Académique Documents

Professionnel Documents

Culture Documents

Hanging Brickwork-Hanger Tie System For Solid Bricks: Nstallation Uide

Transféré par

An-an ChanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hanging Brickwork-Hanger Tie System For Solid Bricks: Nstallation Uide

Transféré par

An-an ChanDroits d'auteur :

Formats disponibles

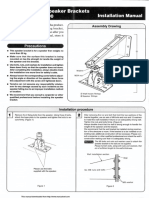

INSTALLATION GUIDE

HANGING BRICKWORK-

HANGER TIE SYSTEM FOR SOLID BRICKS

INSTALLATION PROCEDURE

1. Support angle level 1. Build brickwork up to support angle level on each side of the

opening, ensuring that the top three jamb bricks on one side of

the opening are left out to allow the installation of the last soffit

brick.

2. Install masonry support system in accordance with Ancon

installation guidance and drawings. The Hanger Tie system

uses a support angle with a channel, normally 36/8, welded to

2. the underside.

3. Install temporary support underneath the masonry support

angle to the set distance of the soffit.

Masonry support

system with

4. Offer up one brick and Hanger Tie to mark out dowel

welded channel positions on the brick and remove. Drill two 7mm diameter holes

through each brick at the dowel positions.

3.

5. Install first soffit brick on to former, ensuring that the vertical

joint to the adjacent brick panel is fully filled with type M12 (or

equivalent) mortar.

Masonry support

system with welded

channel 6. Insert Hanger Tie into the channel by turning head through

90º and slide the tie along the channel, pressing it into fresh

mortar. Once in position, cover Tie with more fresh mortar to

create minimum 10mm vertical joint. Ensure the void between

the underside of the support angle and the top of the hung brick

Temporary

support is tightly packed with mortar.

4. 5. 6. Hanger Tie

slides along

Tie head to suit channel profile

channel into

position

Ø

Welded

7mm

Dowel

Hanger Tie

January 2016 Page 1 of 2

INSTALLATION GUIDE

HANGING BRICKWORK-

HANGER TIE SYSTEM FOR SOLID BRICKS

INSTALLATION PROCEDURE

7.

7. Push the next brick onto the dowelled Hanger Tie.

8. Cover the side of the brick with fresh mortar and position next

brick.

9. Repeat steps 6-8 until all soffit bricks are installed. Install SPB

restraint ties as work progresses, typically at 450mm horizontal

8.

centres, ensuring that each tie is completely covered with

mortar.

10. Install final jamb bricks, filling each joint with fresh mortar.

11. Once mortar has achieved design strength, temporary

support may be removed and brickwork may be pointed as

necessary. (Check with your Structural Engineer if unsure).

9. 10. 11.

SPB

Restraint

Tie

While Ancon ensures that its support system will carry the required load and is fully committed to working

closely with all parties in order to achieve successful suspended brickwork, the responsibility for the integrity of

President Way, President Park, Sheffield S4 7UR

the overall design rests with the designer of the masonry feature. Tel: +44 (0) 114 275 5224

The Construction applications and details provided in this guide are indicative only. In every case installation Fax: +44 (0) 114 276 8543

should be entrusted to appropriately qualified and experienced persons. Normal handling precautions should

be taken to avoid physical injury. Ancon Building Products cannot be held responsible for any injury as a result Email: info@ancon.co.uk

of using our products, unless such injury arises as a result of our negligence. Visit: www.ancon.co.uk

Page 2 of 2 © Ancon Building Products, 2016 January 2016

Vous aimerez peut-être aussi

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideD'EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuidePas encore d'évaluation

- Impaling Disc/ Adhesive: Wall Panel Installation GuidesDocument6 pagesImpaling Disc/ Adhesive: Wall Panel Installation GuidesInterior ProjectsPas encore d'évaluation

- Personnel Safety Net System: Installation InstructionsDocument18 pagesPersonnel Safety Net System: Installation InstructionsMehmet Atakan KonanPas encore d'évaluation

- Use Wood Panels as Wall FinishDocument18 pagesUse Wood Panels as Wall FinishLAGAN MARWAHPas encore d'évaluation

- KTM 876 ManualDocument12 pagesKTM 876 ManualAle Stos GPas encore d'évaluation

- Gabions Install GuideDocument2 pagesGabions Install GuideTele2 Phone2100% (1)

- Rocla Alfabloc BrochureDocument12 pagesRocla Alfabloc BrochureJakesPas encore d'évaluation

- A5 Koto Hand-Book For ContractorsDocument73 pagesA5 Koto Hand-Book For ContractorsYasher Meera SaibPas encore d'évaluation

- Mighty Bracket 97705 Support Tool BrochureDocument2 pagesMighty Bracket 97705 Support Tool BrochureHernan GuerraPas encore d'évaluation

- Slope ProtectionDocument3 pagesSlope Protectionshima2727Pas encore d'évaluation

- Sips Erection GuideDocument12 pagesSips Erection GuideKalibabaPas encore d'évaluation

- Bollard Installation Part 2Document5 pagesBollard Installation Part 2Bryan HermawanPas encore d'évaluation

- 04 - WindpostsDocument1 page04 - WindpostsPauloRobertoLiñanFigueiredoPas encore d'évaluation

- S79PF - Installation ManualDocument5 pagesS79PF - Installation Manualakun pc85Pas encore d'évaluation

- Concrete Pipe Installation Guide-CPMDocument17 pagesConcrete Pipe Installation Guide-CPMSankar CdmPas encore d'évaluation

- INSTALLATION-GUIDE-RENO-MATTRESSES-5Document3 pagesINSTALLATION-GUIDE-RENO-MATTRESSES-5Chee Soon LeePas encore d'évaluation

- B) Briefly Discuss With Sketches The Theories and Practices For Key Stone Retaining Wall System, Their Appropriate Application and InstallationDocument3 pagesB) Briefly Discuss With Sketches The Theories and Practices For Key Stone Retaining Wall System, Their Appropriate Application and InstallationAmal AmranPas encore d'évaluation

- Eazistrip Reinforcement Continuity SystemsDocument12 pagesEazistrip Reinforcement Continuity SystemscormolioPas encore d'évaluation

- 04 - WindpostsDocument1 page04 - WindpostsNiemPas encore d'évaluation

- ManualDocument2 pagesManualsantosPas encore d'évaluation

- Porch Post InstallDocument4 pagesPorch Post InstallTimPas encore d'évaluation

- Sliding Door Installation InstructionsDocument2 pagesSliding Door Installation InstructionsJaseSG1Pas encore d'évaluation

- Installation guide for horizontally laid europanel panelsDocument5 pagesInstallation guide for horizontally laid europanel panelsJL A100% (1)

- ABM Terengganu Training Presentation April 2008Document69 pagesABM Terengganu Training Presentation April 2008Wan AzimasPas encore d'évaluation

- Oga 9.6 Installation Manual For KCNDocument20 pagesOga 9.6 Installation Manual For KCNNgadiyantoPas encore d'évaluation

- Brick CladdingDocument8 pagesBrick CladdingAnonymous PWdOlxYPas encore d'évaluation

- Tools Required For Installation: PAC Blocks & LintelsDocument11 pagesTools Required For Installation: PAC Blocks & LintelsNash370Pas encore d'évaluation

- Installation Guide: Issue 1Document16 pagesInstallation Guide: Issue 1RostocaniePas encore d'évaluation

- Architecture/MOS For Masonry Rev.3Document4 pagesArchitecture/MOS For Masonry Rev.3Eva MarquezPas encore d'évaluation

- Method Statement - Installation of Fencing and GateDocument5 pagesMethod Statement - Installation of Fencing and Gategpjegatheesh67% (3)

- New Installation ManualDocument30 pagesNew Installation ManualNgadi YantoPas encore d'évaluation

- Polyvinyl Blanket Barrier Boom Installation Guide 2013Document14 pagesPolyvinyl Blanket Barrier Boom Installation Guide 2013kohatian27796105Pas encore d'évaluation

- Brief Installation Guide For Fibrolit UltraDocument2 pagesBrief Installation Guide For Fibrolit UltraK PreitoPas encore d'évaluation

- Good Construction Practices: Manual For Restoration and Retrofitting of Rural Structures in KashmirDocument27 pagesGood Construction Practices: Manual For Restoration and Retrofitting of Rural Structures in Kashmirjk.dasguptaPas encore d'évaluation

- Fosroc Conbextra Epoxy Grouts Application GuideDocument3 pagesFosroc Conbextra Epoxy Grouts Application GuideChukwuma OgbonnaPas encore d'évaluation

- Thin Brick Installation GuideDocument12 pagesThin Brick Installation GuideGlavanRafaelPas encore d'évaluation

- Deep Piezometer Installation GuideDocument7 pagesDeep Piezometer Installation GuideFrancisco Ordoñez MuñozPas encore d'évaluation

- Self Drilling Systems Product CatalogueDocument15 pagesSelf Drilling Systems Product CatalogueJose Manuel ReyesPas encore d'évaluation

- 2080velocity Duct Gasket Installation Instruction - SEMCO 2016-11Document2 pages2080velocity Duct Gasket Installation Instruction - SEMCO 2016-11Bülent KabadayiPas encore d'évaluation

- BrickworksDocument17 pagesBrickworksSyerifaizal Hj. MustaphaPas encore d'évaluation

- HAB 1 End To End Assembly 11-07-11Document32 pagesHAB 1 End To End Assembly 11-07-11Wamae Kangethe0% (1)

- Secant Pile Wall Construction MethodsDocument54 pagesSecant Pile Wall Construction Methodsariyarathne100% (4)

- Secant Piled Wall Construction TechniquesDocument54 pagesSecant Piled Wall Construction TechniquesK H V V MADUSHANKAPas encore d'évaluation

- User Guide / Guía Del Usuario: Diagonal Projection ScreenDocument8 pagesUser Guide / Guía Del Usuario: Diagonal Projection ScreenLaura LozaPas encore d'évaluation

- StandoffinstallationDocument1 pageStandoffinstallationCITLALLI MACIAS (TALLER CMARQ)Pas encore d'évaluation

- Bikesport Micro-Camper PDFDocument15 pagesBikesport Micro-Camper PDFviocons72Pas encore d'évaluation

- Simplified Radio Chassis HolderDocument1 pageSimplified Radio Chassis HolderHenry PalPas encore d'évaluation

- Composite Stone Veneer: Installation GuideDocument13 pagesComposite Stone Veneer: Installation GuideRajPas encore d'évaluation

- Installation Instructions BWC Waterline Shower ChannelDocument4 pagesInstallation Instructions BWC Waterline Shower ChannelBLUCHERPas encore d'évaluation

- Cavity Instructions 2016Document2 pagesCavity Instructions 2016James GraveyPas encore d'évaluation

- EI Install Manual GEN II 111418Document22 pagesEI Install Manual GEN II 111418mozhi selvamPas encore d'évaluation

- Tap Stand ConstructionDocument22 pagesTap Stand ConstructionKevin PiocPas encore d'évaluation

- Fitting Instruction The Instruction of The Assembly: From ManufacturerDocument2 pagesFitting Instruction The Instruction of The Assembly: From Manufacturerm aliPas encore d'évaluation

- FP McCann Precast Concrete Headwalls InstallationDocument4 pagesFP McCann Precast Concrete Headwalls InstallationgemotorresPas encore d'évaluation

- Tehnickko Uputstvo Za Montazu SistemaDocument8 pagesTehnickko Uputstvo Za Montazu Sistemao5mal13kPas encore d'évaluation

- Kingspan K5 Install GuideDocument10 pagesKingspan K5 Install GuidetekijacPas encore d'évaluation

- Masterseal 909: Re-Injectable Hose For Construction and Cold Joints in ConcreteDocument2 pagesMasterseal 909: Re-Injectable Hose For Construction and Cold Joints in Concretevelmurug_balaPas encore d'évaluation

- Channel Master CM 3020 Deep Fringe Advantage TV Antenna ManualDocument4 pagesChannel Master CM 3020 Deep Fringe Advantage TV Antenna ManualDavid WardPas encore d'évaluation

- Description & InstalationDocument3 pagesDescription & InstalationEhtesham AliPas encore d'évaluation

- Series Anff: Adjustable Neoprene Floating FloorDocument4 pagesSeries Anff: Adjustable Neoprene Floating FloorCarlos Torres OliverosPas encore d'évaluation

- Standard Operating Procedure: PurposeDocument2 pagesStandard Operating Procedure: PurposeAn-an ChanPas encore d'évaluation

- Defect Flow ChartDocument1 pageDefect Flow ChartAn-an ChanPas encore d'évaluation

- 4.0 Screeding Work Instruction ManualDocument2 pages4.0 Screeding Work Instruction ManualAn-an ChanPas encore d'évaluation

- Block Work-Method StatementDocument7 pagesBlock Work-Method StatementA1994486% (22)

- Pre Commissioning Check List of GeneratorDocument26 pagesPre Commissioning Check List of GeneratorSUROHMAN ROHMANPas encore d'évaluation

- SikaTop Seal-107 2011-10 - 1Document4 pagesSikaTop Seal-107 2011-10 - 1hanifPas encore d'évaluation

- Bar Construction PDFDocument1 pageBar Construction PDFJohn KurongPas encore d'évaluation

- Sharing of Good Practices-High QLASSIC Score PDFDocument36 pagesSharing of Good Practices-High QLASSIC Score PDFAn-an ChanPas encore d'évaluation

- Englishhandbook07 03 14Document32 pagesEnglishhandbook07 03 14Yogesh Mhaske100% (1)

- 45m House introduction-AMJHOUSEDocument24 pages45m House introduction-AMJHOUSEAn-an ChanPas encore d'évaluation

- Bomba InspectionDocument30 pagesBomba InspectionAn-an Chan100% (1)

- 4.0 Screeding Work Instruction ManualDocument2 pages4.0 Screeding Work Instruction ManualAn-an ChanPas encore d'évaluation

- MOS Ceiling 2.1.Document10 pagesMOS Ceiling 2.1.An-an ChanPas encore d'évaluation

- Types of sealants and their applicationsDocument6 pagesTypes of sealants and their applicationsAn-an ChanPas encore d'évaluation

- Method Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksDocument16 pagesMethod Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksAn-an ChanPas encore d'évaluation

- Mos BrickworkDocument6 pagesMos BrickworkAn-an Chan100% (3)

- DEFECTDocument11 pagesDEFECTAn-an ChanPas encore d'évaluation

- Method Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksDocument16 pagesMethod Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksAn-an ChanPas encore d'évaluation

- Building PathologyDocument21 pagesBuilding PathologyAn-an ChanPas encore d'évaluation

- AuditoriumDocument45 pagesAuditoriumAn-an Chan100% (1)

- Fire ProtectionDocument58 pagesFire ProtectionAn-an Chan50% (2)

- Sources of LawDocument1 pageSources of LawAn-an ChanPas encore d'évaluation

- Sanitation in IslamDocument32 pagesSanitation in IslamAn-an Chan100% (1)

- Inventory PlanningDocument45 pagesInventory PlanningAn-an ChanPas encore d'évaluation

- Exp 03Document5 pagesExp 03An-an ChanPas encore d'évaluation

- CCM Paper 2Document60 pagesCCM Paper 2Lo Khim NyanPas encore d'évaluation

- Active Fire ProtectiondocxDocument51 pagesActive Fire ProtectiondocxAn-an ChanPas encore d'évaluation

- Soil TestDocument1 pageSoil TestAn-an ChanPas encore d'évaluation

- Experiment No.1 Water Content Determination: PurposeDocument2 pagesExperiment No.1 Water Content Determination: PurposeAn-an ChanPas encore d'évaluation

- Tletvl Technical Drafting Specialization Las Week5 & 6Document10 pagesTletvl Technical Drafting Specialization Las Week5 & 6Nixon AtienzaPas encore d'évaluation

- World Economic Forum BSBDocument7 pagesWorld Economic Forum BSBErlangga Rizqi FitriansyahPas encore d'évaluation

- Developing Ssrs Reports For Dynamics AxDocument23 pagesDeveloping Ssrs Reports For Dynamics AxAhmed Farag IbrahimPas encore d'évaluation

- Proposed 1 Storey Residential Building: Republic of The PhilippinesDocument1 pageProposed 1 Storey Residential Building: Republic of The PhilippinesKristine Anne Montoya QuirantePas encore d'évaluation

- Chapter 6 - Chapter 6. Voice Gateways TroubleshootingDocument500 pagesChapter 6 - Chapter 6. Voice Gateways TroubleshootingmypdPas encore d'évaluation

- How To Restore Rman Backups On A Different Node When The Directory Structures Are DifferentDocument5 pagesHow To Restore Rman Backups On A Different Node When The Directory Structures Are Differentalok_mishra4533Pas encore d'évaluation

- Design For RC Flat SlabsDocument70 pagesDesign For RC Flat SlabsAil AafaaqPas encore d'évaluation

- User Manual: Rovus Arctic Air UltraDocument76 pagesUser Manual: Rovus Arctic Air Ultrad_ghitacPas encore d'évaluation

- GFRC AppliccationDocument79 pagesGFRC AppliccationKristiantoPas encore d'évaluation

- Disk Defrag ReportDocument35 pagesDisk Defrag ReportAsdkjha SadkjasdPas encore d'évaluation

- Helsinki GuideDocument98 pagesHelsinki GuideInês AlvesPas encore d'évaluation

- Unique & Latest Civil Engineering Project, Seminar, Thesis & Presentation Topics - CivilDigital PDFDocument6 pagesUnique & Latest Civil Engineering Project, Seminar, Thesis & Presentation Topics - CivilDigital PDFAlfredo L. Penachos100% (1)

- Is.5503.1.1969 SiloDocument17 pagesIs.5503.1.1969 SiloGautam PaulPas encore d'évaluation

- Report1 - Study of Structural System in Architecture - Post Lintel - 5,10,15,20,24,29Document81 pagesReport1 - Study of Structural System in Architecture - Post Lintel - 5,10,15,20,24,29নূরুন্নাহার চাঁদনী100% (1)

- CHARACTERISTICS-OF-THE-BUILDING-1 FinalDocument25 pagesCHARACTERISTICS-OF-THE-BUILDING-1 FinalDominador Lozano Jr.Pas encore d'évaluation

- LG LSR120H Service ManualDocument60 pagesLG LSR120H Service ManualFrank VartuliPas encore d'évaluation

- Short Cut KeysDocument6 pagesShort Cut Keysجنید سلیم چوہدریPas encore d'évaluation

- Advance Cloud Computing STTPDocument2 pagesAdvance Cloud Computing STTPBhushan JadhavPas encore d'évaluation

- Spring Webflow ReferenceDocument92 pagesSpring Webflow Referencemenna_moustafaPas encore d'évaluation

- Entry-Level Web Developer Seeks Challenging RoleDocument1 pageEntry-Level Web Developer Seeks Challenging RoleShubham MehtaPas encore d'évaluation

- WSM West Salem MachineryDocument7 pagesWSM West Salem Machinerymostafa sherifPas encore d'évaluation

- Flexural DesignDocument38 pagesFlexural DesignJesús Rodríguez RodríguezPas encore d'évaluation

- MTX 4102 SIP ReferenceDocument502 pagesMTX 4102 SIP ReferenceFederico MariottiPas encore d'évaluation

- LSI Starbeam Series Brochure 1994Document6 pagesLSI Starbeam Series Brochure 1994Alan MastersPas encore d'évaluation

- Criticism Agaisnt Eisenmann and Derrida PDFDocument8 pagesCriticism Agaisnt Eisenmann and Derrida PDFPoorna ChinnapaPas encore d'évaluation

- Tekla Structural Detailing Expert with 10+ Years ExperienceDocument4 pagesTekla Structural Detailing Expert with 10+ Years ExperienceGeorgeEdward0% (1)

- VLSI Design1Document29 pagesVLSI Design1Sisay ADPas encore d'évaluation

- 1.introductionc Mobile Computingc CC C CC C C C C C C CDocument4 pages1.introductionc Mobile Computingc CC C CC C C C C C C CFiqri MohidinPas encore d'évaluation

- BRKRST-3114 The Art of Network ArchitectureDocument60 pagesBRKRST-3114 The Art of Network ArchitectureTimucin DIKMEN100% (1)

- Reading Comprehension Practice TestDocument12 pagesReading Comprehension Practice TestGabino SantosPas encore d'évaluation