Académique Documents

Professionnel Documents

Culture Documents

Kolher Courage SV470 Manual Propietario PDF

Transféré par

pinchoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Kolher Courage SV470 Manual Propietario PDF

Transféré par

pinchoDroits d'auteur :

Formats disponibles

SV470-SV620

Owner's Manual

IMPORTANT: Read all safety precautions and instructions carefully before

operating equipment. Refer to operating instruction of

equipment that this engine powers.

Ensure engine is stopped and level before performing any

maintenance or service.

Warranty coverage as outlined in the warranty card and on

KohlerEngines.com. Please review carefully as it provides you

specific rights and obligations.

Record engine information to reference when ordering parts or obtaining warranty coverage.

Engine Model

Specification

Serial Number

Purchase Date

20 590 06 Rev. A KohlerEngines.com

Safety Precautions

WARNING: A hazard that could result in death, serious injury, or substantial property damage.

CAUTION: A hazard that could result in minor personal injury or property damage.

NOTE: is used to notify people of important installation, operation, or maintenance information.

WARNING WARNING WARNING

Explosive Fuel Carbon Accidental

can cause fires Monoxide can Starts can cause

and severe cause severe severe injury or

burns. nausea, fainting death.

or death.

Do not fill fuel Disconnect and

tank while Avoid inhaling ground spark

engine is hot or exhaust fumes. plug lead(s)

running. before servicing.

Engine exhaust gases

Gasoline is extremely contain poisonous carbon

monoxide. Carbon Before working on engine or

flammable and its vapors equipment, disable engine

can explode if ignited. monoxide is odorless,

colorless, and can cause as follows: 1) Disconnect

Store gasoline only in spark plug lead(s). 2)

approved containers, in death if inhaled.

Disconnect negative (–)

well ventilated, unoccupied battery cable from battery.

buildings, away from sparks

or flames. Spilled fuel

could ignite if it comes in

contact with hot parts or

sparks from ignition. Never

use gasoline as a cleaning

agent.

WARNING WARNING WARNING

Rotating Parts Electrical Shock Hot Parts can

can cause can cause injury. cause severe

severe injury. burns.

Do not touch

Stay away while wires while Do not touch

engine is in engine is engine while

operation. running. operating or just

after stopping.

Keep hands, feet, hair,

and clothing away from all Never operate engine with

moving parts to prevent heat shields or guards

injury. Never operate engine removed.

with covers, shrouds, or

guards removed.

California Proposition 65 Warning

Engine exhaust from this product contains chemicals known

to State of California to cause cancer, birth defects, or other

reproductive harm.

2 KohlerEngines.com 20 590 06 Rev. A

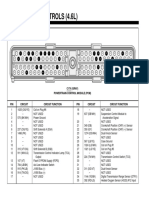

H

C

A

Air Cleaner

A Air Cleaner B C Oil Drain Plug D Oil Filter

Knobs

Main Control

E F Fuel Filter G Oil Fill/Dipstick H Debris Screen

Bracket

Pre-Start Checklist

1. Check oil level. Add oil if low. Do not overfill.

2. Check fuel level. Add fuel if low. Check fuel system components and lines for leaks.

3. Check and clean cooling areas, air intake areas and external surfaces of engine (particularly

after storage).

4. Check that air cleaner components and all shrouds, equipment covers, and guards are in place

and securely fastened.

5. Check spark arrestor (if equipped).

20 590 06 Rev. A KohlerEngines.com 3

Starting Stopping

1. If possible, remove load by disengaging all

PTO driven attachments.

WARNING

2. Position throttle control between half and full

Carbon Monoxide can cause throttle; stop engine.

severe nausea, fainting or death.

Avoid inhaling exhaust fumes. Angle of Operation

Engine exhaust gases contain poisonous Refer to operating instructions of equipment

carbon monoxide. Carbon monoxide is this engine powers. Do not operate this engine

odorless, colorless, and can cause death if exceeding maximum angle of operation; see

inhaled. specification table. Engine damage could result

from insufficient lubrication.

WARNING Engine Speed

NOTE: Do not tamper with governor setting to

Rotating Parts can cause severe increase maximum engine speed.

injury. Overspeed is hazardous and will void

Stay away while engine is in warranty.

operation.

High Altitude Operation

Keep hands, feet, hair, and clothing away

from all moving parts to prevent injury. Never This engine may require a high altitude

operate engine with covers, shrouds, or carburetor kit to ensure correct engine

guards removed. operation at altitudes above 4000 ft.

(1219 meters). To obtain high altitude kit

Refer to operating instructions of equipment information or to find a Kohler authorized dealer

this engine powers for specific starting visit KohlerEngines.com or call 1-800-544-2444

instructions. (U.S. and Canada).

Cold Weather Starting Hints This engine should be operated in its original

configuration below 4000 ft. (1219 meters) as

1. Use proper oil for temperature expected. damage may occur if high altitude carburetor kit

2. Disengage all possible external loads. is installed and operated below 4000 ft. (1219

meters).

3. Use fresh winter grade fuel. Winter grade

fuel has higher volatility to improve starting.

4 KohlerEngines.com 20 590 06 Rev. A

Maintenance Instructions

WARNING

Before working on engine or equipment, disable

Accidental Starts can cause engine as follows: 1) Disconnect spark plug

severe injury or death. lead(s). 2) Disconnect negative (–) battery cable

Disconnect and ground spark from battery.

plug lead(s) before servicing.

Normal maintenance, replacement or repair of emission control devices and systems may be

performed by any repair establishment or individual; however, warranty repairs must be performed

by a Kohler authorized dealer found at KohlerEngines.com or 1-800-544-2444 (U.S. and Canada).

Maintenance Schedule

Every 25 Hours or Annually¹

● Service/replace precleaner (if equipped).

● Replace air cleaner element (if not equipped with precleaner).

Every 100 Hours or Annually¹

● Replace air cleaner element (if equipped with precleaner).

● Change oil and filter.

● Remove cooling shrouds and clean cooling areas.

Every 100 Hours

● Replace fuel filter.

● Check that all fasteners are in place and components are properly secured.

Every 200 Hours²

● Have valve lash checked/adjusted.

Every 500 Hour

● Replace spark plug and set gap.

¹ Perform these procedures more frequently under severe, dusty, dirty conditions.

² Have a Kohler authorized dealer perform this service.

Oil Recommendations Check Oil Level

We recommend use of Kohler oils for best NOTE: To prevent extensive engine wear or

performance. Other high-quality detergent damage, never run engine with oil level

oils (including synthetic) of API (American below or above operating range

Petroleum Institute) service class SJ or higher indicator on dipstick.

are acceptable. Select viscosity based on air

temperature at time of operation as shown in Ensure engine is cool. Clean oil fill/dipstick

table below. areas of any debris.

1. Remove dipstick; wipe oil off.

2. Reinsert dipstick into tube; press completely

10W-30 down.

SAE 30 3. Remove dipstick; check oil level. Level

should be at top of indicator on dipstick.

5W-30

4. If oil is low on indicator, add oil up to top of

°F -20 0 20 32 40 50 60 80 100 indicator mark.

°C -30 -20 -10 0 10 20 30 40

5. Reinstall and secure dipstick.

20 590 06 Rev. A KohlerEngines.com 5

Change Oil and Filter Fuel Recommendations

Change oil while engine is warm.

1. Clean area around oil fill cap/dipstick. WARNING

Remove drain plug and oil fill cap/dipstick.

Allow oil to drain completely. Explosive Fuel can cause fires

2. Clean area around oil filter. Place a container and severe burns.

under filter to catch any oil and remove filter. Do not fill fuel tank while engine is

Wipe off mounting surface. Reinstall drain hot or running.

plug. Torque to 125 in. lb. (14 N·m).

Gasoline is extremely flammable and

3. Place new filter in shallow pan with open end its vapors can explode if ignited. Store

up. Fill with new oil until oil reaches bottom gasoline only in approved containers, in

of threads. Allow 2 minutes for oil to be well ventilated, unoccupied buildings, away

absorbed by filter material. from sparks or flames. Spilled fuel could

4. Apply a thin film of clean oil to rubber gasket ignite if it comes in contact with hot parts or

on new filter. sparks from ignition. Never use gasoline as a

cleaning agent.

5. Refer to instructions on oil filter for proper

installation. NOTE: E15, E20 and E85 are NOT approved

and should NOT be used; effects of

6. Fill crankcase with new oil. Level should be old, stale or contaminated fuel are not

at top of indicator on dipstick. warrantable.

7. Reinstall oil fill cap/dipstick and tighten Fuel must meet these requirements:

securely.

● Clean, fresh, unleaded gasoline.

8. Start engine; check for oil leaks. Stop engine;

correct leaks. Recheck oil level. ● Octane rating of 87 (R+M)/2 or higher.

9. Dispose of used oil and filter in accordance ● Research Octane Number (RON) 90 octane

with local ordinances. minimum.

● Gasoline up to 10% ethyl alcohol, 90%

Oil Sentry™ (if equipped) unleaded is acceptable.

This switch is designed to prevent engine ● Methyl Tertiary Butyl Ether (MTBE) and

from starting in a low oil or no oil condition. Oil unleaded gasoline blend (max 15% MTBE by

Sentry™ may not shut down a running engine volume) are approved.

before damage occurs. In some applications

this switch may activate a warning signal. Read ● Do not add oil to gasoline.

your equipment manuals for more information. ● Do not overfill fuel tank.

● Do not use gasoline older than 30 days.

Fuel Line

Low permeation fuel line must be installed on

carbureted Kohler Co. engines to maintain EPA

and CARB regulatory compliance.

6 KohlerEngines.com 20 590 06 Rev. A

Spark Plugs Breather Tube

Ensure both ends of breather tube are properly

connected.

CAUTION

Electrical Shock can cause injury. Air Cooling

Do not touch wires while engine

is running.

WARNING

Clean out spark plug recess. Remove plug and

replace. Hot Parts can cause severe

burns.

1. Check gap using wire feeler gauge. Adjust

gap, see specification table for adjustment. Do not touch engine while

operating or just after stopping.

2. Install plug into cylinder head.

Never operate engine with heat shields or

3. Torque plug to 20 ft. lb. (27 N·m). guards removed.

Air Cleaner Proper cooling is essential. To prevent over

heating, clean screens, cooling fins, and other

NOTE: Operating engine with loose or external surfaces of engine. Avoid spraying

damaged air cleaner components water at wiring harness or any electrical

could cause premature wear and components. See Maintenance Schedule.

failure. Replace all bent or damaged

components. Repairs/Service Parts

NOTE: Paper element cannot be blown out We recommend that you use a Kohler

with compressed air. authorized dealer for all maintenance,

Loosen knobs and remove air cleaner cover. service, and replacement parts for engine.

To find a Kohler authorized dealer visit

Precleaner (if equipped): KohlerEngines.com or call 1-800-544-2444

1. Remove precleaner. (U.S. and Canada).

2. Replace or wash precleaner in warm water Storage

with detergent. Rinse and allow to air dry.

If engine will be out of service for 2 months or

3. Saturate precleaner with new engine oil; more follow procedure below.

squeeze out excess oil.

1. Add Kohler PRO Series fuel treatment or

4. Reinstall precleaner into cover, aligning hole equivalent to fuel tank. Run engine 2-3

in precleaner with upper cover knob. minutes to get stabilized fuel into fuel system

Paper Element: (failures due to untreated fuel are not

warrantable).

1. Remove element from base; replace

element. 2. Change oil while engine is still warm from

operation. Remove spark plug(s) and pour

2. Install element with pleated side out and seat about 1 oz. of engine oil into cylinder(s).

rubber seal onto edges of base. Replace spark plug(s) and crank engine

Reinstall air cleaner cover and secure with slowly to distribute oil.

knobs. 3. Disconnect negative (-) battery cable.

4. Store engine in a clean, dry place.

20 590 06 Rev. A KohlerEngines.com 7

Troubleshooting

Do not attempt to service or replace major engine components, or any items that require special

timing or adjustment procedures. This work should be performed by a Kohler authorized dealer.

Possible Cause

Dirt In Dirty Faulty

Problem No Improper Fuel Debris Incorrect Engine Dirty Air Spark

Fuel Fuel Line Screen Oil Level Overloaded Cleaner Plug

Will Not Start ● ● ● ● ● ● ●

Hard Starting ● ● ● ● ● ●

Stops Suddenly ● ● ● ● ● ● ●

Lacks Power ● ● ● ● ● ● ●

Operates Erratically ● ● ● ● ● ●

Knocks or Pings ● ● ● ●

Skips or Misfires ● ● ● ● ●

Backfires ● ● ● ● ●

Overheats ● ● ● ● ● ●

High Fuel ● ● ●

Consumption

Engine Specifications

Capacity Spark Plug Maximum Angle

Model Bore Stroke Displacement Oil(Refi of Operation

ll) Gap (@ full oil level)*

SV470

SV480

SV530

SV540 3.7 in. 3.4 in. 36.4 cu. in. 1.6 U.S. qt. 0.03 in. 25°

SV590 (94 mm) (86 mm) (597 cc) 1.5 L (0.76 mm)

SV600

SV610

SV620

*Exceeding maximum angle of operation may cause engine damage from insufficient lubrication.

Additional specification information can be found in service manual at KohlerEngines.com.

Exhaust Emission Control System for models SV470-SV620 is EM for U.S. EPA, California, and

Europe.

Any and all horsepower (hp) references by Kohler are Certified Power Ratings and per SAE J1940

& J1995 hp standards. Details on Certified Power Ratings can be found at KohlerEngines.com.

© 2011 by Kohler Co. All rights reserved.

KohlerEngines.com 20 590 06 Rev. A

Vous aimerez peut-être aussi

- SV710-SV740 SV810-SV840Document8 pagesSV710-SV740 SV810-SV840spedet9919Pas encore d'évaluation

- Lawn Mower PDFDocument8 pagesLawn Mower PDFBruce McarthurPas encore d'évaluation

- Kohler Manual KTDocument24 pagesKohler Manual KTSalvador Lisandro Castillo RamosPas encore d'évaluation

- Kohler HD 775 Owner ManualDocument8 pagesKohler HD 775 Owner ManualOSVALDO MACCARIPas encore d'évaluation

- Kohler XT675 Owner's Manual 14 - 590 - 22 - ENDocument8 pagesKohler XT675 Owner's Manual 14 - 590 - 22 - ENbunkmonkeyPas encore d'évaluation

- XT650, XT675, XT775 Owner's Manual: EN ESS FRCDocument8 pagesXT650, XT675, XT775 Owner's Manual: EN ESS FRCPatrick MolenPas encore d'évaluation

- Command ch18Document24 pagesCommand ch18MARTIN FRANTAPas encore d'évaluation

- Agnum 18 & 20 HP H C: Wner S AnualDocument16 pagesAgnum 18 & 20 HP H C: Wner S AnualCorona CoronaPas encore d'évaluation

- Motor Gasolina Kholer 25 HPDocument20 pagesMotor Gasolina Kholer 25 HPmarco hernandezPas encore d'évaluation

- Kohler 5400 UserDocument8 pagesKohler 5400 UserPeter BellonePas encore d'évaluation

- 17 590 28 en Owner ManualDocument11 pages17 590 28 en Owner ManualAracelly OsorioPas encore d'évaluation

- Command: V C CV18-CV26, CV620-CV750Document24 pagesCommand: V C CV18-CV26, CV620-CV750Jim AndrewsPas encore d'évaluation

- Kohler - 24 - 590 - 32 - EN - Operators ManualDocument8 pagesKohler - 24 - 590 - 32 - EN - Operators ManualtdzeienPas encore d'évaluation

- Agnum 16,18, 20 HP V C: Wner S AnualDocument16 pagesAgnum 16,18, 20 HP V C: Wner S AnualMatthew BurkhalterPas encore d'évaluation

- Kholer Manual UsuarioDocument16 pagesKholer Manual UsuariorebliaPas encore d'évaluation

- B 309 PDFDocument16 pagesB 309 PDFPhagos04Pas encore d'évaluation

- LH640, LH685, LH690 Owner's ManualDocument8 pagesLH640, LH685, LH690 Owner's ManualSalvador Lisandro Castillo RamosPas encore d'évaluation

- Command: Wner S AnualDocument16 pagesCommand: Wner S AnualJamal NasirPas encore d'évaluation

- Kohler Courage SV710-SV740 & Courage Pro SV810-SV840 Service ManualDocument76 pagesKohler Courage SV710-SV740 & Courage Pro SV810-SV840 Service ManualEric OlsonPas encore d'évaluation

- Kohler sv470-sv620 (sv480) Service Manual PDFDocument76 pagesKohler sv470-sv620 (sv480) Service Manual PDFbgflintPas encore d'évaluation

- RH255, RH265 Service ManualDocument56 pagesRH255, RH265 Service ManualBurik8Pas encore d'évaluation

- CH260-CH440 Service ManualDocument76 pagesCH260-CH440 Service ManualizzadtPas encore d'évaluation

- Motor Kohler XT7Document56 pagesMotor Kohler XT7sernielPas encore d'évaluation

- Kohler Engines MODELS K91 (4 HP) Kl6l ,& Kl81 (7 HP) (8 HP) Owners ManualDocument16 pagesKohler Engines MODELS K91 (4 HP) Kl6l ,& Kl81 (7 HP) (8 HP) Owners Manual"The Dangerous One"Pas encore d'évaluation

- Kohler 5400 ManualDocument92 pagesKohler 5400 ManualPeter BellonePas encore d'évaluation

- Kohler SV Service ManualDocument84 pagesKohler SV Service ManualfishuenntPas encore d'évaluation

- KOHLER Engine Manual cv690 607-690Document92 pagesKOHLER Engine Manual cv690 607-690Don PetitjeanPas encore d'évaluation

- CH940-CH1000 Service ManualDocument76 pagesCH940-CH1000 Service ManualIvan CaicedoPas encore d'évaluation

- ch640Document20 pagesch640heartofdixiePas encore d'évaluation

- Service Manual KT715-KT745Document84 pagesService Manual KT715-KT745Anonymous OaBEI2pt100% (1)

- MBA80 Engine Service Manual - KOHLER SH265Document52 pagesMBA80 Engine Service Manual - KOHLER SH265Daniel foucaultPas encore d'évaluation

- CH18-CH25, CH620-CH730, CH740, CH750 Service ManualDocument88 pagesCH18-CH25, CH620-CH730, CH740, CH750 Service ManualIvan CaicedoPas encore d'évaluation

- Service Manual ZT710-ZT740Document84 pagesService Manual ZT710-ZT740spedet9919Pas encore d'évaluation

- Motor KholerDocument72 pagesMotor KholerabrahamsamuelrojasPas encore d'évaluation

- 62 690 01 enDocument88 pages62 690 01 enJuan AlbertoPas encore d'évaluation

- CH18-CH25, CH620-CH730, CH740, CH750 Service ManualDocument92 pagesCH18-CH25, CH620-CH730, CH740, CH750 Service ManualWalter GarciaPas encore d'évaluation

- Kohler Ch980sDocument88 pagesKohler Ch980sWidi PrasetyoPas encore d'évaluation

- Command ch18Document92 pagesCommand ch18paulo loaizaPas encore d'évaluation

- Kohler CH26 Service ManualDocument218 pagesKohler CH26 Service Manualjaken202100% (2)

- Kohler Engine ManualDocument8 pagesKohler Engine ManualRamon ArruaPas encore d'évaluation

- Kohler Comand PRO CV940 - CV1000 Service ManualDocument72 pagesKohler Comand PRO CV940 - CV1000 Service Manualabduallah muhammadPas encore d'évaluation

- Kohler-Command-Pro-24 590 31 enDocument8 pagesKohler-Command-Pro-24 590 31 enbobPas encore d'évaluation

- Motor Kohler 7000seriesDocument96 pagesMotor Kohler 7000seriesoficina GBPas encore d'évaluation

- 24 590 48 enDocument12 pages24 590 48 enspedet9919Pas encore d'évaluation

- Owner's Manual CH640, CH730, CH740: Liquefi Ed Petroleum Gas (LPG) or LPG/Natural Gas (NG) FueledDocument12 pagesOwner's Manual CH640, CH730, CH740: Liquefi Ed Petroleum Gas (LPG) or LPG/Natural Gas (NG) FueledMatthew BurkhalterPas encore d'évaluation

- Kohler CH730 24 - 590 - 54 - ENDocument8 pagesKohler CH730 24 - 590 - 54 - ENRam RunnerPas encore d'évaluation

- Service Manual KT610-KT620, KT715-KT745Document96 pagesService Manual KT610-KT620, KT715-KT745Felipe ArredondoPas encore d'évaluation

- Pro9 0Document52 pagesPro9 0CARLOSPas encore d'évaluation

- kohler14hpDocument8 pageskohler14hpmljrmill.lumberyardPas encore d'évaluation

- Kohler Command Pro CV680-CV23 BedienungsanleitungDocument8 pagesKohler Command Pro CV680-CV23 BedienungsanleitungHinzPas encore d'évaluation

- 24 690 01 enDocument180 pages24 690 01 enBig daddy googlePas encore d'évaluation

- Onan Service Manual DJBA DJB DJC DJE Diesel Engines 967-0751Document77 pagesOnan Service Manual DJBA DJB DJC DJE Diesel Engines 967-0751GreenMountainGenerators75% (8)

- Onan Service Manual MDJA MDJB MDJC MDJE MDJF Marine Diesel Genset Engines 974-0750Document92 pagesOnan Service Manual MDJA MDJB MDJC MDJE MDJF Marine Diesel Genset Engines 974-0750GreenMountainGenerators80% (10)

- Honda Engine ManualDocument45 pagesHonda Engine ManualFlavianPas encore d'évaluation

- 974-0753 Onan RDJC RDJF Diesel Engine Service Manual (09-1984)Document64 pages974-0753 Onan RDJC RDJF Diesel Engine Service Manual (09-1984)Leo BurnsPas encore d'évaluation

- Diesel Engine Care and Repair: A Captain's Quick GuideD'EverandDiesel Engine Care and Repair: A Captain's Quick GuideÉvaluation : 5 sur 5 étoiles5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)D'EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)Pas encore d'évaluation

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualD'EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualPas encore d'évaluation

- 1.3 Hydraulic PumpsDocument15 pages1.3 Hydraulic Pumpsdoan lucPas encore d'évaluation

- Field Service Hurco1990 1999Document491 pagesField Service Hurco1990 1999Reparatii Cnc100% (3)

- Manual Oper. y Manten. 1TN - 3,5TN R Series (Comb. Interna) PDFDocument113 pagesManual Oper. y Manten. 1TN - 3,5TN R Series (Comb. Interna) PDFRicardo BilbaoPas encore d'évaluation

- Fire Pumps and Pump GroupsDocument44 pagesFire Pumps and Pump GroupsDamarys A. Ulloa S.Pas encore d'évaluation

- 2002 Expedition C174 PCM PinoutsDocument3 pages2002 Expedition C174 PCM Pinoutskamaleon dorado0% (1)

- Understanding Complete Test Performed On Induction MotorsDocument5 pagesUnderstanding Complete Test Performed On Induction Motorshino_kaguPas encore d'évaluation

- Cat Telehandlers Specs PDFDocument14 pagesCat Telehandlers Specs PDFgljr32941181011Pas encore d'évaluation

- Automation Objective QuestionsDocument10 pagesAutomation Objective QuestionsSrinivasaReddyM100% (2)

- Despiece BK-119Document2 pagesDespiece BK-119roger perezPas encore d'évaluation

- Cat 320D2Document22 pagesCat 320D2ricsnikPas encore d'évaluation

- Standby Diesel GeneratorDocument8 pagesStandby Diesel GeneratorPiee SyafiePas encore d'évaluation

- Reportte Cambios CPC 2a1Document1 pageReportte Cambios CPC 2a1FERNANDO FERRUSCAPas encore d'évaluation

- 345B SN 55S01001 & 76L01801 & Up-2Document271 pages345B SN 55S01001 & 76L01801 & Up-2A AhmedPas encore d'évaluation

- S.P.Catalog - TNT25 - 2015 Ver - 190715Document187 pagesS.P.Catalog - TNT25 - 2015 Ver - 190715Ignacio PadillaPas encore d'évaluation

- Code of Practice For Installation and Maintenance of Induction MotorsDocument37 pagesCode of Practice For Installation and Maintenance of Induction MotorsHimansu Sekhar JenaPas encore d'évaluation

- Caja 727Document8 pagesCaja 727Esteban Del AngelPas encore d'évaluation

- E 391 Manual 1Document6 pagesE 391 Manual 1naruto akatcyPas encore d'évaluation

- 5P-2378 Master PinDocument5 pages5P-2378 Master PinAlbertoPas encore d'évaluation

- Whirlpool Awo D 41100Document29 pagesWhirlpool Awo D 41100Teodora OnciuPas encore d'évaluation

- ALPM 70399801.cleanedDocument116 pagesALPM 70399801.cleanedIsaac de Jesus Martinez PerezPas encore d'évaluation

- Event Number Event Description Event Type Event Status 3000001287 Tmiii - Oil Filter Elements, Suction Strai Open Tender RFX PublishedDocument13 pagesEvent Number Event Description Event Type Event Status 3000001287 Tmiii - Oil Filter Elements, Suction Strai Open Tender RFX Published4D EngineeringPas encore d'évaluation

- Ojt ReportDocument75 pagesOjt Reportpranav dixitPas encore d'évaluation

- Ic EngineDocument17 pagesIc EngineRajeswar KumarPas encore d'évaluation

- Wirth TPK 2200Document2 pagesWirth TPK 2200PABLOHEREDIAPas encore d'évaluation

- Tuthill C Series Engineering Data PackDocument24 pagesTuthill C Series Engineering Data Packsteve@air-innovations.co.zaPas encore d'évaluation

- ZF-AS Tronic in Trucks: Dirk Stemme / LKS-T DeptDocument28 pagesZF-AS Tronic in Trucks: Dirk Stemme / LKS-T DeptJHAELSON MICHAEL CARDENAS TAFFUR100% (2)

- Assignment - Trent 900Document59 pagesAssignment - Trent 900AzriSafwanRusli100% (3)

- 37 Drillable Cementing BushingDocument1 page37 Drillable Cementing BushingGhinet Teodor-ioanPas encore d'évaluation

- IFB Washing Machine Spare Parts Price ListDocument1 pageIFB Washing Machine Spare Parts Price ListlovingbabiluPas encore d'évaluation

- Eaton Pump Repair v6-1Document30 pagesEaton Pump Repair v6-1Rio de Mario100% (3)