Académique Documents

Professionnel Documents

Culture Documents

BOLL High-Pressure Cleaning Unit: Prolong The Use of Filter Elements

Transféré par

ArshadTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BOLL High-Pressure Cleaning Unit: Prolong The Use of Filter Elements

Transféré par

ArshadDroits d'auteur :

Formats disponibles

BOLL High-Pressure

Cleaning Unit

TYPE 5.04

PROLONG THE USE OF FILTER

ELEMENTS

To efficiently regenerate filter ele-

ments that have become engrained

with contaminants and secure full

functionality, it is recommended to

manually clean the filter mesh from

time to time. Optimum results are

achieved by using the BOLL high-

pressure cleaning unit type 5.04 in

combination with the special cleaning

fluid BOLL-CLEAN 2000.

The unit is suitable for both the clean-

ing of individual filter elements and

for complete filter inserts. Moreover,

it can be used for the cleaning of other

small parts.

SOAK, RINSE, READY!

Cleaning of the filter elements is

easy and trouble-free. The filter ele-

ment is soaked in the soaking tank

filled with the cleaning fluid BOLL-

CLEAN 2000 . The soaking time de-

pends on the type and grade of con-

tamination.

The filter element is then placed

on a perforated plate in the spray- REDUCE COSTS,

ing tank and washed out with a SAVE RESOURCES

high-pressure cleaning lance . The Regular cleaning of filter elements and a micro-filter on the pressure side

process is clean for the user as well filter inserts prolongs their service life of the pump as it is used again and

because the spraying tank is enclosed and reduces expenditure on consum- again over a long period of time, also

and the perforated base plate helps able items. The cleaning fluid is con- giving a cost-saving due to the low

avoid the formation of spray clouds. stantly recycled and being cleaned by consumption of the cleaning fluid.

TWO SIZES AND TWO LANCES

The high-pressure cleaning unit is different, replaceable cleaning lances, ter elements. Moreover, the outside

supplied mounted on a base frame which are fastened to the cleaning of individual multimantle elements

with lockable castors and equipped gun by means of a quick-lock coup can be cleaned with the nozzle.

with a high-pressure pump and a ling. • The cleaning lance type 5.01 with

pump protection filter . The unit is • The cleaning lance type 5.02 with rotary nozzle is particularly suitable

available in two sizes to cover the the flat jet nozzle is suitable for the for cleaning the inside of screw-in

wide range of BOLL filter elements majority of applications, particularly and plug-in candles in case of ex

available (see table). for the outside of star-pleated ele- treme contamination, e.g. fuel and

Both sizes are delivered with two ments, basket elements and ring fil- rolling oil filters.

T E C H N I C A L D ATA

High-pressure cleaning unit type 5.04 Pump motor:

Size 355/500 435/750 • 220/380 V, 50 Hz; 440 V, 60 Hz

Length 995 mm 1285 mm • Protection class IP 55

Width 500 mm 700 mm • Insulation class F

Height 1000 mm 1260 mm • Overload protection by thermal switch

Maximum size of filter elements to be cleaned: Delivery rate of the pump:

Size 355/500 435/750 • max. 9 l/min

Diameter 355 mm 435 mm • Pressure: 85 bar

Length 500 mm 750 mm • Temperature: max. 70° C

BOLL & KIRCH Filterbau GmbH • Siemensstr. 10-14 • D- 50170 Kerpen

Phone: (+49) (0) 22 73-5 62-0 • Fax: (+49) (0) 22 73-5 62-22 3 • e-mail: info@bollfilter.de • http://www.bollfilter.de

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Renewal Regular Passport Application Form (Adult) : Department of Foreign AffairsDocument2 pagesRenewal Regular Passport Application Form (Adult) : Department of Foreign AffairsTahinay KarlPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Use of English Worksheets-Unit-14Document2 pagesUse of English Worksheets-Unit-149k2cwnnk8tPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Soclit Midterms Umali LT2Document2 pagesSoclit Midterms Umali LT2john jkillerzsPas encore d'évaluation

- Somalia Marks International Youth DayDocument3 pagesSomalia Marks International Youth DayUNSOM (The United Nations Assistance Mission in Somalia)Pas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

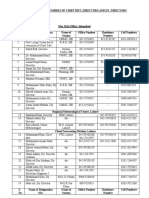

- Contact NumbersDocument2 pagesContact NumbersUsamaPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Lecturer Pak Study (Female) 18 B 2020Document2 pagesLecturer Pak Study (Female) 18 B 2020Mariya IqbalPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Statement by Macomb County Clerk Fred MillerDocument1 pageStatement by Macomb County Clerk Fred MillerWXYZ-TV Channel 7 DetroitPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Youth Quote Book BackupDocument3 pagesYouth Quote Book BackupClaytonPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Andhra Pradesh - Social Question & AnswersDocument4 pagesAndhra Pradesh - Social Question & Answersdeepakdohare1011Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- ChatGPT NotesDocument5 pagesChatGPT NotesUsman HaiderPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Election Laws AssignmentDocument21 pagesElection Laws AssignmentShafaq ZooniPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- BalintawakDocument2 pagesBalintawakJustine UrbanPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Constitution Scavenger HuntDocument6 pagesConstitution Scavenger Hunttimothyjgraham1445Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- PA Citizen's Audit of 2020 ElectionDocument27 pagesPA Citizen's Audit of 2020 ElectionRay BleharPas encore d'évaluation

- LDPD 6260645 023Document76 pagesLDPD 6260645 023miguelqas445566Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Rcat 2023 24Document1 pageRcat 2023 24prashantsingh9227Pas encore d'évaluation

- Local Self Government in PakistanDocument2 pagesLocal Self Government in Pakistanazqan100% (1)

- Lehmann Polish-Ukrainian Coexistence SE Poland (2009)Document213 pagesLehmann Polish-Ukrainian Coexistence SE Poland (2009)Keith HurtPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- KhattakDocument16 pagesKhattakM. TalhaPas encore d'évaluation

- Consortium of National Law Universities: Provisional 2nd List - CLAT 2021 - UGDocument6 pagesConsortium of National Law Universities: Provisional 2nd List - CLAT 2021 - UGAnkitaPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Bill Mauro - WikipediaDocument5 pagesBill Mauro - Wikipediamarcos vallegoPas encore d'évaluation

- The Caste Based Mosaic of Indian PoliticsDocument11 pagesThe Caste Based Mosaic of Indian PoliticsPemsang LamaPas encore d'évaluation

- MDOT Emails Regarding Safety Requirements of Lakeland Frontage RoadDocument11 pagesMDOT Emails Regarding Safety Requirements of Lakeland Frontage RoadRuss LatinoPas encore d'évaluation

- Pol Gov 125Document363 pagesPol Gov 125Aycee ElardoPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- PCI Newspaper - Issue 427-CompressedDocument32 pagesPCI Newspaper - Issue 427-CompressedcanadianinquirerPas encore d'évaluation

- Election Review - CCCXXXDocument6 pagesElection Review - CCCXXXAnonymous Qn8AvWvxPas encore d'évaluation

- Full Download Business A Changing World 10th Edition Ferrell Solutions ManualDocument35 pagesFull Download Business A Changing World 10th Edition Ferrell Solutions Manualhittoonugk100% (26)

- PR1Document11 pagesPR1Pamela100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- 8 The Lure Dangers of Extremist Rethoric PDFDocument9 pages8 The Lure Dangers of Extremist Rethoric PDFOdin de JesusPas encore d'évaluation

- 3 en PDFDocument309 pages3 en PDFInna ShubravskaPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)