Académique Documents

Professionnel Documents

Culture Documents

V11I3 (7) Gözde Ertekin

Transféré par

Sarah FadhlillahCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

V11I3 (7) Gözde Ertekin

Transféré par

Sarah FadhlillahDroits d'auteur :

Formats disponibles

The Effect of Heat-Setting Conditions on the Performance

Characteristics of Warp Knitted Spacer Fabrics

Gözde Ertekin, PhD, Arzu Marmarali

Ege University, Department of Textile Engineering, İzmir, İzmir TURKEY

Correspondence to:

Gözde Ertekin email: gozde.damci@ege.edu.tr

ABSTRACT

Spacer fabrics can be produced by using weaving or In the production of warp knitted spacer fabrics,

nonwoven techniques besides warp and weft knitting especially polyester multifilament and monofilament

processes. Warp knitted spacer fabrics are produced yarns are used as surface layers and spacer yarn,

by using polyester multifilament and monofilament respectively. These fabrics are taken from the

yarns for surface layers and spacer yarn, respectively. knitting machine in the form of closed structures.

After knitting process, surface layers of these fabrics After knitting process, the warp knitted spacer fabrics

are in the closed form. Then these fabrics are are normally subjected to a heat-setting treatment in

subjected to a heat-setting treatment in order to order to increase the structural stability and to

increase their structural stability and to achieve an achieve a determined open form. It is necessary to

open form with holes. In this study, it is aimed to point out that heat-setting of a spacer fabric is not

investigate the effect of heat-setting conditions on the easy to be processed because it is difficult to firmly

performance characteristics of the warp knitted catch the two selvages of the spacer fabric on a

spacer fabrics. Mass per unit area, thickness, air conventional heat-setting machine. In order to solve

permeability, compressibility, dimensional stability this problem, the selvages of both sides of spacer

and compression set properties were measured and fabrics were knitted without spacer yarns. Ye et al.

evaluated statistically in order to determine the mentioned that to extend these fabrics to the desired

effects of heat-setting conditions such as temperature, width during heat-setting process was difficult,

duration of heat-setting and stretching (the tension because of longer underlaps of the spacer yarns or

applied to the samples during heat-setting) on the higher thickness or weight of spacer fabrics [2].

performance characteristics. The results revealed that,

heat-setting process has significant effect on all Fabrics produced from synthetic fibres or from

measured performance characteristics of the samples. blends containing such fibres are subjected to a range

After heat-setting process, air permeability and of different heat treatments during the various stages

compressibility values increases while mass per unit of their production. Heat-setting is the most

area and compression set values decreases. important one, since it gives the product the desired

characteristics to make it suitable for further

INTRODUCTION processing and use by the consumer [3]. Karmakar

Spacer fabrics are three dimensional textile structures explained heat-setting as a heat treatment by which

consisted of two parallel knitted fabrics connected by shape retention, crease resistance, resilience and

a yarn layer called as spacer yarn. The spacer yarn elasticity are imparted to the fibres. It also brings

plays an important role of fabric’s special changes in strength, stretchability, softness,

characteristics. With these special properties like dyeability and sometimes on the colour of the

compression and impact resistance, high material [4]. According to Gacén et.al., heat-setting

breathability, high elastic recovery characteristic, improves the properties of the textile substrate

spacer fabrics offer a lot of possibilities in various (improves shrinkage resistance, removes any creases,

application areas such as medical textiles, automotive guarantees level dyeing and improves the fabric

textiles, geotextiles, protective textiles, sportswear handle) [3]. Militký states in his study the purpose of

and composites. It is possible to produce these fabrics the heat-setting process supported by Mukhopadhyay

by weaving or nonwoven techniques besides warp and Gacén et al. as stabilization of fibre dimensions,

and weft knitting processes. Knitting technology relaxation of internal stresses in the fibre and creation

especially warp knitting technique is the most or stabilization of the crystalline structure [3,5,6].

commonly known and applied technology for the The heat-setting process, which assists in improving

production of spacer fabrics [1]. the morphology of the fibre, is determined by the

Journal of Engineered Fibers and Fabrics 64 http://www.jeffjournal.org

Volume 11, Issue 3 – 2016

temperature, duration of heat-setting, the tension PLA and PET fabrics has been significantly reduced

applied to the substrates during heat-setting and the after dyeing, drying, heat-setting and softening

medium of heat-setting (air, solvents or water) [7]. processes [16]. Jiang et al. investigated the process of

Even a slightest variation in heat-setting conditions, warp knitting mesh for hernia repair and also its

namely temperature, time and tension influence the mechanical properties. They tried various heat-setting

setting effect on the mechanical behaviour of fabrics, conditions and they found that the pushing strength is

regardless of the system used. Basically, heat-setting up to 540N after heat-setting, and 10% higher than

involves the interaction between time and the fabric before heat-setting. The widthwise

temperature, the influence of temperature being more shrinkage in 100°C for 60 minutes is down to 1.5%

important than that of time. The tension at which from 6% before heat-setting. At the same time, the

heat-setting is applied is also an important variable of lengthwise shrinkage is decreased from 4% before

this process [3].The structural and morphological heat-setting to 0.65%. In addition, other advantages

changes due to heat-setting are presented in the are obtained from the heat-setting, improving in the

review by Gupta [8]. handle and increasing in the softness of the fabric

[17]. Idumah and Nwachukwu studied the effect of

Various researchers proposed the heat-setting time of heat-setting and wet processes on the tensile

conditions of polyester fabrics with different values. properties (fabric extension, linearity of load

According to Karmakar, polyester goods are pre-set extension, tensile energy and tensile resilience) of

with hot air on pin stenters for 20-40 sec at 180- PLA and PET fabrics using the KES-FB [7]. Yang

210°C according to the type, density and weight of and Kan examined the effect of heat-setting

the material, with minimum tension on the goods to parameters (treatment time, treatment temperature,

control the dry heat stability less than the accepted and tension) on shrinkage after dyeing and colour

1% shrinkage [4]. Gacén et al. mentioned that, heat- yield of PLA knitted fabric. The results revealed that

setting of polyester (PET) fabrics is usually applied at lower shrinkage and higher colour yield can be

temperatures between 160 and 220°C, and times achieved when: heat-setting time=60 s; heat-setting

within the range of 30-120 seconds [3]. Idumah and temperature=130°C; and tension=0%. After that, the

Nwachukwu stated that, for PET, heat-setting occurs PLA knitted fabric was treated under the optimum

at temperatures of 130-140°C in steam or 190-220°C heat-setting condition and was dyed with 1% depth

in dry air in the presence of some tension and since disperse dye, which produced a better dyeing result.

Tg of PET is approximately 80°C, heat-setting of However, the handle of the heat set PLA knitted

PET above its Tg would allow the polymer structure fabric became stiffer and more resistant to shearing

to attain dimensional stability [7]. The general movement and had worse drape and bending

expectations to determine the heat-setting conditions recovery ability, while the appearance became

are that polyester fabrics are effectively fluffier and rougher [18]. Borhani et al. investigated

dimensionally stable if it is set at a temperature of 30- the influence of some parameters such as the kind of

40°C higher than the temperature to which the fibre is spacer threads and also heat-setting under drawing on

subjected to expose during subsequent processes so moisture transport properties of spacer fabrics. They

as to ensure the fabric attains dimensional stability [4, found that, heat-setting under drawing affects the

7, 8]. fabric dimensional properties and heat-setting under

drawing of spacer fabrics increases the porosity and

The effect of different setting treatment (heat-setting, air permeability of sample while decreases the

presetting, vacuum steaming process) on the thickness and mass per unit area of sample. The heat-

physical, mechanical and dyeability properties of set sample with higher porosity and air permeability

different yarn types were examined by various has higher moisture transfer [19].

researchers [9-15]. Avinç et al. studied a

mathematical model to compare the handle of In this study, it is aimed to investigate the effect of

polylactic acid (PLA) and polyethylene terephthalate heat-setting conditions on the performance

(PET) fabrics throughout finishing steps. They characteristics of the warp knitted spacer fabrics.

measured low stress tensile, shear, bending, Mass per unit area, thickness, air permeability,

compression and surface properties by using the compressibility, dimensional stability and

KES-FB. The results revealed that the mechanical compression set properties were measured and

and surface properties as well as handle of PLA and evaluated statistically in order to determine the

PET fabrics change significantly after different effects of heat-setting conditions such as temperature,

finishing stages. The difference between handle of duration of heat-setting and stretching (the tension

applied to the samples during heat-setting) on the

performance characteristics.

Journal of Engineered Fibers and Fabrics 65 http://www.jeffjournal.org

Volume 11, Issue 3 – 2016

EXPERIMENTAL

Fabric Production diameter was used as spacer yarn to connect two

Spacer fabrics were knitted on a Karl Mayer RD 6 outer layers. Yarn and machine details are listed in

double-needle bar raschel machine equipped with six Table I. The distance between the needle bars of

yarn guide bars (GB). While a 150D/48x4 polyester machine was set at 12.5 and 15 mm to produce the

PTY and 300D/72x3 polyester PTY multifilaments samples in two thicknesses. Surface and cross-

were used to create the top outer and bottom outer sectional views of a fabric before and after heat-

layers. A polyester monofilament of 0.243 mm in setting process are given in Figure 1.

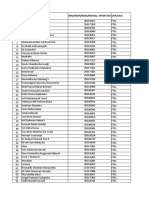

TABLE I. Yarn and machine details.

Layers Guide bars Chain notation Threading Yarn

2-2 / 2-2 / 0-0 / 0-0 / 2-2 / 2-2 / 0-0 / 0-0 /

GB1 2-2 / 2-2 / 1-1 / 1-1 / 3-3 / 3-3 / 1-1 / 1-1 / Half PES PTY 150D/48x4

Top layer

3-3 / 3-3 / 1-1 / 1-1 //

GB2 0-1 / 1-1 / 1-0 / 0-0 // Full PES PTY 300D/72x3

0.243 mm polyester

GB3 Half

Spacer 0-1 / 0-1 / 1-0 / 1-0 // monofilament

yarn 0.243 mm polyester

GB4 Half

0-1 / 0-1 / 1-0 / 1-0 // monofilament

GB5 0-0 / 0-1 / 1-1 / 1-0 // Full PES PTY 300D/72x3

Bottom 1-1 / 2-2 / 2-2 / 0-0 / 0-0 / 2-2 / 2-2 / 0-0 /

layer GB6 0-0 / 2-2 / 2-2 / 1-1 / 1-1 / 3-3 / 3-3 / 1-1 / Half PES PTY 150D/48x4

1-1 / 3-3 / 3-3 / 1-1 //

(a) (b) (c)

(d) (e) (f)

FIGURE 1.(a, d) Surface views of a sample before and after heat-setting process, (b, e) cross-section views along the course direction before and

after heat-setting process, (c, f) cross-section view along the wale direction of a sample before and after heat-setting process.

Brückner (Vn-Sfp-24/6-Q99) heat-setting machine samples during heat-setting was arranged so that the

was used in order to increase the structural stability final width of the samples will be 110 and 160 cm

and to achieve a determined final width (stretching). while the width of unset fabrics which refers to the

The samples were horizontally (course-wise) pinned fabric width after knitting process was 60 cm. After

on the sliding aluminium frame pins and heat set at heat-setting, the fabric samples were allowed to cool

the temperatures of 150°C and 180°C for time down at room temperature for 24 hours. Details of

durations of 1.8 and 3min. The tension applied to the heat-setting process were given in Table II.

Journal of Engineered Fibers and Fabrics 66 http://www.jeffjournal.org

Volume 11, Issue 3 – 2016

The performance characteristics of heat-set samples The dimensional stability of a fabric determines

and unset samples referred to fabric taken from the whether a fabric has the potential to retain its original

knitting machine were compared and analysed shape and remain stable, indicating it will not bubble

statistically. or sag over time, when applied over a substrate, and

its suitability for a specified use. Dimensional

TABLE II. Details of heat-setting process. stability was tested according to the DIN 53377

standard. The samples are cut into square form of 10

Distance

Duration of Temperature x10 cm and are placed in an oven maintained at 90°C

between the Stretching

Nr. heat-setting of heat-

needle bars (cm) for 1h. The dimensional stability value was

(min) setting (0 C)

(mm) calculated according to the Eq. (1):

1 12.5 - - 60

2 12.5 3 180 110 (l O − l F ) (1)

Dimensional stability (%) = x100

3 12.5 1.8 180 110 lO

4 12.5 1.8 180 160

5 12.5 1.8 150 110 where lo: The original dimensions of the specimen

6 15 - - 60

lF: The dimensions of the specimen after

treatment

7 15 3 150 160

8 15 3 150 110

The compression set is the difference between the

9 15 3 180 160 initial thickness and the final thickness of a test piece

10 15 1.8 150 160 of the material after compression for a given time at a

given temperature and after a given recovery time

Fabric Tests and is determined according to TS 2013 EN ISO

Mass per unit area values were measured according 1856 standard. The samples (50x50x25 mm) are

to the TS EN 12127 standard. compressed at a rate of 75% and are placed in an

oven maintained at 70°C for 22h. The compression

Air permeability is the rate of air flow passing set value was calculated according to the Eq. (2):

perpendicularly through a known area under a

prescribed air pressure differential between the two (d O − d r ) (2)

Compression set (%) = x100

surfaces of a material. Air permeability values were dO

obtained by using Textest FX 3300 instrument

according to TS 391 EN ISO 9237. Its principle where do: The original thickness of the specimen

depends in the measurement of air flow passing dr: The thickness value of the specimen

through the fabric at certain pressure gradient Δp. waited for ½ h after experiment

The results of the measurements are averages from

the values of 10 readings. As statistical evaluation ANOVA and Duncan

multiple comparison tests were applied (p=0.05).

Compression stress or compressibility can be defined

as a decrease of initial thickness that occurs with an RESULTS AND ANALYSIS

appropriate increase of compressive force. Initial The performance characteristics of the samples are

thickness is considered as the thickness without given in Table III. The statistical analysis of the

applied force on the fabric surface [20]. samples’ characteristics (Mass per unit area, air

Compressibility tests were carried out by Zwick Z010 permeability, compressibility) showed that, there is a

Instrument based on the ISO 3386 standard. The significant difference (p=.000) between the samples

instrument is composed of a rectangular presser foot for all groups (Table IV). In Table III, the mean

with a contact area of 40x40 cm2, which moves values are marked with the letters ‘a’, ‘b’ and ‘c’ (‘a’

vertically at a speed of 100 mm/min. 2.5 kN was shows the lowest value and ‘c’ shows the highest

applied to the samples and the set compression rate is value). Any levels marked by the same letter showed

40%. The results are averages of 3 readings in kPa. that they were not significantly different.

Journal of Engineered Fibers and Fabrics 67 http://www.jeffjournal.org

Volume 11, Issue 3 – 2016

TABLE III. Performance characteristics of the samples.

Distance

between the Mass per unit Thickness Air Perm. Compressibility Dim. stability Comp. set

Heat-setting conditions SD* SD* SD* SD*

needle beds area (g/m2 ) (mm) (lt/m2s) (kPa) % (% )

(mm)

Unset 1409.86(b) 14.26 11.43 0.077 1462(a) 82.92 4.31(a) 0.276 -1 39.73

Duration (min)

12.5 1.8 711.58(a) 14.46 11.14 0.045 5859(b) 115.45 16.45(b) 0.829 -3 25.52

3 685.6(a) 28.42 11.16 0.049 5994(b) 127.76 17.49(b) 0.434 -3 28.51

Unset 1512.61(b) 28.47 12.35 0.045 1548(a) 54 0.15(a) 0.16 -2 37.3

15

1.8 588.83(a) 6.35 12.76 0.073 6614(b) 106.79 8.74(b) 0.11 -3 33.4

3 578.85(a) 8.72 12.74 0.037 6739(b) 219.88 9.95(b) 0.073 -3 35.98

Unset 1409.86(c) 14.26 11.43 0.077 1462(a) 82.92 4.31(a) 0.276 -1 39.73

Stretching (cm)

12.5 110 711.58(b) 14.46 11.14 0.045 5859(b) 115.45 16.45(c) 0.829 -3 25.52

160 515.26(a) 11.54 10.67 0.07 6807(c) 137.19 11.96(b) 0.166 -3 27.56

Unset 1512.61(c) 28.47 12.35 0.045 1548(a) 54 0.15(a) 0.16 -2 37.3

15 110 731.04(b) 27.47 12.63 0.005 5644(b) 93.081 12.45(c) 0.475 -3 34.47

160 578.85(a) 8.72 12.74 0.037 6739(c) 219.88 9.95(b) 0.073 -3 35.98

Unset 1409.86(b) 14.26 11.43 0.077 1462(a) 82.92 4.31(a) 0.276 -1 39.73

Temperature ( C)

12.5 150 721.89(a) 9.79 11.41 0.056 5587(b) 90.01 13.71(b) 0.136 -3 28.02

0

180 711.58(a) 14.46 11.14 0.045 5859(c) 115.45 16.45(c) 0.829 -3 25.52

Unset 1512.61(b) 28.47 12.35 0.045 1548(a) 54 0.15(a) 0.16 -2 37.3

15 150 578.85(a) 8.72 12.74 0.037 6739(b) 219.88 9.95(b) 0.073 -3 35.98

180 553.28(a) 5.46 12.56 0.014 7009(c) 127.39 8.69(b) 0.139 -3 34.18

* Standard Deviation

TABLE IV. Statistical evaluation (p values) of the samples’ characteristics.

Duration (min) Stretching (cm) Temperature (0 C)

Unset – 1.8 – 3 Unset – 110 – 160 Unset – 150 – 180

Distance between the needle bars (mm) 12.5 15 12.5 15 12.5 15

Mass per unit area 0 0 0 0 0 0

Air permeability 0 0 0 0 0 0

Compressibility 0 0 0 0 0 .054*

*This p value is not statistically significant for α=0.05

The mean values of the mass per unit area showed knitting, the spacer yarns tended to relax into bended

that (Table III), unset fabrics have higher mass per forms. The bending of the spacer yarns resulted in the

unit area values and these values significantly decreasing of the fabric thickness.

decreased after heat-setting process. Statistical

From Figure 2, it can be seen that, heavier unset

evaluation revealed that, heat-setting temperature and

fabrics have lower air permeability values than heat-

duration of heat-setting parameters didn’t have any

set samples. Heat-setting process influences

significant effect on this parameter, on the other hand

statistically the air permeability values of the samples

the tension applied to the samples during heat-setting

significant, as shown in Table IV. While duration of

determined the surface structure and mass per unit

heat-setting doesn’t affect this parameter, heat-setting

area characteristics of the samples. The greater the

temperature and the tension or stretching creates

tension, the higher is the final width of the samples.

differences between air permeability values of the

Consequently, the holes became on fabric surface and

samples. With the increase of the final width of the

the amount of yarn per unit area is decreased.

samples, the size of holes on fabric surface and air

permeability of the samples increases also. The

It was found that the thicknesses of all fabrics were

bigger pores on the surface layer after stretching lead

smaller than the distance set (12.5 and 15 mm)

to passing of the air easily through the fabric

between the two needle bars of the machine. This is

surfaces. Additionally, the air permeability values of

an expected situation because during knitting process,

the fabrics increase as the heat-setting temperature

the spacer yarns were under tensioned states. After

Journal of Engineered Fibers and Fabrics 68 http://www.jeffjournal.org

Volume 11, Issue 3 – 2016

increases as well. It seems possible that these results

are due to decrease of mass per unit area and

thickness. As the fabrics get lighter and thinner, the

amount of air passed through the fabric increases.

FIGURE 3.Compressibility values of the samples.

The dimensional stability characteristics of the

fabrics were measured in both directions: wale-wise

and course-wise. Figure 4 illustrated the dimensional

FIGURE 2. Air permeability values of the samples. stability values in course-wise. According to DIN 53

377, the acceptable limit value of dimensional

Compressibility characteristic of fabrics, along with stability for both directions is ± 3%. The results

the bending, tensile, shear, and surface characteristics indicated that, 3% shrinkage occurred in course

are closely related to fabric handle, drape, and direction after heat-setting, whereas there was no

sewability properties. A fabric that compresses easily dimensional change in wale direction for all fabrics.

is likely to be judged as soft, possessing a low Unset fabrics had lower dimensional change than

compression modulus or high compression [20]. The heat-set fabrics. It could be seen from Figure 4 and

force necessary to compress a fabric has to overcome Table III; heat-setting conditions didn’t have any

the internal stresses of the fibres and the inter-fibre effect on the dimensional stability attributes of the

frictional force [21]. According to Figure 3, the samples.

lowest compressibility values were obtained from

unset fabrics. Also the results indicated that, the

compressibility characteristics decreased as the

thickness values increased. There is statistically

significant difference between the unset and heat-set

samples, as illustrated in Table IV. The parameters of

heat-setting temperature and stretching have

statistically effect on this parameter, whereas it has

not been affected by the duration of heat-setting. With

the increase of the final width of the samples, the

compressibility behaviours decreased. This situation

can be explained by higher mass per unit area values

of the fabrics stretched to 110 cm. When comparing

the effect of heat-setting temperature on this FIGURE 4.Dimensional stability values of the samples.

parameter, as the temperature increased, the

compressibility values increased for the fabrics Compression set value known as aging test is one of

whose distance between the needle beds arranged at the important factors determining the durability and

12.5 mm. Statistical analysis showed that (Table IV) lifetime of spacer fabrics. There is an inverse

there isn’t any significant difference for the fabrics relationship between the durability and compression

their thicknesses arranged at 15 mm. set characteristic of the fabrics. The higher the

Journal of Engineered Fibers and Fabrics 69 http://www.jeffjournal.org

Volume 11, Issue 3 – 2016

compression set, the lower is the durability of the this study, only the stretching parameter affected the

fabrics. It can be seen from Figure5 that, thinner mass per unit area values significantly. The higher

fabrics have lower compression set values, especially the stretching, the lower is the mass per unit area

after heat-setting process. Unset fabrics with higher values of the fabrics.

compression set values offer a shorter lifetime of the Heat-setting temperature and the tension or

fabrics. Heat-setting process has a significant effect stretching parameters create differences between air

for decreasing the compression set characteristic and permeability and compressibility values of the

consequently increasing the durability of the samples. samples while these parameters are not affected by

Additionally, the compression set values of the the duration of heat-setting. With the increase of the

samples increase as the parameters of duration of final width of the samples and the heat-setting

heat-setting and the stretching increase, whereas the temperature, the air permeability of the samples

increase of the heat-setting temperature leads to increased also. On the other hand the compressibility

decrease in compression set values of the samples. property has an inverse relationship with the final

With the increase in the duration of heat-setting, the width of the fabrics.

fabrics are exposed to longer periods of heat which 3% shrinkage occurred in course-wise for all

can reduce the durability of the materials. samples after the heat-setting process.

Additionally when the tension applied to the samples The most important parameter, affected the

during heat-setting increases, the compression set compression set and compressibility characteristics is

values of the fabrics increase as well due to the thickness of the samples. Thinner fabrics have lower

decrease of fibre content per unit area. The effect of compression set values, resulting higher durability

the heat-setting temperature on the compression set and long lifetime. Heat-setting process has a

characteristic can be explained with the increase of significant effect for decreasing the compression set

crystalline structures in the yarn. characteristic and consequently increasing the

durability of the samples. Additionally, the

compression set values of the samples increase as the

parameters of duration of heat-setting and the

stretching increase, whereas the increase of the heat-

setting temperature leads to decrease in compression

set values of the samples.

Due to the heat-setting process, spacer fabrics’

characteristics like compressibility, compression set

and breathability could be enhanced.

ACKNOWLEDGEMENT

The authors wish to thank Ames Tekstil A.Ş. and

Ekoten Tekstil A.Ş. for the supports of production

FIGURE 5. Compression set values of the samples. and heat-setting process and to Ege University

Scientific Research Project Office for the financial

CONCLUSION support of project (No. 12-MUH-050) and to Prof.

This study performs an investigation of the effect of Dr. Kerim Duran for his valuable contributions.

heat-setting conditions on the performance

characteristics of the warp knitted spacer fabrics. REFERENCES

Mass per unit area, thickness, air permeability, [1] Ertekin G. and Marmaralı A., “Heat, air and

compressibility, dimensional stability and water vapor transfer properties of circular

compression set properties were compared with the knitted spacer fabrics”, Tekstil ve

unset fabrics and evaluated statistically in order to Konfeksiyon, 21(4), 2011, 369-373.

determine the effects of heat-setting conditions such [2] Ye X., Hu H., and Feng X., “Development of

as temperature (150°C vs. 180°C), duration of heat- the warp knitted spacer fabrics for cushion

setting (1.8 vs. 3 min) and stretching (110 vs. 160 applications”, Journal of Industrial Textiles,

cm) (the tension applied to the samples during heat- 37 (3), 2008, 213-223.

setting) on the performance characteristics. The [3] Gacén J., Cayuela D., Maillo J., and Gacén I.,

results have clearly demonstrated that: “Physico-chemical analytical techniques for

After heat-setting process, air permeability and evaluation of polyester heatsetting”, The

compressibility values increased while mass per unit Journal of the Textile Institute, 93 (1), 29

area and compression set values decreased. (2002).

Among the heat-setting conditions examined in

Journal of Engineered Fibers and Fabrics 70 http://www.jeffjournal.org

Volume 11, Issue 3 – 2016

[4] Karmakar S.R., “Chemical technology in the [16] Avinç O., Khoddami A. and Hasani H., “A

pre-treatment processes of textiles”, Textile mathematical model to compare the handle of

Science and Technology, 12, 1999, 259. PLA and PET knitted fabrics after different

[5] Militky J., “Handbook of tensile properties of finishing steps” Fibers and Polymers, 12(3),

textile and technical fibers”, Woodhead 2011, 405-413.

Publishing, Edited by Bunsell A.R., 2009, [17] Jiang G. M., Xuhong M. and Dajun L., “Process

251-259. of warp knitting mesh for hernia repair and its

[6] Mukhopadhyay S.K., “Advances in fibre mechanical properties”, Fibres & Textiles in

science”, The Textile Institute Manchester, Eastern Europe, 13(3), 2005, 44-46.

1992, 115. [18] Yang R. H. and Kan C. W., “Effect of heat

[7] Idumah C.I. and Nwachukwu A.N., setting parameters on some properties of PLA

“Comparative analysis of the effect of knitted fabric”, Fibers and Polymers, 14(8),

heatsetting and wet processes on the tensile 2013, 1347-1353.

properties of Poly Lactic Acid (PLA) and [19] Borhani S., Seirafianpour S., Ravandi S.A.H.,

Poly Ethylene Terephthalate (PET) knitted Sheikhzadeh M. and Mokhtari R.,

fabrics”, International Journal of Materials, “Computational and experimental

Methods and Technologies, 1(4), 2013, 45-64. investigation of moisture transport of spacer

[8] Gupta V.B., “Heat setting”, Journal of Applied fabrics”, Journal of Engineered Fibers and

Polymer Science, 83, 2002, 586-609. Fabrics, 5(3), 2010, 42-48.

[9] Şardağ S., Kanık M. and Özdemir Ö., “The [20] Murthyguru I., “Novel approach to study

effect of vacuum steaming processes on compression properties in textiles” Autex

physical and dyeability properties of Research Journal, 5(4), 2005, 176-193.

polyamide 6 yarns”, Textile Research [21] Huang W. and Ghosh T.K., “Online

Journal, 80(15), 2010, 1531-1539. measurement of fabric mechanical properties:

[10] Şardağ S., Kanık M. and Özdemir Ö., “The compressional behavior”, Textile, Fiber and

effects of vacuum steaming process Film Industry Technical Conference, 1, 1999.

parameters on tenacity properties of cotton

and viscose yarns”, Tekstil ve Konfeksiyon, 4, AUTHORS’ ADDRESSES

2011, 343-348. Gözde Ertekin, PhD

[11] Rudolf A., Geršak J. and Sfiligoj Smole M., Arzu Marmarali

“The effect of heat treatment conditions using Ege University

the drawing process on the properties of PET Department of Textile Engineering

filament sewing thread”, Textile Research Bornova

Journal, 82(2), 2011, 161-171. İzmir, İzmir 35100

[12] Şardağ S. and Özdemir Ö., “The effects of TURKEY

tandem and conventional vacuum steaming

methods on the properties of yarns”, Textile

Research Journal, 82(2), 2012, 183-194.

[13] Suesat J., Phillips D.A.S., Wilding M.A. and

Farrington D.W., "The influence of yarn-

processing parameters on the tensile

properties and structure of poly (l-lactic acid)

fibres."Polymer, 44(19), 2003, 5993-6002.

[14] Şardağ S., Özdemir Ö. and Kara İ., “The effects

of heat-setting on the properties of

polyester/viscose blended yarns”, Fibres &

Textiles in Eastern Europe, 15(4), 2007, 50-

53.

[15] Atav R., Çay A., Körlü A.E. and Duran K.,

“Comparison of the effects of various

presettings on the colour of polyamide 6.6

dyed with acid dyestuffs." Coloration

Technology, 122, 5, 2006, 277-281.

Journal of Engineered Fibers and Fabrics 71 http://www.jeffjournal.org

Volume 11, Issue 3 – 2016

Vous aimerez peut-être aussi

- Cotton, Linen & More Fabric GuideDocument33 pagesCotton, Linen & More Fabric GuideShabana Waqar100% (1)

- UNSCEAR 2000 Report Vol.I PDFDocument659 pagesUNSCEAR 2000 Report Vol.I PDFAlejandraGomezPas encore d'évaluation

- 2018 09 01 - Knitting PDFDocument132 pages2018 09 01 - Knitting PDFandreviolino100% (5)

- Toxicity of Synthetic Fibres & HealthDocument4 pagesToxicity of Synthetic Fibres & HealthAustin Publishing GroupPas encore d'évaluation

- ATY Fabric PropertiesDocument5 pagesATY Fabric PropertiesHitesh ShahPas encore d'évaluation

- Daraje GarmentDocument52 pagesDaraje GarmentTesfaye Degefa100% (5)

- Textile Testing: Presented By: Nisha Sangle Ankita Desai Poonam Patil Gayathri RangnathanDocument23 pagesTextile Testing: Presented By: Nisha Sangle Ankita Desai Poonam Patil Gayathri RangnathanChaaya AaldarPas encore d'évaluation

- AATCC Test Method 15Document2 pagesAATCC Test Method 15Tauqeer RazaPas encore d'évaluation

- Investigation of Air Permeability of Cotton & Modal Knitted FabricsDocument6 pagesInvestigation of Air Permeability of Cotton & Modal Knitted FabricsAhmad SamerPas encore d'évaluation

- Spreading MachinesDocument23 pagesSpreading MachinesManish SinghPas encore d'évaluation

- Study of Structure and Properties of Air Jet Textured YarnDocument15 pagesStudy of Structure and Properties of Air Jet Textured Yarnpraveen kumarPas encore d'évaluation

- Heatsetting 140503095740 Phpapp01Document15 pagesHeatsetting 140503095740 Phpapp01Mardiyya Suleiman100% (1)

- Fabric Types and CareDocument58 pagesFabric Types and CareAnissa Manlangit100% (1)

- Technology and Livelihood Education: Quarter 1 - Module 4 Prepare and Cut Materials For Ladies SkirtDocument22 pagesTechnology and Livelihood Education: Quarter 1 - Module 4 Prepare and Cut Materials For Ladies SkirtMERCADER, ERICKA J100% (1)

- Study On Different Types of Dyeing Faults PDFDocument10 pagesStudy On Different Types of Dyeing Faults PDF呂仲書Pas encore d'évaluation

- Project Report On Medical Cotton Manufacturing PlantDocument10 pagesProject Report On Medical Cotton Manufacturing PlantSachin SharmaPas encore d'évaluation

- The Effect of Heat-Setting Conditions On The Performance Characteristics of Warp Knitted Spacer FabricsDocument8 pagesThe Effect of Heat-Setting Conditions On The Performance Characteristics of Warp Knitted Spacer Fabricszeeshan arifPas encore d'évaluation

- International Journal of Clothing Science and Technology: Article InformationDocument13 pagesInternational Journal of Clothing Science and Technology: Article InformationRakhsh KhorvashPas encore d'évaluation

- 2007-4-50-The Effects of Heat SettingDocument4 pages2007-4-50-The Effects of Heat SettingSampurna DasPas encore d'évaluation

- Study of Thermal Comfort Properties of CottonRegenDocument8 pagesStudy of Thermal Comfort Properties of CottonRegenpriyaPas encore d'évaluation

- Parative FullDocument10 pagesParative FullTJPRC PublicationsPas encore d'évaluation

- Heat SettingDocument14 pagesHeat SettingMardiyya SuleimanPas encore d'évaluation

- Ijftr 34 (2) 137-143Document7 pagesIjftr 34 (2) 137-143Mohammad HussainPas encore d'évaluation

- Research Article: Effect of Fibers and Weave Designs On The Thermo-Physiological Comfort of Summer Scarf FabricDocument8 pagesResearch Article: Effect of Fibers and Weave Designs On The Thermo-Physiological Comfort of Summer Scarf FabricMuqarab Hassan 0140Pas encore d'évaluation

- Investigating The Effect of Some Fabric Parameters On The Thermal Comfort Properties of Flat Knitted Acrylic Fabrics For Winter WearDocument11 pagesInvestigating The Effect of Some Fabric Parameters On The Thermal Comfort Properties of Flat Knitted Acrylic Fabrics For Winter WearSudipto BeheraPas encore d'évaluation

- A Comparative Study of The Thermal Insulation Properties of Jute and Jute - Polyester Fibre Blended Nonwoven FabricsDocument7 pagesA Comparative Study of The Thermal Insulation Properties of Jute and Jute - Polyester Fibre Blended Nonwoven FabricsAJER JOURNALPas encore d'évaluation

- Thermoplastic Film Infusion Process For Long-Fiber Reinforced Composites Using Thermally Expandable Elastomer ToolsDocument8 pagesThermoplastic Film Infusion Process For Long-Fiber Reinforced Composites Using Thermally Expandable Elastomer ToolsabiliovieiraPas encore d'évaluation

- Ftee 64 94 PDFDocument3 pagesFtee 64 94 PDFErvinBabicPas encore d'évaluation

- Low Melt PET Blend With Nonrmal Fiber NonwovenDocument11 pagesLow Melt PET Blend With Nonrmal Fiber Nonwovenjothi vel muruganPas encore d'évaluation

- Simulation of The Effects of Structural Parameters of Glass Fiber Fabric On The Thermal Insulation PropertyDocument11 pagesSimulation of The Effects of Structural Parameters of Glass Fiber Fabric On The Thermal Insulation PropertyhawPas encore d'évaluation

- Multi-layered Knitted Fabrics for Thermal InsulationDocument12 pagesMulti-layered Knitted Fabrics for Thermal InsulationSudipto BeheraPas encore d'évaluation

- Bond Structure and Tensile Properties of Thermal Bonded Polypropylene NonwovensDocument5 pagesBond Structure and Tensile Properties of Thermal Bonded Polypropylene NonwovensSEP-PublisherPas encore d'évaluation

- A Study of The Thermal Properties of Bamboo Knitted Fabrics PDFDocument7 pagesA Study of The Thermal Properties of Bamboo Knitted Fabrics PDFPrakash ChidamabaramPas encore d'évaluation

- Studying Effects of Fabric Thickness, Loop Shape Factor, Fabric Tightness Factor and Aerial Weight On Thermal Conductivity of Plain Single Jersey Cotton Knitted Fabric Using Box Behnken DesignDocument8 pagesStudying Effects of Fabric Thickness, Loop Shape Factor, Fabric Tightness Factor and Aerial Weight On Thermal Conductivity of Plain Single Jersey Cotton Knitted Fabric Using Box Behnken DesignIJEACS UKPas encore d'évaluation

- Thermal Comfort Properties of Bifacial FabricsDocument9 pagesThermal Comfort Properties of Bifacial FabricspriyaPas encore d'évaluation

- Nonwoven Kumaşların Kalender Yöntemiyle Birleştirilmesinde Kalender Sıcaklığı Ve Kumaş Katman Sayısının Kumaş Performansına EtkisiDocument11 pagesNonwoven Kumaşların Kalender Yöntemiyle Birleştirilmesinde Kalender Sıcaklığı Ve Kumaş Katman Sayısının Kumaş Performansına EtkisiutkayPas encore d'évaluation

- PCMonwool2019 IOP Conf. Ser. Mater. Sci. Eng. 577 012114 PDFDocument11 pagesPCMonwool2019 IOP Conf. Ser. Mater. Sci. Eng. 577 012114 PDFGurumurthy BRPas encore d'évaluation

- Heat Setting Fabrics for Dimensional StabilityDocument5 pagesHeat Setting Fabrics for Dimensional StabilityFathi MustafaPas encore d'évaluation

- Pan2015 PDFDocument18 pagesPan2015 PDF128mansouriPas encore d'évaluation

- 239 Change of Temperature of Cotton and Polyester Fabrics in Wetting and Drying ProcessDocument14 pages239 Change of Temperature of Cotton and Polyester Fabrics in Wetting and Drying ProcesspriyaPas encore d'évaluation

- Prakash 2013Document9 pagesPrakash 2013haremboraPas encore d'évaluation

- Ijftr 41 (2) 167-172Document6 pagesIjftr 41 (2) 167-172Vo Dai TienPas encore d'évaluation

- Influence of tuck stitch placement on thermal comfort of layered knitsDocument11 pagesInfluence of tuck stitch placement on thermal comfort of layered knitssrini_kalmulaPas encore d'évaluation

- Effect of Lycra Percentages and Loop Length On The PDFDocument8 pagesEffect of Lycra Percentages and Loop Length On The PDFDyeing DyeingPas encore d'évaluation

- Analysis of The Heat Setting ProcessDocument9 pagesAnalysis of The Heat Setting ProcessMardiyya SuleimanPas encore d'évaluation

- Bursting Strengthof Knitted FabricsDocument7 pagesBursting Strengthof Knitted FabricsAyman SebaeiPas encore d'évaluation

- Effect of Elastane Plating On Physical Thermal Comfort Properties of Lyocell Single Jersey Knit Fabric With Different Loop LengthDocument9 pagesEffect of Elastane Plating On Physical Thermal Comfort Properties of Lyocell Single Jersey Knit Fabric With Different Loop LengthMuhammad Bilal QadirPas encore d'évaluation

- Thermophysiological Comfort Properties of Different Knitted Fabrics Used in Cycling ClothesDocument9 pagesThermophysiological Comfort Properties of Different Knitted Fabrics Used in Cycling ClothespriyaPas encore d'évaluation

- The Effect of Fibre Blend On Comfort Characteristics of ElasticDocument7 pagesThe Effect of Fibre Blend On Comfort Characteristics of ElasticGeotamPas encore d'évaluation

- The Effects of Vacuum Steaming Process Parameters On Tenacity Properties of Cotton and Viscose YarnsDocument7 pagesThe Effects of Vacuum Steaming Process Parameters On Tenacity Properties of Cotton and Viscose YarnsMehulPas encore d'évaluation

- Advanced TechnologiesDocument7 pagesAdvanced TechnologiesSherin ShakerPas encore d'évaluation

- 577 6.4.3onofireDocument13 pages577 6.4.3onofirepriyaPas encore d'évaluation

- Ghasemi Nejhad 1993 Issues Related to Processability During the Manufacture of Thermoplastic Composites Using on LineDocument17 pagesGhasemi Nejhad 1993 Issues Related to Processability During the Manufacture of Thermoplastic Composites Using on Line1711076053Pas encore d'évaluation

- Comfort Aspects of Finished Polyester-Cotton and Polyester-Viscose Ring and MJS Yarn FabricsDocument7 pagesComfort Aspects of Finished Polyester-Cotton and Polyester-Viscose Ring and MJS Yarn FabricsAditya ShrivastavaPas encore d'évaluation

- Air-Jet Texturing PDFDocument0 pageAir-Jet Texturing PDFNessre ZeinePas encore d'évaluation

- 1 PBDocument6 pages1 PBmohitPas encore d'évaluation

- Cha-2018-Experimental Determination of The Viscoelastic Parameters of K-BKZ Model and The Influence of Temperature Field On The Thickness DistributionDocument11 pagesCha-2018-Experimental Determination of The Viscoelastic Parameters of K-BKZ Model and The Influence of Temperature Field On The Thickness DistributionTim OpatzPas encore d'évaluation

- 22 591.fullDocument15 pages22 591.fullpriyaPas encore d'évaluation

- Study On Thermal Treatment of Hybrid Technical Yarns: Fibers and Polymers February 2004Document7 pagesStudy On Thermal Treatment of Hybrid Technical Yarns: Fibers and Polymers February 2004Satish KulkarniPas encore d'évaluation

- Polymers: Modeling of Flexible Polyurethane Foam Shrinkage For Bra Cup Moulding Process ControlDocument13 pagesPolymers: Modeling of Flexible Polyurethane Foam Shrinkage For Bra Cup Moulding Process ControlMansi ChaudhariPas encore d'évaluation

- A Biomimic Thermal Fabric With High Moisture PermeabilityDocument6 pagesA Biomimic Thermal Fabric With High Moisture PermeabilitypriyaPas encore d'évaluation

- Paper (Total Appearance Value)Document8 pagesPaper (Total Appearance Value)ravibabayPas encore d'évaluation

- Noor2 PDFDocument10 pagesNoor2 PDFhendriqz679Pas encore d'évaluation

- DSDDocument4 pagesDSDIshwar DudagiPas encore d'évaluation

- Effect of Weave Structure on Air Permeability & SnaggingDocument8 pagesEffect of Weave Structure on Air Permeability & Snaggingzeyin mohammed aumerPas encore d'évaluation

- Dow Elastane Process Singeing FinishingDocument11 pagesDow Elastane Process Singeing Finishingadali2020Pas encore d'évaluation

- Bending and Compression Behaviour of Polyester Air-Jet-Textured and Cotton-Yarn FabricsDocument5 pagesBending and Compression Behaviour of Polyester Air-Jet-Textured and Cotton-Yarn Fabricsanil kapadiaPas encore d'évaluation

- Thermal Properties of 1×1, 2×2, 3×3 Rib Knit Fabrics: Nuray Uçar, Turgut YılmazDocument5 pagesThermal Properties of 1×1, 2×2, 3×3 Rib Knit Fabrics: Nuray Uçar, Turgut YılmazsatexPas encore d'évaluation

- Effect of Different Mercerization Techniques On Tactile Comfort of Cotton FabricDocument6 pagesEffect of Different Mercerization Techniques On Tactile Comfort of Cotton FabricAhmad ButtPas encore d'évaluation

- Maqsood-Seide2018 Article StatisticalModelingOfThermalPrDocument8 pagesMaqsood-Seide2018 Article StatisticalModelingOfThermalPrZaheer AhmadPas encore d'évaluation

- Template Izin-MasukDocument57 pagesTemplate Izin-MasukSarah FadhlillahPas encore d'évaluation

- Rand RR2912Document118 pagesRand RR2912behanchodPas encore d'évaluation

- Metoda Epidemiologi2021Document20 pagesMetoda Epidemiologi2021Sarah FadhlillahPas encore d'évaluation

- 1 SMDocument9 pages1 SMSarah FadhlillahPas encore d'évaluation

- Radiasi Foto Thorax pada AnakDocument51 pagesRadiasi Foto Thorax pada AnakSarah FadhlillahPas encore d'évaluation

- Efek Iklim Kerja Panas Pada Respon FisiologisDocument9 pagesEfek Iklim Kerja Panas Pada Respon FisiologisafifahPas encore d'évaluation

- Daftar PustakaDocument5 pagesDaftar PustakaSarah FadhlillahPas encore d'évaluation

- Jurnal FixDocument9 pagesJurnal FixSarah FadhlillahPas encore d'évaluation

- Howies Autumn2007Document66 pagesHowies Autumn2007KRAPas encore d'évaluation

- Standard Supply and Controls Instruction ManualDocument23 pagesStandard Supply and Controls Instruction ManualJohnsonDan0% (2)

- TLE - HEHN9 10 w1Document7 pagesTLE - HEHN9 10 w1Erlyn AlcantaraPas encore d'évaluation

- CRISIL Research Cust Bulletin Jan12Document20 pagesCRISIL Research Cust Bulletin Jan12cse10vishalPas encore d'évaluation

- As 2001.2.21-1989 Methods of Test For Textiles Physical Tests - Determination of Seam Opening Due To The ApplDocument2 pagesAs 2001.2.21-1989 Methods of Test For Textiles Physical Tests - Determination of Seam Opening Due To The ApplSAI Global - APACPas encore d'évaluation

- As 4142.3-1993 Fibre Ropes Man-Made Fibre Rope For Static Life Rescue LinesDocument7 pagesAs 4142.3-1993 Fibre Ropes Man-Made Fibre Rope For Static Life Rescue LinesSAI Global - APACPas encore d'évaluation

- Airslide Fabric Technical SpecificationDocument1 pageAirslide Fabric Technical SpecificationFurqan ShabbirPas encore d'évaluation

- Docket 90 - 2Document4 pagesDocket 90 - 2denshul49Pas encore d'évaluation

- GSTR-2A Data Entry Instructions Worksheet Name GSTR-2A Table Reference Field NameDocument245 pagesGSTR-2A Data Entry Instructions Worksheet Name GSTR-2A Table Reference Field NameSONI ASSOCIATESPas encore d'évaluation

- KB Presentation EngDocument30 pagesKB Presentation EngPham Hiep HibPas encore d'évaluation

- Abel Traditional-ProductDocument16 pagesAbel Traditional-ProductgeronPas encore d'évaluation

- Vocabulary and Grammar Review - AsdDocument20 pagesVocabulary and Grammar Review - AsdPhương MaiPas encore d'évaluation

- Spreading Machines & EquipmentDocument70 pagesSpreading Machines & EquipmentRaghav GargPas encore d'évaluation

- Applications of Tensile Structures: A ReviewDocument91 pagesApplications of Tensile Structures: A ReviewSilhoutte IllusionPas encore d'évaluation

- Sample Object Clauses Industry WiseDocument37 pagesSample Object Clauses Industry WiseAnjali Rao Padhye67% (3)

- Mapeh 8Document3 pagesMapeh 8Lea BPas encore d'évaluation

- Bluesign Reference List TotalDocument18 pagesBluesign Reference List TotalmehediPas encore d'évaluation

- 177uster Quantum 3Document7 pages177uster Quantum 3Ae LiPas encore d'évaluation

- ArtDocument16 pagesArtAida Larisa GheorghinoiuPas encore d'évaluation