Académique Documents

Professionnel Documents

Culture Documents

RA 022 Risk Assessment - Coring of Manhole

Transféré par

thomsonCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

RA 022 Risk Assessment - Coring of Manhole

Transféré par

thomsonDroits d'auteur :

Formats disponibles

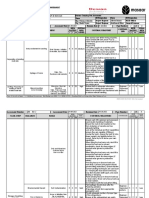

Document Reference

Al Seal Contracting & Trading Co. (WLL) ALSEAL/HSE/CTS-FORM-022

Rev. No. Rev. Date

RISK MANAGEMENT SYSTEM 00 MAY-2018

Page

RISK ASSESSMENT

Al Seal Contracting Risk Management System

Risk Assessment-Coring of Manhole

Contract number and title: RA number: Date:

Element of work: Risk assessment 14/04/2018

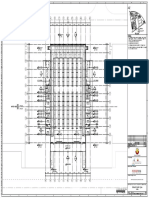

COMMUNICATIONS TOWERS AT AL RUWAIS,

Coring of Manhole

AL GHASHAM AND HALUL ISLAND, Q-406-01

Severity Likelihood Evaluation of risk

NO INJURY 1 RARE 1 12 - 25 High Action required urgently to control the risk, further resources may be required, work must stop immediately

MINOR 2 UNLIKELY 2

MODERATE 3 OFTEN 3

MAJOR 4 LIKELY 4 5 – 10 Med Action required to control the risk, interim measures may be necessary in the short term, able to proceed with work under supervision

FATALITY 5 EXPECTED 5

1–4 Low This represents a low risk, although control measures must be maintained

Initial risk? Residual risk?

Who might be

harmed?

Employees

Risk Rating

Risk Rating

Likelihood

Likelihood

Job Steps Hazards What controls are required? Action by

Severity

Severity

Contractors How?

Public

Others

Environment

Constructi Activities Ignorance All Physical & Mental harm from 5 5 25 HSE induction to be conducted to all 2 2 4 Site

on Site of site rules Construction construction activities personnel engaged prior to start of any Engineers

Personnel work; Activity Hazard Analysis (AHA) to be and

furnished including equipment entry permit Supervisors

request, person entry permit Start briefing

prior to work activities.

AL SEAL CONTRACTING HSE PROCEDURES Page 1 of 8

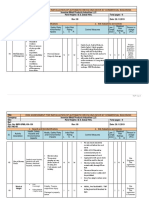

Document Reference

Al Seal Contracting & Trading Co. (WLL) ALSEAL/HSE/CTS-FORM-022

Rev. No. Rev. Date

RISK MANAGEMENT SYSTEM 00 MAY 2018

Page

RISK ASSESSMENT

Language All Non English speakers not being 4 5 15 Where this situation exists, cause 2 2 4 Site

able to understand work adequate levels of communication to be Engineers

instructions or emergency signs achieved through a suitable interpreter. and

etc. The persons concerned must not Supervisors

commence work until a suitable interpreter

is available.

Cause the site rules, emergency signs and

other relevant signs to be communicated

in languages that reflect the site

operative’s needs.

Pre-task briefing and All Workforce The work force doesn’t know 3 4 12 Ensure that the pre-task briefing is given 2 2 4 Site

inspection the pre-task briefing therefore out in a language understood by the Engineers

doesn’t understand the workforce, have it translated. Ask and

potential dangers and control question regarding the briefing to get Supervisors

measures to be implemented. feedback from the staff, this ensures full

comprehension.

Issue any required PPE and replace PPE

that has signs of defect. PPE must include

both hearing protection as well as dust

inhalation protection.

Dust and air debris Persons Risk of eye injuries 3 4 12 Workshop facilities to have eye wash 2 2 4 Site

involved in facilities in place. Eye wash stations will be Engineers

activities and placed at strategic points around site. Light and

others around eye protection will be mandatory for all Supervisors

the working staff & operatives. Roads and haul roads

areas will be damped down as and when

required

Manual Handling Operatives Hand & back injuries, heat 4 3 12 Manual handling training, not lifting loads 2 2 4 Site

stress beyond the capabilities of the operative, Engineers

use of correct hand protection. Supervision and

Supervisors

AL SEAL CONTRACTING HSE PROCEDURES Page 2 of 8

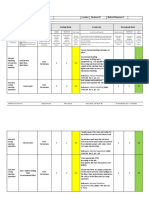

Document Reference

Al Seal Contracting & Trading Co. (WLL) ALSEAL/HSE/CTS-FORM-022

Rev. No. Rev. Date

RISK MANAGEMENT SYSTEM 00 MAY 2018

Page

RISK ASSESSMENT

House Keeping – All Slips, trips & falls 4 4 16 Regular housekeeping inspections, 3 2 6 Site

material, waste. keeping area well prepared and free from Engineers

debris, materials, cables and waste. and

Supervisors

Ground Conditions & All Trips and falls caused by poor, 4 5 20 All accesses, where people have to walk, 1 3 3 Site

Access general access around the site to be well defined, properly constructed Engineers

and to the facilities and and maintained in good condition. and

accommodation Suitable steps to be provided and Supervisors

maintained, where appropriate.

Where appropriate, because of the need of

access during darkness, cause suitable

levels of lighting to be provided and

maintained.

Control of Plant Plant Badly designed or defined haul 4 5 25 Haul road construction to avoid 1 4 4 Site

Operators roads or poorly maintained unnecessary cambers or bends and the Engineers

surfaces leading to a loss of line of the road to be well defined, where and

operator control and appropriate. Supervisors

mechanical damage to plant. Running surface to be maintained in good

condition.

Ground Persons Surveyors, Being struck by moving plant / 5 3 15 Competent & certificated plant operators to 2 2 4 Site

Investigati Engineers & equipment operate all items of plant. Engineers

on other workers Plant certification to be provided prior to and

on site commencing on site, segregation of plant Supervisors

& operatives with barriers & signage,

operatives briefed not to walk / stand

around rear of machinery or items of plant.

Operatives instructed to maintain eye

contact with plant operators at all times.

Operatives to wear high visibility vests &

safety helmets, safety footwear, light eye

protection, overalls. mobile phones not to

be used whilst operating equipment.

AL SEAL CONTRACTING HSE PROCEDURES Page 3 of 8

Document Reference

Al Seal Contracting & Trading Co. (WLL) ALSEAL/HSE/CTS-FORM-022

Rev. No. Rev. Date

RISK MANAGEMENT SYSTEM 00 MAY 2018

Page

RISK ASSESSMENT

Hydro & hand tools / power Tool operators Due to unapproved tools 4 5 20 Before handing out tools, visual 2 2 4 Site

Air Testing tools (unsafe), unauthorised inspection will be carried out, by Engineers

operatives and poor competent electrician. and

supervision hearing protection shall be used if Supervisors

exposed to noise levels of 85 db(a) or

above

Competent operators shall handle the

tools & competent supervision will be

ensured.

All tools used will be well maintained and

defect free.

Electrically operated tools shall comply

with established safety requirements-

double insulated / colour coded / properly

grounded.

appropriate PPE

Use of Ladders Operatives Falls of persons from 3 4 12 Only ladders of class 1 (industrial heavy 2 2 4 Site

involved in the ladders. duty) or class 2 (light trade) ladders, as Engineers

task Collapse of ladders. appropriate, shall be used. and

Dislodgement of ladders. Ladders shall carry identification and shall Supervisors

Contact with, or arcing be free from defect. Inspection shall be

from, power sources. carried out before use and at the regular

intervals specified in the Company

procedure.

Prior to erection, the erection site shall be

surveyed and note taken of any visible

hazard such as loose materials, insecure

structures or exposed power sources.

Erection of ladders shall only be carried

out by fully instructed and trained

operatives.

AL SEAL CONTRACTING HSE PROCEDURES Page 4 of 8

Document Reference

Al Seal Contracting & Trading Co. (WLL) ALSEAL/HSE/CTS-FORM-022

Rev. No. Rev. Date

RISK MANAGEMENT SYSTEM 00 MAY 2018

Page

RISK ASSESSMENT

Ladders shall always be erected on firm

level standings. Where the base is not

level, then suitable and secure packing

will be provided.

Ladders shall be set at an angle of 750 (4

vertical to 1 horizontal).

Ladders shall always be secured on both

stiles, except where this is impracticable

on ladders less than 5 metres which may

be footed for work of short duration.

Ladders shall not be rested against fragile

or flexible supports, such as plastic

guttering.

Ladders shall extend 1.05 metres above

the landing place, except where an

alternative adequate handhold is

provided.

For scaffold access ladders, the preferred

option is that they be erected internally.

Where this is impracticable, the ladder

shall be erected parallel and close to the

scaffold.

Except in specific circumstances of short

duration, work should not be carried out

from ladders.

Only one person is permitted on a ladder

at any one time. That person should have

both hands free to grip the ladder.

Loads should not be carried up ladders;

suitable material handling methods should

be provided.

Suitable pouches, bags or belts should be

AL SEAL CONTRACTING HSE PROCEDURES Page 5 of 8

Document Reference

Al Seal Contracting & Trading Co. (WLL) ALSEAL/HSE/CTS-FORM-022

Rev. No. Rev. Date

RISK MANAGEMENT SYSTEM 00 MAY 2018

Page

RISK ASSESSMENT

provided for the carrying of tools.

Maker’s instructions regarding the use of

extending ladders should be available on

site should always be observed by those

erecting ladders.

Where initial stage access ladders are left

erected out with working hours, then

suitable and effective steps shall be taken

to bar unauthorised access by any

person.

Use of vertical drilling Operatives and Entanglement of hair or 4 4 16 Consideration will be given to the noise 2 2 4 Site

machines others who loose clothing produced by the machine, especially Engineers

involve with Spinning of work piece when drilling sheet metal. This will and

the activities. Cutting of skin by contact depend on speed on the drill and the Supervisors

with drill or hit to others material. Noise assessments may be

(nearby) necessary.

Guards or trip devices will be fitted to

machines before being brought into use.

Means of emergency stopping of

machines will be fitted.

Physical:

First-aid facilities will be provided as

necessary.

Guards and/or trip devices will be in place

before work starts. Any defective guards

will be reported. Suitable eye protection

will be used by personnel using drilling

machines. The work-piece will be held

securely in a vice or similar device, and

the vice secured to the machine bed. The

chuck key will be removed before the drill

is switched on. Loose clothing (including

AL SEAL CONTRACTING HSE PROCEDURES Page 6 of 8

Document Reference

Al Seal Contracting & Trading Co. (WLL) ALSEAL/HSE/CTS-FORM-022

Rev. No. Rev. Date

RISK MANAGEMENT SYSTEM 00 MAY 2018

Page

RISK ASSESSMENT

sleeves and ties) will be removed and

long hair covered before the machine is

switched on. Electrical supply will be fitted

by a competent electrician, and a check

will be made every after three month on

its condition. The result will be recorded.

Warning notices in all relevant languages

to be displayed where necessary.

Managerial/Supervisory:

Only personnel trained to do so will be

permitted to operate drilling machines.

The operators will be reminded to keep

floors clear of obstructions and of the

need to wear PPE required. Notices

requiring eye protection and restricting the

use of machines to trained personnel will

be clearly displayed. A table of

recommended drill speeds for the drill

size and material will be available to all

drill operators.

Management will be trained in the safe

use of drilling machines. Personnel using

drilling machines will be briefed on the

use of the machine and the use of the

needs for guards and tripping devices,

and the potential for injury at the machine.

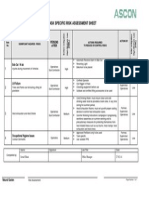

Proceeding Works All Workforce Personal injury from trip 5 4 20 Care to be taken when climbing into or 2 2 4

and others or fall on uneven ground leaving machinery.

who near by Oil Spillage. Always wear proper PPE.

Injury from overturning One vehicle will be made available for the

machinery on unstable or emergencies

uneven ground. Do not operate machinery on ground

AL SEAL CONTRACTING HSE PROCEDURES Page 7 of 8

Document Reference

Al Seal Contracting & Trading Co. (WLL) ALSEAL/HSE/CTS-FORM-022

Rev. No. Rev. Date

RISK MANAGEMENT SYSTEM 00 MAY 2018

Page

RISK ASSESSMENT

Person too close to conditions not suitable for that particular

machine struck /crushed equipment or task.

by excavator. Supervisor to ensure all personnel &

Eye injury from dust. onlookers are clear of machine prior to

Hearing damage from starting excavation work.

prolonged noise of Only certified operators to operate

machinery. machinery.

Fall from height Provide proper access and ladders for

deep excavation.

Operators & others to wear hearing & eye

protection when machinery in use.

Use of Flagmen / Bank men is

recommended when machine are backup

Workers to wear safety hat and to use

inspected ladders

Handling of Heavy loads, Heavy All the rigging / lifting equipment will be

Equipment & equipments tested & certified prior to use. And colour

structure coded. Riggers & flag men will be

deployed to strictly monitor the movement

of the equipment. barrication of the lifting

area will be done to avoid the entry of

unauthorized persons with proper

signage’s are provided

AL SEAL CONTRACTING HSE PROCEDURES Page 8 of 8

Vous aimerez peut-être aussi

- RA 024 Risk Assessment - Precast Concrete WorksDocument14 pagesRA 024 Risk Assessment - Precast Concrete Worksthomson75% (8)

- 04 HIRA For Reinforcement WorkDocument7 pages04 HIRA For Reinforcement WorkMithlesh Singh100% (1)

- Job Safety Analysis - Civil WorksDocument7 pagesJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- 3-REV.1 - Hot Work - Risk Assessment JHADocument16 pages3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- Risk Assessment - Finishing Work (Brick, Plaster, Skim, Tiles, Screeding)Document17 pagesRisk Assessment - Finishing Work (Brick, Plaster, Skim, Tiles, Screeding)Muhd Izzat Iskandar Safarudin100% (3)

- Risk Assessment Of-Shuttering-DeshutteringDocument4 pagesRisk Assessment Of-Shuttering-DeshutteringAbdul Mujeeb67% (3)

- HSE-03-Daily Site Safety ReportDocument3 pagesHSE-03-Daily Site Safety ReportBa N Nhim100% (3)

- RA Construction For Sub-Base & Road Base WorksDocument17 pagesRA Construction For Sub-Base & Road Base WorksBleep NewsPas encore d'évaluation

- Risk Assessment: N C Tucker LTD Plastering 17/06/2019 NTDocument4 pagesRisk Assessment: N C Tucker LTD Plastering 17/06/2019 NTAngela DaveyPas encore d'évaluation

- 7-Asphalt Road Cutting PDFDocument3 pages7-Asphalt Road Cutting PDFAhmed ZaiPas encore d'évaluation

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDocument7 pagesHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDocument11 pagesRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (1)

- Excavation & Backfilling Risk AssessmentDocument6 pagesExcavation & Backfilling Risk AssessmentAbdul Rasheed Mangrio100% (1)

- Risk Assessment For Block & Plastering WorksDocument43 pagesRisk Assessment For Block & Plastering WorksAndres Corsino Kristoffer AL100% (1)

- Risk Assessment For Earthing Work-R1Document3 pagesRisk Assessment For Earthing Work-R1Azhar Mushtaq75% (4)

- RISK ASSESSMENT (Concrete Pouring & Vehicular Movement)Document2 pagesRISK ASSESSMENT (Concrete Pouring & Vehicular Movement)Raza Muhammad Soomro100% (1)

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul WasayPas encore d'évaluation

- RA 021 Risk Assessment - Installation of External Landscape Lighting WorksDocument13 pagesRA 021 Risk Assessment - Installation of External Landscape Lighting Worksthomson50% (2)

- RA 021 Risk Assessment - Installation of External Landscape Lighting WorksDocument13 pagesRA 021 Risk Assessment - Installation of External Landscape Lighting Worksthomson50% (2)

- Soft Landscaping ROW Area Risk AssessmentDocument11 pagesSoft Landscaping ROW Area Risk AssessmentSIBIN100% (2)

- Risk Assessment For Excavation and BackfillingDocument4 pagesRisk Assessment For Excavation and BackfillingShazayn Khan100% (1)

- Risk Assessment Construction of Lighting Pole at Site OfficeDocument9 pagesRisk Assessment Construction of Lighting Pole at Site OfficeSinaPas encore d'évaluation

- Task-Based Risk Assessment Painting WorksDocument6 pagesTask-Based Risk Assessment Painting Worksvinodhyper100% (2)

- 07 EPANET Tutorial-SlidesDocument26 pages07 EPANET Tutorial-SlidesTarhata Kalim100% (1)

- Excavation Risk Assessment KTPS - 8 PAGESDocument7 pagesExcavation Risk Assessment KTPS - 8 PAGESrajalingam100% (1)

- Environmental, Health and Safety Risk AssessmentDocument2 pagesEnvironmental, Health and Safety Risk AssessmentAdnan100% (2)

- Risk Assessment For Installation of Diesel Generator111111Document8 pagesRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- 03 - Risk Assessment-Material ShiftingDocument4 pages03 - Risk Assessment-Material Shifting287Pas encore d'évaluation

- Risk Assessment - Backfilling Around Foul Sewer and Storm Warter ManholesDocument6 pagesRisk Assessment - Backfilling Around Foul Sewer and Storm Warter Manholesloveson70950% (2)

- Ashghal Guide-Qatar Sewerage & Drainage Design ManualDocument60 pagesAshghal Guide-Qatar Sewerage & Drainage Design Manualmounir89% (36)

- TRA For Fabrication, Cutting, Grinding and WeldingDocument3 pagesTRA For Fabrication, Cutting, Grinding and WeldingSaif Ali100% (1)

- 009 Installation of Pumps Risk AssessmentDocument2 pages009 Installation of Pumps Risk AssessmentRadhaKrishnan RPas encore d'évaluation

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- Risk Assessment For Concrete Coring, Chipping and DrillingDocument17 pagesRisk Assessment For Concrete Coring, Chipping and DrillingJayson Escamillan80% (5)

- Company Instrumentation & Control Specialists, Inc Document ID No. Department/s Contractor Revision No Job Title Coring Works Effective DateDocument11 pagesCompany Instrumentation & Control Specialists, Inc Document ID No. Department/s Contractor Revision No Job Title Coring Works Effective DateJayson EscamillanPas encore d'évaluation

- App-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair RoadDocument15 pagesApp-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair Roadloveson709Pas encore d'évaluation

- International: Red Sea S.T.A.R.R.TDocument1 pageInternational: Red Sea S.T.A.R.R.TJunard Lu Hap83% (6)

- Concrete WorkDocument1 pageConcrete WorkChandruPas encore d'évaluation

- Manual Handling Risk AssessmentDocument4 pagesManual Handling Risk Assessmentnelson100% (1)

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Ali QaziPas encore d'évaluation

- RA-Chlorination & Disinfectionof Water Supply SystemDocument11 pagesRA-Chlorination & Disinfectionof Water Supply SystemSanto EPas encore d'évaluation

- Risk Assessment of WaterproofingDocument7 pagesRisk Assessment of WaterproofingAbdul MujeebPas encore d'évaluation

- Risk Assesment For Steel FixingDocument6 pagesRisk Assesment For Steel FixingAzhar Mushtaq33% (3)

- DewateringDocument1 pageDewateringChandruPas encore d'évaluation

- EFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & ShampooDocument4 pagesEFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & Shampoomohammed ayazPas encore d'évaluation

- RA 023 Risk Assessment - FireDocument4 pagesRA 023 Risk Assessment - Firethomson100% (4)

- Risk Assement - (Paint Work)Document6 pagesRisk Assement - (Paint Work)Zohaib TahirPas encore d'évaluation

- 005 Risk Assessment T&C Fire Suppression SystemDocument10 pages005 Risk Assessment T&C Fire Suppression SystemJohn RazaPas encore d'évaluation

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument8 pagesRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- Risk Assessment - Installation of Air CurtainDocument25 pagesRisk Assessment - Installation of Air CurtainMohsin MohdPas encore d'évaluation

- Revised Risk Assessment-Concrete Coring-1Document5 pagesRevised Risk Assessment-Concrete Coring-1riyazkader83% (12)

- Al Qooz Contracting LLC: Hazard Identification and Risk AssesmentDocument8 pagesAl Qooz Contracting LLC: Hazard Identification and Risk Assesmentشاز إياس100% (1)

- Risk Assessment - Wall Reinforcement and FormworkDocument4 pagesRisk Assessment - Wall Reinforcement and FormworkSarfraz Randhawa100% (1)

- Risk Assessment For Water Heaters InstallationDocument6 pagesRisk Assessment For Water Heaters Installationfidgety100% (1)

- Road Asphalt Works-Epc10-Ra-74-R0Document5 pagesRoad Asphalt Works-Epc10-Ra-74-R0tariq1987100% (1)

- Risk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingDocument3 pagesRisk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingSafety Professional0% (1)

- Risk Assesment of Brick & Block WorkDocument40 pagesRisk Assesment of Brick & Block WorkGyanendra Srivastava0% (2)

- Risk Analisis Ramming WorksDocument2 pagesRisk Analisis Ramming Worksdefidmsp39Pas encore d'évaluation

- Risk Assess Plastering 2006 Tcm17 26368Document2 pagesRisk Assess Plastering 2006 Tcm17 26368Anonymous QGHbz92uPas encore d'évaluation

- 10 - Example Risk Assement Cladding InstallationDocument3 pages10 - Example Risk Assement Cladding InstallationAhmed Tarek67% (3)

- Risk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Document16 pagesRisk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Mohsin MohdPas encore d'évaluation

- Risk Assessment - Painting Works (1Document7 pagesRisk Assessment - Painting Works (1Bashir Khan100% (1)

- Soft Landscaping Risk Assessment SheetDocument1 pageSoft Landscaping Risk Assessment SheetMuhammad Ibrahim100% (3)

- Risk Assessment For Concrete WorksDocument4 pagesRisk Assessment For Concrete WorksRafiullah KhanPas encore d'évaluation

- Balinghasay V CastilloDocument1 pageBalinghasay V CastilloMirella100% (3)

- Gothic ArchitectureDocument6 pagesGothic ArchitectureleePas encore d'évaluation

- Genie PDFDocument264 pagesGenie PDFjohanaPas encore d'évaluation

- RELATION AND FUNCTION - ModuleDocument5 pagesRELATION AND FUNCTION - ModuleAna Marie ValenzuelaPas encore d'évaluation

- CSR Report On Tata SteelDocument72 pagesCSR Report On Tata SteelJagadish Sahu100% (1)

- BIM Scope of WorkDocument2 pagesBIM Scope of Workthomson50% (2)

- SH Wire Rope HoistDocument24 pagesSH Wire Rope HoistthomsonPas encore d'évaluation

- Teacher'S Individual Plan For Professional Development SCHOOL YEAR 2020-2021Document2 pagesTeacher'S Individual Plan For Professional Development SCHOOL YEAR 2020-2021Diether Mercado Padua100% (8)

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnPas encore d'évaluation

- GT Crete FR Qaf OmegaDocument4 pagesGT Crete FR Qaf OmegathomsonPas encore d'évaluation

- GT Crete FR Qaf OmegaDocument4 pagesGT Crete FR Qaf OmegathomsonPas encore d'évaluation

- Site Office Ground Floor Plan Layout: State of QATARDocument1 pageSite Office Ground Floor Plan Layout: State of QATARthomsonPas encore d'évaluation

- 20 Ton Mechanical Hull WRSHDocument2 pages20 Ton Mechanical Hull WRSHthomsonPas encore d'évaluation

- State of Qatar: NNBP Buildings and InfrastructureDocument1 pageState of Qatar: NNBP Buildings and InfrastructurethomsonPas encore d'évaluation

- TOLERANCE AS PER - CT-11 ISO 8062-2000: Top ViewDocument1 pageTOLERANCE AS PER - CT-11 ISO 8062-2000: Top ViewthomsonPas encore d'évaluation

- 20 Ton Mechanical Hull WRSHDocument2 pages20 Ton Mechanical Hull WRSHthomsonPas encore d'évaluation

- 20 Ton Crane - Mechanicalwork ShopDocument2 pages20 Ton Crane - Mechanicalwork ShopthomsonPas encore d'évaluation

- 20 Ton Goods RecivedDocument2 pages20 Ton Goods RecivedthomsonPas encore d'évaluation

- 20 Ton Crane - Electrical Work ShopDocument2 pages20 Ton Crane - Electrical Work Shopthomson100% (1)

- Specifications RequestDocument25 pagesSpecifications RequestthomsonPas encore d'évaluation

- Yojananov 2021Document67 pagesYojananov 2021JackPas encore d'évaluation

- A Project Report On "A Comparative Study Between Hero Honda Splendor+ and Its Competitors To Increase The Market Share in MUDHOL RegionDocument70 pagesA Project Report On "A Comparative Study Between Hero Honda Splendor+ and Its Competitors To Increase The Market Share in MUDHOL RegionBabasab Patil (Karrisatte)Pas encore d'évaluation

- Internal Gear Pump: Replaces: 03.08 Material No. R901216585 Type PGH.-3XDocument36 pagesInternal Gear Pump: Replaces: 03.08 Material No. R901216585 Type PGH.-3XbiabamanbemanPas encore d'évaluation

- Knitting in Satellite AntennaDocument4 pagesKnitting in Satellite AntennaBhaswati PandaPas encore d'évaluation

- Ultrasonic Based Distance Measurement SystemDocument18 pagesUltrasonic Based Distance Measurement SystemAman100% (2)

- GT I9100g Service SchematicsDocument8 pagesGT I9100g Service SchematicsMassolo RoyPas encore d'évaluation

- Advanced Statistical Approaches To Quality: INSE 6220 - Week 4Document44 pagesAdvanced Statistical Approaches To Quality: INSE 6220 - Week 4picalaPas encore d'évaluation

- Tso C197Document6 pagesTso C197rdpereirPas encore d'évaluation

- 30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Document64 pages30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Trần MaiPas encore d'évaluation

- Story 1Document3 pagesStory 1api-296631749Pas encore d'évaluation

- Johari WindowDocument7 pagesJohari WindowSarthak Priyank VermaPas encore d'évaluation

- Growing Onion Management and Water NeedsDocument25 pagesGrowing Onion Management and Water NeedsKATE NAVAJAPas encore d'évaluation

- Crown BeverageDocument13 pagesCrown BeverageMoniruzzaman JurorPas encore d'évaluation

- Thesis Topics in Medicine in Delhi UniversityDocument8 pagesThesis Topics in Medicine in Delhi UniversityBecky Goins100% (2)

- A Summer Training ReportDocument39 pagesA Summer Training ReportShubham SainyPas encore d'évaluation

- Regulated and Non Regulated BodiesDocument28 pagesRegulated and Non Regulated Bodiesnivea rajPas encore d'évaluation

- II. Put The Verbs in The Correct FormsDocument3 pagesII. Put The Verbs in The Correct FormsNguyễn Bích DiệpPas encore d'évaluation

- Facultybooklet2011-2012final - 006 (Unlocked by WWW - Freemypdf.com)Document199 pagesFacultybooklet2011-2012final - 006 (Unlocked by WWW - Freemypdf.com)kalam19892209Pas encore d'évaluation

- Lab Report 2Document5 pagesLab Report 2Md jubayer SiddiquePas encore d'évaluation

- 8. Nguyễn Tất Thành- Kon TumDocument17 pages8. Nguyễn Tất Thành- Kon TumK60 TRẦN MINH QUANGPas encore d'évaluation

- USA Nozzle 01Document2 pagesUSA Nozzle 01Justin MercadoPas encore d'évaluation

- Your Bentley Bentayga V8: PresentingDocument9 pagesYour Bentley Bentayga V8: PresentingThomas SeiferthPas encore d'évaluation

- Hydropneumatic Booster Set MFDocument5 pagesHydropneumatic Booster Set MFdonchakdePas encore d'évaluation