Académique Documents

Professionnel Documents

Culture Documents

Ri

Transféré par

wdavid810 évaluation0% ont trouvé ce document utile (0 vote)

7 vues7 pagesTitre original

ri

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

7 vues7 pagesRi

Transféré par

wdavid81Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 7

Resume -22

WORK HISTORY

PERSONAL PARTICULAR

Employee Name : Muhammad Asyraf bin Aziz Nationality :Malaysian

Gender : Male NRIC No. :890527-11-5267

EDUCATIONAL BACKGROUND

Level : Bachelors Degree in Mechanical Engineering (Manufacturing)

Institute / University : University Of Nottingham – Malaysia Campus

Graduation year : 2011

WORK HISTORY AT SRI TAKADA

Employee Code : P-195

Date Joined : 8th October 2014

Current Position : Quality Control Engineer

EXPERIENCES :

Sep 14 – Feb 15 : - As a QC Engineer (Shop Fabrication)

Client : R.S. Associates (India)

Project : BPCL Integrated Refinery Expansion Project (Kochi)

Assisting in preparing PQR, WPS, WQT & WPQ according to

ASME BPVC – Section IX Welding, Brazing & Fusing

Qualification.

Assisting in coordinating and reviewing Radiography Test

Inspection.

Assisting in coordinating and reviewing Penetrant Test.

Material Involved For RT & PT – Carbon Steel (ASTM

A106 eq.), Low Alloy Steel (ASTM A335 eq.), Stainless Steel

(ASTM A312 TP304 eq.)

Codes and Standards Involved For Inspection –

ASME/ASTM BPVC – Section II Part A – Ferrous Material

Specification, ASME BPVC – Section V – Non-destructive

Testing, ASME B31.3 Process Piping.

Mar 15 – Apr 15 : - As a QC Engineer (Shop Fabrication)

Client : R.S. Associates (India)

Project : Mist Eliminator Bypass Piping

Assisting in preparing PQR, WPS, WQT & WPQ according to

ASME BPVC – Section IX Welding, Brazing & Fusing

Qualification.

Assisting in coordinating and reviewing Radiography Test

Inspection.

Assisting in coordinating and reviewing Penetrant Test.

Material Involved For RT & PT – Stainless Steel (ASTM

A312 TP316 eq.)

Codes and Standards Involved For Inspection –

ASME/ASTM BPVC – Section II Part A – Ferrous Material

Specification, ASME BPVC – Section V – Non-destructive

Testing, ASME B31.3 Process Piping.

May 15 – Jun 15 : - As a QC Engineer (Shop Fabrication)

Client : R.S. Associates (India)

Project : Supply Of 2 Unit 56" Pipe Spool for Strainer

Assisting in reviewing Radiography Test Inspection.

Witness and review the Hydrostatic Testing.

Material Involved For RT – Carbon Steel (ASTM A106 eq.).

Codes and Standards Involved For Inspection –

ASME/ASTM BPVC – Section II Part A – Ferrous Material

Specification, ASME BPVC – Section V – Non-destructive

Testing, ASME B31.3 Process Piping.

May 15 – Jun 15 : - As a QC Engineer (Shop Fabrication)

Client : Sagami Manufactures Sdn. Bhd (Malaysia)

Project : Sagami Moi HK Project – Equipment Fabrication

Assisting in coordinating and reviewing Radiography Test

Inspection.

Witness and review the Hydrostatic Testing.

Material Involved For RT – Carbon Steel (ASTM A106 eq.),

Stainless Steel (ASTM A312 TP304 eq.)

Codes and Standards Involved For Inspection –

ASME/ASTM BPVC – Section II Part A – Ferrous Material

Specification, ASME BPVC – Section V – Non-destructive

Testing, ASME BPVC – Section VII Div.1 – Rules for

Construction of Pressure Vessels.

Jun 15 – Dec 15 : - As a QC Engineer (Shop Pre-fabrication)

Client : Sagami Manufactures Sdn. Bhd (Malaysia)

Project : Sagami Moi HK Project - Building & Mechanical

Works

Assisting in preparing PQR, WPS, WQT & WPQ according to

ASME BPVC – Section IX Welding, Brazing & Fusing

Qualification.

Assisting in coordinating and reviewing Radiography Test

Inspection.

Material Involved For RT – Carbon Steel (ASTM A106 eq.),

Stainless Steel (ASTM A312 TP304 eq.)

Codes and Standards Involved For Inspection –

ASME/ASTM BPVC – Section II Part A – Ferrous Material

Specification, ASME BPVC – Section V – Non-destructive

Testing, ASME B31.3 Process Piping.

Aug 15 – Feb 16 : - As a QC Engineer (Shop Fabrication)

Client : Chiyoda (M) Sdn Bhd (Malaysia)

Project : EPCC of Facilities for MTBE Product Transfer from

PC MTBE Port Storage to BPC

Assisting in preparing PQR, WPS, WQT & WPQ according to

ASME BPVC – Section IX Welding, Brazing & Fusing

Qualification.

Assisting in coordinating and reviewing Radiography Test

Inspection.

Assisting in coordinating and reviewing Penetrant Test,

Hardness Test & Positive Material Inspection (PMI).

Material Involved For RT & PT – Carbon Steel (ASTM

A106 eq.), Low Temp. Steel (ASTM A333 eq.).

Codes and Standards Involved For Inspection –

ASME/ASTM BPVC – Section II Part A – Ferrous Material

Specification, ASME BPVC – Section V – Non-destructive

Testing, ASME B31.3 Process Piping, AWS D1.1 – Structural

Welding Code – Steel.

Nov 15 – Jul 16 : - As a QC Engineer (Shop Fabrication)

Client : Chiyoda (M) Sdn Bhd (Malaysia)

Project : EPCC for Flare Replacement & Upgrading at

Tanjung Sulong Export Terminal (TSET)

Assisting in preparing PQR, WPS, WQT & WPQ according to

ASME BPVC – Section IX Welding, Brazing & Fusing

Qualification

Assisting in coordinating and reviewing Radiography Test

Inspection

Assisting in coordinating and reviewing Penetrant Test,

Hardness Test & Positive Material Inspection (PMI)

Material Involved For RT & PT – Carbon Steel (ASTM

A106 eq.), Low Temp. Steel (ASTM A333 eq.), Stainless Steel

(ASTM A312 TP304 eq.)

Codes and Standards Involved For Inspection –

ASME/ASTM BPVC – Section II Part A – Ferrous Material

Specification, ASME BPVC – Section V – Non-destructive

Testing, ASME B31.3 Process Piping, AWS D1.1 – Structural

Welding Code – Steel.

Apr 16 – Jul 16 : - As a QC Engineer (Shop Fabrication)

Client : Sagami Manufactures Sdn. Bhd (Malaysia)

Project : Sagami Shutdown Work - Tank Fabrication,

Installation & Piping Work

Assisting in coordinating and reviewing Radiography Test

Inspection

Witness and review the Hydrostatic Testing

Material Involved For RT – Carbon Steel (ASTM A106 eq.),

Stainless Steel (ASTM A312 TP304 eq.)

Codes and Standards Involved For Inspection –

ASME/ASTM BPVC – Section II Part A – Ferrous Material

Specification, ASME BPVC – Section V – Non-destructive

Testing, ASME BPVC – Section VII Div.1 – Rules for

Construction of Pressure Vessels.

Vous aimerez peut-être aussi

- Piping Isometric Drawing (PW Line) : Project TitleDocument8 pagesPiping Isometric Drawing (PW Line) : Project Titlewdavid81Pas encore d'évaluation

- Thesis 2007 LiDocument235 pagesThesis 2007 Liwdavid81Pas encore d'évaluation

- Adnan - Lined Nipple DrawingDocument1 pageAdnan - Lined Nipple Drawingwdavid81Pas encore d'évaluation

- MOS Pickling and Passivation (David Comment, 29-11-19)Document4 pagesMOS Pickling and Passivation (David Comment, 29-11-19)wdavid81Pas encore d'évaluation

- UKA Runbritain COVID19 v1Document13 pagesUKA Runbritain COVID19 v1wdavid81Pas encore d'évaluation

- Info GraphicDocument29 pagesInfo Graphicwdavid81Pas encore d'évaluation

- JOF (18-20-Dec) PDFDocument1 pageJOF (18-20-Dec) PDFwdavid81Pas encore d'évaluation

- Mul Points Calculation: TH TH TH TH TH TH TH RD ND STDocument2 pagesMul Points Calculation: TH TH TH TH TH TH TH RD ND STwdavid81Pas encore d'évaluation

- Test: Penetrant Test 100% (Weldment and Body/Pipe) : Sri Takada Industries (Malaysia) Sdn. BHDDocument1 pageTest: Penetrant Test 100% (Weldment and Body/Pipe) : Sri Takada Industries (Malaysia) Sdn. BHDwdavid81Pas encore d'évaluation

- Your Payment Receipt - Christmas 2019Document1 pageYour Payment Receipt - Christmas 2019wdavid81100% (1)

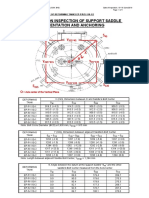

- A. Dimension Inspection of Support Saddle Orientation and AnchoringDocument7 pagesA. Dimension Inspection of Support Saddle Orientation and Anchoringwdavid81Pas encore d'évaluation

- DTank Inspection (DRAFT) Rev.2Document1 pageDTank Inspection (DRAFT) Rev.2wdavid81Pas encore d'évaluation

- Nickel 200 201 PDFDocument20 pagesNickel 200 201 PDFwdavid81Pas encore d'évaluation

- ATank Inspection (DRAFT) Rev.2Document1 pageATank Inspection (DRAFT) Rev.2wdavid81Pas encore d'évaluation

- BTank Inspection (DRAFT) Rev.2Document1 pageBTank Inspection (DRAFT) Rev.2wdavid81Pas encore d'évaluation

- Tank Inspection (DRAFT) Rev.2Document1 pageTank Inspection (DRAFT) Rev.2wdavid81Pas encore d'évaluation

- Pdvsa: Engineering Design ManualDocument3 pagesPdvsa: Engineering Design Manualwdavid81Pas encore d'évaluation

- Nickel WeldingDocument87 pagesNickel Weldingwdavid810% (1)

- Press: StatementDocument26 pagesPress: Statementwdavid81Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Chapter 24 - The Solar SystemDocument36 pagesChapter 24 - The Solar SystemHeather Blackwell100% (1)

- ASHRAE Elearning Course List - Order FormDocument4 pagesASHRAE Elearning Course List - Order Formsaquib715Pas encore d'évaluation

- Roland Fantom s88Document51 pagesRoland Fantom s88harryoliff2672100% (1)

- Check e Bae PDFDocument28 pagesCheck e Bae PDFjogoram219Pas encore d'évaluation

- What Are Some of The Best Books On Computer ScienceDocument9 pagesWhat Are Some of The Best Books On Computer ScienceSarthak ShahPas encore d'évaluation

- Carpentry Grade 8 Week 1 2Document20 pagesCarpentry Grade 8 Week 1 2SANTIAGO ALVISPas encore d'évaluation

- Rs2-Seamanship (Inc Anchoring, Mooring, Berthing, Pilot Ladder)Document19 pagesRs2-Seamanship (Inc Anchoring, Mooring, Berthing, Pilot Ladder)Mdpn. Salvador67% (3)

- National Employment Policy, 2008Document58 pagesNational Employment Policy, 2008Jeremia Mtobesya0% (1)

- Controlador DanfossDocument2 pagesControlador Danfossfrank.marcondes2416Pas encore d'évaluation

- A Brief Tutorial On Interval Type-2 Fuzzy Sets and SystemsDocument10 pagesA Brief Tutorial On Interval Type-2 Fuzzy Sets and SystemstarekeeePas encore d'évaluation

- Topic 1 - ICT Tools at USP - Theoretical Notes With Google AppsDocument18 pagesTopic 1 - ICT Tools at USP - Theoretical Notes With Google AppsAvantika PrasadPas encore d'évaluation

- The Serious Student of HistoryDocument5 pagesThe Serious Student of HistoryCrisanto King CortezPas encore d'évaluation

- Furnace Temperature & PCE ConesDocument3 pagesFurnace Temperature & PCE ConesAbdullrahman Alzahrani100% (1)

- Assignment RoadDocument14 pagesAssignment RoadEsya ImanPas encore d'évaluation

- Percentage and Profit & Loss: Aptitude AdvancedDocument8 pagesPercentage and Profit & Loss: Aptitude AdvancedshreyaPas encore d'évaluation

- Allegro Delivery Shipping Company Employment Application FormDocument3 pagesAllegro Delivery Shipping Company Employment Application FormshiveshPas encore d'évaluation

- CH 15Document58 pagesCH 15Chala1989Pas encore d'évaluation

- 2011-11-09 Diana and AtenaDocument8 pages2011-11-09 Diana and AtenareluPas encore d'évaluation

- Chapter 13Document15 pagesChapter 13anormal08Pas encore d'évaluation

- Hydraulics and PneumaticsDocument6 pagesHydraulics and PneumaticsRyo TevezPas encore d'évaluation

- Heirs of Vinluan Estate in Pangasinan Charged With Tax Evasion For Unsettled Inheritance Tax CaseDocument2 pagesHeirs of Vinluan Estate in Pangasinan Charged With Tax Evasion For Unsettled Inheritance Tax CaseAlvin Dela CruzPas encore d'évaluation

- AppcDocument71 pagesAppcTomy lee youngPas encore d'évaluation

- Coco Mavdi Esl5Document6 pagesCoco Mavdi Esl5gaurav222980Pas encore d'évaluation

- Navi-Planner User ManualDocument331 pagesNavi-Planner User ManualRichard KershawPas encore d'évaluation

- Ward 7Document14 pagesWard 7Financial NeedsPas encore d'évaluation

- Evolis SDK Use Latest IomemDocument10 pagesEvolis SDK Use Latest IomempatrickPas encore d'évaluation

- Introduction To AmplifierDocument8 pagesIntroduction To AmplifierElaine BicolPas encore d'évaluation

- Mahatma Gandhi University: Priyadarshini Hills, Kottayam-686560Document136 pagesMahatma Gandhi University: Priyadarshini Hills, Kottayam-686560Rashmee DwivediPas encore d'évaluation

- Investigative JournalismDocument8 pagesInvestigative JournalismMitchie LlagasPas encore d'évaluation

- Household: Ucsp11/12Hsoiii-20Document2 pagesHousehold: Ucsp11/12Hsoiii-20Igorota SheannePas encore d'évaluation