pagesGuide To Pre-Week Planningjorge samahaPas encore d'évaluation

- The Use of Mathematical Models For Logistics Systems AnalysisDocument10 pagesThe Use of Mathematical Models For Logistics Systems AnalysisHo Van RoiPas encore d'évaluation

- Event Proposal Anukaran: Group-2Document9 pagesEvent Proposal Anukaran: Group-2Srijan SaxenaPas encore d'évaluation

- Secrets of Spoken English by Gaurav FulbrightDocument91 pagesSecrets of Spoken English by Gaurav FulbrightSarthak Singh ChandelPas encore d'évaluation

- Matter GeniusDocument2 pagesMatter Geniusjoas_koolPas encore d'évaluation

- Industrial SafetyDocument22 pagesIndustrial SafetyShivam SagarPas encore d'évaluation

- Eotc Camp Permission Form PDFDocument3 pagesEotc Camp Permission Form PDFapi-238963120Pas encore d'évaluation

- Modularly Harmonized BSC Post Basic Medical Radiologic Technology CurriculumDocument262 pagesModularly Harmonized BSC Post Basic Medical Radiologic Technology CurriculumNigusse Obse100% (1)

- Ftsalesin356: Resume ID Name Date of Birth Resume Title EducationDocument20 pagesFtsalesin356: Resume ID Name Date of Birth Resume Title EducationMaarishettymPas encore d'évaluation

- DLL G6 Q4 WEEK 5 ALL SUBJECTS Mam Inkay PeraltaDocument64 pagesDLL G6 Q4 WEEK 5 ALL SUBJECTS Mam Inkay Peraltaedelberto100% (1)

- Ped 11.Document2 pagesPed 11.Hassel BarayaPas encore d'évaluation

- Manikganj Medicle Hospital, Thesis, ARchitecture BracuDocument47 pagesManikganj Medicle Hospital, Thesis, ARchitecture BracuMahbuba MoumiPas encore d'évaluation

- Nagbalayong National High School: Department of EducationDocument2 pagesNagbalayong National High School: Department of EducationvernaPas encore d'évaluation

- 5 Cat Tools That Every Translator Should Use: 1. Translation Memory SoftwareDocument2 pages5 Cat Tools That Every Translator Should Use: 1. Translation Memory SoftwareYounes Y YounesPas encore d'évaluation

- Material Requisition For Expansion Joints - Taif SiteDocument41 pagesMaterial Requisition For Expansion Joints - Taif SiteAnonymous uLAATWpfPas encore d'évaluation

- PP Vs MamuyacDocument8 pagesPP Vs MamuyacShaine ArellanoPas encore d'évaluation

- Ra 8545Document6 pagesRa 8545KFPas encore d'évaluation

- 3GPP - Ts 36.133Document2 389 pages3GPP - Ts 36.133Kevin NightPas encore d'évaluation