Académique Documents

Professionnel Documents

Culture Documents

Jed 426

Transféré par

ரஞ்சன் ஞானயோளி0 évaluation0% ont trouvé ce document utile (0 vote)

230 vues4 pagesWabco Standard

Titre original

JED 426

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentWabco Standard

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

230 vues4 pagesJed 426

Transféré par

ரஞ்சன் ஞானயோளிWabco Standard

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

CLASS: PLASTICS GLASSNos_25

THERMOPLASTIC POLYMER ON THE BASIS OF 2D

PREV.EDTION | ABBREVIATED TILE ts

88-11 PA 6, 30% glass fibres 852004261

1 Scope

The directives defined in this specification are obligatory on the whole WABCO

AUTOMOTIVE GROUP.

SPECIFICATION

WABCO

POLYAMIDE 6 (PA 6), 30 % GLASS FIBRES 426

This specification deals with a polymeric material for the manufacture of

bodies, caps and rings with medium thermal resistance in the following types:

JED-426.0 for parts which are not exposed to the outdoor atmosphere, in

natural colour (if not stated in the drawing);

JED-426.1 for parts which are exposed to the outdoor atmosphere, UV-resistant

material, colour black.

If JED-426 is indicated in the drawing, JED-426.0 shall be applied.

2

ne wirements

The finished parts shall be homogeneous and free from pores, blisters, and

other defects. The parts must not show any defects such as cracks, voids etc.

within its structure.

The requirements for finished parts can be taken from the drawing, the special

part specification and the technical conditions of delivery JED-367 esta-

blished by WABCO.

All materials, even ingredients in smail quantities (e. g. cadmium), which are

detrimental to health or to the environment are banned from being used.

Ther

nge of ay jon for the r parts

Continuous operational temperature range: 40 °C to #125 °C

Th

Short-term exposure to heat:

to +140 °C

4 ___ Physical properti:

The nominal values given on the following sheets are to be determined accor-

ding to the test methods specified. They refer to materials of equilibrium

moisture content at 23 °C and 50 % relative humidity.

Continuation Page 2 to 4

Page 2 JED-426

5 Initial sampling

At new presentation of a material according to this specification, its tech-

nical data must be indicated (range and mean values according to ISO 2602).

20 test samples (type 1, 10 R527) have to be made available. Whenever pos-

sible, these test samples should be produced by injection moulding into a tool

of the appropriate shape.

The supplier guarantees the customer the indicated technical data for all

deliveries according to this specification.

ase of a

ri.

After positive result of the test sample inspection, finished parts are ordered

extra for the validation tests (life tests). The release - which only refers to

parts coming from this particular mould - is made in case of positive result of

these tests.

Any modification of the material, of its ingredients or of the manufacturing

process parameters of material or finished parts - no matter of which kind or

for which reason - is only permissible after previous release by the department

which is responsible for the technical design.

7___Conditions of delivery

The material and the finished parts must correspond to the technical conditions

of delivery specified in JED-367.

WABCO SPECIFICATION

JED-426 Page 3

Serial | Test Nominal |

No. | Properties | method values __{_Unit

1 Plastics acc. to 1S0 1043 | = PAG {itis

21 Reinforcement, nature TEE glass fibres | -

22 |" Taverage | = - i am

size | t

2.31" content | = 23 i 5

3 Colour i acc.to type {| =

4 Infrared spectrum { - acc.to diagram |

i to be deli- |

| vered with |

samples |

5 Content of regenerated - 0 Log

mater ial i

|

6 Density Iso 1183 | 1.35 + 0.03_{ g/m

7 Ball indentation hardness | ISO 2039 160210} N/mm?

Shore hardness 10 868 - { Shore D_|

8 Melting point | Iso 1218 220 + 5 i °C |

9 Melt flow index {| 1s0 1133 : jo/10 nin. |

10.1 | Temperature of deflection | 180 75 i |

under load | { H

Method A (1,85 N/mm? ' >200 4

Method B (0,45 N/mm? | > 210 1 °C i

{10.2 | Vieat softening tempera- | 150 306 i i

i ture i |

{ Method A | eee |

} Method B } + sc '

fu Coefficient of linear {ASTM 0 696 i i

i thermal expansion, average | } !

{ value between -40 °C 1 1 |

! and +80 °C 1 tis 1 |

111.1 | direction of reinforcement | 2.0t02.5 to 5K! |

7 or flow \ es

111.2 | perpendicular to direction | : hoS xt |

\ of reinforcenent or flow | i | |

112 Shrinkage at moulding | ASTM 955 | i '

112.1 | in direction of flow \ i o3t01 | & |

1 12:2 | perpendicular to direction { { o3to1 } %& f

' of flow i i i

112.3 | postshrinkage after \ : ios |

\ moulding 1000 h at 80 °C_! I i

113.1 | Water content at delivery |ASTM D 570 <1 EEE atte

113.2 | water absorption in air {ASTHD 570! 2.120.2*) | &

! at 23 °C/50 % r. he i i i

143.3 water absorption at 23 °C | IS0 62 | 6.6#0.3*) | % t

*) saturation

WABCO SPECIFICATION

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Ese 18 Ga Set ADocument65 pagesEse 18 Ga Set Aரஞ்சன் ஞானயோளிPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- General Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTDocument16 pagesGeneral Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTரஞ்சன் ஞானயோளிPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- General Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTDocument16 pagesGeneral Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTரஞ்சன் ஞானயோளிPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- NCERT Class 12 Political Science Part 2 PDFDocument197 pagesNCERT Class 12 Political Science Part 2 PDFManikanta LalkotaPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Test Booklet General Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTDocument16 pagesTest Booklet General Studies and Engineering Aptitude: T.B.C.: SKP-U-DSTரஞ்சன் ஞானயோளிPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- CatiaDocument20 pagesCatiaரஞ்சன் ஞானயோளிPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- ResumeDocument3 pagesResumeரஞ்சன் ஞானயோளிPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- 528 JED Specification JED-612 008 en BDocument5 pages528 JED Specification JED-612 008 en Bரஞ்சன் ஞானயோளிPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- 528 JED Specification JED-005M 008 GDocument4 pages528 JED Specification JED-005M 008 Gரஞ்சன் ஞானயோளிPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- 1 Scope: SpecificationDocument5 pages1 Scope: Specificationரஞ்சன் ஞானயோளிPas encore d'évaluation

- 1 Scope: SpecificationDocument5 pages1 Scope: Specificationரஞ்சன் ஞானயோளிPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

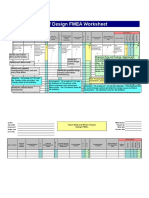

- Example of Design FMEA WorksheetDocument5 pagesExample of Design FMEA Worksheetரஞ்சன் ஞானயோளிPas encore d'évaluation

- Mold Specifications: Mold Spec Mold FunctionDocument2 pagesMold Specifications: Mold Spec Mold Functionரஞ்சன் ஞானயோளிPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Jed-226 408 BDocument7 pagesJed-226 408 Bரஞ்சன் ஞானயோளிPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- SRF Limited: Typical Properties of Tufnyl Rms 1 Steel GreyDocument1 pageSRF Limited: Typical Properties of Tufnyl Rms 1 Steel Greyரஞ்சன் ஞானயோளிPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- 15 - Tolerance Accumulation and AnalysisDocument80 pages15 - Tolerance Accumulation and Analysisரஞ்சன் ஞானயோளிPas encore d'évaluation

- PU SEAL Jed-337 008 en ADocument4 pagesPU SEAL Jed-337 008 en Aரஞ்சன் ஞானயோளிPas encore d'évaluation

- Wabco: SpecificationDocument4 pagesWabco: Specificationரஞ்சன் ஞானயோளிPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Is2102 1 en 0293Document5 pagesIs2102 1 en 0293ரஞ்சன் ஞானயோளிPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)