Académique Documents

Professionnel Documents

Culture Documents

Assignment 3

Transféré par

Sanjay SainTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Assignment 3

Transféré par

Sanjay SainDroits d'auteur :

Formats disponibles

Sri Balaji College of Engg. & Tech.

, Jaipur

Department of Mechanical Engineering

Session (2018-19)

Branch: - Mechanical Engineering

B.Tech. IV Year/ VII Semester Subject: - Operations Management (7ME5A)

Assignment No. 3

Q.1 (a) What is facility location? Explain need for location decisions.

(b)What are the factors that affect facility location explain in details.

Q.2 What is facility layout? Explain the types of layouts with advantages and disadvantages.

Q.3 (a) What is line balancing? Explain the balancing procedure with example.

(b) Define material handling process. Explain different types of material handling equipments

Q.4 Explains the various types of quantitative techniques for location facility?

Q.5 expected location A,B,C have the cost structures shown for producing a product expected to sell at

rs 100 per unit. Find the most economical location for an expected volume of 2000 units per year. Also

calculate the range of annual volume of production for which each of the location A, B and C would be

most economical. Use location break even analysis.

Location Fixed cost per year Variable cost per unit

A 25000/- .50

B 50000/- .25

C 80000/- .15

Q.6 (a) Describe different levels of planning and differentiate between long range, intermediate range

and short range planning.

(b) Write short note on MRP-II and ERP.

Q.7 What is material requirement planning (MRP)? What are the inputs and outputs required by the

MRP processing logic?

Q.8 What is meant by Aggregate production planning? Explain the techniques of aggregate planning

through flow chart.

Q.9 PC Mark (P) Ltd is a personal computer assembling company based at Hyderabad. Its marketing

department has given the demand forecast shown in table below. Every worker assemble two computers

a day. The overtime cost is Rs.3 per day per unit in excess of the maximum capacity of the factory, that

is, 200 units. The company wants to find the total cost involved in the following plans: (a) level output

plan, (b) Chase plan , and (c) an intermediate plan(a combination of level output rate and chase plans) .

Month Jan. Feb. March April May June

Demand forecast 1000 3000 1000 5000 7000 2000

No. of working days 24 25 20 22 20 24

Q.10 What do you mean by Master Production Schedule? Explain in detail with suitable example.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Program of ActivitiesDocument2 pagesProgram of ActivitiesVon Limuel LopezPas encore d'évaluation

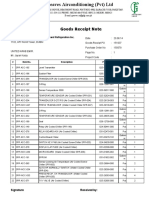

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocument4 pagesGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanPas encore d'évaluation

- Cross Border Data Transfer Consent Form - DecemberDocument3 pagesCross Border Data Transfer Consent Form - DecemberFIDELIS MUSEMBIPas encore d'évaluation

- Finding Targets PDFDocument9 pagesFinding Targets PDFSteve TangPas encore d'évaluation

- GL Career Academy Data AnalyticsDocument7 pagesGL Career Academy Data AnalyticsDeveloper GuidePas encore d'évaluation

- Changing Sentences in The Simple Present Tense Into PassiveDocument4 pagesChanging Sentences in The Simple Present Tense Into PassiveBernadette NartePas encore d'évaluation

- Toftejorg TZ-75 Rotary Jet Head - Portable: Fast, Effective Impact CleaningDocument3 pagesToftejorg TZ-75 Rotary Jet Head - Portable: Fast, Effective Impact CleaningSamo SpontanostPas encore d'évaluation

- World English 2ed 1 WorkbookDocument80 pagesWorld English 2ed 1 WorkbookMatheus EdneiPas encore d'évaluation

- تأثير العناصر الثقافية والبراغماتية الأسلوبية في ترجمة سورة الناس من القرآن الكريم إلى اللغة الإ PDFDocument36 pagesتأثير العناصر الثقافية والبراغماتية الأسلوبية في ترجمة سورة الناس من القرآن الكريم إلى اللغة الإ PDFSofiane DouifiPas encore d'évaluation

- 1.2 The Basic Features of Employee's Welfare Measures Are As FollowsDocument51 pages1.2 The Basic Features of Employee's Welfare Measures Are As FollowsUddipta Bharali100% (1)

- Scan WV1DB12H4B8018760 20210927 1800Document6 pagesScan WV1DB12H4B8018760 20210927 1800Sergio AlvarezPas encore d'évaluation

- Bosch KE-Jetronic System DescriptionDocument3 pagesBosch KE-Jetronic System DescriptionJack Tang50% (2)

- CE-23113-SP-902-R01-00 Asset SpecificationDocument14 pagesCE-23113-SP-902-R01-00 Asset SpecificationСветлана ФайберPas encore d'évaluation

- Mediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsDocument15 pagesMediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsWitty MindsPas encore d'évaluation

- Reviewer in PE&H 1st Quarter 18-19Document7 pagesReviewer in PE&H 1st Quarter 18-19rhex minasPas encore d'évaluation

- Ateneo de Naga University: Professional Training For Teacher 4.0Document10 pagesAteneo de Naga University: Professional Training For Teacher 4.0Rosemarie BrionesPas encore d'évaluation

- Formulae HandbookDocument60 pagesFormulae Handbookmgvpalma100% (1)

- Antenna Systems - Standard Format For Digitized Antenna PatternsDocument32 pagesAntenna Systems - Standard Format For Digitized Antenna PatternsyokomaPas encore d'évaluation

- Topic 3 Intellectual RevolutionDocument20 pagesTopic 3 Intellectual RevolutionOlive April TampipiPas encore d'évaluation

- Hexoloy SP Sic TdsDocument4 pagesHexoloy SP Sic TdsAnonymous r3MoX2ZMTPas encore d'évaluation

- SQL and Hand BookDocument4 pagesSQL and Hand BookNaveen VuppalaPas encore d'évaluation

- NCRA Membership InformationDocument1 pageNCRA Membership Informationbkharkreader1301Pas encore d'évaluation

- S25580 MSDS Corn Starch FisherchiDocument6 pagesS25580 MSDS Corn Starch FisherchiProcurement ProlinePas encore d'évaluation

- Thesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKDocument194 pagesThesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKAhmedPas encore d'évaluation

- Natal Chart Report PDFDocument17 pagesNatal Chart Report PDFAnastasiaPas encore d'évaluation

- "Large Quote Goes Here.": Title or Heading HereDocument2 pages"Large Quote Goes Here.": Title or Heading HereHesti RianaPas encore d'évaluation

- Sustainable Development Precautionary PR 2Document12 pagesSustainable Development Precautionary PR 2PramodPas encore d'évaluation

- I.A.-1 Question Bank EM-3 (Answers)Document11 pagesI.A.-1 Question Bank EM-3 (Answers)UmmPas encore d'évaluation

- With You: Full-Line CatalogDocument68 pagesWith You: Full-Line CatalogCOMIPas encore d'évaluation

- HP Scanjet N9120 (Service Manual) PDFDocument394 pagesHP Scanjet N9120 (Service Manual) PDFcamilohto80% (5)