Académique Documents

Professionnel Documents

Culture Documents

24aa515, 24LC515, 24FC515

Transféré par

dorudDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

24aa515, 24LC515, 24FC515

Transféré par

dorudDroits d'auteur :

Formats disponibles

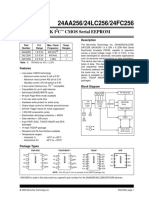

24AA515/24LC515/24FC515

512K Bit I2C™ CMOS Serial EEPROM

Device Selection Table Package Type

Part VCC Max Clock Temp PDIP

Number Range Frequency Ranges A0 1 8 VCC

24XX515

24AA515 1.8-5.5V 400 kHz† I A1 2 7 WP

24LC515 2.5-5.5V 400 kHz I A2 3 6 SCL

24FC515 2.5-5.5V 1 MHz I

VSS 4 5 SDA

†100

kHz for VCC < 2.5V.

Features SOIC

• Low power CMOS technology

A0 1 8 VCC

- Maximum write current 3 mA at 5.5V

24XX515

- Maximum read current 400 µA at 5.5V A1 2 7 WP

- Standby current 100 nA typical at 5.5V 3 6

A2 SCL

• 2-wire serial interface bus, I 2C™ compatible

VSS 4 5 SDA

• Cascadable for up to four devices

• Self-timed ERASE/WRITE cycle

• 64-byte page-write mode available

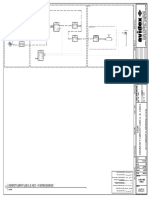

• 5 ms max write-cycle time Block Diagram

• Hardware write protect for entire array

• Output slope control to eliminate ground bounce A0 A1 WP HV GENERATOR

• Schmitt trigger inputs for noise suppression

• 100,000 erase/write cycles

I/O MEMORY EEPROM

• Electrostatic discharge protection > 4000V CONTROL CONTROL XDEC ARRAY

• Data retention > 200 years LOGIC LOGIC

PAGE LATCHES

• 8-pin PDIP, SOIC packages

• Temperature ranges:

I/O

- Industrial (I): -40°C to +85°C SCL

YDEC

Description SDA

The Microchip Technology Inc. 24AA515/24LC515/ VCC

24FC515 (24XX515*) is a 64K x 8 (512K bit) Serial VSS SENSE AMP

Electrically Erasable PROM, capable of operation R/W CONTROL

across a broad voltage range (1.8V to 5.5V). It has

been developed for advanced, low power applications

such as personal communications or data acquisition.

This device has both byte-write and page-write capabil-

ity of up to 64 bytes of data. This device is capable of

both random and sequential reads. Reads may be

sequential within address boundaries 0000h to 7FFFh

& 8000h to FFFFh. Functional address lines allow up to

four devices on the same data bus. This allows for up

to 2 Mbits total system EEPROM memory. This device

is available in the standard 8-pin plastic DIP and SOIC

packages.

*24XX515 is used in this document as a generic part number for the 24AA515/24LC515/24FC515 devices.

2001 Microchip Technology Inc. Preliminary DS21673A-page 1

24AA515/24LC515/24FC515

1.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings†

VCC .............................................................................................................................................................................6.5V

All inputs and outputs w.r.t. VSS .......................................................................................................... -0.6V to VCC +1.0V

Storage temperature ...............................................................................................................................-65°C to +150°C

Ambient temp. with power applied ..........................................................................................................-65°C to +125°C

Soldering temperature of leads (10 seconds) .......................................................................................................+300°C

ESD protection on all pins ......................................................................................................................................................≥ 4 kV

† NOTICE: Stresses above those listed under “Maximum Ratings” may cause permanent damage to the device. This

is a stress rating only and functional operation of the device at those or any other conditions above those indicated in

the operational listings of this specification is not implied. Exposure to maximum rating conditions for extended periods

may affect device reliability.

1.1 DC Characteristics

DC CHARACTERISTICS Industrial (I): VCC = +1.8V to 5.5V TAMB = -40°C to +85°C

Param.

Sym Characteristic Min Max Units Conditions

No.

D1 A0, A1, SCL, SDA, and

WP pins:

D2 VIH High level input voltage 0.7 VCC — V VCC ≥ 2.5V

D3 VIL Low level input voltage — 0.3 VCC V VCC ≥ 2.5V

0.2 V CC V VCC < 2.5V

D4 VHYS Hysteresis of Schmitt 0.05 VCC — V VCC ≥ 2.5V (Note)

Trigger inputs

(SDA, SCL pins)

D5 VOL Low level output voltage — 0.40 V IOL = 3.0 mA @ VCC = 4.5V

IOL = 2.1 mA @ VCC = 2.5V

D6 ILI Input leakage current -10 10 µA VIN = VSS or VCC, WP = V SS

VIN = VSS or VCC, WP = V CC

D7 ILO Output leakage current -10 10 µA VOUT = VSS or VCC

D8 CIN, Pin capacitance — 10 pF VCC = 5.0V (Note)

COUT (all inputs/outputs) TAMB = 25°C, fC= 1 MHz

D9 ICC Read Operating current — 500 µA VCC = 5.5V, SCL = 400 kHz

ICC Write — 3 mA VCC = 5.5V

D10 ICCS Standby current — 5 µA SCL = SDA = VCC = 5.5V

A0, A1, WP = VSS, A2 = VCC

Note: This parameter is periodically sampled and not 100% tested.

DS21673A-page 2 Preliminary 2001 Microchip Technology Inc.

24AA515/24LC515/24FC515

1.2 AC Characteristics

AC CHARACTERISTICS Industrial (I): VCC = +1.8V to 5.5V TAMB = -40°C to +85°C

Param.

Sym Characteristic Min. Max. Units Conditions

No.

1 FCLK Clock frequency — 100 kHz 1.8V ≤ VCC ≤ 2.5V

— 400 2.5V ≤ VCC ≤ 5.5V

— 1000 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

2 THIGH Clock high time 4000 — ns 1.8V ≤ VCC ≤ 2.5V

600 — 2.5V ≤ VCC ≤ 5.5V

500 — 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

3 TLOW Clock low time 4700 — ns 1.8V ≤ VCC ≤ 2.5V

1300 — 2.5V ≤ VCC ≤ 5.5V

500 — 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

4 TR SDA and SCL rise time — 1000 ns 1.8V ≤ VCC ≤ 2.5V

(Note 1) — 300 2.5V ≤ VCC ≤ 5.5V

— 300 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

5 TF SDA and SCL fall time — 300 ns All except, 24FC515

(Note 1) — 100 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

6 THD :STA START condition hold time 4000 — ns 1.8V ≤ VCC ≤ 2.5V

600 — 2.5V ≤ VCC ≤ 5.5V

250 — 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

7 TSU:STA START condition setup time 4700 — ns 1.8V ≤ VCC ≤ 2.5V

600 — 2.5V ≤ VCC ≤ 5.5V

250 — 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

8 THD:DAT Data input hold time 0 — ns (Note 2)

9 TSU:DAT Data input setup time 250 — ns 1.8V ≤ VCC ≤ 2.5V

100 — 2.5V ≤ VCC ≤ 5.5V

100 — 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

10 TSU:STO STOP condition setup time 4000 — ns 1.8V ≤ VCC ≤ 2.5V

600 — 2.5V ≤ VCC ≤ 5.5V

250 — 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

11 TSU:WP WP setup time 4000 — ns 1.8V ≤ VCC ≤ 2.5V

600 — 2.5V ≤ VCC ≤ 5.5V

600 — 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

12 THD:WP WP hold time 4700 — ns 1.8V ≤ VCC ≤ 2.5V

1300 — 2.5V ≤ VCC ≤ 5.5V

1300 — 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

13 TAA Output valid from clock — 3500 ns 1.8V ≤ VCC ≤ 2.5V

(Note 2) — 900 2.5V ≤ VCC ≤ 5.5V

— 400 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

14 TBUF Bus free time: Time the bus 4700 — ns 1.8V ≤ VCC ≤ 2.5V

must be free before a new 1300 — 2.5V ≤ VCC ≤ 5.5V

transmission can start 500 — 2.5V ≤ VCC ≤ 5.5V (24FC515 only)

15 TOF Output fall time from VIH 10 + 0.1CB 250 ns All except, 24FC515 (Note 1)

minimum to VIL maximum 250 24FC515 (Note 1)

CB ≤ 100 pF

16 TSP Input filter spike suppression — 50 ns All except, 24FC515 (Notes 1 and 3)

(SDA and SCL pins)

17 TWC Write cycle time (byte or page) — 5 ms

18 Endurance 100 k — cycles 25°C, V CC = 5.0V, Block Mode (Note 4)

Note 1: Not 100% tested. CB = total capacitance of one bus line in pF.

2: As a transmitter, the device must provide an internal minimum delay time to bridge the undefined region (minimum

300 ns) of the falling edge of SCL to avoid unintended generation of START or STOP conditions.

3: The combined TSP and VHYS specifications are due to new Schmitt trigger inputs which provide improved noise spike

suppression. This eliminates the need for a TI specification for standard operation.

4: This parameter is not tested but established by characterization. For endurance estimates in a specific application,

please consult the Total Endurance Model which can be obtained on Microchip’s website @www.microchip.com.

2001 Microchip Technology Inc. Preliminary DS21673A-page 3

24AA515/24LC515/24FC515

FIGURE 1-1: BUS TIMING DATA

5 4

2 D4

SCL

7

3 8 9 10

SDA

6

IN

16

13 14

SDA

OUT

(protected)

WP 11 12

(unprotected)

DS21673A-page 4 Preliminary 2001 Microchip Technology Inc.

24AA515/24LC515/24FC515

2.0 PIN DESCRIPTIONS 2.5 Write Protect (WP)

The descriptions of the pins are listed in Table 2-1. This pin can be connected to either VSS, VCC or left

floating. An internal pull-down resistor on this pin will

TABLE 2-1: PIN FUNCTION TABLE keep this device in the unprotected state if left floating.

If tied to VSS or left floating, normal memory operation

Name PDIP SOIC Function is enabled (read/write the entire memory 0000h-

FFFFh).

A0 1 1 User Configurable Chip Select

If tied to VCC, WRITE operations are inhibited. Read

A1 2 2 User Configurable Chip Select

operations are not affected.

A2 3 3 Non-Configurable Chip Select.

This pin must be hard wired to

logical 1 state (VCC). Device 3.0 FUNCTIONAL DESCRIPTION

will not operate with this pin The 24XX515 supports a bi-directional 2-wire bus and

left floating or held to logical 0 data transmission protocol. A device that sends data

(V SS). onto the bus is defined as a transmitter, and a device

VSS 4 4 Ground receiving data as a receiver. The bus must be con-

SDA 5 5 Serial Data trolled by a master device which generates the serial

clock (SCL), controls the bus access, and generates

SCL 6 6 Serial Clock

the START and STOP conditions while the 24XX515

WP 7 7 Write Protect Input works as a slave. Both master and slave can operate

VCC 8 8 +1.8 to 5.5V (24AA515) as a transmitter or receiver, but the master device

+2.5 to 5.5V (24LC515) determines which mode is activated.

+4.5 to 5.5V (24FC515)

2.1 A0, A1 Chip Address Inputs

The A0, A1 inputs are used by the 24XX515 for multiple

device operations. The levels on these inputs are com-

pared with the corresponding bits in the slave address.

The chip is selected if the compare is true.

Up to four devices may be connected to the same bus

by using different chip select bit combinations. If left

unconnected, these inputs will be pulled down inter-

nally to VSS.

2.2 A2 Chip Address Input

The A2 input is non-configurable chip select. This pin

must be tied to VCC in order for this device to operate.

2.3 Serial Data (SDA)

This is a bi-directional pin used to transfer addresses

and data into and data out of the device. It is an open-

drain terminal, therefore, the SDA bus requires a pull-

up resistor to VCC (typical 10 kΩ for 100 kHz, 2 kΩ for

400 kHz and 1 MHz).

For normal data transfer SDA is allowed to change only

during SCL low. Changes during SCL high are

reserved for indicating the START and STOP condi-

tions.

2.4 Serial Clock (SCL)

This input is used to synchronize the data transfer from

and to the device.

2001 Microchip Technology Inc. Preliminary DS21673A-page 5

24AA515/24LC515/24FC515

4.0 BUS CHARACTERISTICS The data on the line must be changed during the LOW

period of the clock signal. There is one bit of data per

The following bus protocol has been defined: clock pulse.

• Data transfer may be initiated only when the bus Each data transfer is initiated with a START condition

is not busy. and terminated with a STOP condition. The number of

• During data transfer, the data line must remain the data bytes transferred between the START and

stable whenever the clock line is HIGH. Changes STOP conditions is determined by the master device.

in the data line while the clock line is HIGH will be

interpreted as a START or STOP condition. 4.5 Acknowledge

Accordingly, the following bus conditions have been Each receiving device, when addressed, is obliged to

defined (Figure 4-1). generate an acknowledge signal after the reception of

each byte. The master device must generate an extra

4.1 Bus not Busy (A) clock pulse which is associated with this acknowledge

Both data and clock lines remain HIGH. bit.

Note: The 24XX515 does not generate any

4.2 Start Data Transfer (B) acknowledge bits if an internal program-

A HIGH to LOW transition of the SDA line while the ming cycle is in progress.

clock (SCL) is HIGH determines a START condition. All A device that acknowledges must pull down the SDA

commands must be preceded by a START condition. line during the acknowledge clock pulse in such a way

4.3 Stop Data Transfer (C) that the SDA line is stable LOW during the HIGH period

of the acknowledge related clock pulse. Of course,

A LOW to HIGH transition of the SDA line while the setup and hold times must be taken into account. Dur-

clock (SCL) is HIGH determines a STOP condition. All ing reads, a master must signal an end of data to the

operations must end with a STOP condition. slave by NOT generating an acknowledge bit on the

4.4 Data Valid (D) last byte that has been clocked out of the slave. In this

case, the slave (24XX515) will leave the data line HIGH

The state of the data line represents valid data when, to enable the master to generate the STOP condition.

after a START condition, the data line is stable for the

duration of the HIGH period of the clock signal.

FIGURE 4-1: DATA TRANSFER SEQUENCE ON THE SERIAL BUS

(A) (B) (D) (D) (C) (A)

SCL

SDA

START ADDRESS OR DATA STOP

CONDITION ACKNOWLEDGE ALLOWED CONDITION

VALID TO CHANGE

FIGURE 4-2: ACKNOWLEDGE TIMING

Acknowledge

Bit

SCL 1 2 3 4 5 6 7 8 9 1 2 3

SDA Data from transmitter Data from transmitter

Transmitter must release the SDA line at this point Receiver must release the SDA line at this point

allowing the Receiver to pull the SDA line low to so the Transmitter can continue sending data.

acknowledge the previous eight bits of data.

DS21673A-page 6 Preliminary 2001 Microchip Technology Inc.

24AA515/24LC515/24FC515

5.0 DEVICE ADDRESSING FIGURE 5-1: CONTROL BYTE

FORMAT

A control byte is the first byte received following the

start condition from the master device (Figure 5-1). The Read/Write Bit

control byte consists of a 4-bit control code; for the

24XX515, this is set as 1010 binary for read and write Chip Select

operations. The next bit of the control byte is the block Control Code Bits

select bit (B0). This bit acts as the A15 address bit for

accessing the entire array. The next two bits of the con-

S 1 0 1 0 B0 A1 A0 R/W ACK

trol byte are the chip select bits (A1, A0). The chip

select bits allow the use of up to four 24XX515 devices

Slave Address

on the same bus and are used to select which device is

accessed. The chip select bits in the control byte must Start Bit Acknowledge Bit

correspond to the logic levels on the corresponding A1

and A0 pins for the device to respond. These bits are in

effect the two most significant bits of the word address. 5.1 Contiguous Addressing Across

The last bit of the control byte defines the operation to Multiple Devices

be performed. When set to a one, a read operation is

selected, and when set to a zero, a write operation is The chip select bits A1, A0 can be used to expand the

selected. The next two bytes received define the contiguous address space for up to 2 Mbit by adding up

address of the first data byte (Figure 5-2). Because to four 24XX515's on the same bus. In this case, soft-

only A14…A0 are used, the upper address bit is a don’t ware can use A0 of the control byte as address bit A16

care. The upper address bits are transferred first, fol- and A1 as address bit A17. It is not possible to sequen-

lowed by the less significant bits. tially read across device boundaries.

Following the start condition, the 24XX515 monitors the Each device has internal addressing boundary limita-

SDA bus checking the device type identifier being tions. This divides each part into two segments of 256K

transmitted. Upon receiving a 1010 code and appropri- bits. The block select bit ‘B0’ controls access to each

ate device select bits, the slave device outputs an “half” rather than address bit location A15.

acknowledge signal on the SDA line. Depending on the Sequential read operations are limited to 256K blocks.

state of the R/W bit, the 24XX515 will select a read or To read through four devices on the same bus, eight

write operation. random read commands must be given.

This device has an internal addressing boundary limita-

tion that is divided into two segments of 256K bits.

Block select bit ‘B0’ is used in place of address bit loca-

tion ‘A15’ to control access to each segment.

FIGURE 5-2: ADDRESS SEQUENCE BIT ASSIGNMENTS

CONTROL BYTE ADDRESS HIGH BYTE ADDRESS LOW BYTE

B A A A A A A A A A A A

1 0 1 0 0 1 0 R/W X • • • • • •

14 13 12 11 10 9 8 7 0

CONTROL BLOCK CHIP

SELECT SELECT X = Don’t Care Bit

CODE

BIT BITS

2001 Microchip Technology Inc. Preliminary DS21673A-page 7

24AA515/24LC515/24FC515

6.0 WRITE OPERATIONS incremented by one. If the master should transmit more

than 64 bytes prior to generating the stop condition, the

6.1 Byte Write address counter will roll over and the previously

received data will be overwritten. As with the byte write

Following the start condition from the master, the operation, once the stop condition is received, an inter-

control code (four bits), the block select (one bit) the nal write cycle will begin (Figure 6-2). If an attempt is

chip select (two bits), and the R/W bit (which is a logic made to write to the array with the WP pin held high, the

low) are clocked onto the bus by the master transmitter. device will acknowledge the command but no write

This indicates to the addressed slave receiver that the cycle will occur, no data will be written, and the device

address high byte will follow after it has generated an will immediately accept a new command.

acknowledge bit during the ninth clock cycle. There-

fore, the next byte transmitted by the master is the 6.3 Write Protection

high-order byte of the word address and will be written The WP pin allows the user to write-protect the entire

into the address pointer of the 24XX515. The next byte array (0000-FFFF) when the pin is tied to VCC. If tied to

is the least significant address byte. After receiving VSS or left floating, the write protection is disabled. The

another acknowledge signal from the 24XX515, the WP pin is sampled at the STOP bit for every write

master device will transmit the data word to be written command (Figure 1-1) Toggling the WP pin after the

into the addressed memory location. The 24XX515 STOP bit will have no effect on the execution of the

acknowledges again and the master generates a stop write cycle.

condition. This initiates the internal write cycle and dur-

ing this time, the 24XX515 will not generate acknowl- Note: Page write operations are limited to writing

edge signals (Figure 6-1). If an attempt is made to write bytes within a single physical page, regard-

to the array with the WP pin held high, the device will less of the number of bytes actually being

acknowledge the command but no write cycle will written. Physical page boundaries start at

occur, no data will be written, and the device will imme- addresses that are integer multiples of the

diately accept a new command. After a byte write com- page buffer size (or ‘page size’) and end at

mand, the internal address counter will point to the addresses that are integer multiples of

address location following the one that was just written. [page size - 1]. If a page write command

attempts to write across a physical page

6.2 Page Write

boundary, the result is that the data wraps

The write control byte, word address, and the first data around to the beginning of the current page

byte are transmitted to the 24XX515 in the same way (overwriting data previously stored there),

as in a byte write. But instead of generating a stop con- instead of being written to the next page as

dition, the master transmits up to 63 additional bytes, might be expected. It is therefore neces-

which are temporarily stored in the on-chip page buffer sary for the application software to prevent

and will be written into memory after the master has page write operations that would attempt to

transmitted a stop condition. After receipt of each word, cross a page boundary.

the six lower address pointer bits are internally

FIGURE 6-1: BYTE WRITE

S

BUS ACTIVITY T S

CONTROL ADDRESS ADDRESS

MASTER A T

R BYTE HIGH BYTE LOW BYTE DATA O

T P

SDA LINE S1 0 1 0B AA

0 10 0

X P

A A A A

BUS ACTIVITY C C C C

K K K K

X = don’t care bit

FIGURE 6-2: PAGE WRITE

S

T S

BUS ACTIVITY A CONTROL ADDRESS ADDRESS T

MASTER R BYTE HIGH BYTE LOW BYTE DATA BYTE 0 DATA BYTE 63 O

T P

SDA LINE BAA X P

S10 1 0 0 1 00

A A A A A

BUS ACTIVITY C C C C C

K K K K K

X = don’t care bit

DS21673A-page 8 Preliminary 2001 Microchip Technology Inc.

24AA515/24LC515/24FC515

7.0 ACKNOWLEDGE POLLING FIGURE 7-1: ACKNOWLEDGE

POLLING FLOW

Since the device will not acknowledge during a write

cycle, this can be used to determine when the cycle is

complete (This feature can be used to maximize bus

throughput.) Once the stop condition for a write com-

mand has been issued from the master, the device ini- Send

tiates the internally timed write cycle. ACK polling can Write Command

be initiated immediately. This involves the master

sending a start condition, followed by the control byte

Send Stop

for a write command (R/W = 0). If the device is still busy

Condition to

with the write cycle, then no ACK will be returned. If no

Initiate Write Cycle

ACK is returned, then the start bit and control byte must

be resent. If the cycle is complete, then the device will

return the ACK, and the master can then proceed with

the next read or write command. See Figure 7-1 for Send Start

flow diagram.

Send Control Byte

with R/W = 0

Did Device NO

Acknowledge

(ACK = 0)?

YES

Next

Operation

2001 Microchip Technology Inc. Preliminary DS21673A-page 9

24AA515/24LC515/24FC515

8.0 READ OPERATION 24XX515 as part of a write operation (R/W bit set to 0).

After the word address is sent, the master generates a

Read operations are initiated in the same way as write start condition following the acknowledge. This termi-

operations with the exception that the R/W bit of the nates the write operation, but not before the internal

control byte is set to one. There are three basic types address pointer is set. Then, the master issues the

of read operations: current address read, random read, control byte again but with the R/W bit set to a one. The

and sequential read. 24XX515 will then issue an acknowledge and transmit

the 8-bit data word. The master will not acknowledge

8.1 Current Address Read the transfer but does generate a stop condition which

The 24XX515 contains an address counter that main- causes the 24XX515 to discontinue transmission

tains the address of the last word accessed, internally (Figure 8-2). After a random read command, the inter-

incremented by one. Therefore, if the previous read nal address counter will point to the address location

access was to address n (n is any legal address), the following the one that was just read.

next current address read operation would access data

from address n + 1.

8.3 Sequential Read

Upon receipt of the control byte with R/W bit set to one, Sequential reads are initiated in the same way as a ran-

the 24XX515 issues an acknowledge and transmits the dom read except that after the 24XX515 transmits the

8-bit data word. The master will not acknowledge the first data byte, the master issues an acknowledge as

transfer but does generate a stop condition and the opposed to the stop condition used in a random read.

24XX515 discontinues transmission (Figure 8-1). This acknowledge directs the 24XX515 to transmit the

next sequentially addressed 8-bit word (Figure 8-3).

FIGURE 8-1: CURRENT ADDRESS Following the final byte transmitted to the master, the

READ master will NOT generate an acknowledge but will gen-

S erate a stop condition. To provide sequential reads, the

T S 24XX515 contains an internal address pointer which is

BUS ACTIVITY A CONTROL DATA T

MASTER R BYTE BYTE O incremented by one at the completion of each opera-

T P tion. This address pointer allows half the memory con-

SDA LINE S 1 0 1 0 B A A 1 P tents to be serially read during one operation.

0 1 0

A N Sequential read address boundaries are 0000h to

BUS ACTIVITY C O 7FFFh and 8000h to FFFFh. The internal address

K

A pointer will automatically roll over from address 7FFF to

C

K address 0000 if the master acknowledges the byte

received from the array address 7FFF. The internal

8.2 Random Read address counter will automatically roll over from

address FFFFh to address 8000h if the master

Random read operations allow the master to access acknowledges the byte received from the array

any memory location in a random manner. To perform address FFFFh.

this type of read operation, first the word address must

be set. This is done by sending the word address to the

FIGURE 8-2: RANDOM READ

S S

BUS ACTIVITY T T S

A CONTROL ADDRESS ADDRESS A CONTROL DATA T

MASTER

R BYTE HIGH BYTE LOW BYTE R BYTE BYTE O

T T P

B A A

SDA LINE S 1 0 1 0 0 X S 1 0 1 0 B A A1 P

0 1 0 0 1 0

A A A A N

BUS ACTIVITY C C C C O

K K K K A

C

X = Don’t Care Bit K

FIGURE 8-3: SEQUENTIAL READ

CONTROL S

BUS ACTIVITY T

BYTE DATA n DATA n + 1 DATA n + 2 DATA n + X

MASTER O

P

SDA LINE P

A A A A N

C C C C O

BUS ACTIVITY K K K K A

C

K

DS21673A-page 10 Preliminary 2001 Microchip Technology Inc.

24AA515/24LC515/24FC515

9.0 PACKAGING INFORMATION

9.1 Package Marking Information

8-Lead PDIP (300 mil) Example:

XXXXXXXX 24LC515

XXXXXNNN I/PNNN

YYWW YYWW

8-Lead SOIC (208 mil) Example:

XXXXXXXX 24LC515

XXXXXXXX I/SM

YYWWNNN YYWWNNN

Legend: XX...X Customer specific information*

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

Note: In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line thus limiting the number of available characters

for customer specific information.

* Standard marking consists of Microchip part number, year code, week code, traceability code (facility

code, mask rev#, and assembly code). For marking beyond this, certain price adders apply. Please

check with your Microchip Sales Office.

2001 Microchip Technology Inc. Preliminary DS21673A-page 11

24AA515/24LC515/24FC515

8-Lead Plastic Dual In-line (P) – 300 mil (PDIP)

E1

n 1

A A2

L

c

A1

β B1

p

eB B

Units INCHES* MILLIMETERS

Dimension Limits MIN NOM MAX MIN NOM MAX

Number of Pins n 8 8

Pitch p .100 2.54

Top to Seating Plane A .140 .155 .170 3.56 3.94 4.32

Molded Package Thickness A2 .115 .130 .145 2.92 3.30 3.68

Base to Seating Plane A1 .015 0.38

Shoulder to Shoulder Width E .300 .313 .325 7.62 7.94 8.26

Molded Package Width E1 .240 .250 .260 6.10 6.35 6.60

Overall Length D .360 .373 .385 9.14 9.46 9.78

Tip to Seating Plane L .125 .130 .135 3.18 3.30 3.43

Lead Thickness c .008 .012 .015 0.20 0.29 0.38

Upper Lead Width B1 .045 .058 .070 1.14 1.46 1.78

Lower Lead Width B .014 .018 .022 0.36 0.46 0.56

Overall Row Spacing § eB .310 .370 .430 7.87 9.40 10.92

Mold Draft Angle Top α 5 10 15 5 10 15

Mold Draft Angle Bottom β 5 10 15 5 10 15

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-018

DS21673A-page 12 Preliminary 2001 Microchip Technology Inc.

24AA515/24LC515/24FC515

8-Lead Plastic Small Outline (SM) – Medium, 208 mil (SOIC)

E1

D

2

n 1

B

c

A A2

A1

β L

Units INCHES* MILLIMETERS

Dimension Limits MIN NOM MAX MIN NOM MAX

Number of Pins n 8 8

Pitch p .050 1.27

Overall Height A .070 .075 .080 1.78 1.97 2.03

Molded Package Thickness A2 .069 .074 .078 1.75 1.88 1.98

Standoff § A1 .002 .005 .010 0.05 0.13 0.25

Overall Width E .300 .313 .325 7.62 7.95 8.26

Molded Package Width E1 .201 .208 .212 5.11 5.28 5.38

Overall Length D .202 .205 .210 5.13 5.21 5.33

Foot Length L .020 .025 .030 0.51 0.64 0.76

Foot Angle φ 0 4 8 0 4 8

Lead Thickness c .008 .009 .010 0.20 0.23 0.25

Lead Width B .014 .017 .020 0.36 0.43 0.51

Mold Draft Angle Top α 0 12 15 0 12 15

Mold Draft Angle Bottom β 0 12 15 0 12 15

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

Drawing No. C04-056

2001 Microchip Technology Inc. Preliminary DS21673A-page 13

24AA515/24LC515/24FC515

NOTES:

DS21673A-page 14 Preliminary 2001 Microchip Technology Inc.

24AA515/24LC515/24FC515

ON-LINE SUPPORT Systems Information and Upgrade Hot

Line

Microchip provides on-line support on the Microchip

World Wide Web (WWW) site. The Systems Information and Upgrade Line provides

The web site is used by Microchip as a means to make system users a listing of the latest versions of all of

files and information easily available to customers. To Microchip's development systems software products.

view the site, the user must have access to the Internet Plus, this line provides information on how customers

and a web browser, such as Netscape or Microsoft can receive any currently available upgrade kits.The

Explorer. Files are also available for FTP download Hot Line Numbers are:

from our FTP site. 1-800-755-2345 for U.S. and most of Canada, and

1-480-792-7302 for the rest of the world. 013001

Connecting to the Microchip Internet Web

Site

The Microchip web site is available by using your

favorite Internet browser to attach to:

www.microchip.com

The file transfer site is available by using an FTP ser-

vice to connect to:

ftp://ftp.microchip.com

The web site and file transfer site provide a variety of

services. Users may download files for the latest

Development Tools, Data Sheets, Application Notes,

User's Guides, Articles and Sample Programs. A vari-

ety of Microchip specific business information is also

available, including listings of Microchip sales offices,

distributors and factory representatives. Other data

available for consideration is:

• Latest Microchip Press Releases

• Technical Support Section with Frequently Asked

Questions

• Design Tips

• Device Errata

• Job Postings

• Microchip Consultant Program Member Listing

• Links to other useful web sites related to

Microchip Products

• Conferences for products, Development Systems,

technical information and more

• Listing of seminars and events

2001 Microchip Technology Inc. DS21673A-page 15

24AA515/24LC515/24FC515

READER RESPONSE

It is our intention to provide you with the best documentation possible to ensure successful use of your Microchip prod-

uct. If you wish to provide your comments on organization, clarity, subject matter, and ways in which our documentation

can better serve you, please FAX your comments to the Technical Publications Manager at (480) 792-4150.

Please list the following information, and use this outline to provide us with your comments about this Data Sheet.

To: Technical Publications Manager Total Pages Sent

RE: Reader Response

From: Name

Company

Address

City / State / ZIP / Country

Telephone: (_______) _________ - _________ FAX: (______) _________ - _________

Application (optional):

Would you like a reply? Y N

Device: 24AA515/24LC515/24FC515 Literature Number: DS21673A

Questions:

1. What are the best features of this document?

2. How does this document meet your hardware and software development needs?

3. Do you find the organization of this data sheet easy to follow? If not, why?

4. What additions to the data sheet do you think would enhance the structure and subject?

5. What deletions from the data sheet could be made without affecting the overall usefulness?

6. Is there any incorrect or misleading information (what and where)?

7. How would you improve this document?

8. How would you improve our software, systems, and silicon products?

DS21673A-page 16 2001 Microchip Technology Inc.

24AA515/24LC515/24FC515

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. X /XX

Examples:

Device Temperature Package a) 24AA515T-I/SM: Tape and Reel, Industrial

Range Temperature, SOIC package.

b) 24LC515-I/P: Industrial Temperature, PDIP

package.

Device 24AA515: = 512K Bit 1.8V I2C CMOS Serial EEPROM c) 24LC515-I/SM: Industrial Temperature,

24AA515T: = 512K Bit 1.8V I2C CMOS Serial EEPROM SOIC package.

(Tape and Reel)

24LC515: = 512K Bit 2.5V I2C CMOS Serial EEPROM d) 24LC515T-I/SM: Tape and Reel, Industrial

24LC515T: = 512K Bit 2.5V I2C CMOS Serial EEPROM Temperature, SOIC package.

(Tape and Reel)

24FC515: = 512K Bit 2.5V I2C CMOS Serial EEPROM

24FC515T: = 512K Bit 2.5V I2C CMOS Serial EEPROM

(Tape and Reel)

Temperature Range I = -40°C to +85°C

Package P = Plastic DIP (300 mil Body), 8-lead

SM = Plastic SOIC (208 mil Body), 8-lead

SALES AND SUPPORT

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences and recom-

mended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX: (480) 792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

2001 Microchip Technology Inc. Preliminary DS21673A-page 17

24AA515/24LC515/24FC515

NOTES:

DS21673A-page 18 Preliminary 2001 Microchip Technology Inc.

24AA515/24LC515/24FC515

Information contained in this publication regarding device Trademarks

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to The Microchip name and logo, the Microchip logo, PIC,

ensure that your application meets with your specifications. PICmicro, PICMASTER, PICSTART, PRO MATE, KEELOQ,

No representation or warranty is given and no liability is SEEVAL, MPLAB and The Embedded Control Solutions

assumed by Microchip Technology Incorporated with respect Company are registered trademarks of Microchip Technology

to the accuracy or use of such information, or infringement of Incorporated in the U.S.A. and other countries.

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical com- Total Endurance, ICSP, In-Circuit Serial Programming,

ponents in life support systems is not authorized except with FilterLab, MXDEV, microID, FlexROM, fuzzyLAB, MPASM,

express written approval by Microchip. No licenses are con- MPLINK, MPLIB, PICC, PICDEM, PICDEM.net, ICEPIC,

veyed, implicitly or otherwise, under any intellectual property Migratable Memory, FanSense, ECONOMONITOR, Select

rights. Mode and microPort are trademarks of Microchip Technology

Incorporated in the U.S.A.

Serialized Quick Term Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2001, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999. The

Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro® 8-bit MCUs, K EELOQ® code hopping

devices, Serial EEPROMs and microperipheral

products. In addition, Microchip’s quality

system for the design and manufacture of

development systems is ISO 9001 certified.

2001 Microchip Technology Inc. DS21673A-page 19

WORLDWIDE SALES AND SERVICE

AMERICAS ASIA/PACIFIC Japan

Microchip Technology Japan K.K.

Corporate Office Australia

Benex S-1 6F

2355 West Chandler Blvd. Microchip Technology Australia Pty Ltd

3-18-20, Shinyokohama

Chandler, AZ 85224-6199 Suite 22, 41 Rawson Street

Kohoku-Ku, Yokohama-shi

Tel: 480-792-7200 Fax: 480-792-7277 Epping 2121, NSW

Kanagawa, 222-0033, Japan

Technical Support: 480-792-7627 Australia

Web Address: http://www.microchip.com Tel: 61-2-9868-6733 Fax: 61-2-9868-6755 Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Rocky Mountain China - Beijing Korea

2355 West Chandler Blvd. Microchip Technology Consulting (Shanghai) Microchip Technology Korea

Chandler, AZ 85224-6199 Co., Ltd., Beijing Liaison Office 168-1, Youngbo Bldg. 3 Floor

Tel: 480-792-7966 Fax: 480-792-7456 Unit 915 Samsung-Dong, Kangnam-Ku

New China Hong Kong Manhattan Bldg. Seoul, Korea 135-882

Atlanta No. 6 Chaoyangmen Beidajie Tel: 82-2-554-7200 Fax: 82-2-558-5934

500 Sugar Mill Road, Suite 200B Beijing, 100027, No. China Singapore

Atlanta, GA 30350 Tel: 86-10-85282100 Fax: 86-10-85282104 Microchip Technology Singapore Pte Ltd.

Tel: 770-640-0034 Fax: 770-640-0307 200 Middle Road

China - Chengdu

Austin - Analog #07-02 Prime Centre

Microchip Technology Consulting (Shanghai)

8303 MoPac Expressway North Singapore, 188980

Co., Ltd., Chengdu Liaison Office

Suite A-201 Tel: 65-334-8870 Fax: 65-334-8850

Rm. 2401, Ming Xing Financial Tower

Austin, TX 78759 Taiwan

No. 88 TIDU Street

Tel: 512-345-2030 Fax: 512-345-6085 Microchip Technology Taiwan

Chengdu 610016, China

Boston Tel: 86-28-6766200 Fax: 86-28-6766599 11F-3, No. 207

2 Lan Drive, Suite 120 Tung Hua North Road

China - Fuzhou

Westford, MA 01886 Taipei, 105, Taiwan

Tel: 978-692-3848 Fax: 978-692-3821 Microchip Technology Consulting (Shanghai) Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

Co., Ltd., Fuzhou Liaison Office

Boston - Analog Rm. 531, North Building

Unit A-8-1 Millbrook Tarry Condominium Fujian Foreign Trade Center Hotel

97 Lowell Road EUROPE

73 Wusi Road

Concord, MA 01742 Fuzhou 350001, China Denmark

Tel: 978-371-6400 Fax: 978-371-0050 Tel: 86-591-7557563 Fax: 86-591-7557572 Microchip Technology Denmark ApS

Chicago China - Shanghai Regus Business Centre

333 Pierce Road, Suite 180 Microchip Technology Consulting (Shanghai) Lautrup hoj 1-3

Itasca, IL 60143 Co., Ltd. Ballerup DK-2750 Denmark

Tel: 630-285-0071 Fax: 630-285-0075 Room 701, Bldg. B Tel: 45 4420 9895 Fax: 45 4420 9910

Dallas Far East International Plaza France

4570 Westgrove Drive, Suite 160 No. 317 Xian Xia Road Arizona Microchip Technology SARL

Addison, TX 75001 Shanghai, 200051 Parc d’Activite du Moulin de Massy

Tel: 972-818-7423 Fax: 972-818-2924 Tel: 86-21-6275-5700 Fax: 86-21-6275-5060 43 Rue du Saule Trapu

Dayton China - Shenzhen Batiment A - ler Etage

Two Prestige Place, Suite 130 91300 Massy, France

Microchip Technology Consulting (Shanghai)

Miamisburg, OH 45342 Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Co., Ltd., Shenzhen Liaison Office

Tel: 937-291-1654 Fax: 937-291-9175 Rm. 1315, 13/F, Shenzhen Kerry Centre, Germany

Detroit Renminnan Lu Arizona Microchip Technology GmbH

Tri-Atria Office Building Shenzhen 518001, China Gustav-Heinemann Ring 125

32255 Northwestern Highway, Suite 190 Tel: 86-755-2350361 Fax: 86-755-2366086 D-81739 Munich, Germany

Farmington Hills, MI 48334 Hong Kong Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Tel: 248-538-2250 Fax: 248-538-2260 Microchip Technology Hongkong Ltd. Germany - Analog

Los Angeles Unit 901, Tower 2, Metroplaza Lochhamer Strasse 13

18201 Von Karman, Suite 1090 223 Hing Fong Road D-82152 Martinsried, Germany

Irvine, CA 92612 Kwai Fong, N.T., Hong Kong Tel: 49-89-895650-0 Fax: 49-89-895650-22

Tel: 949-263-1888 Fax: 949-263-1338 Tel: 852-2401-1200 Fax: 852-2401-3431 Italy

New York India Arizona Microchip Technology SRL

150 Motor Parkway, Suite 202 Microchip Technology Inc. Centro Direzionale Colleoni

Hauppauge, NY 11788 India Liaison Office Palazzo Taurus 1 V. Le Colleoni 1

Tel: 631-273-5305 Fax: 631-273-5335 Divyasree Chambers 20041 Agrate Brianza

1 Floor, Wing A (A3/A4) Milan, Italy

San Jose

No. 11, O’Shaugnessey Road Tel: 39-039-65791-1 Fax: 39-039-6899883

Microchip Technology Inc.

2107 North First Street, Suite 590 Bangalore, 560 025, India United Kingdom

San Jose, CA 95131 Tel: 91-80-2290061 Fax: 91-80-2290062 Arizona Microchip Technology Ltd.

Tel: 408-436-7950 Fax: 408-436-7955 505 Eskdale Road

Winnersh Triangle

Toronto

Wokingham

6285 Northam Drive, Suite 108

Berkshire, England RG41 5TU

Mississauga, Ontario L4V 1X5, Canada

Tel: 44 118 921 5869 Fax: 44-118 921-5820

Tel: 905-673-0699 Fax: 905-673-6509

06/01/01

DS00000A-page 20 Preliminary 2001 Microchip Technology Inc.

Vous aimerez peut-être aussi

- 24l1026i Memoria EEPROM 1024kDocument28 pages24l1026i Memoria EEPROM 1024kMarta_d_ePas encore d'évaluation

- 24FC1025 EepromDocument28 pages24FC1025 EepromAnirudh ReddyPas encore d'évaluation

- 24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMDocument29 pages24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMSudhagarSubbiyanPas encore d'évaluation

- 24C32Document12 pages24C32SilviuCocoloșPas encore d'évaluation

- 24LC04B PDFDocument22 pages24LC04B PDFEddy RosarioPas encore d'évaluation

- 24AA64/24LC64/24FC64: 64K I C Serial EEPROMDocument28 pages24AA64/24LC64/24FC64: 64K I C Serial EEPROMJuan Luis Pineda GonzálezPas encore d'évaluation

- 32K 5.0V I C Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Serial EEPROM: Features Package Typesinsomnium86Pas encore d'évaluation

- 24AA256/24LC256: 256K I C Cmos Serial EepromDocument12 pages24AA256/24LC256: 256K I C Cmos Serial EepromWelleyPas encore d'évaluation

- 24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMDocument34 pages24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMKhalid BenaribaPas encore d'évaluation

- Datasheet PDFDocument26 pagesDatasheet PDFNicoli LourençoPas encore d'évaluation

- 32K 2.5V I C Serial EEPROM: Features Package TypesDocument12 pages32K 2.5V I C Serial EEPROM: Features Package Typesinsomnium86Pas encore d'évaluation

- 24AA02/24LC02B: 2KI C Serial EEPROMDocument24 pages24AA02/24LC02B: 2KI C Serial EEPROMMayk OzPas encore d'évaluation

- 24AA16/24LC16B: 16K I C Serial EEPROMDocument25 pages24AA16/24LC16B: 16K I C Serial EEPROMDaniel VásquezPas encore d'évaluation

- 24AA02/24LC02B: 2KI C Serial EEPROMDocument32 pages24AA02/24LC02B: 2KI C Serial EEPROMhanifPas encore d'évaluation

- 24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738Document32 pages24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738İbrahim DemircioğluPas encore d'évaluation

- 24 LC 256Document38 pages24 LC 256johnPas encore d'évaluation

- 24aa512 Mic PDFDocument28 pages24aa512 Mic PDFkt2018Pas encore d'évaluation

- 24LC08 PDFDocument30 pages24LC08 PDFJaime BarrancoPas encore d'évaluation

- EEPROM 24LC256 - Microchip PDFDocument28 pagesEEPROM 24LC256 - Microchip PDFValdir DerlannPas encore d'évaluation

- 24AA08/24LC08B: 8KI C Serial EEPROMDocument30 pages24AA08/24LC08B: 8KI C Serial EEPROMjosePas encore d'évaluation

- 21711c PDFDocument24 pages21711c PDFAbdessamad EladakPas encore d'évaluation

- 24aa08 - 24lc08 Eeprom PDFDocument40 pages24aa08 - 24lc08 Eeprom PDFEdgar DauzonPas encore d'évaluation

- 32K 5.0V I C Smart Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Smart Serial EEPROM: Features Package TypesRamon LopezPas encore d'évaluation

- 1K 5.0V I C™ Serial EEPROM: Features: DescriptionDocument36 pages1K 5.0V I C™ Serial EEPROM: Features: DescriptionDanna PerezPas encore d'évaluation

- 24AA00/24LC00/24C00: 128 Bit I C™ Bus Serial EEPROMDocument12 pages24AA00/24LC00/24C00: 128 Bit I C™ Bus Serial EEPROMmacepaPas encore d'évaluation

- I2c EEPROM 24xx256 DsDocument28 pagesI2c EEPROM 24xx256 DsRizwan AmirPas encore d'évaluation

- Atmel 24c02 PDFDocument30 pagesAtmel 24c02 PDFMAX GPas encore d'évaluation

- 32K 5.0V I C Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Serial EEPROM: Features Package TypesChrono GtzPas encore d'évaluation

- 24Lc08B/16B Modules: 8K/16K I C Serial Eeproms in Iso MicromodulesDocument12 pages24Lc08B/16B Modules: 8K/16K I C Serial Eeproms in Iso MicromodulesarminPas encore d'évaluation

- Ic PDFDocument36 pagesIc PDFdharamPas encore d'évaluation

- 24AA02H 24LC02BH 2K I2C Serial EEPROM With Half Array Write Protect 20002105BDocument40 pages24AA02H 24LC02BH 2K I2C Serial EEPROM With Half Array Write Protect 20002105BAlhassan Ahmed OmranPas encore d'évaluation

- 24aa256uid 256k I2c Serial Eeprom With Eui48 Eui64 20005215dDocument28 pages24aa256uid 256k I2c Serial Eeprom With Eui48 Eui64 20005215dAbhishek BhattacharjeePas encore d'évaluation

- 1K 2.5V Dual Mode I C Serial EEPROM: Features Package TypesDocument12 pages1K 2.5V Dual Mode I C Serial EEPROM: Features Package TypesVictor TruccoPas encore d'évaluation

- 24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-ProtectDocument24 pages24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-Protecta4rfanPas encore d'évaluation

- 16K I C Serial EEPROM Extended (M) Operating Temperatures: Number V Range Max. Clock Frequency Temp. RangesDocument22 pages16K I C Serial EEPROM Extended (M) Operating Temperatures: Number V Range Max. Clock Frequency Temp. RangeshcarcaroPas encore d'évaluation

- 24lc512 DatasheetDocument27 pages24lc512 DatasheetLeonardo QuevedoPas encore d'évaluation

- 24AA16 24LC16B 24FC16 16K I2C Serial EEPROM 20001703PDocument49 pages24AA16 24LC16B 24FC16 16K I2C Serial EEPROM 20001703Pmarko.jojicoo777Pas encore d'évaluation

- 24AA128/24LC128/24FC128: 128K I C Cmos Serial EepromDocument26 pages24AA128/24LC128/24FC128: 128K I C Cmos Serial EepromcraponzelPas encore d'évaluation

- 25AA640/25LC640/25C640: 64K Spi Bus Serial EEPROMDocument11 pages25AA640/25LC640/25C640: 64K Spi Bus Serial EEPROMAndrey OliveiraPas encore d'évaluation

- 8K/16K 5.0V SPI Bus Serial EEPROM: Features Package TypesDocument12 pages8K/16K 5.0V SPI Bus Serial EEPROM: Features Package Typesrıdvan71Pas encore d'évaluation

- 21073K PDFDocument24 pages21073K PDFadfumegaPas encore d'évaluation

- 24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMDocument45 pages24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMJuan Carlos CrespoPas encore d'évaluation

- 22131c PDFDocument24 pages22131c PDFAdilsonAmorimPas encore d'évaluation

- 25 LC 1024Document28 pages25 LC 1024hyd27Pas encore d'évaluation

- 24AA128/24LC128/24FC128: 128K I C Serial EEPROMDocument44 pages24AA128/24LC128/24FC128: 128K I C Serial EEPROMJosemar M. FerreiraPas encore d'évaluation

- 25AA1024Document30 pages25AA1024Bình MaiPas encore d'évaluation

- 24AA024 MicrochipTechnologyDocument22 pages24AA024 MicrochipTechnologydasdrachePas encore d'évaluation

- 24AA04/24LC04B/24FC04: 4KI C Serial EEPROMDocument45 pages24AA04/24LC04B/24FC04: 4KI C Serial EEPROMDinu Racautanu MironPas encore d'évaluation

- 25AA160A/B, 25LC160A/B: 16K SPI Bus Serial EEPROMDocument26 pages25AA160A/B, 25LC160A/B: 16K SPI Bus Serial EEPROMmuglanPas encore d'évaluation

- 25AA640/25LC640: 64K Spi Bus Serial EEPROMDocument12 pages25AA640/25LC640: 64K Spi Bus Serial EEPROMinsomnium86Pas encore d'évaluation

- 24C64 - EepromDocument20 pages24C64 - Eepromropay61705Pas encore d'évaluation

- 24AA256/24LC256/24FC256: 256K I C Serial EEPROMDocument42 pages24AA256/24LC256/24FC256: 256K I C Serial EEPROMAbhishek BhattacharjeePas encore d'évaluation

- 25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMDocument23 pages25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMЕвгенийPas encore d'évaluation

- 24C1 Memoria Eeprom SankeyDocument11 pages24C1 Memoria Eeprom Sankeyjavier venturaPas encore d'évaluation

- 24C320-EP MicrochipTechnologyDocument12 pages24C320-EP MicrochipTechnologyMateus CorrêaPas encore d'évaluation

- CAT24C32: 32-Kb I C Cmos Serial Eeprom Features Device DescriptionDocument18 pagesCAT24C32: 32-Kb I C Cmos Serial Eeprom Features Device DescriptionPierpaolo GustinPas encore d'évaluation

- 4 PDFDocument31 pages4 PDFAgus OrtizPas encore d'évaluation

- 11aa02iud 1wire MicrochipDocument32 pages11aa02iud 1wire MicrochipManutenção eletrônicaPas encore d'évaluation

- Linear IC Applications: A Designer's HandbookD'EverandLinear IC Applications: A Designer's HandbookÉvaluation : 4 sur 5 étoiles4/5 (1)

- Install A Crisscross With Any Leg Vise Hardware, Begin HereDocument24 pagesInstall A Crisscross With Any Leg Vise Hardware, Begin Herexx xxxPas encore d'évaluation

- Control Valve L H 3 3Document2 pagesControl Valve L H 3 3eshopmanual baruPas encore d'évaluation

- VG Cables For Marine Engineering 02Document24 pagesVG Cables For Marine Engineering 02SyazieliKamaruzamanPas encore d'évaluation

- 27.classroom Objects BDocument21 pages27.classroom Objects BAleksandra VuPas encore d'évaluation

- Ir 2230 Part Mannual PDFDocument150 pagesIr 2230 Part Mannual PDFbhripulPas encore d'évaluation

- Moriniservices5 PDFDocument44 pagesMoriniservices5 PDFMoto TOWPas encore d'évaluation

- Hydraulic System:: R. Qasim Abbas D Automatic Control I 4Document5 pagesHydraulic System:: R. Qasim Abbas D Automatic Control I 4علي حسين علاوي ثوينيPas encore d'évaluation

- 17HX Stepper Hybrid 198-200 v6.09Document5 pages17HX Stepper Hybrid 198-200 v6.09dharmil.gopaniPas encore d'évaluation

- FL-2100B AMP Operators ManualDocument7 pagesFL-2100B AMP Operators Manualoctavian barbuPas encore d'évaluation

- cbr250rr 2021Document115 pagescbr250rr 2021Sam SamiPas encore d'évaluation

- ASK 21 Mi: To y and To Train Whenever You WantDocument4 pagesASK 21 Mi: To y and To Train Whenever You WantahdickwongPas encore d'évaluation

- Control Valve Data SheetDocument1 pageControl Valve Data SheetKelly Perez LopezPas encore d'évaluation

- Braun BrewSense Coffee Maker KF6050 ManualDocument28 pagesBraun BrewSense Coffee Maker KF6050 ManualT-BuzzardPas encore d'évaluation

- HMW-1270-T5 - (MTU-18V2000G26F) - (Open-Skid-K59) - (STAMFORD) - (Data-Sheet) - AS22DSE8620 MKIIDocument13 pagesHMW-1270-T5 - (MTU-18V2000G26F) - (Open-Skid-K59) - (STAMFORD) - (Data-Sheet) - AS22DSE8620 MKIIVignesh RamalingamPas encore d'évaluation

- PDF Operator39s Manual Moba Matic 1 Can and Moba Mini Matic DLDocument73 pagesPDF Operator39s Manual Moba Matic 1 Can and Moba Mini Matic DLVitalii KrasnokutskiyPas encore d'évaluation

- Aptio V Status CodesDocument13 pagesAptio V Status CodesKevin TatePas encore d'évaluation

- Common Joints and SplicesDocument3 pagesCommon Joints and SplicesNota Belz70% (10)

- 051790c0.sch-1 - Tue May 21 09:07:19 2002Document19 pages051790c0.sch-1 - Tue May 21 09:07:19 2002Italo BocattuPas encore d'évaluation

- Swench Brochure Ударный КлючDocument4 pagesSwench Brochure Ударный КлючMasterrPas encore d'évaluation

- Brochure Rectifier Sg825863ben c00!09!2016 LRDocument8 pagesBrochure Rectifier Sg825863ben c00!09!2016 LRsubhashkpn86Pas encore d'évaluation

- Wireless Digital Code Lock With A Status DisplayDocument19 pagesWireless Digital Code Lock With A Status Display95sagar95Pas encore d'évaluation

- Safety Valve, Bronze: Serie 14 Type 1481 - With Lever Type 1482 - With CapDocument2 pagesSafety Valve, Bronze: Serie 14 Type 1481 - With Lever Type 1482 - With CapSami KahtaniPas encore d'évaluation

- Lincoln 3Document50 pagesLincoln 3RZ EmiPas encore d'évaluation

- Ae02000 - Ventiladores para InvernaderosDocument4 pagesAe02000 - Ventiladores para Invernaderosjose rangelPas encore d'évaluation

- ForkliftsDocument21 pagesForkliftsManual ForkliftPas encore d'évaluation

- Pickup Bartolini Wiring ConductorDocument2 pagesPickup Bartolini Wiring ConductorClau gomesPas encore d'évaluation

- 2-Wire, RH+T Transmitters: 2 X 4 20 Ma Outputs Ip65/Ip66 Dual LCD Display Flameproof SC805, SC806, SC807Document6 pages2-Wire, RH+T Transmitters: 2 X 4 20 Ma Outputs Ip65/Ip66 Dual LCD Display Flameproof SC805, SC806, SC807Ravi Kant GuptaPas encore d'évaluation

- Av500 Wiring Diagrams-Av501Document1 pageAv500 Wiring Diagrams-Av501Mary Sharlene IjanPas encore d'évaluation

- 4 Way TrafficDocument31 pages4 Way TrafficEmeka Nelson Offornedo80% (5)

- PL Feature - Boot Flash Loader - Um PDFDocument89 pagesPL Feature - Boot Flash Loader - Um PDFerradicaPas encore d'évaluation