Académique Documents

Professionnel Documents

Culture Documents

Optimal Shipping Assignment

Transféré par

Agung Fadhilah PutraTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Optimal Shipping Assignment

Transféré par

Agung Fadhilah PutraDroits d'auteur :

Formats disponibles

SI - 5151

ANALISIS REKAYASA

1. Problem 9-14

Hardrock Concrete’s owner has decided to increase the capacity at his smallest plant

(see Problem 9-13). Instead of producing 30 loads of concrete per day at plant 3, that

plant’s capacity is doubled to 60 loads.

Find the new optimal solution using the northwest corner rule and stepping-

stone method.

How has changing the third plant’s capacity altered the optimal shipping

assignment ?

Discuss the concepts of degeneracy and multiple optimal solutions with regard to

this problem.

Answer :

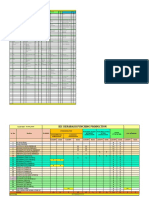

Initial Feasibel Solution Using Northwest Corner Rules

To Project Plant

From Project A Project B Project C

Dummy Capacities

10 4 11 0

Plant 1 40 30 10 - 10

- 70

12 5 8 0

Plant 2 - 20 30 - 50

9 7 6 0

Plant 3 - - 30 30 60

Project

40 50 60 30 180

Requirements

Note: occupied squares = number rows + number columns – 1

3+4–1=6

Transport cost :

Route

Unit Shipped Cost per Unit Total Cost ( $ )

From to

Plant 1 Project A 40 10 400

Plant 1 Project B 30 4 120

Plant 2 Project B 20 5 100

Plant 2 Project C 30 8 240

Plant 3 Project C 30 6 180

Plant 3 Dummy 30 0 0

Total 1040

Muhammad Iqbal - 25017070

Diketahui total biaya awal (sebelum dioptimasi) adalah sebesar $ 1040. Selanjutnya

dilakukan perhitungan apakah total biaya transportasi tesebut dapat dikurangi atau

tidak.

Check for optimal solution

Plant 1 to Project C = 11 – 4 + 5 – 8 = 4

Closed Path: P1C – P1B + P2B – P2C

Plant 1 to dummy = 0 – 4 + 5 – 8 + 6 – 0 = -1

Closed Path: P1D – P1B + P2B – P2C +P3C – P3D

Plant 2 to Project A = 12 – 5 + 4 – 10 = 1

Closed Path: P2A – P2B + P1B – P1A

Plant 2 to dummy = 0 – 8 + 6 – 0 = -2

Closed Path: P2D – P2C + P3C – P3D

Plant 3 to Project A = 9 – 6 + 8 – 5 + 4 – 10 = 0

Closed Path: P3A – P3C + P2C – P2B + P1B –P1A

Plant 3 to Project B = 7 – 6 + 8 – 5 = 4

Closed Path: P3B - P3C + P2C – P2B

Setelah dilakukan beberapa percobaan menggunakan stepping-stone method, didapat

nilai terkecil yaitu -2, sehingga perubahan tabel menjadi seperti berikut:

First Solution

To Project Plan

From Project A Project B Project C

Dummy Capacities

10 4 11 0

Plant 1 40 30 10 - - 70

10

12 5 8 0

Plant 2 - 20 30 50

9 7 6 0

Plant 3 - - 60 0 60

Project

40 50 60 30 180

Requirements

occupied squares = number rows + number columns – 1

3 + 4 – 1 = 6 (tidak cocok)

Muhammad Iqbal - 25017070

Karena jumlah kotak yang terisi hanya 5, maka kotak “plant 3-dummy” diisi angka ‘0”,

sehingga jumlah kotak yang terisi menjadi 6

Check for optimal solution

Plant 1 to Project C = 11 – 6 + 0 – 0 + 5 – 4 = 6

Closed Path: P1C – P3C + P3dummy – P2dummy + P2B – P1B

Plant 1 to dummy = 0 – 0 + 5 – 4 = 1

Closed Path: P1dummy – P2dummy + P2B – P1B

Plant 2 to Project A = 12 – 5 + 4 – 10 = 1

Closed Path: P2A – P2B + P1B – P1A

Plant 2 to Project C = 8 – 6 + 0 -0 = 2

Closed Path: P2C – P3C + P3dummy – P2dummy

Plant 3 to Project A = 9 – 0 + 0 – 5 + 4 – 10 = -2

Closed Path: P3A – P3dummy + P2dummy – P2B + P1B – P1A

Plant 3 to Project B = 7 – 0 + 0 – 5 = 2

Closed Path: P3B - P3dummy + P2dummy – P2B

Karena masih ada yang negatif, hal ini menunjukkan bahwa masih dapat dioptimasi lagi.

Second solution

To Project Plan

From Project A Project B Project C

Dummy Capacities

10 4 11 0

Plant 1 40 30 10 - - 70

10

12 5 8 0

Plant 2 - 20 30 50

9 7 6 0

Plant 3 0 - 60 60

Project

40 50 60 30 180

Requirements

occupied squares = number rows + number columns – 1

3 + 4 – 1 = 6 ( sesuai)

Check for optimal solution

Plant 1 to Project C = 11 – 10 + 9 – 6 = 4

Closed Path:

Muhammad Iqbal - 25017070

Plant 1 to dummy =0–4+5–0=1

Closed Path:

Plant 2 to Project A = 12 – 5 + 4 – 10 = 1

Closed Path:

Plant 2 to Project C = 8 – 5 + 4 – 10 + 9 – 6 = 0

Closed Path:

Plant 3 to Project B = 7 – 4 + 10 – 9 = 4

Closed Path:

Plant 3 to dummy = 0 – 0 + 5 – 4 + 10 – 9 = 2

Closed Path:

Semua hasil perhitungan telah menghasilkan hasil yang positif, dengan angka terkecil

yaitu “0”, hal ini menunjukkan bahwa operasi yang dilakukan telah menghasilkan

hasil yang optimum atau paling hemat. Besarnya biaya minimum yang dikeluarkan

untuk transportasi tersebut ditunjukkan pada tabel berikut.

Route

Unit Shipped Cost per Unit Total Cost ($)

From to

Plant 1 Project A 40 10 400

Plant 1 Project B 30 4 120

Plant 2 Project B 20 5 100

Plant 2 Project dummy 30 0 0

Plant 3 Project dummy 0 9 0

Plant 3 Project C 60 6 360

Total 980

Berdasarkan model terakhir, didapatkan biaya transportasi sebesar $ 980. Hal ini

menunjukkan bahwa terjadi penghematan sebesar $ 1040 - $ 980 = $ 60

2. Problem 9-15

Formulate the Hardrock Concrete Company transportation problem in 9-13 as a

linear transportation program and solve using computer software. What would

change in the linear program if the change program in problem 9-14 were

implemented?

Muhammad Iqbal - 25017070

Answer :

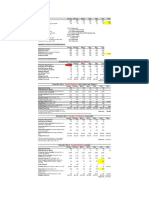

Input data

Data

COSTS Project A Project B Project C Dummy Supply

Plant 1 10 4 11 0 70

Plant 2 12 5 8 0 50

Plant 3 9 7 6 0 60

Demand 40 50 60 30 180 \ 180

Shipments

Shipments Project A Project B Project C Dummy Row Total

Plant 1 40 30 70

Plant 2 20 30 50

Plant 3 30 30 60

Column Total 40 50 60 30 180 \ 180

Total Cost 1040

Output data

Data

COSTS Project A Project B Project C Dummy Supply

Plant 1 10 4 11 0 70

Plant 2 12 5 8 0 50

Plant 3 9 7 6 0 60

Demand 40 50 60 30 180 \ 180

Shipments

Shipments Project A Project B Project C Dummy Row Total

Plant 1 20 50 0 0 70

Plant 2 0 0 20 30 50

Plant 3 20 0 40 0 60

Column Total 40 50 60 30 180 \ 180

Total Cost 980

Berdasarkan hasil software QM, dapat dilihat bahwa hasil yang dilakukan dengan

cara manual ( soal 9-14 ) adalah menghasilkan hasil yang sama ketika dikerjakan

menggunakan software QM, yaitu sebesar $ 980

3. Problem 9-21

Finnish Furniture manufactures tables in facilities located in three cities—Reno,

Denver, and Pittsburgh. The tables are then shipped to three retail stores located in

Muhammad Iqbal - 25017070

Phoenix, Cleveland, and Chicago. Management wishes to develop a distribution

schedule that will meet the demands at the lowest possible cost. The shipping cost

per unit from each of the sources to each of the destinations is shown in the following

table:

To

From Phoenix Cleveland Chicago

Reno 10 16 19

Denver 12 14 13

Pittsburgh 18 12 12

The available supplies are :

120 units from Reno

200 from Denver

160 from Pittsburgh

Phoenix has a demand of 140 units, Cleveland has a demand of 160 units, and

Chicago has a demand of 180 units. How many units should be shipped from each

manufacturing facility to each of the retail stores if cost is to be minimized? What is

the total cost?

Answer :

To

Cleveland Plan

From Phoenix (A) Chicago (C)

(B) Capacities

10 16 19

Reno (D) 120 - 10 120

12 14 13

Denver (E) 20 160 20 200

18 12 12

Pittsburgh (F) - - 160 160

Project

140 160 180 480

Requirements

Muhammad Iqbal - 25017070

Route

Unit shipped Unit Cost Total Cost

From To

Reno Phoenix 120 10 1200

Denver Phoenix 20 12 240

Denver Cleveland 160 14 2240

Denver Chicago 20 13 260

Pittsburgh Chicago 160 12 1920

TOTAL 5860

Stepping-stone method

Reno to Cleveland = 16 – 10 + 12 – 14 = 4

Closed Path: DB – DA + EA – EB

Reno to Chicago = 19 – 10 + 12 – 13 = 8

Closed Path: DC – DA + EA – EC

Pittsburgh to Phoenix= 18 – 12 + 13 – 12 = 7

Closed Path: FA – FC + EC - EA

Pittsburgh to Phoenix= 12 – 12 + 13 – 14 = -1

Closed Path: FB – FC + EC – EB

Terdapat nilai minus 1 pada rute Pittsburgh ke phoenix. Hal ini menunjukkan bahwa

operasi masih bisa dilakukan perbaikan untuk mendapatkan biaya yang paling

minimum.

To

Cleveland Plan

From Phoenix (A) Chicago (C)

(B) Capacities

10 16 19

Reno (D) 120 - 10 - 120

12 14 13

Denver (E) 20 - 180 200

18 12 12

Pittsburgh (F) - 160 - 160

Project

140 160 180 480

Requirements

Muhammad Iqbal - 25017070

Stepping-stone method

Reno to Chicago = 19 – 10 + 12 – 13 = 8

Closed Path: DC – DA + EA – EC

Reno to Cleveland = Tidak dapat dilakukan stepping-stone method

Denver to Clevelad = Tidak dapat dilakukan stepping-stone method

Pittsburgh to Phoenix = Tidak dapat dilakukan stepping-stone method

Pittsburgh to Chicago = Tidak dapat dilakukan stepping-stone method

Tidak terdapat hasil yang negatif, sehingga proses iterasi dapat dihentikan. Total

cost hasil optimasi dapat dilihat pada tabel berikut:

Route

Unit shipped Unit Cost Total Cost

From To

Reno Phoenix 120 10 1200

Denver Phoenix 20 12 240

Pittsburgh Cleveland 160 12 1920

Denver Chicago 180 13 2340

TOTAL 5700

Sehingga total cost yang minimum adalah sebesar $ 5700, dimana Cleveland

mendapatkan supply dari Pittsburg sebanyak yang dibutuhkan Cleveland yaitu

sebanyak 160. Begitupula dengan Chicago, yang mendapatkan supply sebanyak 180

dari Denver. Sementara Phoenix harus men supply dari dua tempat, yaitu dari Reno

sebesar 120 dan dari Denver sebesar 20.

4. Problem 9-22

Finnish Furniture has experienced a decrease in the demand for tables in Chicago;

the demand has fallen to 150 units (see Problem 9-21).

What special condition would exist?

What is the minimum-cost solution?

Will there be any units remaining at any of the manufacturing facilities?

First Solution

To

Cleveland Plan

From Phoenix (A) Chicago (C)

(B) Capacities

10 16 19 0

Reno (D) 120 - 10 120

12 14 13 0

Denver (E) 20 160 20 200

18 12 12 0

Pittsburgh (F) - - 130 30 160

Muhammad Iqbal - 25017070

Project

140 160 150 480

Requirements

Cost for first alternatif = (120x10)+(20x12)+(160x14)+(20x13)+(130x12)

= $5500

Menggunakan metode stepping-stone

Reno to Cleveland = 16 – 14 + 12 - 10 = 4

Reno to Chicago = 19 – 10 + 12 - 13 = 8

Reno to Dummy = 0 – 10 + 12 –13+12-0= 1

Denver to Dummy = 0 – 13 + 12 - 0 = -1

Pittsburgh to Phoenix = 18 – 12 + 13 - 12 = 7

Pittsburgh to Cleveland = 12 – 12 + 13 - 14 = -1

Masih terdapat nilai yang negatif, sehingga perlu dilakukan iterasi

Second solution

To

Cleveland Plan

From Phoenix (A) Chicago (C)

(B) Capacities

10 16 19 0

Reno (D) 120 - 10 120

12 14 13 0

Denver (E) 20 30 150 200

18 12 12 0

Pittsburgh (F) - 130 30 160

Project

140 160 150 480

Requirements

Cost for second alternatif = (120x10)+(20x12)+(30x14)+(150x13)+(130x12)

= $5370

metode stepping-stone

• Reno to Cleveland = 16 – 14 + 12 - 10 = 4

• Reno to Chicago = 19 – 10 + 12 - 13 = 8

• Reno to Dummy = 0 – 10 + 12 – 14 + 12 - 0 = 0

• Denver to Dummy = 0 – 14 + 12 - 0 = -2

• Pittsburgh to Phoenix = 18 – 12 + 14 - 12 = 8

• Pittsburgh to Chicago = 12 – 13 + 14 - 12 = 1

Masih ada yang negatif , sehingga harus dilakukan iterasi lagi

Muhammad Iqbal - 25017070

Thrird solution

To

Cleveland Plan

From Phoenix (A) Chicago (C)

(B) Capacities

10 16 19 0

Reno (D) 120 - 10 120

12 14 13 0

Denver (E) 20 150 30 200

18 12 12 0

Pittsburgh (F) - 160 0 160

Project

140 160 150 480

Requirements

Cost for third alternatif = (120x10)+(20x12)+(150x13)+(30x0)+(160x12)

= $5310

metode stepping-stone

Reno to Cleveland = 16 – 12 + 0 – 0 + 12 - 10 = 6

Reno to Chicago = 19 – 10 + 12 - 13 = 8

Reno to Dummy = 0 – 0 + 12 - 10 = 2

Denver to Cleveland = 14 – 0 + 0 - 12 = 2

Pittsburgh to Phoenix = 18 – 0 + 0 - 12 = 6

Pittsburgh to Chicago = 12 – 0 + 0 - 13 =0

Sudah tidak ada yang negatif, hal ini menunjukkan bahwa sudah didapatkan

komposisi yang optimum atau paling hemat. Yaitu sebesar $5310 atau terdapat

penghematan sebesar $190

5. Problem 9.35

Don Levine Corporation is considering adding an additional plant to its three existing

facilities in Decatur, Minneapolis, and Carbondale. Both St. Louis and East St. Louis

are being considered. Evaluating only the transportation costs per unit as shown in

the tables below and on the next page, which site is best?

Answer :

East St. Louis

Muhammad Iqbal - 25017070

First Solution

From Minnea- Carbon- East St. Supply

Decatur

To polis dale Louis Capacity

20 17 21 29

Blue Earth 250 250

25 27 20 30

Ciro 50 150 200

22 25 22 30

Des

50 150 150 350

moines

Demand

300 200 150 150 800

Capacity

Cost for first alternatif = (250x20)+(50x25)+(150x27)+(50x25)+(150x22)+(150x30)

= 19,350

Using the stepping-stone method, the following improvement indices are computed:

Path:

Decatur to Des Moines = 22-25+27-25 = -1

Minneapolis to Blue E = 17-27+25-20 = -5

Carbondale to Blue E = 21-22+25-27+25-20 = 2

Carbondale to Ciro = 20-22+25-27 = -4

East St. to Blue E = 29-30+25-27+25-20 = 2

East St. to Ciro = 30-30+25-27 = -2

Second Solution

From Minnea- Carbon- East St. Supply

Decatur

To polis dale Louis Capacity

20 17 21 29

Blue Earth 100 150 250

25 27 20 30

Ciro 200 200

22 25 22 30

Des

50 150 150 350

moines

Demand

300 200 150 150 800

Capacity

Muhammad Iqbal - 25017070

Cost for second alternatif =

(100x20)+(200x25)+(150x17)+(50x25)+(150x22)+(150x30)

= 18,600

Using the stepping-stone method, the following improvement indices are computed:

Path:

Decatur to Des Moines = 22-25+17-20 = -6

Minneapolis to Ciro = 27-17+20-25 = 5

Carbondale to Blue E = 21-17+25-22 = 7

Carbondale to Ciro = 20-25+20-17+25-22 = 1

East St. to Blue E = 29-30+25-17 = 7

East St. to Ciro = 30-25+20-17+25-30 = 3

Third Solution

From Minnea- Carbon- East St. Supply

Decatur

To polis dale Louis Capacity

20 17 21 29

Blue Earth 50 200 250

25 27 20 30

Ciro 200 200

22 25 22 30

Des

50 150 150 350

moines

Demand

300 200 150 150 800

Capacity

Cost for third alternatif = (50x20)+(200x25)+( 50x22)+(200x17)+(150x22)+(150x30)

= 18,300

Using the stepping-stone method, the following improvement indices are computed:

Path:

Minneapolis to Ciro = 27-17+20-25 = 5

Minneapolis to Des M = 25-17+20-22 = 6

Carbondale to Blue E = 21-22+22-20 = 1

Carbondale to Ciro = 20-22+22-25 = -5

East St. to Blue E = 29-30+22-20 = -1

East St. to Ciro = 30-30+22-25 = -3

Muhammad Iqbal - 25017070

Fourth Solution

From Minnea- Carbon- East St. Supply

Decatur

To polis dale Louis Capacity

20 17 21 29

Blue Earth 50 200 250

25 27 20 30

Ciro 50 150 200

22 25 22 30

Des

200 150 350

moines

Demand

300 200 150 150 800

Capacity

Cost for fourth alternatif = (50x20)+(50x25)+( 200x22)+(200x17)+(150x20)+(150x30)

= 17,550

Using the stepping-stone method, the following improvement indices are computed:

Path:

Minneapolis to Ciro = 27-17+20-25 = 5

Minneapolis to Des M = 25-17+20-22 = 6

Carbondale to Blue E = 21-20+25-20 = 6

Carbondale to Des M = 22-20+25-22 = 5

East St. to Blue E = 29-30+22-20 = -1

East St. to Ciro = 30-30+22-25 = -3

Fifth Solution

From Minnea- Carbon- East St. Supply

Decatur

To polis dale Louis Capacity

20 17 21 29

Blue Earth 50 200 250

25 27 20 30

Ciro 150 50 200

22 25 22 30

Des

250 100 350

moines

Demand

300 200 150 150 800

Capacity

Muhammad Iqbal - 25017070

Cost for fifth alternatif = (50x20)+( 250x22)+(200x17)+(150x20)+(50x30)+(100x30)

= 17,400

Using the stepping-stone method, the following improvement indices are computed:

Path:

Decatur to Ciro = 25-30+30-22 = 3

Minneapolis to Ciro = 27-30+30-22+20-17 = 8

Minneapolis to Des M = 25-17+20-22 = 6

Carbondale to Blue E = 21-20+22-30+30-20 = 3

Carbondale to Des M = 22-30+30-20 = 2

East St. to Blue E = 29-30+22-20 = 1

Kesimpulan :

Transportation cost, which additional plant East St. Louis = 17,400

Transportation cost, which additional plant St. Louis = 17,250

Optimal Solution, additional plant St. Louis = 17,250

St. Louis

First Solution

From Minnea- Carbon- Supply

Decatur St. Louis

To polis dale Capacity

20 17 21 27

Blue Earth 250 250

25 27 20 28

Ciro 50 150 200

22 25 22 31

Des

50 150 150 350

moines

Demand

300 200 150 150 800

Capacity

Cost for first alternatif = (250x20)+(50x25)+(150x27)+(50x25)+(150x22)+(150x31)

= 19,500

Muhammad Iqbal - 25017070

Using the stepping-stone method, the following improvement indices are computed:

Path:

Decatur to Des Moines = 22-25+27-25 = -1

Minneapolis to Blue E = 17-27+25-20 = -5

Carbondale to Blue E = 21-20+25-27+25-22 = 2

Carbondale to Ciro = 20-22+25-27 = -4

St.Louis to Blue E = 27-31+25-27+25-20 = -1

St.Louis to Ciro = 28-31+25-27 = -5

Second Solution

From Minnea- Carbon- Supply

Decatur St. Louis

To polis dale Capacity

20 17 21 27

Blue Earth 100 150 250

25 27 20 28

Ciro 200 200

22 25 22 31

Des

50 150 150 350

moines

Demand

300 200 150 150 800

Capacity

Cost for second alternatif :

= (100x20)+(200x25)+(150x17)+(50x25)+(150x22)+(150x31)

= 18,750

Using the stepping-stone method, the following improvement indices are computed:

Path:

Decatur to Des Moines = 22-25+17-20 = -6

Minneapolis to Ciro = 27-17+20-25 = 5

Carbondale to Blue E = 21-22+25-17 = 7

Carbondale to Ciro = 20-25+20-17+25-22 = 1

St.Louis to Blue E = 27-31+25-17 = 4

St.Louis to Ciro = 28-31+25-17+20-25 = 0

Muhammad Iqbal - 25017070

Third Solution

From Minnea- Carbon- Supply

Decatur St. Louis

To polis dale Capacity

20 17 21 27

Blue Earth 50 200 250

25 27 20 28

Ciro 200 200

22 25 22 31

Des

50 150 150 350

moines

Demand

300 200 150 150 800

Capacity

Cost for third alternatif = (50x20)+(200x25)+(50x22)+(200x17)+(150x22)+(150x30)

= 18,300

Using the stepping-stone method, the following improvement indices are computed:

Path:

Minneapolis to Ciro = 27-17+20-25 = 5

Minneapolis to Des M. = 25-17+20-22 = 6

Carbondale to Blue E = 21-22+22-20 = 1

Carbondale to Ciro = 20-25+22-22 = -5

St.Louis to Blue E = 27-31+22-20 = -2

St.Louis to Ciro = 28-31+22-25 = -6

Fourth Solution

From Minnea- Carbon- Supply

Decatur St. Louis

To polis dale Capacity

20 17 21 27

Blue Earth 50 200 250

25 27 20 28

Ciro 50 150 200

22 25 22 31

Des

200 150 350

moines

Demand

300 200 150 150 800

Capacity

Muhammad Iqbal - 25017070

Cost for fourth alternatif = (50x20)+(50x25)+(200x22)+(200x17)+(150x22)+(150x28)

= 17,550

Using the stepping-stone method, the following improvement indices are computed:

Path:

Minneapolis to Ciro = 27-17+20-25 = 5

Minneapolis to Des M. = 25-17+20-22 = 6

Carbondale to Blue E = 21-22+22-20 = 1

Carbondale to Ciro = 20-25+22-22 = -5

St.Louis to Blue E = 27-28+25-20 = 4

St.Louis to Des M. = 31-28+25-22 = 6

Fifth Solution

From Minnea- Carbon- Supply

Decatur St. Louis

To polis dale Capacity

20 17 21 27

Blue Earth 50 200 250

25 27 20 28

Ciro 50 150 200

22 25 22 31

Des

250 100 350

moines

Demand

300 200 150 150 800

Capacity

Cost for fifth alternatif = (50x20)+(250x22)+(200x17)+(50x20)+(100x22)+(150x28)

= 17,300

Using the stepping-stone method, the following improvement indices are computed:

Path:

Decatur to Ciro = 25-20+22-22 = 5

Minneapolis to Ciro = 27-20+22-22+20-17 = 10

Minneapolis to Des M. = 25-22+20-17 = 6

Carbondale to Blue E = 21-20+22-22 = 1

St.Louis to Blue E = 27-28+20-22+22-20 = -1

St.Louis to Des M. = 31-28+20-22 = 1

Muhammad Iqbal - 25017070

Sixth Solution

From Minnea- Carbon- Supply

Decatur St. Louis

To polis dale Capacity

20 17 21 27

Blue Earth 200 50 250

25 27 20 28

Ciro 100 100 200

22 25 22 31

Des

300 50 350

moines

Demand

300 200 150 150 800

Capacity

Cost for sixth alternatif = (300x22)+(200x17)+(100x20)+(50x22)+(50x27)+(100x28)

= 17,250

Using the stepping-stone method, the following improvement indices are computed:

Path:

Decatur to Blue E = 20-22+22-20+28-27 = 1

Decatur to Ciro = 25-20+22-22 = 5

Minneapolis to Ciro = 27-28+27-17 = 9

Minneapolis to Des M. = 25-22+20-28+27-17 = 5

Carbondale to Blue E = 21-27+28-20 = 2

St.Louis to Des M. = 31-28+20-22 = 1

Diperoleh biaya minimum sebesar 17,250.

Muhammad Iqbal - 25017070

Vous aimerez peut-être aussi

- Aggregate PlanningDocument5 pagesAggregate PlanningIsaiahPas encore d'évaluation

- Family Budget Planner: Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Total AvgDocument8 pagesFamily Budget Planner: Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Total AvgRuznaya RuzPas encore d'évaluation

- Robbins, Coulter, Sidani, Jamali: Management: Second Arab World EditionDocument45 pagesRobbins, Coulter, Sidani, Jamali: Management: Second Arab World EditionHassan ElbayyaPas encore d'évaluation

- Simulation Exam - Construction Depth - Spring 2015Document43 pagesSimulation Exam - Construction Depth - Spring 2015Sean CrossPas encore d'évaluation

- Initial Feasibel Solution Using Northwest Corner RulesDocument24 pagesInitial Feasibel Solution Using Northwest Corner RulesRoi MilyardiPas encore d'évaluation

- Production Plan Issue Date: 01.01.2019Document166 pagesProduction Plan Issue Date: 01.01.2019Sanjeev KumarPas encore d'évaluation

- Tower Schedule Edit Malas 4Document47 pagesTower Schedule Edit Malas 4Agung Fadhilah PutraPas encore d'évaluation

- Tower Schedule Edit Malas 4Document47 pagesTower Schedule Edit Malas 4Agung Fadhilah PutraPas encore d'évaluation

- Tower Schedule Edit Malas 4Document47 pagesTower Schedule Edit Malas 4Agung Fadhilah PutraPas encore d'évaluation

- Daily Packing Report 2018-19Document23 pagesDaily Packing Report 2018-19pthimanshuPas encore d'évaluation

- Experiment No. 6: Shannon Hartley TheoremDocument5 pagesExperiment No. 6: Shannon Hartley TheoremDhiraj DhaneshPas encore d'évaluation

- Ch16 Aggregate PlanningDocument3 pagesCh16 Aggregate PlanningAngela MariaPas encore d'évaluation

- Week 1 - Review of Discrete Structure 1 - Presentation - PDF - 2Document33 pagesWeek 1 - Review of Discrete Structure 1 - Presentation - PDF - 2Sarah HipolitoPas encore d'évaluation

- PORTER - 013121 - TransportationAssignmentDuality ProblemsDocument13 pagesPORTER - 013121 - TransportationAssignmentDuality ProblemsAnne PorterPas encore d'évaluation

- Procurement ManagementDocument10 pagesProcurement ManagementRishabh AgarwalPas encore d'évaluation

- Analisa CostingDocument32 pagesAnalisa CostingpicalnitaPas encore d'évaluation

- MRP (KONSINYASI) BontanGDocument18 pagesMRP (KONSINYASI) BontanGhendra21tambaPas encore d'évaluation

- Lab Report 3Document6 pagesLab Report 3Bappy Hossen100% (1)

- Transportation and Assignment ModelsDocument12 pagesTransportation and Assignment ModelsElvaa Riannaa Msr100% (1)

- Form Pengendalian UkurDocument14 pagesForm Pengendalian UkurmercuriusPas encore d'évaluation

- Hyundai E&CDocument17 pagesHyundai E&CabergeenPas encore d'évaluation

- MRP Inventory ProjectionsDocument5 pagesMRP Inventory ProjectionsReynaldo RaygadaPas encore d'évaluation

- BisleriDocument12 pagesBisleriutuutkarshPas encore d'évaluation

- Chapter-02 Statement of Cash FlowsDocument16 pagesChapter-02 Statement of Cash Flowsmd. hasanuzzamanPas encore d'évaluation

- FebmrpDocument2 107 pagesFebmrpVijay VadgaonkarPas encore d'évaluation

- Ch16 Aggregate PlanningDocument3 pagesCh16 Aggregate PlanningPutri Rizky DwisumartiPas encore d'évaluation

- Prevention Costs: Appraisal Costs: Internal Failure Costs: External Failure CostsDocument35 pagesPrevention Costs: Appraisal Costs: Internal Failure Costs: External Failure CostsRaniaPas encore d'évaluation

- 021 1700 023e 10d - MarineDocument52 pages021 1700 023e 10d - MarineWon Kyoung ChoiPas encore d'évaluation

- MATERI - 7 .Manajemen PengadaanDocument33 pagesMATERI - 7 .Manajemen PengadaanyasrannuddinPas encore d'évaluation

- 02 CAS-4-FormatDocument1 page02 CAS-4-FormatMOORTHY.KEPas encore d'évaluation

- QC Report SummaryDocument32 pagesQC Report SummaryGorat Victor SibueaPas encore d'évaluation

- MRP WorksheetDocument3 pagesMRP WorksheetBudy s RaharjaPas encore d'évaluation

- Slides For Chapter 15 MRPDocument25 pagesSlides For Chapter 15 MRPabed311Pas encore d'évaluation

- Consider The Problem of Paris Paint Presented in Problem 32 Lebih NEWDocument9 pagesConsider The Problem of Paris Paint Presented in Problem 32 Lebih NEWMuhammad Afdila GhulfiPas encore d'évaluation

- 2013 Collin Technologies Case StudyDocument54 pages2013 Collin Technologies Case StudyHimanshu AgrawalPas encore d'évaluation

- 2.job & Contract CostingDocument38 pages2.job & Contract CostingNaga ChandraPas encore d'évaluation

- Construction Engineering Tutorial Work 1 9Document47 pagesConstruction Engineering Tutorial Work 1 9Matthew100% (1)

- Project Monitoring and Control - EVA PDFDocument35 pagesProject Monitoring and Control - EVA PDFTosif MirPas encore d'évaluation

- Review of Planning Hierarchy and Material Requirements Planning (MRPDocument8 pagesReview of Planning Hierarchy and Material Requirements Planning (MRPKim WooPas encore d'évaluation

- The Barrett Textile Mill Was Checked by Inspectors Enforcing Occupational PDFDocument2 pagesThe Barrett Textile Mill Was Checked by Inspectors Enforcing Occupational PDFDoreenPas encore d'évaluation

- Capacity Planning FinalizeDocument85 pagesCapacity Planning FinalizeHansel Ramirez BaruelaPas encore d'évaluation

- Chapter 4 SolutionsDocument13 pagesChapter 4 SolutionsAhmed FahmyPas encore d'évaluation

- Vii TransportationDocument24 pagesVii TransportationNovinda AuliaPas encore d'évaluation

- Perusahaan Hardrock_Nadia Putri RahmayaniDocument2 pagesPerusahaan Hardrock_Nadia Putri Rahmayaninadiaputrirahmayani64Pas encore d'évaluation

- Project-plant-requirement transportation tableDocument57 pagesProject-plant-requirement transportation tableĐạt Nguyễn SongPas encore d'évaluation

- Projecta$10$12$940Projectb$4$5$750Projectc$11$8$660Plant Capacities705030150Document3 pagesProjecta$10$12$940Projectb$4$5$750Projectc$11$8$660Plant Capacities705030150Getu WeyessaPas encore d'évaluation

- Penyelesaian: A) Northwest Corner RuleDocument5 pagesPenyelesaian: A) Northwest Corner RuleHarly KabutPas encore d'évaluation

- Unit 1 Lesson 17: Test For Optimal Solution To A Transportation Problem Learning ObjectiveDocument10 pagesUnit 1 Lesson 17: Test For Optimal Solution To A Transportation Problem Learning ObjectiveMehran M ZargarPas encore d'évaluation

- Transportation 50Document17 pagesTransportation 50Aditya Singh PatelPas encore d'évaluation

- Tranportation ProblemsDocument13 pagesTranportation ProblemsAnne PorterPas encore d'évaluation

- Assignment Solutions #4Document6 pagesAssignment Solutions #4Arunprakash Natarajan100% (3)

- Transportation Model and Applications: Mr. B. B. Tripathy Siom 1Document25 pagesTransportation Model and Applications: Mr. B. B. Tripathy Siom 1Ajay KaushikPas encore d'évaluation

- 171 Studymat 1 Final Eve-Morn SolutionDocument13 pages171 Studymat 1 Final Eve-Morn SolutionSneha Angre100% (1)

- Chapter 6 Work AssignmentDocument17 pagesChapter 6 Work AssignmentNghĩa NgôPas encore d'évaluation

- Lab 03Document4 pagesLab 03KASHIF zamanPas encore d'évaluation

- CE120 EarthworksDocument4 pagesCE120 EarthworksDJ KillPas encore d'évaluation

- Operation ResearchDocument26 pagesOperation ResearchAmandeep Singh MankuPas encore d'évaluation

- Test 2 QMTDocument4 pagesTest 2 QMTNurulMadihahPas encore d'évaluation

- X X X X: Answer: 300Document4 pagesX X X X: Answer: 300zohaibPas encore d'évaluation

- What Is The Critical Path? 2. What Is The Expected Duration For The Whole Project?Document2 pagesWhat Is The Critical Path? 2. What Is The Expected Duration For The Whole Project?Christine Niones100% (1)

- Ecn 1100 Worksheet #2Document3 pagesEcn 1100 Worksheet #2Suraj SomaiPas encore d'évaluation

- Ff4.2 TransportationDocument14 pagesFf4.2 Transportationsridhartks100% (1)

- OPTIMIZING TRANSPORTATION COSTSDocument67 pagesOPTIMIZING TRANSPORTATION COSTSjayaram prakash kPas encore d'évaluation

- PDF 108Document3 pagesPDF 108Kaveendra SandunPas encore d'évaluation

- Industrial3 - بحوث العملياتDocument12 pagesIndustrial3 - بحوث العملياتtalaba4fayoum100% (1)

- BCG-5: S A CH - V: 05 Operation Rese RDocument4 pagesBCG-5: S A CH - V: 05 Operation Rese RGeeta GuptaPas encore d'évaluation

- Pelat Beton Bertulang - Hitung Tonase Tulangan, Luas Bekisting, Volume BetonDocument6 pagesPelat Beton Bertulang - Hitung Tonase Tulangan, Luas Bekisting, Volume BetonalamsyahPas encore d'évaluation

- Normal DistributionDocument6 pagesNormal DistributionLayla AlhoshanPas encore d'évaluation

- Optimal Shipping AssignmentDocument18 pagesOptimal Shipping AssignmentAgung Fadhilah PutraPas encore d'évaluation

- Whats NewDocument17 pagesWhats NewSalehPas encore d'évaluation

- SUrat LAmaran EnglishDocument1 pageSUrat LAmaran EnglishAgung Fadhilah PutraPas encore d'évaluation

- Gambar CYCLEDocument1 pageGambar CYCLEAgung Fadhilah PutraPas encore d'évaluation

- 2009 Sol Z TableDocument2 pages2009 Sol Z TableFauzi AzzamahsyariPas encore d'évaluation

- Readme InstallDocument1 pageReadme InstallRaka PratamaPas encore d'évaluation

- CrackDocument1 pageCrackanon-623374Pas encore d'évaluation

- Format WorkplanDocument8 pagesFormat WorkplanAgung Fadhilah PutraPas encore d'évaluation

- HLTV ReadmeDocument9 pagesHLTV Readmewillquem16100% (4)

- WinRar-Rar 5.01 Console VersionDocument40 pagesWinRar-Rar 5.01 Console VersionRuquan PhuahPas encore d'évaluation

- CrackDocument1 pageCrackanon-623374Pas encore d'évaluation

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- NssrviceDocument4 pagesNssrviceAgung Fadhilah PutraPas encore d'évaluation

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Cheat Sheet TutorialDocument2 pagesCheat Sheet TutorialMaria FarinaPas encore d'évaluation

- AI ManualDocument9 pagesAI ManualVikrant MayekarPas encore d'évaluation

- On The Geometric Ramsey Numbers of TreesDocument10 pagesOn The Geometric Ramsey Numbers of TreesPhilip NgemPas encore d'évaluation

- Logic Sheet 2 AnswersDocument7 pagesLogic Sheet 2 AnswersAhmedGamalPas encore d'évaluation

- Bawden - Quasi Quotation in LispDocument9 pagesBawden - Quasi Quotation in Lispjblair33Pas encore d'évaluation

- Looking For A Challenge 2 enDocument27 pagesLooking For A Challenge 2 enZaidPas encore d'évaluation

- 125-Article Text-694-1-10-20210625Document25 pages125-Article Text-694-1-10-20210625Haikal LimansahPas encore d'évaluation

- Data Mining Social Networks Represented as GraphsDocument34 pagesData Mining Social Networks Represented as GraphssairamPas encore d'évaluation

- CH 09Document32 pagesCH 09Momin AzizPas encore d'évaluation

- GATE Questions 18-7-14 GateDocument116 pagesGATE Questions 18-7-14 GateDELFIN BIJUPas encore d'évaluation

- DAA ManualDocument30 pagesDAA ManualXdxdPas encore d'évaluation

- Quadratic & PolynomialDocument2 pagesQuadratic & PolynomialceyoniPas encore d'évaluation

- Cs6402-Design and Analysis of Algorithms Unit-IDocument29 pagesCs6402-Design and Analysis of Algorithms Unit-IBALAKRISHNANPas encore d'évaluation

- Distributed Dynamic Frequency Allocation in Fractional Frequency Reused Relay Based Cellular NetworksDocument21 pagesDistributed Dynamic Frequency Allocation in Fractional Frequency Reused Relay Based Cellular NetworksShweta SharmaPas encore d'évaluation

- Regression Analysis in Machine Learning - JavatpointDocument1 pageRegression Analysis in Machine Learning - Javatpointleak naPas encore d'évaluation

- Activity 1Document4 pagesActivity 1BERNADETTEPas encore d'évaluation

- Homework 2 CSE 101Document1 pageHomework 2 CSE 101KelPas encore d'évaluation

- Cs 010406 Theory of ComputationDocument2 pagesCs 010406 Theory of ComputationTaran Aulakh0% (1)

- Unbalanced Transportation ProblemDocument7 pagesUnbalanced Transportation ProblemJojo ContiPas encore d'évaluation

- MODULE 3 - Syntax AnalysisDocument110 pagesMODULE 3 - Syntax Analysis4JK18CS031 Lavanya PushpakarPas encore d'évaluation

- CSO-102: Data Structures - Tasks 1 & 2.: InputDocument2 pagesCSO-102: Data Structures - Tasks 1 & 2.: InputDivyansh Chandra Roy 4-Year B.Tech. Chemical EngineeringPas encore d'évaluation

- Outline Numerical Methods and ComputationsDocument3 pagesOutline Numerical Methods and ComputationsCharles SeyPas encore d'évaluation

- ISC Computer Science Question Paper 2016 Solved For Class 12 - A Plus Topper 3Document1 pageISC Computer Science Question Paper 2016 Solved For Class 12 - A Plus Topper 3samm guptaPas encore d'évaluation

- Computation of Phasor From Discrete Fourier Transform: S. A. Soman Department of Electrical Engineering, IIT BombayDocument17 pagesComputation of Phasor From Discrete Fourier Transform: S. A. Soman Department of Electrical Engineering, IIT Bombayindula123Pas encore d'évaluation

- 4 Numerical Differentiation IntegrationDocument62 pages4 Numerical Differentiation IntegrationRagnar LothbrokPas encore d'évaluation

- LOGIC GATES by Gaurav Arora (Target Physics)Document9 pagesLOGIC GATES by Gaurav Arora (Target Physics)OjasPas encore d'évaluation

- DSA SPL NotesDocument5 pagesDSA SPL NotesDebanik DebnathPas encore d'évaluation