Académique Documents

Professionnel Documents

Culture Documents

RHH RHM RHA Installation Manual

Transféré par

Loading Dock ProCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

RHH RHM RHA Installation Manual

Transféré par

Loading Dock ProDroits d'auteur :

Formats disponibles

Rite-Hite® & By Rite-Hite

Dock Leveler

Installation Manual

RHM & ML-900

Mechanical Dock Leveler

part of the SMOOTH TRANSITION DOK SYSTEMTM

RHM Shown

RHH Hydra-RiteTM / Base

& HL-900 Hydraulic

Dock Leveler

part of the SMOOTH TRANSITION DOK SYSTEMTM

RHH Shown

RHA & AL-900

Air Powered

Dock Leveler

part of the SMOOTH TRANSITION DOK SYSTEMTM

RHA Shown

MADE IN U.S.A.

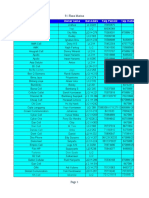

This Manual Covers Levelers Built After Serial Numbers:

RHM Series: 04ID410001M and up RHH Series: 13GD480708M and up RHA Series: 04ID400001M and up

ML Series: 04CD100001M and up HL Series: 13GD480708M and up AL Series: 04CD130001M and up

PRINTED IN U.S.A. PUBLICATION NO. 1237

RITE-HITE PRINT SHOP RITE-HITE PART NO. 0128126

JANUARY 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

TABLE OF CONTENTS

NOTICE TO USER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SAFETY WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

SHIMMING DETAIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

LEVELER ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

BUMPER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

LIP SUPPORT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

TYPICAL COMPLETE INSTALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

GENISYS WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

RITE-HITE WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BACK COVER

NOTICE TO USER

®

Your local Rite-Hite representative provides a Planned Maintenance Program (P.M.P.) which can be fitted to your

®

specific operation. Call your local representative or Rite-Hite at 414-355-2600.

The Rite-Hite products in this manual are covered by one or more of the following U.S. patents: 5,546,623;

5,553,987; 5,582,498; 5,664,930; 5,702,223; 5,762,459 (RE: 37,570); 5,882,167; 6,065,172; 6,070,283; 6,085,375;

6,089,544; 6,092,970; 6,106,212; 6,116,839; 6,190,109; 6,276,016; 6,311,352; 6,318,947; 6,322,310; 6,360,394;

6,368,043; 6,431,819; 6,488,464; 6,499,169; 6,505,713; 6,520,472; 6,524,053; 6,634,049; 6,726,432; 6,773,221;

6,832,403; 6,880,301; 7,032,267; 7,062,814; 7,134,159; 7,213,285; 7,216,391; 7,363,670; 7,380,305; 7,503,089;

7,533,431; 7,546,655; 7,584,517; 7,681,271; 7,823,239; 7,841,823; 7,877,831; 7,914,042; 8,006,811; 8,065,770;

8,141,189; 8,191,194; 8,286,757; 8,287,223; 8,303,235; 8,307,956; 8,443,474; 8,464,384; 8,464,846; 8,465,245 and

® TM ® ® TM

pending U.S and foreign patent applications. RITE-HITE , THINMAN , SAFE-T-LIP , HYDRACHEK , WHEEL-LOK ,

® ® TM ® TM TM ®

DOK-LOK , DUAL-DOK , SAFE-T-STRUT , DOK-COMMANDER , JUMBO , HYDRA-RITE , SAFE-T-GATE , RITE-

TM TM ®

VU LIGHT COMMUNICATION SYSTEM and SMOOTH TRANSITION DOK SYSTEM , are trademarks of Rite-Hite .

2 Pub. No. 1237 - January 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

SAFETY WARNING

When working with electrical or electronic con-

trols, make sure that the power source has been

locked out and tagged out according to OSHA

regulations and approved local electrical codes.

D

OP O N

ER O T

XX

AT

XX XXX

XX X

E

XX XXX

XX XX

XX X

X

FIGURE 1 - LOCKOUT/TAGOUT

LOCKOUT/TAGOUT PROCEDURES

The Occupational Safety and Health Administration (OSHA) requires, in addition to posting safety warnings and barri-

cading the work area (including, but not limited to, trucking office and loading docks), that the power supply has been

locked in the OFF position or disconnected. It is mandatory that an approved lockout device is utilized. An example of

a lockout device is illustrated. The proper lockout procedure requires that the person responsible for the repairs is the

only person who has the ability to remove the lockout device.

In addition to the lockout device, it is also a requirement to tag the power control in a manner that will clearly note that

repairs are under way and state who is responsible for the lockout condition. Tagout devices have to be constructed

and printed so that exposure to weather conditions, or wet and damp locations, will not cause the tag to deteriorate or

become unreadable.

RITE-HITE® does not recommend any particular lockout device, but recommends the utilization of an OSHA approved

device (refer to OSHA regulation 1910.147). RITE-HITE® also recommends the review and implementation of an entire

safety program for the Control of Hazardous Energy (Lockout/Tagout). These regulations are available through OSHA

publication 3120.

This is the highest level statement. Failure to The statements used with this level of warning

follow the listed instructions will most likely deal with a safe operating procedure. If the pro-

result in severe injury or death. cedure is ignored the possibility of personal

injury may exist.

This is a statement of serious hazard. Failure to IMPORTANT is used to draw attention to a pro-

follow the listed instructions could place the cedure that needs to be followed to prevent

individual at risk of serious injury or death. machine damage.

Pub. No. 1237 - January 2014 3

RITE-HITE® & Genisys Dock Leveler Installation Manual

OTHER IMPORTANT OPERATIONAL SAFETY WARNINGS

Never be under the dock leveler platform or lip Always barricade the dock leveler at ground

without: level and dock level from any form of traffic

when maintenance is required.

• Installing the Safe-T-StrutTM or other

supporting device.

• If lip needs to be extended, follow

procedures shown under Safety Devices on

the following page.

Inspect the dock leveler monthly to ensure that

• Turning off power to the control box. there are no broken or worn parts which could

cause injury to personnel or damage to the

• Locking out and tagging out the main equipment.

power source, as shown under Safety

Warnings on preceding page.

• Before starting installation or maintenance,

check and follow the safety procedures of

the facility where the dock leveler is being

installed.

• Never enter a truck/trailer until its brakes are

set, air has been dumped from air ride

suspension (if applicable), and you have

visually inspected to be sure truck/trailer is

securely held in place by a vehicle restraint

or wheel chock per OSHA regulations.

• Never operate the leveler with you, anyone,

or anything on, or in front of the leveler, or

without a truck/trailer parked in position, or

from on the truck/trailer bed.

• DO NOT operate with anyone under platform

or in front of the lip.

• When leveler is not in use, always store it so

that it is supported by the lip supports and

that it is level with the surrounding dock

floor.

• If a malfunction does occur, always call your

authorized RITE-HITE® service representative

immediately.

4 Pub. No. 1237 - January 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

SAFETY DEVICES RITE-HITE LEVELERS

Never be under the dock leveler platform or lip • Post warnings and barricades at dock level

without: and at drive level to indicate that work is

being done around and under the leveler

• Installing the Safe-T-Struttm. See below right. platform.

This can be done with the assistance of

another person by: • Lockout/Tagout power to the leveler and post

warnings when work is being performed on

- Raise leveler until platform reaches its the leveler.

highest position and lip extends.

Continue to maintain this position.

- Then have assistant insert the smaller end

of the Safe-T-StrutTM through the hole in

the middle of the leveler lip and place the

strut’s wider open end over the base

located on the leveler’s front frame. Align

the holes on the base and the Safe-T-

StrutTM so that the leveler may be secured

with the retaining pin and safety clip.

- Release the push button on powered

levelers allowing the Safe-T-StrutTM to rest

on the underside of the lip.

• Lockout/Tagout power supply.

- Turn off the power to the control box.

- Lockout/tagout the main power source, as

shown under Safety Warnings on the

inside front cover of this manual.

- Always barricade the leveler at dock level

and drive level to prevent any

unauthorized use of the leveler.

Remove the Maintenance Support.

• For Safe-T-StrutTM removal, have an

assistant raise the leveler to its highest

position with lip fully extended. Release the

safety clip and remove retaining pin. Lift strut

off base, and remove from lip. Return the

Safe-T-StrutTM to the proper storage position.

• If you are unable to install the Maintenance

Support properly, contact your authorized

RITE-HITE® Service Representative or RITE-

HITE® Customer Service at 1-414-355-2600.

FIGURE 2 - INSTALL SAFE-T-STRUTTM SUPPORT

Pub. No. 1237 - January 2014 5

RITE-HITE® & Genisys Dock Leveler Installation Manual

SAFETY DEVICES GENISYS LEVELERS

Never be under the dock leveler platform or lip • Post warnings and barricades at dock level

without: and at drive level to indicate that work is

being done around and under the leveler

• Installing the Maintenance Support. See platform.

below right. This can be done with the

assistance of another person by: • Lockout/Tagout power to the leveler and post

warnings when work is being performed on

- Raise leveler until platform reaches its the leveler.

highest position and lip extends.

Continue to maintain this position.

- Then have assistant insert the

Maintenance Support over the base INSERT INTO CUP

located on the leveler’s front frame.

- Release the pushbutton on powered

levelers allowing the support to rest inside

the lip cup on the underside of the lip.

• Lockout/Tagout power supply.

- Turn off the power to the control box.

- Lockout/tagout the main power source, as

shown under Safety Warnings on the

inside front cover of this manual.

- Always barricade the leveler at dock level

and drive level to prevent any

unauthorized use of the leveler.

Remove the Maintenance Support.

• For Maintenance Support removal, have an

assistant raise the leveler to its highest

position with lip fully extended. Lift the

support off base. Return the Maintenance INSERT ONTO

Support to the proper storage position.

BASE

• If you are unable to install the Maintenance

FIGURE 3 - INSTALL MAINTENANCE SUPPORT

Support properly, contact your authorized

RITE-HITE® Service Representative or RITE-

HITE® Customer Service at 1-414-355-2600.

6 Pub. No. 1237 - January 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

INSTALLATION INSTRUCTIONS

PREPARATION PRIOR TO INSTALLATION

1. Check pit to insure it meets pit details. If pit does not

3” 15º

match pit details, contact your local representative or 2”

RITE-HITE® before proceeding. DIA. 1-1/2”

NOTE: Unit may not operate properly if pit is not 1-1/2”

correct.

2. Leave shipping bands on leveler until instructed to 8”

remove them. Flat

3 -1/2”

3. RHA and AL Series Only: Verify there are no

protrusions from the pit floor located under the tower

3/4”

assembly. If so, remove protrusions as required. Nut,

(example: grind down anchor bolt heads) Flat, 1-3/4” 1” Dia.

3/8” x 3” x 8” Threaded Rod,

4. RHH, HL, RHA and AL Series Only: Verify that

Hard Rolled Steel 1” Dia. x 2” LG.

leveler voltage matches the voltage supplied at pit,

and that proper electrical junction box or

weatherproof outlet has been installed. 2 required, Supplied by others.

5. Clean out pit and remove all debris from work area. FIGURE 4 - HANDLING PLATE

INSTALLATION PROCEDURES

1. Handling plates must be inserted into the forward 2. Attach lifting chain, lift leveler and position above pit.

handling holes of the toe guards. See Figure 4 and 5. Lower leveler into pit. See Figure 5.

Handling Plate

Lifting Chain

Nut Toe guard

Handling Plate

Rear Transition

Top Of Leveler Plate

Shipping Bands

Lip Dock Floor

Platform Assy.

Front Frame Angle

Frame

See Step #3

Front Curb Angle

Dock Face Pit Floor

Rear Curb Angle

Side Curb Angle

FIGURE 5 - PLACEMENT OF LEVELER

Pub. No. 1237 - January 2014 7

RITE-HITE® & Genisys Dock Leveler Installation Manual

INSTALLATION INSTRUCTIONS CONT.

3. Center leveler in pit so that equal gaps are

maintained on each side of the leveler. See Figure 6.

4. Push leveler straight back until the front frame angle

is flush with the front curb angle. If the pit is not

square, push leveler straight back until the front

frame angle is completely behind the front curb angle

by no more than 1/4 inch. The front frame angle

should never extend past the front curb angle.

NOTES: One Inch

Maximum Cut

a. If the leveler cannot be pushed back far enough, the

back edge of the rear transition plate can be cut off

up to 1 inch. If trimming the back edge of angle does

not allow frame to be positioned properly in pit,

contact your local representative or RITE-HITE® for

assistance. Check the area between the rear

transition plate and the back of the pit. If a gap exists,

place spacers between the rear transition plate and

the rear curb angle. Tack weld spacers to the rear

transition plate only. See Figure 7 and 8.

b. Minimum electrode must be 1/8", 7018 or better.

FIGURE 7 - TRIM TRANSITION PLATE

2 places

each spacer

1/4” Tack

as necessary.

Fill gap between rear

Rear edge of leveler frame must be against rear transition plate and

curb angle. Shim or trim rear transition plate as rear curb angle on

necessary. If pit is not square, See Figure 6. each end with a 3

inch long spacer.

Equal gaps

must be

C

Equal gaps must be maintained on L

maintained on each side each side of

of the leveler. leveler.

Fill gap between rear

C transition plate and

L

rear curb angle

behind hinge lugs.

Spacer must span

distance from outside

TOP VIEW OF to outside of hinge

LEVELER IN PIT lugs

Frame must be in contact with

rear curb angle

FIGURE 6 - LEVELER PLACEMENT FIGURE 8 - REAR FRAME SPACERS

8 Pub. No. 1237 - January 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

INSTALLATION INSTRUCTIONS CONT.

8. Place a mark on the face of the front frame angle to

indicate the frame centerline. Also, place a mark on

the face of the lip to indicate the lip/platform

centerline.

• ALWAYS ground to the frame or front pit 9. Shift the front frame angle sideways so that the frame

angle when welding. DO NOT ground welding centerline matches up with the lip/platform centerline

equipment to any electrical components. DO (using the lines drawn earlier). Once frame and

NOT ground to leveler platform when welding platform have been centered in the pit, tack weld the

on leveler frame. Damage to bearings or front frame angle and shims to the front curb angle.

electrical components may result.

10. Mechanical leveler: Pull and hold the release chain

to raise the platform. Install maintenance support.

• DO NOT connect green ground lead into

control box or junction box until all welding Powered leveler: Manually raise platform and extend

is complete. lip on powered levelers. Install maintenance support.

11. Remove handling plates from platform.

• Protect Air Tower, Motors, Hose and

Hydraulic Lines from damage due to welding, 12. Lift rear frame of leveler until platform is level with

grinding or sharp objects. dock floor. Cut and place shims under the rear frame

support posts. Tack shims together and to rear frame

5. Remove lifting chain from handling plates. angle. See Figure 14.

6. Lift front frame of leveler until platform is level with Mechanical leveler: Be sure to shim underneath the

dock floor. Cut and place shims under below dock snubbing cable mount on front frame angle. See

stops, located on front frame angle and maintenance Figures 9 through 14.

support base. Tack shims together and to front frame

Hydraulic leveler (Base & HL Only): Place shims

angle. See Figure 14.

underneath the main cylinder clevis on frame as

IMPORTANT: For model specific shimming details shown. See Figures 9 through 14.

see Figures 9 through 12.

IMPORTANT: Insure all shims are in place at this

NOTE: For levelers with 20 inch lips, lift bottom of time. Tack shims together and to frame. See Figures

front frame angle until it is at 19-1/2 inches below 9 through 13.

dock floor, and add shims. See Figure 14.

Shipping bands are under tension. Wear safety

glasses and protective gloves. Stand to one

side when cutting bands to avoid being cut by

the bands.

7. Remove and discard all shipping bands.

Pub. No. 1237 - January 2014 9

RITE-HITE® & Genisys Dock Leveler Installation Manual

INSTALLATION INSTRUCTIONS CONT.

Front Curb Angle Side Curb Angle

Center Shim Under Rear

Frame Support Posts.

Centered Under Ramp Cylinder Shim Size:

Clevis Plates. 4x3x*

Shim Size: 4 x 4 x * Qty. 1 Qty. 4

22”

Shim Size:

4x3x* 10”

Qty. 5 CL

6”

10”

NOTE: Prior To Welding Shims

22” See Installation

Procedures 8 & 9!

NOTE: Portions of Frame and

Platform Removed for Rear Curb

Clarity Angle

* Height of Shim Pack Will Vary Depending On Pit Depth.

FIGURE 9 - SHIMMING DETAILS - RHH4000 (BASE) & HL900

Front Curb Angle Side Curb Angle

Shim Size:

4x3x*

Qty. 4

NOTE: Prior To Welding Shims

See Installation Center Shim Under Rear

Procedures 8 & 9! Frame Support Posts.

Shim Size:

Shim Size: 4x3x*

4x6x* 22” Qty. 4

Qty. 2

10”

6”

CL

6”

10”

22”

NOTE: Portions of Frame and

Platform Removed for

Rear Curb

Clarity

Angle

* Height of Shim Pack Will Vary Depending On Pit Depth.

FIGURE 10 - SHIMMING DETAILS - RHH4000 HYDRA-RITETM

10 Pub. No. 1237 - January 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

INSTALLATION INSTRUCTIONS CONT.

Front Curb Angle Side Curb Angle

Shim Size:

4x3x*

Qty. 4 NOTE: Prior To Welding Shims

See Installation Center Shim Under Rear

Procedures 8 & 9! Frame Support Posts.

Shim Size:

Use Shim Size Of 4x3x*

4 x 6 x * Qty. 2 Qty. 6

22”

When Leveler Is Equipped

With Stump Out Option. 6” 10”

See Figure 13 CL

6”

10”

22”

Use Shim Size Of

4 x 3 x * Qty. 1 NOTE: Portions of Frame and

When Leveler Is Not Equipped Platform Removed for Rear Curb

With Stump Out Option. Clarity Angle

Pit floor underneath the

Tower assy. must be * Height of Shim Pack Will Vary Depending On Pit Depth.

free of protrusions.

(example: anchor bolt heads)

FIGURE 11 - SHIMMING DETAILS - RHA4000 & AL900

Front Curb Angle Side Curb Angle

On Narrow Frame

Mechanical Levelers

Center Shim Under NOTE: Prior To Welding Shims

Snubbing Chain Mount See Installation Center Shim Under Rear

Shim Size: 4 x 3 x * Qty. 1 Procedures 8 & 9! Frame Support Posts.

Shim Size:

4x3x*

22” Qty. 4 (Narrow Frames)

Shim Size: Qty. 6 (Wide Frames)

4x3x* 10”

Qty. 5 CL

6”

10”

22”

NOTE: Portions of Frame and

Platform Removed for

Rear Curb

Clarity

Angle

* Height of Shim Pack Will Vary Depending On Pit Depth.

FIGURE 12 - SHIMMING DETAILS - RHM4000 & ML900

Pub. No. 1237 - January 2014 11

RITE-HITE® & Genisys Dock Leveler Installation Manual

INSTALLATION INSTRUCTIONS CONT.

Stump Out Each

Assembly Side 1/4”

Shim Thickness Must Shims Must Extend

Ensure Contact With Beyond Size Of

Pit Floor Stump Out Assembly CL

Stump Out Shimming Detail

NOTE: Shims are field installed

Each

Stump Out Side 1/4”

Assembly

Pedestal Must Be Contained

Under Stump Out Assembly

6” Channel Or Equivalent CL

(Example 4 x 2 Tube,

2 x 3 Channels, Etc..)

Factory DPC

Pedestal To Be Centered

Bottom Plate Must Extend Under Stump Out Assembly

Cut Length To Ensure Around Support Pedestal

Contact With Pit Floor

Stump Out Deep Pit Conversation Shimming Detail

FIGURE 13 - STUMP OUT ASSEMBLY SHIMMING DETAILS

12 Pub. No. 1237 - January 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

INSTALLATION INSTRUCTIONS CONT.

Front Frame Angle Each Shim

1/4”

Each Shim

1/4”

Each Shim

1/4” Shim

Front Curb Angle Main Cylinder Mount

Frame Recessed 1/4”

Each Shim

1/4”

Shim(s)

Front Frame Angle Center Frame

Each Shim

1/4”

RHH (Base) & HL Only

Each Shim

1/4”

Shim

Front Curb Angle

Frame Flush

Snubbing Cable Mount

When No Front Frame Angle Rear Frame Support Post

Gap Is

1/16” 1”

Present

Shim To Be

Flush with

1/4” 1”

Pit Steel

Each Shim Center Shim

1/4”

Rear Frame Under Each

1/16” 2” Support Post.

Front Frame

Full Range Toe Guard

Narrow Frame ML9

Shipping Bolt Location

and RHM Only

Safe-T-Strut Dock Floor

19-1/2”

Support Post

Insert Shims Under Rear

Frame Support Posts.

SOME COMPONENTS

REMOVED FOR

CLARITY

FIGURE 14 - SHIM WELDING DETAIL

Pub. No. 1237 - January 2014 13

RITE-HITE® & Genisys Dock Leveler Installation Manual

INSTALLATION INSTRUCTIONS CONT.

Chamfer Top Bar 3/16” x 1” x 2”

Edge Only Center On Plate. 3/16” Tack

3/16” Tack

4”

3/16”

4”

Frame End Weldment

2X Frame End Weldment Fabricated In Field.

See Details Above.

2X Place Weldment Into Pit At Each End Of Rear Frame.

Chamfer To Face Leveler. Push To Rear Pit Wall And Tack

Weld To Rear Frame.

DO NOT Weld Curb Steel Joint!

Concrete Slab Joint

2X Knock Off Top Bar After Tack Welding End

Plates Into Position.

2X Only Weld Chamfer

3/16” 4” Plate To Rear Frame

G

Instructions:

1. Fabricate frame end weldments prior to installation in field.

2. Apply welding clamp to leveler frame.

3. Remove paint from ends of rear frame.

4. Place frame end weldment into pit at each end of rear frame. Chamfer to face leveler.

Push to rear pit wall and tack weld to rear frame.

5. Knock off top bar after tack welding end plates into position.

6. Only weld chamfered plate to rear frame. DO NOT weld to side pit steel.

7. Remove weld debris and grind welds smooth.

8. Apply touch up paint to all weld and grind areas.

NOTE: If Leveler can be accessed prior to being installed into pit, plates can be welded to

end of frame prior to dropping into pit.

FIGURE 15 - ALTERNATIVE INSTALLATION FOR SHRINK COMPENSTATED FLOOR

14 Pub. No. 1237 - January 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

INSTALLATION INSTRUCTIONS CONT.

Each End

Each Spacer

1/4” 1/4” 5

At Each Chamfer

1/4” Location

CL CL

When No

Spacer

1/4” 3 MIN. Exists

FIGURE 16 - REAR WELD LOCATION

13. Check to insure leveler is still centered and level in 18. RHA & AL Series Only: Insert platform attachment

pit before final welding. rods on each side of the Air Tower. Manually raise left

side of the Air Tower and secure to J-hooks on

14. Weld rear frame to curb steel at chamfered locations

platform stringer.

at back edge of rear frame angle. See figure 16.

19. RHA & AL Series Only: Raise right side of the Air

15. Weld front frame angle to the front curb angle. See

Tower and ensure platform attachment rod is on top

figure 14.

of the stringer anchor loops. Secure a S-hooks

16. Clean and paint all weld and grind marks. around each anchor loop and the platform attachment

rod. Chain should be snug - no slack.

17. RHA & AL Series Only: Place Air Tower Tub into

leveler frame correctly. Floor to be clear of 21. RHA & AL Series Only: Plug blower motor into pit

obstructions where tub is located. Make certain tub outlet. Make sure cord is routed clear of tub to avoid

hold down chains are connected to the tub’s d-rings being crushed or pinched.

and chain is snug (no slack). See figure 17.

21. Remove front shipping bolts from each Toe guard if

leveler is equipped with toe guards. Verify toe guards

move up and down freely.

Stops for side

Tub opening on

Leveler Frame

Attach chain assembly to

d-rings on Tub, both sides.

Stops for side

Tub opening on

Leveler Frame

FIGURE 17 - TUB PLACEMENT

Pub. No. 1237 - January 2014 15

RITE-HITE® & Genisys Dock Leveler Installation Manual

INSTALLATION INSTRUCTIONS CONT.

21. Complete Bumper and Lip Support installation

procedures found in this manual. See pages 17 and

18.

22. Verify Lip Stop Bolt adjustment. See figure 19.

• The control box and all wiring should be

23. Lubricate leveler. installed by a qualified electrician in

24. Mechanical leveler: Mount inside operation sign and accordance with all national and local

operate leveler several times and verify proper electrical codes.

operation. Adjustments may be needed to insure

proper operation. Adjust as needed. Reference • If rigid conduit is installed, bonding must be

Owners Manual for proper operation and maintained between conduit connections by

adjustments. using ground bushings and a jumper wire.

25. Powered leveler: Install Electrical Components

Control Box Installation Guidelines -

Temperature Controlled Applications.

a. Conduit should be routed to enter through the bottom

• When drilling holes in the box, DO NOT allow or side of the enclosure. A drip leg may be needed if

the drill to go too deeply into the box. the conduit could fill with water.

Damage to the control systems may occur.

b. Seal the conduit in any location where the conduit

• DO NOT turn control box upside down to drill transitions temperature zones that may produce

any access holes. Cover internal electrical condensation.

components prior to drilling - this will prevent c. Spacers should be installed between the enclosure

debris from contacting the internal electrical and the wall to provide tempature insulation and air

components. flow.

• Remove all debris from box using a shop Complete electrical installation. operate leveler

vacuum. NEVER use air to blow debris from several times to verify proper operation. Adjustments

the control box. may be needed to insure proper operation. Adjust as

needed. Reference Owners Manual for proper

operation and adjustments.

CONTROL BOX AND CONDUIT

INSTALLATION PROCEDURES.

1. Install the control box on a wall adjacent to the

overhead door at approximately 48" above the floor

level. See Figure 24.

2. Drill a hole for the power supply conduit (by others) in

the bottom of the control box. All holes drilled

through the control box must be through the

bottom of the box.

16 Pub. No. 1237 - January 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

LEVELER ADJUSTMENTS

LIP LATCH BOLT ADJUSTMENT

Flat On Bolt Head To Be Parallel To

(RHA & AL ONLY) Bottom Of Lip Crank Mount.

The lip latch bolt is factory adjusted. If the lip does NOT

latch when the leveler is fully raised and remain latched

as the platform lowers, the lip latch bolt may need to be

readjusted. Use the following procedure to readjust the lip

latch bolt: See figure 18.

1. Loosen the jam nuts on the lip latch bolt.

1 1/8” Preset

2. Turn the bolt clockwise one full turn at a time.

3. Tighten the jam nuts on the lip latch bolt.

4. Follow normal operating procedures to verify

that the lip latch has been adjusted correctly

and holds the lip out as the platform lowers. Test

unit three times to make sure it latches all three

times, if not readjust.

NOTE: DO NOT over adjust the lip latch bolt.

When properly adjusted the lip should just latch in.

If you have over adjusted the lip may not release,

or it will bend the delatch rod over time. Re-adjust

bolt until lip no longer latches and then make one FIGURE 18 - LIP LATCH BOLT

full turn of the bolt until lip just latches.

LIP STOP BOLT ADJUSTMENT (ALL UNITS)

The lip stop bolt adjusts the position of the lip when the

leveler is stored to allow the lip to be centered on lip

supports when stored.

Lip

NOTE: Lip stop bolt will need to be adjusted on Stop Bolt

longer lips to allow lip to be centered in the lip

keepers.

Lip

Centered

In Keepers

Standard Lip Safe-T-Lip®

FIGURE 19 - LIP STOP BOLT

Pub. No. 1237 - January 2014 17

RITE-HITE® & Genisys Dock Leveler Installation Manual

BUMPER INSTALLATION

LAMINATED BUMPER INSTALLATION 4. Secure other end of each bumper with concrete

(Standard) anchor bolts. Torque each bolt to 120 ft-lbs.

1. Tack weld each bumper in position as shown in figure 5. Weld the bumper side plate to the front vertical pit

20. angle.

2. Each bumper should be secured with two 5/8 inch 6. Clean and paint all weld and grind marks.

concrete anchor bolts that are a minimum of 4 inch 7. Apply logo decal to front curb angle. See Figure 20.

long. (Ref. Rawl anchor 6942 - supplied by others.)

3. Using bumper mounting holes as a guide drill two 5/8

inch holes per bumper that are approximately 1/2

inch deeper than the bolt length that will be used.

Dock Floor

Min. 5/8” x 4”

Concrete Anchors

(Supplied By Others

Laminated Bumper

1/4”

1/4”

Leveler Lip

Logo Decal

Side of Leveler Pit

2 Places

1/4”

FIGURE - 20 LAMINATED BUMPER INSTALLATION

18 Pub. No. 1237 - January 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

LIP SUPPORT INSTALLATION

NOTE: RHH, HL, RHA and AL Dock Levelers

Dock NOTE: Dimensions are Based On

It is suggested to add two installation tabs just behind

Standard Pit Details

the lip to support the leveler platform even and flush CL

with the dock floor before lip support installation. See

21-3/4” Ref.

Figure 21.

Installation Tabs 8 -1/2”

21-3/4” 1 - 1/4”

Lip Supports (2 ea.)

FIGURE - 21 INSTALLATION TABS 5/8” Dia. x 4” LG. Min. 1”

Concrete Anchors. (4 ea.) 10”

(Supplied By Others)

1. Place marks 21-3/4” out from pit centerline on front

pit angle. See Figure 21.

2. On levelers with lips greater than 20” install lip keeper FRONT VIEW

mounting plate. See Figure 23.

3. Locate the centerline of the lip support assemblies.

Dock Height

4. Remove maintenance support and lower the leveler

until it is flush with dock level and lip is fully pendant.

5. Position lip support assemblies along the edge of the Lip

Length

lip and mark the bottom of lip support on front pit Front Frame Angle

+ 3/4”

angle.

Shim

6. Fully weld along the lip support and front pit angle. (Supplied By Others)

See Figure 22. 1/4”

Front Curb Angle

Pit

Floor

Typ. 1/4”

2 Places 1/4”

Top View

Typ.

2 Places (2 ea.) 1/4” x 8” x 10” LG. M-1020

1/4”

Lip Support Mounting Plate

(Supplied By Others)

SIDE VIEW

Side View Front View

NOTE: Tack weld lip supports into place and check

to insure leveler platform is even and flush

with dock floor before final welding.

FIGURE - 22 LIP SUPPORT

FIGURE - 23 LIP MOUNTING PLATE

7. Repeat the procedure for the second lip support

assembly.

8. Clean and paint all weld and grind marks.

Pub. No. 1237 - January 2014 19

RITE-HITE® & Genisys Dock Leveler Installation Manual

TYPICAL COMPLETE INSTALLATION

(INSIDE WALL)

Customer

Branch

Circuit

Disconnect.

(Supplied By Others)

Mechanical Leveler

Operation Sign

(Supplied By Rite-Hite)

Powered Leveler

Powered

Control Box

Leveler

Assembly.

Shown

(Supplied By Rite-Hite)

Dock

Bumpers

(2 ea.)

Dock Face

Approach

FIGURE - 24 TYPICAL INSTALLATION

20 Pub. No. 1237 - January 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

NOTES

Pub. No. 1237 - January 2014 21

RITE-HITE® & Genisys Dock Leveler Installation Manual

NOTES

22 Pub. No. 1237 - January 2014

RITE-HITE® & Genisys Dock Leveler Installation Manual

GENISYS WARRANTY

Genisys Dock Leveler by Rite-Hite®

Standard Warranty Policy

Rite-Hite® warrants to and for the sole benefit of the original purchaser that Genisys by Rite-Hite® (hereinafter "Genisys") Dock

Levelers shall be free from defects in material and workmanship subject to the following:

Length of Time: All products are warranted for a one year period commencing on the earlier date of approved installation or

the (30th) day after the date of shipment. This warranty covers the repair or replacement of the defective product or

component at Rite-Hite's sole election and expense, including reasonable labor, reasonable travel and freight.

Component Scope: The structural components protected by this warranty include the rear frame, deck, lip, front and rear hinge

area and working range toe guards on all Genisys Dock Levelers.

• On HL Series dock levelers, all cylinders, pumps, hoses, fittings, electrical motors and control panels are covered.

• On ML Series mechanical levelers, springs, chains, lip extension mechanism, main counterbalance and ramp control are

covered.

• On AL Series dock levelers, air tower assy., lip extension mechanism, chains and control panels are covered.

With an additional 5 year warranty on the air tower assy.

Repair part freight costs will be borne by Rite-Hite® via standard shipping terms. Charges for overnight or special freight

requirements will be billed to the end user, General Contractor or Genisys Representative and must be approved at time of

shipment.

Warranty claims will not be accepted if the parts and/or assemblies have not been installed on Genisys products or the

installation has not been carried out in accordance with Genisys installation instructions.

If a part is replaced during the standard warranty period, it will be covered for the remainder of the warranty period for the dock

leveler.

The above warranties are in lieu of any other warranties, either expressed or implied, including but not limited to any warranty

of merchantability or implied warranty of fitness for a particular application.

In no event shall Rite-Hite® or any of its subsidiaries be responsible for or liable to anyone, including third parties, for special,

indirect, punitive, incidental or consequential damages, even if Rite-Hite® Representative has been advised of the possibility of

such damages. Such excluded damages include, but are not limited to, loss of goodwill, loss of profits, loss of use, interruption

of business, or other similar indirect financial loss.

This limited warranty shall be void and of no effect:

• if product is altered or modified from its original condition as installed or as delivered at or from the factory

• to the extent that the product defect is the direct result of improper installation, operation beyond capacity, or other than in

accordance with Genisys instructions, careless or negligent use, or failure to maintain the product as recommended by the

Genisys owner's manual.

• if Rite-Hite® or the Genisys Representative is not notified of the defect and such notification failure creates additional

component or product stress which compounds the cost for defect correction.

• if the product is not adjusted and lubricated on the intervals and to the extent required in the Genisys Owner's Manual.

• if the product is moved and reinstalled from its original installation point without advising Rite-Hite® or a Rite-Hite®

Representative.

By Rite-Hite

Pub. No. 1237 - January 2014 23

RITE-HITE STANDARD WARRANTY

Rite-Hite warrants that its products will be free from defects in design, materials, and workmanship for a period

of 365 days from the date of shipment. All claims for breach of this warranty must be made within 30 days after

the defect is or can, with reasonable care, be detected and in no event no more than 30 days after the warran-

ty has expired. In order to be entitled to the benefits of this warranty, the products must have been properly

installed, maintained, and operated within their rated capacities and/or specified design parameters, and not oth-

erwise abused. Periodic lubrication and adjustment is the sole responsibility of the owner. This warranty is Rite-

Hite’s exclusive warranty. RITE-HITE EXPRESSLY DISCLAIMS ALL IMPLIED WARRANTIES, INCLUDING

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS. Non-standard warranties, if any, must

be specified by Rite-Hite in writing.

In the event of any defects covered by this warranty, Rite-Hite will remedy such defects by repairing or replac-

ing any defective equipment or parts, bearing all the costs for parts, labor, and transportation. This shall be the

exclusive remedy for all claims whether based on contract, negligence, or strict liability.

LIMITATION OF LIABILITY

RITE-HITE SHALL NOT IN ANY EVENT BE LIABLE FOR ANY LOSS OF USE OF ANY EQUIPMENT OR INCI-

DENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND, WHETHER FOR BREACH OF WARRANTY, NEG-

LIGENCE, OR STRICT LIABILITY.

Global Sales & Service Office:

RITE-HITE

8900 N. Arbon Drive

P.O. Box 245020

Milwaukee, Wisconsin 53224

Phone: 414-355-2600

1-800-456-0600

www.ritehite.com

Representatives in all Major Cities

Vous aimerez peut-être aussi

- Relays Relais Relais Relè: 3 EditionDocument80 pagesRelays Relais Relais Relè: 3 EditionAussi SidPas encore d'évaluation

- Asdooeidk 33201Document48 pagesAsdooeidk 33201Joze MartinezPas encore d'évaluation

- De-119957 Diving SafetyDocument5 pagesDe-119957 Diving SafetyJithuJohnPas encore d'évaluation

- RepairDiagnostics PT 01 C0G36Z008E 3MBDocument6 pagesRepairDiagnostics PT 01 C0G36Z008E 3MBJosé Da Silva MataPas encore d'évaluation

- LIT2299 Rev 10 PD12C Parts ListDocument28 pagesLIT2299 Rev 10 PD12C Parts ListYuliana Andrea Zapata RubioPas encore d'évaluation

- MXT Manual PDFDocument36 pagesMXT Manual PDFhüseyin100% (1)

- Vickers: PVQ Piston PumpsDocument56 pagesVickers: PVQ Piston Pumpsplasticos_jfm6580Pas encore d'évaluation

- AHRI-880 (I-P) - 2011 With Addendum 1Document19 pagesAHRI-880 (I-P) - 2011 With Addendum 1RCYABOPas encore d'évaluation

- Codigos y Partes de CoronaDocument56 pagesCodigos y Partes de CoronaAntony Moreno0% (1)

- CR 919Document30 pagesCR 919gebre100% (1)

- Technical ManualDocument109 pagesTechnical Manualleo_turfPas encore d'évaluation

- Excel Vba ExamplesDocument133 pagesExcel Vba Examplesggkmurty100% (1)

- Parker Valve Mobile Pulsar VPL-VP-VPO Model Code Book HY14-0108Document32 pagesParker Valve Mobile Pulsar VPL-VP-VPO Model Code Book HY14-0108NopPas encore d'évaluation

- Palfinger 56000Document3 pagesPalfinger 56000WaldomiroCanoPas encore d'évaluation

- Parker Serie P1+PDDocument84 pagesParker Serie P1+PDRodrigo IglesiasPas encore d'évaluation

- COSO Presentation FinalDocument52 pagesCOSO Presentation FinalSwati PandeyPas encore d'évaluation

- Selenoid Have VP 1z PDFDocument8 pagesSelenoid Have VP 1z PDFHiskia Napoleon KacaribuPas encore d'évaluation

- Hitachi Zaxis 270 Class Excavator Operator's Manual SN 010310 and Up PDFDocument14 pagesHitachi Zaxis 270 Class Excavator Operator's Manual SN 010310 and Up PDFsekfsekmddde100% (1)

- SS350 Series Air StartersDocument8 pagesSS350 Series Air StartersRICARDO MAMANI GARCIAPas encore d'évaluation

- Lokomat ProDocument36 pagesLokomat ProSergio CastroPas encore d'évaluation

- TR60 Parts BookDocument392 pagesTR60 Parts Bookfernandoj100% (1)

- Samsung SonoAce R3 Ultrasound - Service Manual PDFDocument178 pagesSamsung SonoAce R3 Ultrasound - Service Manual PDFRamilson Machado67% (3)

- AL4000DDocument74 pagesAL4000Dtazjuan1Pas encore d'évaluation

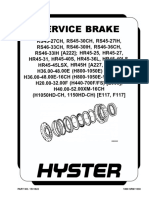

- Hyster Service TechDocument36 pagesHyster Service Techspam_rqlPas encore d'évaluation

- Data AbelDocument91 pagesData AbelDinar DirhamPas encore d'évaluation

- Service / Parts Manual: Models: Wolfpac 3100 Wolfpac 3100R (Rops Option) Wolfpac 3100D (Diesel Roller)Document124 pagesService / Parts Manual: Models: Wolfpac 3100 Wolfpac 3100R (Rops Option) Wolfpac 3100D (Diesel Roller)madman440100% (1)

- Weidmuller Analog Signal ConditionersDocument65 pagesWeidmuller Analog Signal ConditionersYaseen SagarPas encore d'évaluation

- Hygienic Design GuidelinesDocument87 pagesHygienic Design Guidelinesneilradcliffe100% (4)

- Linde C80 Required PartsDocument1 pageLinde C80 Required Partssameera19911014Pas encore d'évaluation

- 2013 Us Shop Tech BrochureDocument16 pages2013 Us Shop Tech Brochurefollowjesus100% (1)

- SiRRAN LTEnet-EPC ProductBrochure01Document5 pagesSiRRAN LTEnet-EPC ProductBrochure01ecompeanPas encore d'évaluation

- 038 1084E - Hydraulic Dock Leveler - Owner S ManualDocument32 pages038 1084E - Hydraulic Dock Leveler - Owner S ManualAndres F. Trujillo100% (1)

- USB Link Adapter Guide 2013 PDFDocument2 pagesUSB Link Adapter Guide 2013 PDFjorge luisPas encore d'évaluation

- Omega 600S ManualDocument36 pagesOmega 600S ManualLeandroPas encore d'évaluation

- Parts Catalog - Option Detail: Content For Engine Serial Number (ESN) : 37211299Document3 pagesParts Catalog - Option Detail: Content For Engine Serial Number (ESN) : 37211299nurdinzaiPas encore d'évaluation

- Godwin Pumps Parts Manual PDFDocument1 pageGodwin Pumps Parts Manual PDFAlvaro TreviñoPas encore d'évaluation

- Oasis Sykes Pumps WP150-60Document2 pagesOasis Sykes Pumps WP150-60JayPas encore d'évaluation

- 4 X 5 and 5 X 6 Parts & Service Manual TUL-C-600 - A PDFDocument47 pages4 X 5 and 5 X 6 Parts & Service Manual TUL-C-600 - A PDFzachPas encore d'évaluation

- Special ToolsDocument24 pagesSpecial ToolsSuka MuttAstroPas encore d'évaluation

- Haldex Air Brake Systen and ProductsDocument164 pagesHaldex Air Brake Systen and Productshebert perezPas encore d'évaluation

- Sky Trak 6036 ServicioDocument280 pagesSky Trak 6036 ServicioCarlos IrabedraPas encore d'évaluation

- 15.murphy pv380R2 Operations PDFDocument58 pages15.murphy pv380R2 Operations PDFlcsandovalr989Pas encore d'évaluation

- Catalogo TrasnferDocument52 pagesCatalogo Trasnferalexg27Pas encore d'évaluation

- Nexiq User Manual PDFDocument94 pagesNexiq User Manual PDFTobias Ken100% (1)

- SM Tm3989 Knott A4Document1 pageSM Tm3989 Knott A4Marc GlebPas encore d'évaluation

- TD1469-01 Service Manual TT-Axle 60-0xDocument72 pagesTD1469-01 Service Manual TT-Axle 60-0xabdelhadi houssinPas encore d'évaluation

- Re92105 2003-11Document32 pagesRe92105 2003-11Madhu RajagopalanPas encore d'évaluation

- Frenos Hystter 455Document38 pagesFrenos Hystter 455Eduardo SaaPas encore d'évaluation

- Hydraulic Diagram Basic Machine: E:4 E Schematics - Common HydraulicsDocument4 pagesHydraulic Diagram Basic Machine: E:4 E Schematics - Common HydraulicsANH LÊ100% (1)

- BanbgroupDocument59 pagesBanbgroupVenkata RajuPas encore d'évaluation

- Dura-Flo Lowers: Instructions - PartsDocument22 pagesDura-Flo Lowers: Instructions - Partscorsini999Pas encore d'évaluation

- 0240 1183 4Document12 pages0240 1183 4Marko ŠkaraPas encore d'évaluation

- Parker Product GuidesectionDocument51 pagesParker Product GuidesectionNicolas RibeiroPas encore d'évaluation

- Data Download HGM1770 V1.6 enDocument19 pagesData Download HGM1770 V1.6 enJohn GarnetPas encore d'évaluation

- Parts List 859 Series: Effective: June 15, 2009 Supersedes: HY25-2859 Dated January 2007Document20 pagesParts List 859 Series: Effective: June 15, 2009 Supersedes: HY25-2859 Dated January 2007francis_15inPas encore d'évaluation

- S 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomDocument6 pagesS 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuPas encore d'évaluation

- Nitrogen Gas Charging Kits Brochure WEBDocument12 pagesNitrogen Gas Charging Kits Brochure WEBmnvijaybabuPas encore d'évaluation

- Ferrari - Cap6.2 Manutenzione F121618 EDocument36 pagesFerrari - Cap6.2 Manutenzione F121618 EjessicaPas encore d'évaluation

- Volvo WB 1 Bulletins TransWay WB PDFDocument2 pagesVolvo WB 1 Bulletins TransWay WB PDFmhan imanPas encore d'évaluation

- ASBEILA S30G 1-12hp Compressor R134a Refrigeration LBP Technical Datasheet Specs SpecificationDocument8 pagesASBEILA S30G 1-12hp Compressor R134a Refrigeration LBP Technical Datasheet Specs SpecificationRicardoHagelPas encore d'évaluation

- Safe-Aid Ts350 Entry Level Hydraulic SystemDocument6 pagesSafe-Aid Ts350 Entry Level Hydraulic SystemZian HennPas encore d'évaluation

- SYMC Eu IV DTC Description V1 070307Document28 pagesSYMC Eu IV DTC Description V1 070307Sooziet RegmiPas encore d'évaluation

- Fuel System Supplement: Cat C4.4 Acert & C7.1 ACERT U.S. EPA Tier 3 Equivalent/ EU Stage IIIA Equivalent EnginesDocument28 pagesFuel System Supplement: Cat C4.4 Acert & C7.1 ACERT U.S. EPA Tier 3 Equivalent/ EU Stage IIIA Equivalent EnginesAlberto PAPas encore d'évaluation

- Workshop Manual Newage 85m2 GearboxesDocument15 pagesWorkshop Manual Newage 85m2 Gearboxesdjordjes123Pas encore d'évaluation

- 2008, Eaton, Flow DividersDocument20 pages2008, Eaton, Flow DividersVelibor KaranovićPas encore d'évaluation

- SANY Heavy Industry Co., Ltd. Quality Changes The WorldDocument66 pagesSANY Heavy Industry Co., Ltd. Quality Changes The Worldavtonika38Pas encore d'évaluation

- Control Unit Maxi: ScanrecoDocument3 pagesControl Unit Maxi: ScanrecoJose GodoyPas encore d'évaluation

- 3 Mast: Technical Manual Publ. No. 6193.008 1225Document28 pages3 Mast: Technical Manual Publ. No. 6193.008 1225----Pas encore d'évaluation

- Air Compressor Intallation PDFDocument6 pagesAir Compressor Intallation PDFvictoverPas encore d'évaluation

- RHV Installation ManualDocument24 pagesRHV Installation ManualGaurav TingnePas encore d'évaluation

- RHM Owners ManualDocument24 pagesRHM Owners ManualDANIEL BUSTOSPas encore d'évaluation

- BS Iso 05667-22-2010Document48 pagesBS Iso 05667-22-2010mohamed senoussiPas encore d'évaluation

- Invitation English XIDocument4 pagesInvitation English XIFinandyaPas encore d'évaluation

- Aprilia Pegaso 650 Repair ManualDocument139 pagesAprilia Pegaso 650 Repair ManualphotarasPas encore d'évaluation

- Linux Commands 1Document8 pagesLinux Commands 1Sathish SaranyaPas encore d'évaluation

- Electrical Email Method of Exchanging MessagesDocument2 pagesElectrical Email Method of Exchanging MessagesVick54GraversenPas encore d'évaluation

- BIG-IP Local Traffic Manager ImplementationsDocument224 pagesBIG-IP Local Traffic Manager ImplementationskannanciscoPas encore d'évaluation

- ACCA Application Process For Accountancy Qualifications - Accountancy Qualifications - ACCA - ACCA GlobalDocument5 pagesACCA Application Process For Accountancy Qualifications - Accountancy Qualifications - ACCA - ACCA GlobalMsta EffPas encore d'évaluation

- Part 4: Network Layer Part A: AlgorithmsDocument42 pagesPart 4: Network Layer Part A: Algorithmspptdownload81Pas encore d'évaluation

- Catálogo de Bujias BoschDocument4 pagesCatálogo de Bujias BoschRodrigo Vidal EscrivàPas encore d'évaluation

- Tugas 6Document5 pagesTugas 6Adji NugrahPas encore d'évaluation

- Lab Manual of C++Document14 pagesLab Manual of C++Ammar AbbasiPas encore d'évaluation

- IFA Smart PCs FV v6 0 Sep22 enDocument80 pagesIFA Smart PCs FV v6 0 Sep22 enKANINTA YUDHAPas encore d'évaluation

- FC-ZE1 EngDocument15 pagesFC-ZE1 EngLazaros KafkiasPas encore d'évaluation

- Power Drive Garage Door OpenerDocument44 pagesPower Drive Garage Door OpenerAndres AguirrePas encore d'évaluation

- Air Vee BendingDocument4 pagesAir Vee BendingMohak Patel100% (1)

- BSC CommandsDocument15 pagesBSC CommandsPa AjayPas encore d'évaluation

- 船用CE检测报告Document178 pages船用CE检测报告Jun Rong FooPas encore d'évaluation

- Mts Lang EngDocument103 pagesMts Lang EngYamin MuhamadPas encore d'évaluation