Académique Documents

Professionnel Documents

Culture Documents

Troubleshooting Guide: Asset Family Centrifugal Process Pumps

Transféré par

Pedro ViegasTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Troubleshooting Guide: Asset Family Centrifugal Process Pumps

Transféré par

Pedro ViegasDroits d'auteur :

Formats disponibles

Troubleshooting Guide

Drawing & Photos

Asset Family

CENTRIFUGAL PROCESS PUMPS

Applicable Asset(s) Running & Control Parameters

Static Discharge Head (hd)

Static Suction Head (hs)

R342;R344;R765;R877;R98

Pressure [bar]

Impeler DN

Imp. RPM

d[Kg/m3]

Q[m3/h]

°C

Set Value

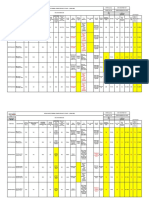

Failure Modes (Symptoms)

D. Insufficient Discharge Pressure E. Short Bearing Life

C. Intermittent Operation F. Short Mechanical Seal Life

B. Insufficient Capacity G. Vibration and Noise

A. No liquid delivery H. Power Demand Execessive

Type Possible Causes Nr. A B C D E F G H Possible Solutions

# Check NPSHa ( Net Positive Suction Head Available ) / NPSHr (Net Positive

Pump is cavitating Suction Head Required ) Margin ;

1 2 1 1 9 1

(Symptom for liquid vaporizing in suction system - Horizontal Pumps) # If pump is above liquid level,raise liquid level closer to pump ;

Suction Problems

# If liquid Is above pump, Increase liquid level elevation ;

# Fill Pump & Suction Piping.Complete with liquid;

# Eliminate high points in suctions;

Pump not primed (air in system) 2 1 2 #Remove all non-condensibles (Air from Pump, piping and valves);

# Eliminate High piping;

# Check for faulty foot valve or check valve.

# Check for gas/air ingress through suction system/piping;

Non-Condensibles in Liquid 3 4 2 3 1

# Install gas separation chamber.

Supply Tank Empty 4 3 # Refill supply tank

Obstruction In lines or pump housing 5 9 7 7 # Inspect and clean

Strainer Partially Clogged 6 3 # Inspect and clean

Pump Impeller Clogged 7 8 8 5 # Check for damage and clean

Hydraulic System

Suction or/& Discharging Valve(s) Closed 8 9 # Check Down & Open Valves

# Heat up Liquid to reduce viscosity;

# Increase the size of discharging piping to reduce pressure loss (if possible);

Viscosity too High 9 7 5 4

# Use larger driver or change type of pump;

# Slow pump down

Specific Gavity to High 10 2 # Check design specific gravity

# Increase system resistance to obtain design flow;

Total System Head Lower than Design Head of Pump 11 4 11

# Check design parameters such as impeller size , etc..

# Decrease system resistance to obtain design flow;

Total System Head Higher than Design Head of Pump 12 6 5 4 10 2

# Check design parameters such as impeller size , etc..

Unsuitable Pumps in Parallel Operation 13 7 6 6 # Check design parameters

Improper Mechanical Seal 14 1 # Check mechanical seal selection

Speed to High 15 1 # Check Motor voltage - slow down driver

Speed to Low 16 4 4 2 # Drive problems. Consulting drive parameters

Worng direction of rotation 17 5 3 6 # Check rotation with arrow on casing if existent- Reverse polarity on motor

Impeller installed backward (Bouble suction imp.) 18 10 12 # Inspect & correct

Misalignment 19 1 2 4 7 # Chec angular & Parallel Alignment between pump & driver

Mechanical System

# Check for misalignement

Casing disorted from execissive pipe strain 20 2 3 5 # Check pump for wear between casing and rotating elements;

# Analyze piping loads.

Inadequate grouting of base 21 6 # Check grouting & regrout if required.

# Check deflection (should not execeed 0.002"). Replace shaft & bearings if

Bent Shaft 22 3 4 7 8

necessary

Internal Wear 23 8 9 # Check impeller clearances

# Inspect part for deflects - Repair or Replace.Use bearing troubleshooting

Mechanical Deflects Worn, Rusted, Defective Bearings 24 5 8 10 guide ;

# Check lubrication procedures.

Unbalance - Driver 25 5 7 9 # Run Driver disconnected from pump unit-perform vibration analysis.

Unbalance - Pump 26 4 6 3 # Investigate natural frequency

Electric Motor Problems 27 6 8 10 11 # Consult Electric Motor Troubleshooting Guide

Note(s):

For vibration & short bearing life related causes , refer to special sections on bearing failure troubleshooting guide & vibration diagnostics

Vous aimerez peut-être aussi

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersD'EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersÉvaluation : 5 sur 5 étoiles5/5 (2)

- Courseware - O&M of Valves & ActuatorsDocument154 pagesCourseware - O&M of Valves & Actuatorssandeep_bcplPas encore d'évaluation

- Hopkinson Valves IOM ManualDocument7 pagesHopkinson Valves IOM ManualGiorgiana RosuPas encore d'évaluation

- Basic Valve and Testing Method - 1Document37 pagesBasic Valve and Testing Method - 1Fouad OudinaPas encore d'évaluation

- Control Valve CharacteristicsDocument3 pagesControl Valve CharacteristicsgifitrianggraeniPas encore d'évaluation

- Control Valve TerminologyDocument18 pagesControl Valve TerminologyAbd Elrahman HamdyPas encore d'évaluation

- Types of Control ValvesDocument8 pagesTypes of Control ValvesRishi Kant SharmaPas encore d'évaluation

- متابعة صيانة التكييف المركزيDocument52 pagesمتابعة صيانة التكييف المركزيRomou Alsaaq100% (1)

- Unit 1Document55 pagesUnit 1Eileen LeePas encore d'évaluation

- M2.7 ValvesDocument27 pagesM2.7 ValvesUJWAL UMESHPas encore d'évaluation

- Valves: Technical Industrial InstituteDocument31 pagesValves: Technical Industrial InstituteZakPas encore d'évaluation

- Operating Instructions: Sempell Series Vse/Vsr Full Lift and Normal Safety Relief ValveDocument16 pagesOperating Instructions: Sempell Series Vse/Vsr Full Lift and Normal Safety Relief Valveayman akrabPas encore d'évaluation

- Pressure-Control Valves PDFDocument15 pagesPressure-Control Valves PDFRagab Abulmagd100% (1)

- Birkett Safety Relief Valves: Simply Photocopy and Fax To Us For More Information On..Document52 pagesBirkett Safety Relief Valves: Simply Photocopy and Fax To Us For More Information On..Mark RomeroPas encore d'évaluation

- Lacos Sweeping Basin SystemDocument18 pagesLacos Sweeping Basin SystemSanto EPas encore d'évaluation

- Acv Automatic Control Valves PDFDocument20 pagesAcv Automatic Control Valves PDFabdallah391Pas encore d'évaluation

- Side Stream FiltrationDocument1 pageSide Stream FiltrationAmit ChaudharyPas encore d'évaluation

- 3.1.WasteWater Treatment Procedure - FLOCDocument4 pages3.1.WasteWater Treatment Procedure - FLOChaseeb100% (1)

- Valves: Presented by D.Nagababu (Get-Pp)Document54 pagesValves: Presented by D.Nagababu (Get-Pp)SatishSathyamevaJayathePas encore d'évaluation

- Chemical Dosing PotsDocument3 pagesChemical Dosing PotsBuddhika100% (1)

- HVAC Preventive Maintenance Checklists-12Document61 pagesHVAC Preventive Maintenance Checklists-12JawadPas encore d'évaluation

- Part-Turn Gearboxes GS 50.3 - GS 250.3: Assembly, Commissioning Operation InstructionsDocument56 pagesPart-Turn Gearboxes GS 50.3 - GS 250.3: Assembly, Commissioning Operation InstructionsSergio Sosa Nava100% (1)

- API 576 Inspection of Pressure-Relieving DevicesDocument19 pagesAPI 576 Inspection of Pressure-Relieving DevicesTahseen JwadPas encore d'évaluation

- Pump Basics1Document34 pagesPump Basics1sambasivammePas encore d'évaluation

- Process Flow Diagram For ETP PlantDocument1 pageProcess Flow Diagram For ETP PlantenqPas encore d'évaluation

- LX HI ManualDocument52 pagesLX HI ManualMalik MentuPas encore d'évaluation

- PUMPS Lecture 2024Document37 pagesPUMPS Lecture 2024aidenpierce8876Pas encore d'évaluation

- 290 08 PDFDocument4 pages290 08 PDFmlevPas encore d'évaluation

- P&IDDocument4 pagesP&IDFaiz NordinPas encore d'évaluation

- WTP - Opeation Engineer - GulfDocument2 pagesWTP - Opeation Engineer - GulfmaniyarasanPas encore d'évaluation

- IEEE Standard Device NumbersDocument1 pageIEEE Standard Device NumbersBA GomPas encore d'évaluation

- Pumps: Pumps and Its TypesDocument34 pagesPumps: Pumps and Its TypesAmir Hamza100% (1)

- Protection Relay CodeDocument1 pageProtection Relay CodebenPas encore d'évaluation

- 2sog Valve ExercisingDocument5 pages2sog Valve ExercisingAgus TrionoPas encore d'évaluation

- B7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallDocument30 pagesB7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallSMBEAUTYPas encore d'évaluation

- Waterres Training Operator Onsite Training Sop Lift StationDocument1 pageWaterres Training Operator Onsite Training Sop Lift StationVinish HARIDAS NAIRPas encore d'évaluation

- LUFT AHU Installation Startup MaintananceDocument38 pagesLUFT AHU Installation Startup MaintananceUğur DarcanPas encore d'évaluation

- C22-Yb60-F-4765 - 0 Sa3-Ps2, Butterfly Valve, Test ProceduresDocument8 pagesC22-Yb60-F-4765 - 0 Sa3-Ps2, Butterfly Valve, Test Proceduressartaj100% (1)

- Globe Valve General Installation Operation & Maintenance ManualDocument5 pagesGlobe Valve General Installation Operation & Maintenance ManualViba Fluid ControlPas encore d'évaluation

- QA-F-VN-PCM - T & C Check List For ChillerDocument2 pagesQA-F-VN-PCM - T & C Check List For ChillerKevin TranPas encore d'évaluation

- Contorl ValvesDocument8 pagesContorl ValvesGaurav MishraPas encore d'évaluation

- Upvc SubmittalDocument52 pagesUpvc Submittalraja bharathi0% (1)

- Lecture 4 Water Pipe Sizing PDFDocument26 pagesLecture 4 Water Pipe Sizing PDFAlchea Aldeguer100% (1)

- Air Filter PDFDocument15 pagesAir Filter PDFArun KarthikeyanPas encore d'évaluation

- c2 PDFDocument78 pagesc2 PDFSyazaa SalimPas encore d'évaluation

- Appendix-3.0 Scope of Chiller Maintenance WorksDocument3 pagesAppendix-3.0 Scope of Chiller Maintenance Worksnoormuddassirkhan100% (1)

- Ultra Filtration SystemDocument5 pagesUltra Filtration SystemAbdul SamadPas encore d'évaluation

- Welcome: A Seminar Presention ONDocument24 pagesWelcome: A Seminar Presention ONsushil kumarPas encore d'évaluation

- Master Chilled Wate Entrance No HX Rev JMD 20120817-1Document8 pagesMaster Chilled Wate Entrance No HX Rev JMD 20120817-1AshPas encore d'évaluation

- Pumps and Industrial ApplicationDocument19 pagesPumps and Industrial Applicationdevasree reddyPas encore d'évaluation

- Scope of Work Template For AirconDocument2 pagesScope of Work Template For AirconKimberly Mae SelladoPas encore d'évaluation

- Split Type Airconditioner CS-C9DKD CU-C9DKD Service ManualDocument85 pagesSplit Type Airconditioner CS-C9DKD CU-C9DKD Service Manualchrspta67% (3)

- Gestra Condensate ManualDocument172 pagesGestra Condensate ManualGeorge ClaessenPas encore d'évaluation

- Disk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0Document16 pagesDisk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0otsontek9227Pas encore d'évaluation

- Procedure For Testing & Commissioning of Water Booster Jockey PumpsDocument3 pagesProcedure For Testing & Commissioning of Water Booster Jockey Pumpsvin ssPas encore d'évaluation

- Industrial Waste Water Treatment Auxiliary System Post Maintenance ChecksDocument11 pagesIndustrial Waste Water Treatment Auxiliary System Post Maintenance ChecksAbeer arifPas encore d'évaluation

- Internship ReportDocument7 pagesInternship ReportMoiz EhsanPas encore d'évaluation

- Equipment Specification Project - RFQ - #: XXXXXX XXXXX ES-223116Document17 pagesEquipment Specification Project - RFQ - #: XXXXXX XXXXX ES-223116Calin SeraphimPas encore d'évaluation

- Final Enquiry List For ValvesDocument12 pagesFinal Enquiry List For ValvesnikhilPas encore d'évaluation

- Inspection Poster GilsonDocument2 pagesInspection Poster GilsonJosé Álvarez RoblesPas encore d'évaluation

- Dot Point Bar PowerPoint DiagramDocument1 pageDot Point Bar PowerPoint DiagramPedro ViegasPas encore d'évaluation

- 7 Global Golden Rules of Safety - List of Rules - Lean VersionDocument1 page7 Global Golden Rules of Safety - List of Rules - Lean VersionPedro ViegasPas encore d'évaluation

- An Insider's Guide To CMMS Functions, Selection and ImplementationDocument26 pagesAn Insider's Guide To CMMS Functions, Selection and ImplementationPedro ViegasPas encore d'évaluation

- Enova - Pedro Insigths 2023Document5 pagesEnova - Pedro Insigths 2023Pedro ViegasPas encore d'évaluation

- 7 Reasons To Do Laser AlignmentDocument8 pages7 Reasons To Do Laser AlignmentPedro ViegasPas encore d'évaluation

- 7 Global Golden Rules of Safety - Rule 7 - Vehicles, Mobile Equipment & Workplace - DraftDocument11 pages7 Global Golden Rules of Safety - Rule 7 - Vehicles, Mobile Equipment & Workplace - DraftPedro ViegasPas encore d'évaluation

- IR Checks of Conveyor Idler RollersDocument5 pagesIR Checks of Conveyor Idler RollersPedro ViegasPas encore d'évaluation

- Alignment CourseDocument167 pagesAlignment Coursedennis_packiaraj3063100% (20)

- 7 Global Golden Rules of Safety - Rule 5 - LOTO & Work Permit - DraftDocument5 pages7 Global Golden Rules of Safety - Rule 5 - LOTO & Work Permit - DraftPedro ViegasPas encore d'évaluation

- 7 Global Golden Rules of Safety - Rule 2 - Body Protection - DraftDocument6 pages7 Global Golden Rules of Safety - Rule 2 - Body Protection - DraftPedro ViegasPas encore d'évaluation

- 7 Global Golden Rules of Safety - Rule 6 - Handling, Loading & Unloading of Loads Fall Hazards Work at Height - DraftDocument6 pages7 Global Golden Rules of Safety - Rule 6 - Handling, Loading & Unloading of Loads Fall Hazards Work at Height - DraftPedro ViegasPas encore d'évaluation

- 7 Global Golden Rules of Safety - Rule 4 - Machinery & Rotary Part Protection - DraftDocument7 pages7 Global Golden Rules of Safety - Rule 4 - Machinery & Rotary Part Protection - DraftPedro ViegasPas encore d'évaluation

- 7 Global Golden Rules of Safety - List of Rules - Lean VersionDocument1 page7 Global Golden Rules of Safety - List of Rules - Lean VersionPedro ViegasPas encore d'évaluation

- 7 Global Golden Rules of Safety - Rule 1 - Safety Priority - DraftDocument4 pages7 Global Golden Rules of Safety - Rule 1 - Safety Priority - DraftPedro ViegasPas encore d'évaluation

- Spiral Freezer Gearbox FailuresDocument7 pagesSpiral Freezer Gearbox FailuresPedro ViegasPas encore d'évaluation

- FPS Spiral Brochure V12smDocument8 pagesFPS Spiral Brochure V12smPedro ViegasPas encore d'évaluation

- (Name / Logo) : Internal Strengths Internal WeaknesssesDocument7 pages(Name / Logo) : Internal Strengths Internal WeaknesssesPedro ViegasPas encore d'évaluation

- 7 Global Golden Rules of Safety - List of RulesDocument1 page7 Global Golden Rules of Safety - List of RulesPedro ViegasPas encore d'évaluation

- 7 Global Golden Rules of Safety - Rule 3 - Safety Walks, Communication & Report - DraftDocument3 pages7 Global Golden Rules of Safety - Rule 3 - Safety Walks, Communication & Report - DraftPedro ViegasPas encore d'évaluation

- Pros and Cons List TemplateDocument2 pagesPros and Cons List TemplatePedro ViegasPas encore d'évaluation

- Accurate Failure Data - A Culture of Reliability - Failure CodesDocument8 pagesAccurate Failure Data - A Culture of Reliability - Failure CodesPedro ViegasPas encore d'évaluation

- Shop Online For Industrial Printers, Labels, Signs, Lockout & More - HSE Lockout Equipament PDFDocument4 pagesShop Online For Industrial Printers, Labels, Signs, Lockout & More - HSE Lockout Equipament PDFPedro ViegasPas encore d'évaluation

- The Golden Rules of SafetyDocument11 pagesThe Golden Rules of SafetyPedro ViegasPas encore d'évaluation

- 70 30 PhenomenonDocument2 pages70 30 PhenomenonPedro ViegasPas encore d'évaluation

- Backlog ManagementDocument3 pagesBacklog ManagementPedro ViegasPas encore d'évaluation

- 10 Ways To Reduce Reactive Maintenance: Ten Actions Worth ConsideringDocument4 pages10 Ways To Reduce Reactive Maintenance: Ten Actions Worth ConsideringPedro ViegasPas encore d'évaluation

- A Day in The Life of A Proactive PDM TechnicianDocument6 pagesA Day in The Life of A Proactive PDM TechnicianPedro ViegasPas encore d'évaluation

- Accurate Failure Data - A Culture of Reliability - Failure CodesDocument8 pagesAccurate Failure Data - A Culture of Reliability - Failure CodesPedro ViegasPas encore d'évaluation

- CMMS Failure CodesDocument9 pagesCMMS Failure CodesPedro ViegasPas encore d'évaluation

- How Does Your Maintenance Organization Use TimeDocument2 pagesHow Does Your Maintenance Organization Use TimePedro ViegasPas encore d'évaluation

- CompressDocument14 pagesCompressAnonymous gfR3btyU0% (1)

- Numerical Techniques For Global AtmosphericDocument577 pagesNumerical Techniques For Global AtmosphericTatiana N. LeónPas encore d'évaluation

- Global Competitiveness ReportDocument7 pagesGlobal Competitiveness ReportSHOIRYAPas encore d'évaluation

- Product DetailsDocument215 pagesProduct DetailsEric MagnayePas encore d'évaluation

- RICS APC Candidate Guide-Aug 2015-WEB PDFDocument24 pagesRICS APC Candidate Guide-Aug 2015-WEB PDFLahiru WijethungaPas encore d'évaluation

- Mba Mini Project ReportDocument32 pagesMba Mini Project ReportAvneesh KumarPas encore d'évaluation

- 358 IG Fashion Pack PDFDocument4 pages358 IG Fashion Pack PDFbovsichPas encore d'évaluation

- One For All Urc-8350 Instruction Manual PDF DownloadDocument5 pagesOne For All Urc-8350 Instruction Manual PDF DownloademinaPas encore d'évaluation

- Nagpur Company List 2Document10 pagesNagpur Company List 2Kaushik BachanPas encore d'évaluation

- 14.symmetrix Toolings LLPDocument1 page14.symmetrix Toolings LLPAditiPas encore d'évaluation

- Bagheri Gavkosh2021Document17 pagesBagheri Gavkosh2021Dan Alfred SebualaPas encore d'évaluation

- Report Managerial Finance@UniklDocument18 pagesReport Managerial Finance@UniklLee WongPas encore d'évaluation

- Lolcat - Linux Cat Command Make Rainbows & Unicorns - LinuxsecretsDocument1 pageLolcat - Linux Cat Command Make Rainbows & Unicorns - LinuxsecretsAli BadPas encore d'évaluation

- Hach Company v. In-SituDocument8 pagesHach Company v. In-SituPatent LitigationPas encore d'évaluation

- Kathrein 739624Document2 pagesKathrein 739624anna.bPas encore d'évaluation

- Yashu Internship Report 21Document45 pagesYashu Internship Report 21Lakshmi dayanand DayaPas encore d'évaluation

- Harrowererickson 1941Document16 pagesHarrowererickson 1941Flavia ChPas encore d'évaluation

- Smart Phone Usage Among College Going StudentsDocument9 pagesSmart Phone Usage Among College Going StudentsAkxzPas encore d'évaluation

- Strategic PlanningDocument24 pagesStrategic PlanningSara Sharma0% (1)

- Designing The Highway: Reported By: Juvy Ann Acabo Czarina AguilarDocument12 pagesDesigning The Highway: Reported By: Juvy Ann Acabo Czarina AguilarCzarinaCanarAguilarPas encore d'évaluation

- Istqb Agile Tester Learning Objectives SingleDocument3 pagesIstqb Agile Tester Learning Objectives SingleSundarPas encore d'évaluation

- Medicinecomplete Clark Drug and PoisonDocument25 pagesMedicinecomplete Clark Drug and PoisonArménio SantosPas encore d'évaluation

- ALLOY 7150-T7751 PLATE AND 7150-T77511 EXTRUSIONS: Alcoa Mill ProductsDocument4 pagesALLOY 7150-T7751 PLATE AND 7150-T77511 EXTRUSIONS: Alcoa Mill Productshitesh_tilalaPas encore d'évaluation

- Intructional Tools With The Integration of TechnologyDocument44 pagesIntructional Tools With The Integration of TechnologyAlwyn SacandalPas encore d'évaluation

- Materials Science and Engineering ADocument10 pagesMaterials Science and Engineering Akhudhayer1970Pas encore d'évaluation

- Sinteza Engleza TradusaDocument6 pagesSinteza Engleza TradusaRobert TintaPas encore d'évaluation

- ERP Final PPT 22-4Document10 pagesERP Final PPT 22-4ramesh pokhriyaalPas encore d'évaluation

- Sciencedirect Sciencedirect SciencedirectDocument7 pagesSciencedirect Sciencedirect SciencedirectMiguel AngelPas encore d'évaluation

- Arbitrage Calculator 3Document4 pagesArbitrage Calculator 3Eduardo MontanhaPas encore d'évaluation