Académique Documents

Professionnel Documents

Culture Documents

LCM

Transféré par

mihirhotaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

LCM

Transféré par

mihirhotaDroits d'auteur :

Formats disponibles

Central Food Technological Research Institute, Mysore – 570 020

LEAF CUP MACHINE

INTRODUCTION

Forest and agricultural raw materials like leaves, leafy sheaths and Pseudo-stems were

traditionally used for storing or serving foods. Physicochemical studies on wet/dry leaves of banana,

beautia, bauhinia and arecanut sheath have revealed that their functional properties are better than

those of paper. It was found possible to convert them into small package forms like cups and trays

for substituting the modern paper and plastic materials. Market samples of dry leaves of banana and

beautia showed initial microbial loads and it was found that by brief treatment of dry leaves of

banana and beautia for a few minutes in hypo-chlorite solution, the microbial load could be reduced.

i) The leaf cup-making machine is a simple pedal operated machine, which is manually

operated with minimum power consumption.

ii) It requires only 300 watts of electric power for the heating units and can be worked on the

domestic line (220 volts).

iii) The machine can be located in any village/towns where electricity and

leaves of banana, beautia, bauhinia and arecanut palm sheaths are available in plenty.

iv) The leaf cups/plates manufactured in the unit is hygienically superior

RAW MATERIAL

Abundantly available agricultural and forest products such as leaves of banana, beautia,

bauhinia and sheath of arecanut palms in only arecanut growing areas are available. There is no

dearth for the availability of raw material

PLANT AND MACHINERY

List of suppliers:

The leaf cup-making machine has been designed by CFTRI and the drawings for the machine

can be obtained from CFTRI. However, the addresses of few firms who have obtained design

drawings from CFTRI for fabrication and supply of leaf cup/plate making machines are given

below:

ANIL AND CO.

68, NGO’s Colony, N R Mohalla Post, Mysore – 570 007

Tel: 08212-491 849, Mobile: 94480 41849

SREE MURAGAN INDUSTRIES

Plot No.68/W, Hootagalli Industrial Area, Belawadi Post, Mysore-570 018

Ph: Off: 0821-6450511, Res: 6450510,

KALI AERATED WATER WORKS

68, 11/77, Vivekanandar Street, P.B.No.2, Virudhunagar – 626 001 (TN)

Ph: 04562-43636, Fax: 04562-43872

A.M.I.ENGINEERING

Station Road, Opp. Veena Cinema, Patna-800 001,

Fax: 0612-2224274; Mobile: 9973437800; 9431016895;

E-mail: ashwani@amienggfarmer.com

NALANDA AGRO WORKS

Nalanda Nagar, Kurji, Patna - 800 010

Ph: Off: 0612-263886 Res: 0612-267706

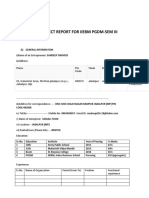

PROJECT COST – FIXED COST – WORKING CAPITAL (in Rs. ‘000)

(estimate for a model project)

a) Building (shop) (20 M2) 55.00

b) Cost of machine with 3 different dies 45.00

c) Misc. fixed assets 5.00

d) Pre-operative expenses 5.00

Total fixed capital 110.00

Working capital margin 8.00

Total Project cost 118.00

Total working capital required at 20% of turnover 32.00

Means of finance

Promoters contribution 35.50

Term loan 82.50

PRODUCTION - (estimate)

The leg operated leaf cup-making machine can produce 250-300 leaf cups or 100 areca

sheath cups per hour by a single skilled operator and a helper.

Capacity Production of 2000-2500 cups/plates per shift/day.

Optimum utilization capacity: 70%

TECHNOLOGY/MANUFACTURING PROCESS-AVAILABILITY

CFTRI has developed design drawing on leaf cup making machine. There are more than

2000 leaf cup making machines fabricated as per CFTRI design is estimated to be in operation in

the country, distributed in UP, Bihar, Maharastra, Gujarat, AP, and Karnataka. However, most of

the units are reported to be concentrated in UP and Bihar.

Vous aimerez peut-être aussi

- Process Code No. 951 Instant PicklesDocument2 pagesProcess Code No. 951 Instant PicklesIboyaima singhPas encore d'évaluation

- Amla Spread: Central Food Technological Research Institute, Mysore - 570 020Document2 pagesAmla Spread: Central Food Technological Research Institute, Mysore - 570 020Sathyendra RaoPas encore d'évaluation

- Mysore AnnatroDocument2 pagesMysore AnnatroWinston MarajPas encore d'évaluation

- Visvesvaraya Technological University Belagavi, Karnataka - 590018Document8 pagesVisvesvaraya Technological University Belagavi, Karnataka - 590018Ashik PoojaryPas encore d'évaluation

- Fabrication Analysis of Incence Stick Making Machine: Project Reference No.: 39S - Be - 0930Document33 pagesFabrication Analysis of Incence Stick Making Machine: Project Reference No.: 39S - Be - 0930Alan IndomenicoPas encore d'évaluation

- 1 s2.0 S2214785322061193 MainDocument5 pages1 s2.0 S2214785322061193 Mainnkkumawat76Pas encore d'évaluation

- Design & Fabrication of Banana Fiber Extracting MachineDocument6 pagesDesign & Fabrication of Banana Fiber Extracting MachinekirubelPas encore d'évaluation

- Design and Fabrication of Compost MachineDocument8 pagesDesign and Fabrication of Compost MachineIJRASETPublicationsPas encore d'évaluation

- Design and Development of Foot Operated Areca-Nut Leaf Plate Manufacturing MachineDocument6 pagesDesign and Development of Foot Operated Areca-Nut Leaf Plate Manufacturing MachineIJRASETPublicationsPas encore d'évaluation

- CENTRAL FOOD TECHNOLOGICAL RESEARCH INSTITUTE CHUTNEY SPREADS PROCESSDocument1 pageCENTRAL FOOD TECHNOLOGICAL RESEARCH INSTITUTE CHUTNEY SPREADS PROCESSJulius OctaviusPas encore d'évaluation

- 02 08 Edeh John MULTI ROLLER Abrasive ENDDocument12 pages02 08 Edeh John MULTI ROLLER Abrasive ENDashraf.imraishPas encore d'évaluation

- Design and Development of Peanut Peeler MachineDocument7 pagesDesign and Development of Peanut Peeler MachineKristoffer SamsonPas encore d'évaluation

- Entpreneurship Development IIEBMDocument19 pagesEntpreneurship Development IIEBMsaneep dwivediPas encore d'évaluation

- VTU Belagavi Project Synopsis on Design and Fabrication of Groundnut Harvesting MachineDocument8 pagesVTU Belagavi Project Synopsis on Design and Fabrication of Groundnut Harvesting MachineHārshã LūçkyPas encore d'évaluation

- Arecanut PlateDocument7 pagesArecanut PlatesukiPas encore d'évaluation

- Rice & Dal Mill Machinery PDFDocument9 pagesRice & Dal Mill Machinery PDFSHASHI SHEKARPas encore d'évaluation

- IJRTI2210061Document3 pagesIJRTI2210061Villan teamPas encore d'évaluation

- Project SynopsisDocument4 pagesProject SynopsisLohith MPas encore d'évaluation

- Review On Pulverization MachineDocument7 pagesReview On Pulverization MachineIJRASETPublicationsPas encore d'évaluation

- Smart and Optimized Dough Maker For Domestic UseDocument5 pagesSmart and Optimized Dough Maker For Domestic UseInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Project Profile on Production of Apiculture EquipmentDocument14 pagesProject Profile on Production of Apiculture EquipmentmekonnenPas encore d'évaluation

- Fabrication and Automation of Seed Sowing Machine Using IotDocument10 pagesFabrication and Automation of Seed Sowing Machine Using IotMani KarthikeyanPas encore d'évaluation

- Rectangular Jaggery ProcessDocument10 pagesRectangular Jaggery ProcessSachinPas encore d'évaluation

- Design and Fabrication of Multi-Purpose Cutting Machine For Agricultural UsesDocument12 pagesDesign and Fabrication of Multi-Purpose Cutting Machine For Agricultural UsesIJRASETPublicationsPas encore d'évaluation

- Final Dinesh ProjectDocument16 pagesFinal Dinesh ProjectAravindhan LPas encore d'évaluation

- Pulse Milling: 1.0 Product and Its ApplicationsDocument7 pagesPulse Milling: 1.0 Product and Its ApplicationsAmol BondrePas encore d'évaluation

- Design and Fabrication of Crop ReaperDocument9 pagesDesign and Fabrication of Crop ReaperIJRASETPublicationsPas encore d'évaluation

- tutti frutti project reportDocument2 pagestutti frutti project reportSri VamsiPas encore d'évaluation

- Thesis Final Proposal PresentationDocument25 pagesThesis Final Proposal Presentationkibromkb100% (1)

- Presentation (1) (12) - 121619Document14 pagesPresentation (1) (12) - 121619instagram3196Pas encore d'évaluation

- Groundnut Sheller Machine PDFDocument8 pagesGroundnut Sheller Machine PDFTanvi Khurana100% (4)

- Bread Production Capacity & StandardsDocument7 pagesBread Production Capacity & StandardsS_VenkatPas encore d'évaluation

- Shrimp Papad Production GuideDocument5 pagesShrimp Papad Production GuideRaj GiriPas encore d'évaluation

- Automatic Mysore Bonda Making Machine Using Solar EnergyDocument2 pagesAutomatic Mysore Bonda Making Machine Using Solar EnergyInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Prototype of The Chopping Machine For The Fronds and Leaves of Oil PalmsDocument6 pagesPrototype of The Chopping Machine For The Fronds and Leaves of Oil PalmsFachreza ArdianPas encore d'évaluation

- Journalnx DesignDocument3 pagesJournalnx DesignJournalNX - a Multidisciplinary Peer Reviewed JournalPas encore d'évaluation

- Pneumatic Conveyor With Paddy CollecterDocument4 pagesPneumatic Conveyor With Paddy Collectersjayavahini19Pas encore d'évaluation

- Spinning MaterialtodayDocument5 pagesSpinning MaterialtodayfacebookdeepuPas encore d'évaluation

- IotPresentationppt (1) (12) - 121619Document15 pagesIotPresentationppt (1) (12) - 121619rjnarayan019Pas encore d'évaluation

- Solar Powered Seed Sowing Machine: Kalash Singhal, Gaurav PrajapatiDocument4 pagesSolar Powered Seed Sowing Machine: Kalash Singhal, Gaurav PrajapatiMahantPas encore d'évaluation

- Poultry Feed Mixing Machine Design AnalyDocument11 pagesPoultry Feed Mixing Machine Design AnalyAjay lokhandePas encore d'évaluation

- Fruit Jam Slices: Central Food Technological Research Institute MYSORE - 570 020Document2 pagesFruit Jam Slices: Central Food Technological Research Institute MYSORE - 570 020Rizka Dwi AnissatunisaPas encore d'évaluation

- Design and Fabrication of A Multipurpose Agriculture RobotDocument10 pagesDesign and Fabrication of A Multipurpose Agriculture RobotIJRASETPublicationsPas encore d'évaluation

- Review On Multipurpose Agriculture RobotDocument8 pagesReview On Multipurpose Agriculture RobotIJRASETPublicationsPas encore d'évaluation

- Profile On BeehivesDocument18 pagesProfile On BeehivesKaramara Training & ConsultancyPas encore d'évaluation

- Agricultural Shredder MachineDocument9 pagesAgricultural Shredder Machineahmad fauziPas encore d'évaluation

- Multipurpose Agricultural EquipmentDocument8 pagesMultipurpose Agricultural EquipmentManiranjan KumarPas encore d'évaluation

- Multicrop Harvesting MachineDocument9 pagesMulticrop Harvesting MachineIJRASETPublicationsPas encore d'évaluation

- ON SUGAR CANE BUD CHIPPER Update-1Document17 pagesON SUGAR CANE BUD CHIPPER Update-1விக்னேஷ் வரன்Pas encore d'évaluation

- Design, Construction and Performance Evaluation of A at Screen Hammer Mill MachineDocument10 pagesDesign, Construction and Performance Evaluation of A at Screen Hammer Mill MachineDaniella SabacPas encore d'évaluation

- Project Profile On Mini Flour Mill: Prod U CTDocument11 pagesProject Profile On Mini Flour Mill: Prod U CTSunil ShawPas encore d'évaluation

- Improvement of Basic Tools and Their Economic Processes in AgricultureDocument4 pagesImprovement of Basic Tools and Their Economic Processes in AgricultureIJRASETPublicationsPas encore d'évaluation

- Smart Solar Powered Variable Pitch Autonomous Seed Sowing and Spraying MachineDocument20 pagesSmart Solar Powered Variable Pitch Autonomous Seed Sowing and Spraying Machineshubham patilPas encore d'évaluation

- Design and Fabrication of Solar Automatic Cow Dung CleanerDocument10 pagesDesign and Fabrication of Solar Automatic Cow Dung CleanerIJRASETPublicationsPas encore d'évaluation

- BISCUIT PRODUCTION FROM 200 TPADocument7 pagesBISCUIT PRODUCTION FROM 200 TPAAnonymous EAineTizPas encore d'évaluation

- Multi Purpose Agriculture MachineDocument22 pagesMulti Purpose Agriculture MachineSubbu Varma100% (3)

- Mini Flour Mill KarnalDocument9 pagesMini Flour Mill KarnalAnand Kishore100% (2)

- Waste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesD'EverandWaste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Global Forest Sector Outlook 2050: Assessing Future Demand and Sources of Timber for a Sustainable EconomyD'EverandGlobal Forest Sector Outlook 2050: Assessing Future Demand and Sources of Timber for a Sustainable EconomyPas encore d'évaluation

- Optimization of Manufacturing Systems Using the Internet of ThingsD'EverandOptimization of Manufacturing Systems Using the Internet of ThingsÉvaluation : 4 sur 5 étoiles4/5 (4)

- Laser Like Focus On LearningDocument1 pageLaser Like Focus On LearningmihirhotaPas encore d'évaluation

- A.I. Classes From Microsoft Aim To Educate ExecutivesDocument2 pagesA.I. Classes From Microsoft Aim To Educate ExecutivesmihirhotaPas encore d'évaluation

- Olic Solar Pump YojanaDocument2 pagesOlic Solar Pump YojanamihirhotaPas encore d'évaluation

- KannadaDocument8 pagesKannadamihirhotaPas encore d'évaluation

- KannadaDocument8 pagesKannadamihirhotaPas encore d'évaluation

- Odisha Food Processing DeptDocument1 pageOdisha Food Processing DeptmihirhotaPas encore d'évaluation

- BeeKeep SBEC AddressDocument2 pagesBeeKeep SBEC Addressmihirhota100% (1)

- SJ25 Manual-EN V1.4Document23 pagesSJ25 Manual-EN V1.4KatarinaSchinaglPas encore d'évaluation

- Mentha Arvensis Mentha Pipperita Mentha Spicata Mentha CitrataDocument1 pageMentha Arvensis Mentha Pipperita Mentha Spicata Mentha CitratamihirhotaPas encore d'évaluation

- Palmarosa DetailsDocument22 pagesPalmarosa Detailsmihirhota0% (1)

- Transcend User ManualDocument11 pagesTranscend User ManualmihirhotaPas encore d'évaluation

- AteesDocument3 pagesAteesmihirhotaPas encore d'évaluation

- CSIR-CIMAP Incense Stick TrainingDocument2 pagesCSIR-CIMAP Incense Stick Trainingmihirhota100% (1)

- Workout RoutineDocument2 pagesWorkout RoutinemihirhotaPas encore d'évaluation

- ASHWAGANDHA DetailsDocument24 pagesASHWAGANDHA DetailsmihirhotaPas encore d'évaluation

- Entities Recognised As StartupDocument3 pagesEntities Recognised As StartupmihirhotaPas encore d'évaluation

- Ashwagandha PDFDocument22 pagesAshwagandha PDFgo25101992Pas encore d'évaluation

- Tender DGPS 08-17Document21 pagesTender DGPS 08-17mihirhotaPas encore d'évaluation

- HBase Architecture PDFDocument32 pagesHBase Architecture PDFmihirhotaPas encore d'évaluation

- TendernoticeDocument3 pagesTendernoticemihirhotaPas encore d'évaluation

- TendernoticeDocument3 pagesTendernoticemihirhotaPas encore d'évaluation

- Mapreduce Program in Java Using Eclipse Counting Words With Hadoop-Running Your First ProgramDocument2 pagesMapreduce Program in Java Using Eclipse Counting Words With Hadoop-Running Your First ProgrammihirhotaPas encore d'évaluation

- MapR - Set Up A Lab Environment in Amazon Web ServicesDocument14 pagesMapR - Set Up A Lab Environment in Amazon Web ServicesfaisalwasimPas encore d'évaluation

- Offerings Mudra LoansDocument5 pagesOfferings Mudra LoansmihirhotaPas encore d'évaluation

- Vedanta CSR: Onkar +91-9937088151Document3 pagesVedanta CSR: Onkar +91-9937088151mihirhotaPas encore d'évaluation

- Certification PortfolioDocument1 pageCertification PortfoliomihirhotaPas encore d'évaluation

- HBase Architecture PDFDocument32 pagesHBase Architecture PDFmihirhotaPas encore d'évaluation

- M 2-I T H: Problems With Traditional Large-Scale Systems and Need For HadoopDocument1 pageM 2-I T H: Problems With Traditional Large-Scale Systems and Need For HadoopmihirhotaPas encore d'évaluation

- Odule Ig: Overview Session On Flume, Oozie and ZookeeperDocument1 pageOdule Ig: Overview Session On Flume, Oozie and ZookeepermihirhotaPas encore d'évaluation

- CapstoneDocument23 pagesCapstoneA - CAYAGA, Kirby, C 12 - HermonPas encore d'évaluation

- Ujian Semester 2Document18 pagesUjian Semester 2Yudha Herdiansyah YudikatPas encore d'évaluation

- Yoruba RecipesDocument68 pagesYoruba RecipesXorenxo100% (1)

- Effectiveness of Banana Peel Fertilizer on Plant GrowthDocument42 pagesEffectiveness of Banana Peel Fertilizer on Plant GrowthNadeja Joy C. Peralta100% (1)

- Treasuryofbotany01lind PDFDocument648 pagesTreasuryofbotany01lind PDFsebastián GiraldoPas encore d'évaluation

- LIKHADocument22 pagesLIKHAAngelica SampangPas encore d'évaluation

- Extraction, Characterization and Enzymatic Degumming of Banana FiberDocument11 pagesExtraction, Characterization and Enzymatic Degumming of Banana FiberJohanita CoraLi Velasque OroscoPas encore d'évaluation

- Entreprenuership and Business PlanningDocument9 pagesEntreprenuership and Business PlanningRica de GuzmanPas encore d'évaluation

- The Impact of Chitosan and Guava Leaf Extract As Preservative To Extend The Shelf-Life of FruitsDocument7 pagesThe Impact of Chitosan and Guava Leaf Extract As Preservative To Extend The Shelf-Life of FruitsAbigail DontonPas encore d'évaluation

- Crop Production Guide Horticulture Crops 2020Document442 pagesCrop Production Guide Horticulture Crops 2020RakshitaPas encore d'évaluation

- Major Fruitcrops Quarterly Bulletin, April - June 2019 Per PSADocument28 pagesMajor Fruitcrops Quarterly Bulletin, April - June 2019 Per PSAteodyPas encore d'évaluation

- Advances in Production Technology of BananaDocument51 pagesAdvances in Production Technology of BananaJabroot KhanPas encore d'évaluation

- Banana: Balbisiana, Depending On Their Genomic Constitution - Bananas Are Vigorously GrowingDocument6 pagesBanana: Balbisiana, Depending On Their Genomic Constitution - Bananas Are Vigorously GrowingPromisePas encore d'évaluation

- Banana Peel's Potential as Eco-Friendly Shoe Polish AlternativeDocument4 pagesBanana Peel's Potential as Eco-Friendly Shoe Polish AlternativeRon Joshua Quirap67% (3)

- Toets Future and PrepositionsDocument4 pagesToets Future and PrepositionslalitafonsecaPas encore d'évaluation

- Philippines Banana Chips Industry AnalysisDocument3 pagesPhilippines Banana Chips Industry AnalysisNeil Mahilum DeclaroPas encore d'évaluation

- Chapter 1-5 Group 2Document24 pagesChapter 1-5 Group 2Johnbill Barangan80% (5)

- Kidapawan City National High SchoolDocument9 pagesKidapawan City National High SchoolIya Elica LambanPas encore d'évaluation

- Herbal MedicineDocument29 pagesHerbal MedicineChickz HunterPas encore d'évaluation

- Banana Fiber: Environmental Friendly Fabric: Uraiwan PitimaneeyakulDocument5 pagesBanana Fiber: Environmental Friendly Fabric: Uraiwan Pitimaneeyakularif septaPas encore d'évaluation

- Examen B2Document11 pagesExamen B2ana vericatPas encore d'évaluation

- احمد ابراهيمDocument25 pagesاحمد ابراهيمAhmd amynPas encore d'évaluation

- Uji Organoleptik Dan Kimia Selai Berbahan Dasar Kulit Pisang TONGKAT LANGIT (Musa Troglodytarum L.)Document13 pagesUji Organoleptik Dan Kimia Selai Berbahan Dasar Kulit Pisang TONGKAT LANGIT (Musa Troglodytarum L.)Mohammad Afif PrabowoPas encore d'évaluation

- Why Banana Domestication MattersDocument14 pagesWhy Banana Domestication MattersJeff HunemeierPas encore d'évaluation

- Food and FarmingDocument38 pagesFood and FarmingKevin LlorentePas encore d'évaluation

- BP Banana (Draft) (2) 12.6.17Document93 pagesBP Banana (Draft) (2) 12.6.17Derwin DomiderPas encore d'évaluation

- Leaves As Dining Plates Food Wraps and Food PackinDocument15 pagesLeaves As Dining Plates Food Wraps and Food PackinAfrizal AfriyandraPas encore d'évaluation

- The Use of 1-Methylcyclopropene (1-MCP) On Fruits and VegetablesDocument21 pagesThe Use of 1-Methylcyclopropene (1-MCP) On Fruits and VegetablesJeritahTongonyaPas encore d'évaluation

- Academic Question Paper Test 15Document23 pagesAcademic Question Paper Test 15Rohan Prajapati67% (3)

- Banana and Its By-Product Utilisation An OverviewDocument7 pagesBanana and Its By-Product Utilisation An Overviewbahasa_280181Pas encore d'évaluation