Académique Documents

Professionnel Documents

Culture Documents

crs2 16 22 en PDF

Transféré par

Anonymous AmiH5STitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

crs2 16 22 en PDF

Transféré par

Anonymous AmiH5SDroits d'auteur :

Formats disponibles

Diesel Systems

Common Rail Systems CRS2 with 1,600

to 2,200 bar and solenoid injectors

CRS2-22 system overview With fuel prices on the rise and increasingly stricter

emissions standards, the modern, economical and

Metering Pressure environmentally friendly diesel is the first choice for

unit control Rail-pressure

valve Rail sensor powertrains.

Bosch offers cost-efficient and performance-optimized

Check

High-pressure valve solutions for reducing fuel consumption and conse-

pump

Actu- Sensors quently vehicle operating costs: the CRS2 Common

Fuel filter ators

Solenoid Rail Systems series. Fast-switching solenoid injectors

Pre-supply pressure

injector

Electric pre-

EDC

High pressure

with short injection intervals are central parts of these

supply pump

Tank

Return line systems.

Pre-filter Electr. lines

The CRS2 series is suitable for diesel engines with up

to eight cylinders and a wide power and torque range.

Customer benefits The modular systems can be adapted to multiple

▶▶Efficient and versatile due to modular system engine types.

design: for engines with 2 to 8 cylinders

▶▶Efficient and fuel-saving in part due to Bosch is experienced in series application of the

start/stop compatibility CRS2: the 1,600 bar system CRS2-16 is already in

▶▶Adaptable for fuels with critical lubricating use in millions of vehicles. Later system variants with

characteristics (robustness package) pressures up to 2,200 bar are modularly based on the

▶▶Easy integration into existing and new CRS2-16. With increased pressure and technical

engine series modifications, these systems help to fulfill today’s and

▶▶Application for Euro 6 and similar norms future emission targets. In addition, higher injection

▶▶Reduction of emissions and combustion pressures mean more flexibility for designing the basic

noise due to reduced hydraulic flow rate engine and the exhaust-gas treatment.

Customer benefits: CRS2-16 Possible applications

▶▶Robust system – proven millions of times The CRS2 is used in passenger-car engines with 2 to 8

▶▶Cost benefits and reduction of system cylinders. Additionally, applications in light-duty

complexity due to possibility of commercial vehicles are possible. With appropriate

one-governor control adaptation, the CRS2 can also be used for off-highway

operation (please refer to the CRS2-OHW datasheet).

Customer benefits: CRS2-18/-20

This further development of the reliable passenger-car

▶▶Increased flexibility for basic engine design

system for additional fields of application generates

and application of exhaust-gas treatment

cost benefits. Featuring solutions for all diesel-fuel

Customer benefits: CRS2-20 qualities, the established CRS2 series can be applied

▶▶Increased hydraulic efficiency and CO₂ in all regions worldwide.

optimization due to reduced return flow

Diesel Systems | Common Rail Systems CRS2 with 1,600 to 2,200 bar and solenoid injectors

CRS2-16 CRS2-18 CRS2-20 CRS2-22 System design and function

Technical features The system can be configured with two different

Engine cylinders 2 – 6 3 – 6 3 – 8 3–8 high-pressure pumps: with the fuel-lubricated CP4 or

Max. system pressure 1,600 bar 1,800 bar 2,000 bar 2,200 bar – in systems with 1,800 or 2,000 bar – also with the

Max. number of oil-lubricated CP4i.

injections 8 8 8 8

Min. injection The powerful second-generation solenoid injectors

separation time 800 µs 350 µs 200 µs 200 µs

offer engine developers a high degree of flexibility

Operating voltage 12/24 V 12 V 12 V 12 V

for injection-rate shaping. Up to eight single injections

Emission target Euro Euro Euro Euro

per stroke are performed in a narrow time slot.

corresponding to 4/5/6 5/6 5/6 5/6

This multiple-injection capability contributes to the

Service life (PC/LD) 300,000/400,000 km

reduction of fuel consumption and consequently

Application PC, LD

improved CO2 emission as well as further emissions

and engine-noise reduction.

CRS2-20 system components (example)

The improved magnet core of the CRI2-16 injector

1 2 3 achieves high power when opening the solenoid valve.

The split armature module enables higher dynamics in

controlling the nozzle needle and a very short injection

separation time.

The injectors for pressures above 1,800 bar have a

pressure-balanced solenoid. This enables a further

leap forward in system pressure.

4 5

In addition, the CRI2-20/-22 injectors feature an

integrated high-pressure volume that reduces pressure

1 CP4-20/1 high-pressure pump

2 CP4i high-pressure pump

oscillations. Hydraulic efficiency is increased due to

3 CRI2-20 solenoid injector a reduced return flow.

4 HFR-20 high-pressure rail

5 EDC17 control unit EDC Electronic Diesel Control by Bosch controls the

entire injection process, the boost pressure and the

exhaust-gas recirculation.

Outlook

CRS2 system technology will allow further pressure

increases in the course of further development. Our

proven modular system design will, of course, be

maintained.

Bosch: Automotive competence from a single source

Comprehensive range of services and know-how Robert Bosch GmbH

Diesel Systems

System and network competence

Postfach 30 02 20

Innovator and technology leader 70442 Stuttgart

Germany

Warrantor for quality and dependability Fax: +49 711 811-45090

diesel@bosch.com

Worldwide presence

www.future-with-diesel.com

Universal partner

Printed in Germany

292000P119-C/CCA-201309-En

© Robert Bosch GmbH 2013. All rights reserved, also regarding any disposal, exploitation, reproduction,

editing, distribution, as well as in the event of applications for industrial property rights

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 455 Rancher 460: Workshop ManualDocument52 pages455 Rancher 460: Workshop Manualbilly dillpicker100% (4)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Calibracion de Valvulas John Deere 6090Document3 pagesCalibracion de Valvulas John Deere 6090青春只是一张黑白画。100% (1)

- AJ Duratec and L3 Engine Systems GuideDocument53 pagesAJ Duratec and L3 Engine Systems GuideNguyễn Chánh SĩPas encore d'évaluation

- 07 DiagnosticsDocument124 pages07 DiagnosticsManuel KusminskyPas encore d'évaluation

- 1.2 3cyl EngineDocument17 pages1.2 3cyl Engineeurohaus100% (4)

- Actual Sysem Setup Alpha LubricatorDocument7 pagesActual Sysem Setup Alpha LubricatorRanjan DiptanshuPas encore d'évaluation

- Backpressure 250Document2 pagesBackpressure 250epicenterrulezPas encore d'évaluation

- Hydro Mechanical Fuel Control System Constant Speed Range: Propeller MaintenanceDocument12 pagesHydro Mechanical Fuel Control System Constant Speed Range: Propeller MaintenancePatrio PamungkasPas encore d'évaluation

- Datasheet 12M26.3 enDocument3 pagesDatasheet 12M26.3 ennaufragato0% (1)

- AB35049U English VersionDocument214 pagesAB35049U English VersionsaifulPas encore d'évaluation

- M&M 245 DI Engine Fuel Injection EquipmentDocument2 pagesM&M 245 DI Engine Fuel Injection EquipmentRavikant Saini100% (1)

- Cylinder Head: Components For Removal and InstallationDocument40 pagesCylinder Head: Components For Removal and InstallationTeo CovaPas encore d'évaluation

- Engine Identification ReportDocument3 pagesEngine Identification Reportbraulio cesarPas encore d'évaluation

- Air Starting System Slide Set 1Document10 pagesAir Starting System Slide Set 1Jigar PatelPas encore d'évaluation

- دليل مختبر محركاتDocument69 pagesدليل مختبر محركاتabood mohammadPas encore d'évaluation

- Rocket Performance and Efficiency: 0.1 But First, What Is A Rocket Engine?Document11 pagesRocket Performance and Efficiency: 0.1 But First, What Is A Rocket Engine?Nitya AnjaliPas encore d'évaluation

- Compresor Tuflo 550Document6 pagesCompresor Tuflo 550Ramón José Aponte FrancoPas encore d'évaluation

- F1 Crankcase Assy.: NOTES: V5 Engine Model:172MMDocument17 pagesF1 Crankcase Assy.: NOTES: V5 Engine Model:172MMryan FosterPas encore d'évaluation

- 2013 Se 250ir Manual Sib...Document55 pages2013 Se 250ir Manual Sib...Jair RosaPas encore d'évaluation

- Narnarayan Shastri Institute of Technology: Presentation OnDocument20 pagesNarnarayan Shastri Institute of Technology: Presentation Onhellovers60Pas encore d'évaluation

- Force Outboard Gearcase & Drive PartsDocument7 pagesForce Outboard Gearcase & Drive PartsMarine Parts ChinaPas encore d'évaluation

- 01 - Engine Operations Systems and DrivelineDocument31 pages01 - Engine Operations Systems and DrivelineFabio BosioPas encore d'évaluation

- Specification Table:: kVA KW KG1-5AS3 KG1 - 7.5AS4 KG1 - 10AS5 KG1-12.5AS2Document2 pagesSpecification Table:: kVA KW KG1-5AS3 KG1 - 7.5AS4 KG1 - 10AS5 KG1-12.5AS2VILLA SIVAPRASADPas encore d'évaluation

- Isuzu Engine Diagnostic Chart GuideDocument2 pagesIsuzu Engine Diagnostic Chart GuideKarenPas encore d'évaluation

- CONVERGE BibliographyDocument6 pagesCONVERGE BibliographyabeytofirkyaluPas encore d'évaluation

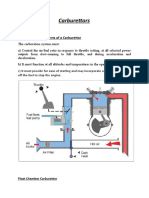

- CarburettorsDocument12 pagesCarburettorsrohitPas encore d'évaluation

- Ford Engines CatalogDocument18 pagesFord Engines CatalogAngel QuirogaPas encore d'évaluation

- Using EngMod2T To Investigate Transfer Port StaggerDocument6 pagesUsing EngMod2T To Investigate Transfer Port StaggerpachukiPas encore d'évaluation

- ECM Gran Vitara V6 H27Document6 pagesECM Gran Vitara V6 H27Alexa SaltosPas encore d'évaluation

- Internal Combustion Engine: Teknik Mesin Universitas Maarif Hasyim Latf SidoarjoDocument158 pagesInternal Combustion Engine: Teknik Mesin Universitas Maarif Hasyim Latf SidoarjoAdhi PrayogaPas encore d'évaluation