Académique Documents

Professionnel Documents

Culture Documents

Oral Practical & Experience Part 1Y2018 PDF

Transféré par

mrepzzzTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Oral Practical & Experience Part 1Y2018 PDF

Transféré par

mrepzzzDroits d'auteur :

Formats disponibles

ORAL PRACTICAL PROBLEM & EXPERIENCE (PART-1)

(FOR MASTER PLUMBER BOARD EXAM)

BY

ROGELIO C DE DIOS JR, PME, RMP

Practical Experience Part 1 by Engr. Roger De Dios 1

Table of Contents

1.0 Plan Reading and Interpretation

2.0 Standard & Specification (accepted by RNPC)

3.0 Plumbing Materials

Practical Experience Part 1 by Engr. Roger De Dios 2

1.0 Plan reading and Interpretation

Objective: Reading and interpretation of plans, symbols and

legends.

Practical Experience Part 1 by Engr. Roger De Dios 3

Practical Experience Part 1 by Engr. Roger De Dios 4

Practical Experience Part 1 by Engr. Roger De Dios 5

Practical Experience Part 1 by Engr. Roger De Dios 6

Practical Experience Part 1 by Engr. Roger De Dios 7

Practical Experience Part 1 by Engr. Roger De Dios 8

Practical Experience Part 1 by Engr. Roger De Dios 9

Practical Experience Part 1 by Engr. Roger De Dios 10

Practical Experience Part 1 by Engr. Roger De Dios 11

Practical Experience Part 1 by Engr. Roger De Dios 12

Practical Experience Part 1 by Engr. Roger De Dios 13

Practical Experience Part 1 by Engr. Roger De Dios 14

Practical Experience Part 1 by Engr. Roger De Dios 15

Practical Experience Part 1 by Engr. Roger De Dios 16

Practical Experience Part 1 by Engr. Roger De Dios 17

Practical Experience Part 1 by Engr. Roger De Dios 18

Practical Experience Part 1 by Engr. Roger De Dios 19

Practical Experience Part 1 by Engr. Roger De Dios 20

Practical Experience Part 1 by Engr. Roger De Dios 21

Practical Experience Part 1 by Engr. Roger De Dios 22

Practical Experience Part 1 by Engr. Roger De Dios 23

Practical Experience Part 1 by Engr. Roger De Dios 24

Practical Experience Part 1 by Engr. Roger De Dios 25

Practical Experience Part 1 by Engr. Roger De Dios 26

Practical Experience Part 1 by Engr. Roger De Dios 27

Practical Experience Part 1 by Engr. Roger De Dios 28

Practical Experience Part 1 by Engr. Roger De Dios 29

Practical Experience Part 1 by Engr. Roger De Dios 30

Practical Experience Part 1 by Engr. Roger De Dios 31

Practical Experience Part 1 by Engr. Roger De Dios 32

Practical Experience Part 1 by Engr. Roger De Dios 33

Practical Experience Part 1 by Engr. Roger De Dios 34

Practical Experience Part 1 by Engr. Roger De Dios 35

Practical Experience Part 1 by Engr. Roger De Dios 36

Practical Experience Part 1 by Engr. Roger De Dios 37

Practical Experience Part 1 by Engr. Roger De Dios 38

Practical Experience Part 1 by Engr. Roger De Dios 39

Practical Experience Part 1 by Engr. Roger De Dios 40

Practical Experience Part 1 by Engr. Roger De Dios 41

Practical Experience Part 1 by Engr. Roger De Dios 42

Practical Experience Part 1 by Engr. Roger De Dios 43

Practical Experience Part 1 by Engr. Roger De Dios 44

Practical Experience Part 1 by Engr. Roger De Dios 45

Practical Experience Part 1 by Engr. Roger De Dios 46

Practical Experience Part 1 by Engr. Roger De Dios 47

Practical Experience Part 1 by Engr. Roger De Dios 48

Practical Experience Part 1 by Engr. Roger De Dios 49

Practical Experience Part 1 by Engr. Roger De Dios 50

Practical Experience Part 1 by Engr. Roger De Dios 51

Practical Experience Part 1 by Engr. Roger De Dios 52

Practical Experience Part 1 by Engr. Roger De Dios 53

Practical Experience Part 1 by Engr. Roger De Dios 54

Joints/connection symbol

Practical Experience Part 1 by Engr. Roger De Dios 55

Practical Experience Part 1 by Engr. Roger De Dios 56

Practical Experience Part 1 by Engr. Roger De Dios 57

Practical Experience Part 1 by Engr. Roger De Dios 58

Practical Experience Part 1 by Engr. Roger De Dios 59

Joints/connection symbol

Practical Experience Part 1 by Engr. Roger De Dios 60

Practical Experience Part 1 by Engr. Roger De Dios 61

Practical Experience Part 1 by Engr. Roger De Dios 62

Practical Experience Part 1 by Engr. Roger De Dios 63

Practical Experience Part 1 by Engr. Roger De Dios 64

Practical Experience Part 1 by Engr. Roger De Dios 65

Practical Experience Part 1 by Engr. Roger De Dios 66

Practical Experience Part 1 by Engr. Roger De Dios 67

Practical Experience Part 1 by Engr. Roger De Dios 68

Practical Experience Part 1 by Engr. Roger De Dios 69

Practical Experience Part 1 by Engr. Roger De Dios 70

Other related symbol

Practical Experience Part 1 by Engr. Roger De Dios 71

Exercises: Identify the Plumbing symbols below:

1.0

2.0

Practical Experience Part 1 by Engr. Roger De Dios 72

3.0

Practical Experience Part 1 by Engr. Roger De Dios 73

4.0

Practical Experience Part 1 by Engr. Roger De Dios 74

5.0

Practical Experience Part 1 by Engr. Roger De Dios 75

2.0 Standard & Specification

Weight and Quality of materials as per Plumbing Code Chapter

14 (Plumbing Code Part 2 )

Practical Experience Part 1 by Engr. Roger De Dios 76

Materials

Standards Applicable to Plumbing Materials

A material shall be considered approved if it meets one or more of the

standards. Materials shall be used only as provided and as permitted

elsewhere in the Code.

Practical Experience Part 1 by Engr. Roger De Dios 77

Practical Experience Part 1 by Engr. Roger De Dios 78

Practical Experience Part 1 by Engr. Roger De Dios 79

Materials

Standards Applicable to Plumbing Materials

A material shall be considered approved if it meets one or more of the

standards. Materials shall be used only as provided and as permitted

elsewhere in the Code.

Practical Experience Part 1 by Engr. Roger De Dios 80

Specification (How to prepare)

Practical Experience Part 1 by Engr. Roger De Dios 81

3.0 Plumbing Materials

Objective: Shapes, sizes, dimensions, qualities and uses of

different kinds and classes of pipes, fittings, gauge, valves and

regulators.

Practical Experience Part 1 by Engr. Roger De Dios 82

Practical Experience Part 1 by Engr. Roger De Dios 83

2.10 Materials for Water Line Distribution

Practical Experience Part 1 by Engr. Roger De Dios 84

Practical Experience Part 1 by Engr. Roger De Dios 85

Practical Experience Part 1 by Engr. Roger De Dios 86

Practical Experience Part 1 by Engr. Roger De Dios 87

Practical Experience Part 1 by Engr. Roger De Dios 88

Practical Experience Part 1 by Engr. Roger De Dios 89

Practical Experience Part 1 by Engr. Roger De Dios 90

Practical Experience Part 1 by Engr. Roger De Dios 91

Practical Experience Part 1 by Engr. Roger De Dios 92

Practical Experience Part 1 by Engr. Roger De Dios 93

Practical Experience Part 1 by Engr. Roger De Dios 94

Practical Experience Part 1 by Engr. Roger De Dios 95

Practical Experience Part 1 by Engr. Roger De Dios 96

Practical Experience Part 1 by Engr. Roger De Dios 97

Practical Experience Part 1 by Engr. Roger De Dios 98

Practical Experience Part 1 by Engr. Roger De Dios 99

Practical Experience Part 1 by Engr. Roger De Dios 100

Practical Experience Part 1 by Engr. Roger De Dios 101

Practical Experience Part 1 by Engr. Roger De Dios 102

Practical Experience Part 1 by Engr. Roger De Dios 103

Practical Experience Part 1 by Engr. Roger De Dios 104

Practical Experience Part 1 by Engr. Roger De Dios 105

Practical Experience Part 1 by Engr. Roger De Dios 106

Practical Experience Part 1 by Engr. Roger De Dios 107

Practical Experience Part 1 by Engr. Roger De Dios 108

2.11 Valves for Water Distribution

Practical Experience Part 1 by Engr. Roger De Dios 109

VALVES

Valves up to and including 51 mm in size shall be brass or other

approved materials. Sizes over 51 mm may have cast iron or brass

bodies. Each gate valve shall be a full way type with working parts of

non-corrosive materials

Common Valves can be categorized into the following application:

Ball valve - for on/off control without pressure drop, and ideal for quick

shut-off, since a 90° turn offers complete shut-off angle, compared to

multiple turns required on most manual valves.

Butterfly valve- for flow regulation in large pipe diameters.

Check valve- or non-return valve, allows the fluid to pass in one

direction only.

Gate valve - mainly for on/off control, with low pressure drop.

Globe valve - good for regulating flow.

Practical Experience Part 1 by Engr. Roger De Dios 110

The two principal types of valves used to stop the flow of water in water

supply systems are gate valves and globe valves. A gate valve is

operated by raising and lowering the double-faced wedge-shaped gate.

When the valve is closed, the two faces of the gate are tightly pressed

against the seats, thus effecting a double seal.

The chief advantages of a gate valve are its tight seal and

full size straightway opening, which offers no greater resistance to the

flow of water than would an ordinary pipe coupling or other fitting of

equal length.

Practical Experience Part 1 by Engr. Roger De Dios 111

GATE VALVE

Practical Experience Part 1 by Engr. Roger De Dios 112

Globe Valves

The type of valve most commonly used for water supply systems is the

globe valve This type of valve has an inlet and outlet end, and a valve

disk, a, that closes against the pressure.

The principal objections to the use of globe valves are, that the opening,

through the seat of the valve is never the full area of the corresponding

size of pipe, and therefore not only restricts the flow but offers

considerable frictional resistance; furthermore, the opening is not

straightway, consequently it offers additional frictional resistance to the

flow of water.

Practical Experience Part 1 by Engr. Roger De Dios 113

GLOBE VALVE

Practical Experience Part 1 by Engr. Roger De Dios 114

Common type of valves

Practical Experience Part 1 by Engr. Roger De Dios 115

Check Valves

A check valve is an automatic valve that opens to the pressure of

water on one side but closes tightly when pressure is applied to the

opposite end of the valve. Where it is necessary that water should

always flow in one direction and there is a possibility of a reverse flow, a

check valve should be used. There are two common types of check

valves; lift check valves, and swing check valves.

Practical Experience Part 1 by Engr. Roger De Dios 116

LIFT CHECK VALVE

Practical Experience Part 1 by Engr. Roger De Dios 117

Swing Check Valve

It derives its name from the fact that the metal flap, a, yielding to the

pressure of water, swings on the pivot, b, and thus presents a

straightway opening for the flow of water. This type of check valve

compares with the lift check valve about as a gate valve compares with

a globe valve. The swing check valve offers less resistance to the flow of

water through it and has a straightway opening of almost the full size of

the valve. In the lift check valve, on the contrary, the water must pass

through a reduced opening in the valve seat and must make two right

angle turns while doing so.

Practical Experience Part 1 by Engr. Roger De Dios 118

SWING CHECK VALVE

Practical Experience Part 1 by Engr. Roger De Dios 119

Angle Valves

A type of valve much used for controlling the water supply to separate

fixtures .It is known as an angle valve and is a modification of the globe

valve. The openings to an angle valve are at right angles to each other so

that the valve can serve the dual purpose of controlling the water and

changing the direction of the pipe. Angle valves are made with metal

seats and with seats of soft materials, the latter being the better kind for

use on water supplies.

Practical Experience Part 1 by Engr. Roger De Dios 120

ANGLE VALVE

Practical Experience Part 1 by Engr. Roger De Dios 121

Practical Experience Part 1 by Engr. Roger De Dios 122

Angle Valves

A type of valve much used for controlling the water supply to separate

fixtures .It is known as an angle valve and is a modification of the globe

valve. The openings to an angle valve are at right angles to each other so

that the valve can serve the dual purpose of controlling the water and

changing the direction of the pipe. Angle valves are made with metal

seats and with seats of soft materials, the latter being the better kind for

use on water supplies.

Practical Experience Part 1 by Engr. Roger De Dios 123

ANGLE VALVE

Practical Experience Part 1 by Engr. Roger De Dios 124

Practical Experience Part 1 by Engr. Roger De Dios 125

Practical Experience Part 1 by Engr. Roger De Dios 126

2.12 Tanks

Practical Experience Part 1 by Engr. Roger De Dios 127

Practical Experience Part 1 by Engr. Roger De Dios 128

Practical Experience Part 1 by Engr. Roger De Dios 129

Practical Experience Part 1 by Engr. Roger De Dios 130

2.20 DWV Pipes and Fittings Material

Practical Experience Part 1 by Engr. Roger De Dios 131

Practical Experience Part 1 by Engr. Roger De Dios 132

Practical Experience Part 1 by Engr. Roger De Dios 133

Practical Experience Part 1 by Engr. Roger De Dios 134

Practical Experience Part 1 by Engr. Roger De Dios 135

Practical Experience Part 1 by Engr. Roger De Dios 136

Practical Experience Part 1 by Engr. Roger De Dios 137

Practical Experience Part 1 by Engr. Roger De Dios 138

END OF ORAL PRACTICE AND EXPERIENCE

(PART 1 )

THANK YOU!

Practical Experience Part 1 by Engr. Roger De Dios 139

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

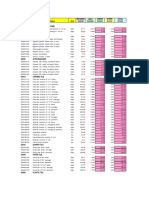

- Costcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 01 General 01020 ProfessionalDocument3 pagesCostcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 01 General 01020 ProfessionalmrepzzzPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Costcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 16 ElectricalDocument2 pagesCostcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 16 ElectricalmrepzzzPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Costcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 08 Doors and Windows 08100 Metal Doors and FramesDocument2 pagesCostcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 08 Doors and Windows 08100 Metal Doors and FramesJeffreyPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- ConcreteDocument4 pagesConcretemrepzzzPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- FinishesDocument6 pagesFinishesmrepzzzPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Costcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 04 Masonry 04200 Unit MasonryDocument1 pageCostcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 04 Masonry 04200 Unit MasonrymrepzzzPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- FurnishingsDocument1 pageFurnishingsJeffreyPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- EquipmentDocument1 pageEquipmentmrepzzzPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- 2012 Green Plumbing Mechanical CodeDocument173 pages2012 Green Plumbing Mechanical CodeAS VatsalPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- BXPHARMADocument4 pagesBXPHARMASayeedPas encore d'évaluation

- Costcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 14 Conveying Systems 14200 ElevatorsDocument1 pageCostcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 14 Conveying Systems 14200 ElevatorsmrepzzzPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Preboard Schedule 2018 PDFDocument2 pagesPreboard Schedule 2018 PDFmrepzzzPas encore d'évaluation

- Field FormulasDocument39 pagesField FormulasRoma EstradaPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- BXPHARMADocument4 pagesBXPHARMASayeedPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- StaadPro Knowledge BaseDocument251 pagesStaadPro Knowledge Baseingsabrina100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- NBCPDocument17 pagesNBCPArch. Jan EchiverriPas encore d'évaluation

- TV SpliterDocument12 pagesTV SpliterSherif M. ElgebalyPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Interlocking & Curb Stone Rev.1Document3 pagesInterlocking & Curb Stone Rev.1Shaddy Joseph Endrawes100% (1)

- Qcs 2007 Section 1 Part-1 IntroductionDocument6 pagesQcs 2007 Section 1 Part-1 IntroductionRotsapNayrbPas encore d'évaluation

- School CodeDocument68 pagesSchool CodemrepzzzPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Quality of Bid ChecklistDocument5 pagesQuality of Bid ChecklistmrepzzzPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- R3 DReferDocument335 pagesR3 DReferbenness11Pas encore d'évaluation

- Estimating Acoustical Ceilings ChecklistDocument1 pageEstimating Acoustical Ceilings ChecklistRyanPas encore d'évaluation

- Qcs 2007 0110Document6 pagesQcs 2007 0110RotsapNayrbPas encore d'évaluation

- BXPHARMADocument4 pagesBXPHARMASayeedPas encore d'évaluation

- July 2015 Master Plumber Terms IncludedDocument5 pagesJuly 2015 Master Plumber Terms Includedzenzen1100% (1)

- QCS General Index PDFDocument1 pageQCS General Index PDFmrepzzzPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Engineering Mathematics FormulaDocument4 pagesEngineering Mathematics FormulaMaw IubuybPas encore d'évaluation

- Board of Master Plumber-SBDocument7 pagesBoard of Master Plumber-SBdereckaPas encore d'évaluation

- 4 (Nse"r.: MaterialDocument78 pages4 (Nse"r.: MaterialAvishek GuptaPas encore d'évaluation

- Building Storage and Piping SystemDocument30 pagesBuilding Storage and Piping SystemarjunPas encore d'évaluation

- Arita Dossing Pump 2022Document17 pagesArita Dossing Pump 2022chandra atmaPas encore d'évaluation

- 03.hyd System Part1Document69 pages03.hyd System Part1Samidi100% (5)

- Safety Analysis Function Evaluation Chart: TBBM Tanjung Uban ProjectDocument3 pagesSafety Analysis Function Evaluation Chart: TBBM Tanjung Uban ProjectAriz Joelee ArthaPas encore d'évaluation

- Routing Schematic Diagram: TRUE R5.500Document2 pagesRouting Schematic Diagram: TRUE R5.500zamir zamirPas encore d'évaluation

- Pumps & Pumping Systems: Training Session On Energy EquipmentDocument40 pagesPumps & Pumping Systems: Training Session On Energy EquipmentAmir Chip100% (1)

- External Plumbing BoqDocument4 pagesExternal Plumbing BoqHarsh jainPas encore d'évaluation

- Hydraulic Scheme JCB JS130WDocument2 pagesHydraulic Scheme JCB JS130Wkokosik22100% (1)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Pipes ListDocument14 pagesPipes ListRonak GorPas encore d'évaluation

- Hydraulic 2Document15 pagesHydraulic 2Lonardo WajihPas encore d'évaluation

- ME 4232: Fluid Power Control Lab: Answer KeyDocument3 pagesME 4232: Fluid Power Control Lab: Answer KeyBryan PhamPas encore d'évaluation

- LC HPM 280型手动泵说明书Document9 pagesLC HPM 280型手动泵说明书DariusPas encore d'évaluation

- Group 00: WWW - Caproni.bg Caproni@caproni - BGDocument20 pagesGroup 00: WWW - Caproni.bg Caproni@caproni - BGDan StroescuPas encore d'évaluation

- Loc LineDocument20 pagesLoc LineVijaymohan KanugulaPas encore d'évaluation

- List of FUSO Machine SOLD OUT 2018-2019: No Model Vin Number Engine No YearDocument15 pagesList of FUSO Machine SOLD OUT 2018-2019: No Model Vin Number Engine No YearVannak KongPas encore d'évaluation

- 1st ASSIGNMENT - FPEDocument1 page1st ASSIGNMENT - FPEsujay uiPas encore d'évaluation

- ITP-format For VesselsDocument5 pagesITP-format For VesselsHanuman RaoPas encore d'évaluation

- LT 23074Document1 pageLT 23074Vu Duy PhuongPas encore d'évaluation

- Resume: RAJASTHAN (322218) INDIADocument4 pagesResume: RAJASTHAN (322218) INDIAjitendra guptaPas encore d'évaluation

- Project ReportDocument62 pagesProject ReportAll_regPas encore d'évaluation

- TURK PLAST (PPRC Green+Blue+PE GAS) 01-02-2021 - OutstationDocument1 pageTURK PLAST (PPRC Green+Blue+PE GAS) 01-02-2021 - OutstationicrcgisPas encore d'évaluation

- Water Supply BOQDocument4 pagesWater Supply BOQyunes alsharafiPas encore d'évaluation

- Pump Performance Datasheet: Operating Conditions LiquidDocument4 pagesPump Performance Datasheet: Operating Conditions LiquidVaibhav SharmaPas encore d'évaluation

- CP 010 Oil Sealed Vacuum Pumps072019Document208 pagesCP 010 Oil Sealed Vacuum Pumps072019LuigiPas encore d'évaluation

- Hydro Control D20Document46 pagesHydro Control D20mimmoPas encore d'évaluation

- Manual Llave XQ140 20yDocument42 pagesManual Llave XQ140 20yErick TovarPas encore d'évaluation

- EbaraDocument10 pagesEbarachu42Pas encore d'évaluation

- Boiler Feed Pump New 1Document39 pagesBoiler Feed Pump New 1789krishnaPas encore d'évaluation

- Piping Daily Progrss Report MMGP: Gulf Asia Contracting Company LLCDocument3 pagesPiping Daily Progrss Report MMGP: Gulf Asia Contracting Company LLCAbdul raheem syedPas encore d'évaluation