Académique Documents

Professionnel Documents

Culture Documents

Waukesha Sentron LD 500011 1 10

Transféré par

David PomaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Waukesha Sentron LD 500011 1 10

Transféré par

David PomaDroits d'auteur :

Formats disponibles

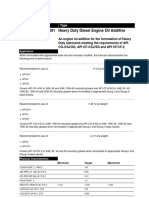

SERVICE BULLETIN

TOPIC: Lubrication System

IDENT NO: 12-1880AF

DATE: November 2010

SUPERSEDES: 12-1880AE

SUBJECT: Dresser Waukesha® Oil Recommendations

MODELS AFFECTED: All Dresser Waukesha Engines

SUMMARY INFORMATION AND INSTRUCTIONS

Use this service bulletin to identify the oil needs and Dresser Waukesha engines are heavy-duty industrial-

specifications of all Dresser Waukesha engines. type engines which require heavy-duty lubricating oils.

Listing is by current production model and fuel type. The basic requirements are high lubricating quality,

high thermal stability and good control of

This bulletin revision provides Dresser Waukesha’s

contaminants.

current lubricating oil recommendations as a

guideline. Dresser Waukesha’s engine product line consists of

spark-ignited industrial gas engines from the VSG

TABLE OF CONTENTS through the 16V275GL+ models. The lubricating oil

requirements and systems change greatly between

TOPIC................................................................ PAGE each model and fuel type.

Information and Instructions ..................................... 1

Lube Oil Performance............................................... 1 LUBE OIL PERFORMANCE

Oil Designations........................................................ 2

Supplementary Lube Oil Additives............................ 2 There are hundreds of commercial crankcase oils

Lube Oil Recommendations ..................................... 2 marketed today. Obviously, engine manufacturers or

users cannot completely evaluate the numerous

Catalyst Contaminants.............................................. 3

commercial oils. The performance of a lubricant, like

Lube Oil Filtration Requirements .............................. 3

that of any manufactured product, is the responsibility

Extended Lube Oil Drain Intervals ............................ 3 of the refiner and supplier. The Dresser Waukesha

Dresser Waukesha Cogeneration Installations......... 3 Warranty is limited to the repair or replacement of

12V/18V 220GL Installations .................................... 5 parts that fail due to defective material or workmanship

Sour Gas, Digester Gas, Alternative Fuel Gas during the warranty period. The Dresser Waukesha

and Landfill Gas Recommendations .................. 5 Warranty does not include responsibility for

Recommended Lube Oils for Landfill Gas satisfactory performance of the lubricating oil.

Applications ........................................................ 6

With the exception of cogeneration, the 220GL

Lube Oil Condemning Limits..................................... 7 products and special or prototype installations,

Lube Oil Viscosity Selection ..................................... 9 Dresser Waukesha has made it a practice not to

Multi-Viscosity Lube Oils......................................... 10 recommend oil by brand name.

Synthetic Lube Oils................................................. 10

Low Ambient Temperature Operation..................... 10 Dresser Waukesha strongly recommends monitoring

the condition of the engine oil through the use of a

Lube Oil Consumption Guidelines .......................... 10

good oil analysis program.

Formulas for Determining Lube Oil Consumption

Rate.................................................................. 11

Recommended Oil Change Intervals...................... 11

Service Bulletin 12-1880AF

© 11/2010 Page 1 of 13

Service Bulletin No. 12-1880AF

OIL DESIGNATIONS LUBE OIL RECOMMENDATIONS

Oil is designated in several ways: American Petroleum Dresser Waukesha recommends the use of oil

Institute (API), Society of Automotive Engineers formulated specifically for natural gas engines and

(SAE), American Society for Testing and Materials meeting minimum ash requirements based on engine

(ASTM) performance classifications and Military model. The ash-forming constituents in oil

Designation. Since no gas engine industry oil formulations provide detergency, corrosion protection

performance designations exist, it is the responsibility and anti-wear protection. In addition, the ash produced

of the engine operator to verify with their oil supplier during combustion of these additives will provide

that the oil they select has proven field performance in protection against valve face and seat recession.

their specific engine make and model. This oil must However, use of oils containing a higher ash level than

also meet the minimum requirements specified by specified in the tables may increase engine deposits

Dresser Waukesha as listed in the included tables. and decrease component life.

SUPPLEMENTARY LUBE OIL ADDITIVES NOTICE

Quality oils formulated specifically for natural gas Dresser Waukesha gas engines use specifically

engines have sufficient additives to meet formulated oils. Dresser Waukesha does not

requirements. Dresser Waukesha does not recommend gasoline or diesel oil formulations for

recommend the addition of oil additives to these lube use with its engines. Use of gasoline or diesel

oils. formulations may cause severe engine damage. The

Dresser Waukesha warranty is limited to the repair

or replacement of parts that fail due to defective

material or workmanship during the warranty period.

The Dresser Waukesha warranty does not provide

coverage for unsatisfactory performance of lube oil.

Table 1: Lube Oil Recommendations by Engine Model

GAS ENGINE MODELS SULFATED ASH WT% *, **, ***

VSG F11 G, GSI, GSID 0.35 – 1.0

F18, H24, L36, P48 G, GL, GLD/GLD/2 0.45 – 0.75

VGF

F18, H24, L36, P48, GSI, GSID 0.35 – 0.55

F2895, F3521, L5790, L7042, P9390 G, GSI, GL 0.35 – 1.0

VHP SERIES

F3524, L5794, L7044, GSI, L5774, L5794, LT 0.45 – 0.75

275GL/GL+

8L, 12V, 16V 0.35 – 1.0

AT25/27GL SERIES

16V150 LTD 0.4 – 0.55

APG SERIES

12V220 GL, 18V220 GL See Table 3

* Oils must be specifically formulated for gas engines using highly refined mineral oil base stocks. The ash requirements are a percentage by

weight with both metallic and ashless additive systems. A maximum of 0.10% zinc is recommended.

** Oil with 0.35% ash or less may be used in naturally aspirated and catalyst-equipped naturally aspirated or turbocharged engines with the

understanding that valve recession may occur, thus shortening the normally expected valve and seat life.

*** Use 1.0% ash oil for the VHP and AT engines only if needed due to higher than normal valve recession rates.

Service Bulletin 12-1880AF

Page 2 of 13 © 11/2010

Service Bulletin No. 12-1880AF

CATALYST CONTAMINANTS DRESSER WAUKESHA COGENERATION

INSTALLATIONS

The following contaminants are known catalyst

deactivators and should be avoided when selecting Dresser Waukesha does not ordinarily recommend

lubricating oils for installations with catalysts since lube oils by brand name. However, based on actual

they contribute to shortened catalyst life: heavy and field experience, the oils listed in Table 2 are specified

base metals such as lead, mercury, arsenic, antimony, for cogeneration installations with forced hot water

zinc, copper, tin, iron, nickel, chrome, sulfur and cooling systems at 212° – 265°F (100° – 129°C) or

phosphorus. Generally these individual elements ebullient cooling at 250°F (121°C).

should not exceed 1 ppm or collectively exceed 5 ppm

at the catalyst inlet. Specific exceptions: phosphorus It is especially important that the lube oils used in

or silicon compounds at the catalyst inlet are not to cogeneration applications utilize base stocks with

exceed 1 ppm and sulfur compounds at the catalyst good thermal stability. With a minimum of 4000+ hours

inlet are not to exceed 100 ppm. Always consult the of experience, the lube oils listed in Table 2 are known

catalyst supplier for specific recommendations for the to give satisfactory performance in high-temperature

catalyst being used. cooling systems applications.

Do not confuse the concentration of these elements in NOTE: See Table 1 for lube oil sulfated ash

the exhaust gas flow AT THE CATALYST INLET with recommendations for Dresser Waukesha gas engine

the concentration of these elements in the lube oil models.

itself. Additions to the list of approved lube oils may be made

with substantiating data for a lube oil meeting the

LUBE OIL FILTRATION REQUIREMENTS following criteria:

The quality of oil filtration will directly affect engine • Used in similar applications with 212° – 265°F (100°

component life. Dresser Waukesha’s basic filtration – 129°C) jacket water temperatures.

requirement is 90% efficient at 15 microns for all full-

• A minimum of 6 months operation with documented

flow sock and paper elements, and 98% efficient at 25

engine inspection data.

microns for fiberglass disposable and cleanable full-

flow metal mesh elements. Mesh or screen sizes • No signs of lube oil degradation, carbon or

larger than 25 microns are not acceptable. lacquering problems (based on normal lube oil

change intervals, the engine should be clean).

Lube oil filter elements should be changed when the

lube oil is changed or when the pressure drop across

the lube oil filter exceeds values stated in specific

engine maintenance manuals.

Dresser Waukesha’s complete oil filter performance

specifications are shown in Dresser Waukesha

Standard Sheets S-08486 and S-08486-1. Always see

the latest available version.

EXTENDED LUBE OIL DRAIN INTERVALS

Extended oil drain intervals are not recommended

unless the engine uses a functional Microspin®

centrifuge as well as Dresser Waukesha-supplied oil

filtration components. The Microspin centrifuge, in

conjunction with Dresser Waukesha-supplied oil

filtration components, will remove spent additives and

other by-products of combustion, allowing an increase

in scheduled lube oil drain and lube oil filter element

change intervals. Dresser Waukesha recommends

that a lube oil analysis program be used to determine

oil change intervals when condemning limits are

reached. See Table 5. See Table 12 and Table 13 for

the recommended maximum number of hours

between normal lube oil drain and lube oil filter

element changes without a lube oil analysis program.

Service Bulletin 12-1880AF

© 11/2010 Page 3 of 13

Service Bulletin No. 12-1880AF

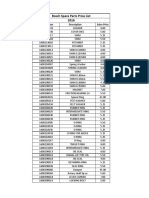

Table 2: Recommended Lube Oils for Cogeneration Applications (Using Pipeline Quality Gas)

BRAND TYPE PERCENT OF SULFATED ASH

Chevron HDAX Low Ash SAE 40 0.50

Estor Super

Exxon Co. USA, SAE 40 0.45

Exxon Co. International

Estor Elite (Synthetic)

Esso Imperial Oil, SAE 20W40 0.45

Exxon Co. USA

Estor Select 40

Esso Imperial Oil, SAE 40 0.95

Exxon Co. USA

Mobil Pegasus 1 (Synthetic) SAE 15W40 0.51

Mobil Pegasus 1005 SAE 40 0.54

Mobil Pegasus 905 SAE 40 0.54

Mobil Pegasus 805 SAE 40 0.54

Mobil Pegasus 710 (89) SAE 40 0.94

Petro Canada, Sentron CG40 SAE 40 0.92

Petro Canada Sentron LD 5000 SAE 40 0.57

Roloil Mahler HA (USA)

Roloil Mogas - AC (Italy) SAE 40 0.90

Q8 Mahler HA (rest of world)

Roloil Mahler MA (USA)

Roloil Mogas (Italy) SAE 40 0.50

Q8 Mahler MA (rest of world)

Shell Mysella MA

SAE 40 0.90

SIPC (Outside USA only)

Shell Mysella XL SAE 40 0.50

Repsol YPF

SAE 40 0.50

Vectis LA-540

Citgo Pacemaker GEO 1640 SAE 40 0.50

Conoco Elmar LA4 EXD SAE 40 0.50

76 Triton 5005 EXD SAE 40 0.50

Valvoline GEO LA40 SAE 40 0.58

Service Bulletin 12-1880AF

Page 4 of 13 © 11/2010

Service Bulletin No. 12-1880AF

12V/18V 220GL INSTALLATIONS It is especially important that the lube oils used in

cogeneration applications utilize virgin base stocks

Dresser Waukesha does not ordinarily recommend with good thermal stability. The lube oils listed in

lube oils by brand name for specific products. Table 3 are known to give satisfactory performance in

However, based on actual field experience, the lube high-temperature cooling system applications.

oils listed in Table 3 are specified for all 220GL

installations.

Table 3: Recommended Lube Oils for All 220GL Applications (Using Pipeline Quality Gas)

SULPHATED ASH (%W)

SUPPLIER BRAND NAME TYPE

ASTM D 874

Nateria MH 40 SAE 40 0.45

Total Nateria P 405 SAE 40 0.42

Nateria X 405 (Synthetic) SAE 15W40 0.45

Mobil Pegasus 705 SAE 40 0.49

Mobil Pegasus 805 SAE 40 0.54

Exxon Mobil Mobil Pegasus 905 SAE 40 0.54

Mobil Pegasus 1005 SAE 40 0.54

Mobil Pegasus 1 (Synthetic) SAE 15W40 0.51

Mysella LA SAE 40 0.45

Shell Mysella XL SAE 40 0.50

Texaco Geotex LA SAE 40 0.45

Chevron HDAX LA SAE 40 0.50

Castrol Duratec L SAE 40 0.45

BP Energas NGL SAE 40 0.45

Idemitsu Appolloil GHP 40L SAE 40 0.45

Petro-Canada Sentron LD 5000 SAE 40 0.57

Contact Dresser Waukesha Application Engineering Alternative fuel sources are attracting increasing

for the potential for additions to the list of approved interest today as a low-cost fuel or because of their

220GL oils. environmental benefits. However, there are issues that

arise due to the sulfur compounds (H2S, etc.),

SOUR GAS, DIGESTER GAS, siloxanes and halide constituents in these fuels.

ALTERNATIVE FUEL GAS AND LANDFILL Hydrogen sulfide (H2S), siloxanes and total organic

GAS RECOMMENDATIONS halide as chloride (TOH/CI) bring with them totally

different challenges for the engine and lube oil. See

the current version of S-07884-7, Gaseous Fuel

! WARNING Specification for Waukesha Engines, for additional

information.

Dresser Waukesha assumes no

!

liability or responsibility for The use of landfill, digester or other waste gas makes

potential damage to the the selection of an engine lube oil, lube oil analysis

environment or any personal injury and lube oil drain intervals far too complicated to

caused by using landfill gases or address completely here because the lube oil

sour gases as fuel. It is the engine requirements change as the TOH/Cl level increases.

owner’s/customer’s sole Anyone operating with landfill, digester or other waste

responsibility to carefully analyze gas must review the current version of S-07884-7,

any fuel gases they choose to use. Gaseous Fuel Specification for Waukesha Engines, to

Use of these gases is at the fully understand the ramifications of operating an

owner’s/customer’s own risk. engine with that type of fuel gas.

NOTE: Low BTU fuel gases 400-660 BTU/FT3 LHV

must meet the requirements specified in the current

version of Standard S-07884-7, Gaseous Fuel

Specification for Waukesha Engines. (Always see the

latest version.)

Service Bulletin 12-1880AF

© 11/2010 Page 5 of 13

Service Bulletin No. 12-1880AF

RECOMMENDED LUBE OILS FOR RECOMMENDATION #2

LANDFILL GAS APPLICATIONS Used lube oil analysis is mandatory for alternative fuel

applications. Lube oil change periods are determined

Dresser Waukesha recommends lube oil specifically by TBN (Total Base Number), TAN (Total Acid

formulated for landfill gas applications. Always follow Number), oxidation and nitration level in the used lube

the lube oil manufacturer’s instructions and do not use oil samples. The user must change the lube oil when

the oil beyond their recommendations. Some landfill the TBN level falls to 30% of the new lube oil value or

gas formulated lube oils can cause excessive buildup TAN increases by 2.5 – 3.0 above the new lube oil

of abnormal ash deposits in the combustion chamber value. The method of measuring TBN in used lube oil

when used outside of their recommendations. Landfill is shown in Table 5.

gas engine lube oils should only be used in engines

applied to landfill gas operation and not digester gas The DEXSIL® Corporation has developed the Q2000

operation. field test kit. This kit is used to determine the chlorine

contamination of engine lube oil exposed to chlorine

Table 4: Recommended Lube Oils – Landfill Gas

containing fuels such as landfill gas. This field test kit

Applications

is highly accurate and allows the operator to obtain

PERCENT OF timely test results in the field. The lube oil must be

BRAND TYPE

SULFATED ASH sampled every 50 hours in order to establish an initial

Mobil Pegasus 610 (446) SAE 40 0.98* “trend.” Dresser Waukesha has experienced good

Mobil Pegasus 605 (426) SAE 40 0.48 results with this kit. Ordering information may be

Chevron HDAX LFG SAE 40 0.71 obtained from the DEXSIL Corporation, One Hamden

Park Drive, Hamden, CT 06517.

* These lube oils have a higher sulfated ash level than specified in

Table 1 for the F18, H24, L36, P48, G, GSI, GSID, GL, GLD, GLD2

and F3524, L5794, L7044, GSI, L5774, L5794, LT Engines. These ! CAUTION

lube oils may be used but be aware that engine life cycle may

decrease due to an increase in engine deposits. TOH/CI does not affect TBN levels

!

the same as sulfur compounds.

The best approach to improving engine life cycle is to

filter out or absorb contaminants in the fuel gas before Therefore, the 30% TBN depletion

they reach the engine. There are various companies (50% TBN depletion on 220 GL

manufacturing and promoting gas filtration and engines) as an indicator of a

absorption processes. However, Dresser Waukesha change interval only applies to the

makes no endorsement of these products or services. applications where fuel gas does

Their performance is solely the responsibility of their not contain halides.

manufacturers.

The following lube oil recommendations will minimize RECOMMENDATION #3

corrosion problems normally encountered with fuel

gas containing H2S and TOH/CI: Increase the jacket water temperature to 210° – 235°F

(99° – 113°C) and lube oil temperature to 185° –

RECOMMENDATION #1 200°F (85° – 93°C). 275GL/GL+ and AT25/27GL

Select a gas engine lube oil with a high alkalinity series engines are limited to a maximum of 180°F

reserve, 7 to 13 TBN (Total Base Number). Alkalinity (82°C) lube oil temperature. 220GL series engines are

reserve in the lube oil is measured in TBN. The higher limited to a maximum of 212°F (100°C) jacket water

the TBN, the more reserve. outlet temperature, and 176°F (80°C) lube oil inlet

temperature. Increased temperatures will reduce

Contact your lube oil supplier for an appropriate condensation which will reduce the concentration of

choice. Also follow the appropriate ash content acids within the crankcase. High-temperature

percent by weight for the specific engine model. thermostats are available for most models.

Any question on lubricants to be used with alternative

fuel gases should be directed to the Field Service

Department or Sales Engineering Department prior to

selecting a lube oil.

Service Bulletin 12-1880AF

Page 6 of 13 © 11/2010

Service Bulletin No. 12-1880AF

LUBE OIL CONDEMNING LIMITS Lube oil condemning limits are established by the

engine manufacturer’s experience and/or used lube oil

testing. Laboratory testing, using the parameters

! WARNING shown in Table 5, will help determine the used lube

oil’s suitability for continued use.

Engine lube oil is extremely hot

and is under pressure. Use caution Before taking a lube oil sample, clean the sample

when sampling engine lube oil for outlet valve. This prevents any debris in the sample

analysis. outlet valve from contaminating the lube oil sample.

Draw the lube oil sample at engine operating

temperature before the full-flow lube oil filters.

Table 5: Used Lube Oil Testing and Recommended Condemnation Limits

Natural gas fuel engine lube oil samples should be taken based on trend experience or @ 500 hours maximum

CONDEMNING LIMITS

STANDARD TEST

ANALYSIS METRICS ALL OTHER DRESSER

METHOD USED 12V/18V 220GL

WAUKESHA ENGINES

WEAR METALS:

Iron (Fe) 30 ppm max

Aluminum (Al) 10 ppm max

Copper (Cu) 15 ppm max

Lead (Pb) 20 ppm max Wear Metals By Trend Analysis

(Investigate source(s) of rising

Tin (Sn) ASTM D5185 10 ppm max wear Metal(s). Change oil

Chromiun (Cr) 10 ppm max based upon Analysis report

recommendations.)

Nickel (Ni) 10 ppm max

Silver (Ag) Wear Metals By Trend Analysis

Change oil based upon Report

Titanium (Ti) recommendations.

CONTAMINANTS:

Silicon (Si) 20 ppm max Follow analysis report

recommendations

ASTM D5185

Sodium (Na) Any detectable amount (> 5 Any detectable amount (> 5

Potassium (K) ppm) as coolant leak indicator ppm) as coolant leak indicator

ASTM D6443 (XRF) or ASTM

Chlorine (Cl) 900 ppm max 900 ppm max

D2622 (XRF)

Soot FTIR Above 2.5% by volume Above 2.5% by volume

ASTM D1744 or Above 0.3% by weight Above 0.1% by weight

Water % by IR & Karl Fischer ASTM D6304-04A (3000 ppm) (1000 ppm)

(Na & K) Any detectable amount (Na & K) Any detectable amount (> 5

Glycol (pos/neg) ASTM D2982

(> 5 ppm) ppm)

MULTI-SOURCE:

Boron (B)

Molybdenum (Mo) Multi-source by Analysis Report Multi-source by Analysis Report

ASTM D5185 Recommendations Recommendations

Antimony (Sb) (if contaminant) (if contaminant)

Manganese (Mn)

Continued on next page

Service Bulletin 12-1880AF

© 11/2010 Page 7 of 13

Service Bulletin No. 12-1880AF

Table 5: Used Lube Oil Testing and Recommended Condemnation Limits (Continued)

Natural gas fuel engine lube oil samples should be taken based on trend experience or @ 500 hours maximum

CONDEMNING LIMITS

STANDARD TEST

ANALYSIS METRICS ALL OTHER DRESSER

METHOD USED 12V/18V 220GL

WAUKESHA ENGINES

ADDITIVES:

Magnesium (Mg)

Calcium (Ca)

Additive levels are information Additive levels are information

Barium (Ba) ASTM D5185 only only

Phosphorous (P)

Zinc (Zn)

CHARACTERISTICS:

Viscosity (40°C) +50% change

ASTM D445 -20/+30% change

Viscosity (100°C) +25% change

TAN ASTM D664 2.5 rise over new oil * 3.0 rise over new oil *

ASTM D2896 (new & used oil) Drop to 30% of new TBN *

TBN or ASTM D4739 (new & used Drop to 50% of new TBN *

oil) Not applicable to TOH/Cl

Oxidation 40 Abs/cm Peak Height (Single 40 Abs/cm Peak Height (Single

ASTM E2412-04 ANNEX A2 Point Baseline) Method Point Baseline) Method

Nitration

Oxidation 25 Abs @ 1700 cm¯ ¹ Peak Area 25 Abs @ 1735 cm¯ ¹ Peak Area

Method Method

ASTM E2412-04 ANNEX A1

20 Abs @ 1625 cm¯ ¹ Peak Area 25 Abs @ 1625 cm¯ ¹ Peak Area

Nitration

Method Method

ASTM D92

Flash Point 356°F (180°C) 356°F (180°C)

(Cleveland Open Cup)

MAXIMUM MONITORED MAXIMUM MONITORED

PARTICLE COUNTS:

LEVELS ** LEVELS **

ISO Code ISO 4406 24/24/20 24/24/20

4 micron 160,000 particles/ml 160,000 particles/ml

6 micron 80,000 80,000

10 micron 30,000 30,000

14 micron 5,000 5,000

ISO 11500

21 micron 1,000 1,000

38 micron 100 100

70 micron 12 12

100 micron 8 8

* Sweeten the sump lube oil by adding new lube oil when TBN level falls below the TAN level so the lube oil can continue to neutralize acids.

Resample sweetened lube oil to verify proper TAN/TBN levels. If TAN/TBN condemning limits are reached and sump sweetening is not done,

the lube oil must be changed to reestablish proper lube oil alkalinity protection from acid formation.

** Do not condemn the lube oil based solely on particle count levels unless a severe rise in any micron level occurs in the 500 hour lube oil

sample analysis. Inspect the engine filtration system (improperly seated elements, holes in elements, a stuck open filter bypass valve, a non-

functional centrifuge, etc.) if an early hour excessive rise is seen in particle counts. Longer term, consider other lube oil condemning limits in

Table 5 along with rising particle counts in the decision to change lube oil and filters.

NOTICE

Actual lube oil change intervals must be determined

by engine inspection and lube oil analysis in

conjunction with the condemning limits.

Service Bulletin 12-1880AF

Page 8 of 13 © 11/2010

Service Bulletin No. 12-1880AF

In order to obtain a reasonable life expectancy for – Elevate the lube oil temperature to 185° – 200°F

Dresser Waukesha engines operating on fuel gas (85° – 93°C), 180°F (82°C) maximum for AT

containing some level of halogens, our experience models, and 176°F (80°C) for 220GL models.

dictates the following:

– Use of high TBN oil (7.0 – 13.0)

• To achieve a life expectancy equivalent to an engine

operating on pipeline quality natural gas, remove all – Bypass lubrication oil filtration. Dresser

halogen compounds and abrasives from the fuel Waukesha has introduced the Microspin

gas. cleanable lube oil filtering system. The Microspin

system utilizes the cleaning capabilities of a

• Reasonable life can be expected if the Total Organic centrifuge coupled with cleanable filter elements.

Halide as Chloride (TOH/CI) concentration of the The Microspin system utilizes Dresser

fuel does not exceed 8.5 micrograms per BTU (µg/ Waukesha’s current lube oil filtration canister for

BTU) (150 µg/liter). Total Organic Halide as

the cleanable elements. The centrifuge is

Chloride equals the sum of all halogenated

installed as a bypass system working in

compounds expressed as chloride (Cl) in

conjunction with the cleanable filter elements.

micrograms per BTU (µg/BTU) (or µg/liter) at

Standard Temperature and Pressure (STP). See the • A fuel gas containing a TOH/CI concentration above

most current version of S-07884-7, Gaseous Fuel 8.5 µg/BTU (150 µg/liter) requires pre-treatment of

Specification for Waukesha Engines. Reasonable the fuel in order to make it suitable for use in a

life can also be expected with increased Dresser Waukesha engine.

maintenance and operating adjustments to the

engine, such as: LUBE OIL VISCOSITY SELECTION

Typical changes in maintenance and operation at The operating temperature of the lube oil in the sump

this chloride level are: or header is the best guide for selecting the proper

SAE grade of lube oil. When the oil temperature is

– Decreased lube oil change interval (150 hours to unknown, add 120°F (67°C) to the ambient

start) temperature to obtain an estimated lube oil sump

– Condemn the lube oil when the 900 ppm temperature.

chlorine limit in used lube oil is reached. This will Table 6: VSG Sump Temperature and SAE Number

aid in establishing a lube oil change interval.

SUMP TEMPERATURE SAE NUMBER

– Perform a lube oil analysis at least every 50 210° – 250°F (99° – 121°C) 40

hours to start. 160° – 210°F (71° – 99°C) 30

– Elevate the jacket water temperature to 212° –

235°F (100° – 113°C).

Table 7: VGF / VHP Sump and Header Temperatures and SAE Number

SUMP TEMPERATURE HEADER TEMPERATURE SAE NUMBER

160° – 230°F 160° – 195°F

40

(71° – 110°C) (71° – 91°C)

Below 160°F (71°C) Below 160°F (71°C) 30

Table 8: 275GL / GL+ & ATGL Sump and Header Temperatures and SAE Number

SUMP TEMPERATURE HEADER TEMPERATURE SAE NUMBER

160° – 230°F 160° – 180°F

(71° – 110°C) (71° – 82°C) 40

Table 9: 220GL Sump and Header Temperatures and SAE Number

SUMP TEMPERATURE HEADER TEMPERATURE SAE NUMBER

194° – 203°F 167° – 176°F

(90° – 95°C) (75° – 80°C) 40

Service Bulletin 12-1880AF

© 11/2010 Page 9 of 13

Service Bulletin No. 12-1880AF

Table 10: 16V150LTD / APG1000 Sump and Header Temperatures and SAE Number

SUMP TEMPERATURE HEADER TEMPERATURE SAE NUMBER

195° – 205°F 180° – 190°F

(90° – 96°C) (82° – 88°C) 40

NOTE: Do not operate engines with an oil header Synthetic lube oils are not recommended for

temperature below 140°F (60°C). Engines that exceed alternative fuel gas applications without prior approval

195°F (91°C) header temperature or 215°F (102°C) by Dresser Waukesha.

sump temperature should have reduced lube oil

change intervals based upon lube oil analysis (see LOW AMBIENT TEMPERATURE

Table 5). OPERATION

MULTI-VISCOSITY LUBE OILS At low ambient temperatures, use a lube oil which will

provide proper lubrication when the engine is hot and

Use multi-viscosity lube oils only for engines in cold working. For engines of 1,000 cu. in. (16.4 L)

starting applications. Multi-viscosity lube oil may displacement and above, operating at ambient

deteriorate in continuous operation, allowing the lube temperatures below 50°F (10°C), lube oil and jacket

oil to lose viscosity through shearing. In this state, the water heaters are required to warm oil and water for

lube oil may not supply sufficient lubricating film and/or faster starting and load application. Dresser

pressure. Therefore, utilize a lube oil analysis program Waukesha will supply information on these starting

to determine the lube oil change interval. devices upon request.

SYNTHETIC LUBE OILS 220GL APPLICATIONS

To avoid any troubles when starting under cold

Based on developments by lube oil manufacturers and

ambient conditions, and because of the extra pressure

the release of their synthetic lube oils, Dresser

drop involved by the external circuit, it is mandatory

Waukesha now recognizes these products as being

that lube oil temperature in the external circuit does

suitable for all Dresser Waukesha stoichiometric (“rich

not fall down below 68°F (20°C).

burn”) and lean burn gas engines. Table 2 and Table 3

include synthetic lube oils. This minimum temperature can be achieved by two

different means:

When synthetic lube oils are selected, Dresser

Waukesha suggests contacting the Dresser • Either the external circuit (piping, control valve and

Waukesha Field Service or Sales Engineering cooler) is located in a warm area where temperature

Departments for oil change interval recommendations never falls below 68°F (20°C), such as inside a

if lube oil analysis is not done. However, a lube oil building rather than outside.

analysis program is always recommended by Dresser

Waukesha. Actual lube oil change intervals must be • Or the external circuit is fitted with a warming

established through a lube oil analysis program and system (electrical resistance or preheaters and

circulation) which regulates lube oil temperature to a

visual inspection of engine components. Typical areas

minimum of 68°F (20°C).

to look for lube oil breakdown are exhaust valve stems,

piston ring area and piston undercrown. Synthetic lube

LUBE OIL CONSUMPTION GUIDELINES

oil change intervals are 3 to 5 times longer than those

of mineral oils. However, lube oil filter change intervals Typical gross lube oil consumption rates for all Dresser

remain at 1,000 to 1,500 hours of operation, so that Waukesha engines are:

contaminant buildup does not result in excessive lube

oil filter pressure drop.

Table 11: Typical Gross Oil Consumption Rate

MODEL LBS/HP-HR GRAMS/HP-HR GRAMS/KW-HR

All 0.0002 – 0.002 0.091 – 0.910 0.121 – 1.22

NOTE: Lube oil consumption rates given above are a general guide and not meant to be used as condemning limits or for determining

overhaul requirements. Lube oil treatment, losses and changes not included.

Service Bulletin 12-1880AF

Page 10 of 13 © 11/2010

Service Bulletin No. 12-1880AF

FORMULAS FOR DETERMINING LUBE RECOMMENDED OIL CHANGE

OIL CONSUMPTION RATE INTERVALS

The following formulas may be useful for determining

the engine lube oil consumption rate. NOTICE

LBS 7.3 x Number of Gallons of Oil Used More frequent lube oil changes may be necessary

= with some types of lube oil as well as with the

HP-HR HP x Hours of Operation

presence of other factors including, but not limited

to, a dusty environment, a marginal installation, the

LBS 1.82 x Number of Quarts of Oil Used internal engine condition and/or operation of an

= engine that has malfunctioning carburetion

HP-HR HP x Hours of Operation

equipment. The lube oil drain should be as complete

as possible, including draining of used lube oil from

Grams 875 x Number of Liters of Oil Used low-lying plumbing in the lubrication system. Dresser

=

HP-HR HP x Hours of Operation Waukesha recommends that the lube oil be

monitored with a professional lube oil analysis

program. However, extended lube oil change

Grams 875 x Number of Liters of Oil Used intervals may cause varnish deposits, lube oil

=

kWb-HR kWb (corrected) x Hours of Operation oxidation or sludge conditions to appear in the

engine which a lube oil analysis program may not

detect. Contact your local Dresser Waukesha

Distributor for periodic engine maintenance

recommendations.

NOTE: Lube oil drain intervals can be extended if

Microspin oil filtration is used, the Microspin remains

functional, Dresser Waukesha-supplied lube oil

filtration components are used, a good lube oil

analysis program is used and acceptable levels of

engine part deposits are found during visual

inspection.

Service Bulletin 12-1880AF

© 11/2010 Page 11 of 13

Service Bulletin No. 12-1880AF

Table 12: Recommended Lube Oil Change Intervals for Engines Receiving Normal Maintenance and Using Natural Gas

Fuel without a Lube Oil Analysis Program

Table 12 is provided as a guide to engine lube oil change intervals when lube oil analysis is extremely difficult to

obtain by customers/end users of Dresser Waukesha engines.

ENGINES EBULLIENT COOLED

OPERATED IN OR HOT WATER

ISO STANDARD OR EXCESS OF SYSTEM WITH

ENGINE MODEL CONTINUOUS ISO STD ENGINE WATER STANDBY DUTY

POWER RATING POWER OR TEMPERATURE OF

PEAK 211°F (99°C) OR

SHAVING ABOVE

FOR ENGINES OPERATING WITH LUBE OIL SUMP TEMPERATURE OF 230°F (110°C) OR BELOW

VSG SERIES F11 300 hours or

Normal 720 hours* 300 hours N/A

Natural Gas and HD-5 Propane annually

FOR ENGINES OPERATING WITH LUBE OIL HEADER TEMPERATURE OF 195°F (91°C) OR BELOW

VGF G, GL, GLD/GLD/2 Normal 1,000 hours

500 hours or

LOW CAPACITY (Extended 1,250 500 hours 500 hours

annually

Natural Gas and HD-5 Propane hours**)

VGF G, GL, GLD/GLD/2 Normal 2,100 hours

500 hours or

HIGH CAPACITY (Extended 2,350 1,000 hours 1,000 hours

annually

Natural Gas and HD-5 Propane hours**)

VGF GSID, GSI

Normal 720 hours 500 hours or

LOW CAPACITY (Extended 900 hours**)

500 hours 500 hours

annually

Natural Gas and HD-5 Propane

VGF GSID, GSI Normal 1,500 hours

500 hours or

HIGH CAPACITY (Extended 1,750 720 hours 720 hours

annually

Natural Gas and HD-5 Propane hours**)

VHP SERIES Normal 1,000 hours 500 hours or

LOW CAPACITY (Extended 1,500 500 hours 500 hours

annually

Natural Gas and HD-5 Propane hours**)

VHP SERIES

500 hours or

HIGH CAPACITY Normal 3,000 hours** – – annually

Natural Gas with Extender Package

275GL/GL+ Normal 3,000 hours (Extended 4,000

AT25/27GL SERIES hours**) or sooner by analysis. Sample every See Table 5 for condemning limits.

Natural Gas 720 hours.

APG SERIES

16V150LTD Normal 1,500 hours**** – – Not Allowed

Natural Gas

Normal 3,000 hours for

12V/18V 220GL engines shipped after 500 hours or

Natural Gas March 2011; – – annually

otherwise 1,500 hours

for filters only***, ****

* Attainable with 15.5:1 air/fuel ratio (carburetor adjusted to 1.15% CO in the exhaust). If best economy carburetor setting, 17.0:1 – 17.7:1

air/fuel ratio (1.4 – 2.1% O2 in the exhaust), is used, lube oil change hours should be reduced to 300 operating hours.

** Extended lube oil drain intervals listed are acceptable if a Microspin centrifuge that remains functional in service use in conjunction with a

Dresser Waukesha-supplied oil filtration system is utilized and a lube oil analysis program is followed (see Table 5), with visual inspection of

power cylinder components at 4,000 hrs. after start of test to determine the extended lube oil change interval. Part deposit inspection pass/fail

criteria must hinge on acceptable industry standards of deposit evaluation of varnish, lacquer and carbon on valve stems, piston ring grooves

and piston undercrown. Lube oil filter change intervals remain per the respective engines’ maintenance manual recommendations. The

extended lube oil drain interval hours shown in Table 12 above may be exceeded if all oil analysis metrics published in Table 5 remain within

specification limits using engine lube oil analysis.

*** Up to 6,000 hour lube oil change with synthetic oil on 220GL models is possible, but only based upon lube oil analysis. Filter change

intervals remain per Table 12.

**** No overload allowed on APG engine models.

NOTE: Change lube oil filter elements when lube oil is changed.

Service Bulletin 12-1880AF

Page 12 of 13 © 11/2010

Service Bulletin No. 12-1880AF

Table 13: Recommended Lube Oil Change Intervals for Engines Receiving Normal Maintenance and Using Gaseous

Fuel Containing H2S @ 0.1% by Volume (1000 ppm) or Less Based Upon Lube Oil Analysis (see Table 5)

A lube oil change is required at the TBN/TAN crossover point.

EBULLIENT COOLED

OR HOT WATER

ENGINES OPERATED

ISO STANDARD OR SYSTEM WITH

ENGINE IN EXCESS OF ISO

PRIME POWER ENGINE WATER STANDBY DUTY

MODEL STD POWER OR PEAK

RATING TEMPERATURE OF

SHAVING

211°F (99°C) OR

ABOVE

FOR ENGINES OPERATING WITH ELEVATED LUBE OIL SUMP TEMPERATURE

VSG SERIES 360 hours* 250 hours N/A 250 hours or annually

VGF SERIES 360 hours 250 hours 360 hours 250 hours or annually

VHP SERIES 360 hours 250 hours 360 hours 250 hours or annually

NOTE: AT series engines are limited to a maximum of 180°F (82°C) lube oil temperature.

275GL/GL+ &

AT25/27GL 500 hours or sooner by lube oil analysis. Sample every

See Table 5 for condemning limits.

SERIES 100 hours.

Natural Gas

* Attainable with 15.5:1 air/fuel ratio (carburetor adjusted to 1.15% CO in the exhaust). If best economy carburetor setting, 17.0:1 – 17.7:1

air/fuel ratio (1.4 – 2.1% O2 in the exhaust), is used, lube oil change hours should be reduced to 300 operating hours.

NOTE: Change lube oil filter elements when lube oil is changed.

Table 14: Duty Cycle Definitions

ISO STANDARD OR The highest load and speed which can be applied 24 hours a day, 7 days a week, 365 days per

year, except for normal maintenance. It is permissible to operate the engine at up to 10 percent

CONTINUOUS POWER overload, or the maximum load indicated by the intermittent rating, whichever is lower, for two hours

RATING: each 24-hour period.

GENERATOR STANDBY In a system used as backup or secondary source of electrical power, this rating is the output the

engine will produce continuously (no overload), 24 hours a day, for the duration of the prime power

POWER RATING: source outage.

INTERMITTENT POWER This rating is the highest load and speed that can be applied in variable speed mechanical system

RATING: application only. Operation at this rating is limited to a maximum of 3500 hours per year.

Peak shaving is operation of an engine for a limited time to meet the short-term peak power

GENERATOR PEAK SHAVING: requirements. Speed, loading and hours per year of operation will affect the recommended oil

change interval.

Service Bulletin 12-1880AF

© 11/2010 Page 13 of 13

Vous aimerez peut-être aussi

- PDS Lubrizol CV7101 PDFDocument3 pagesPDS Lubrizol CV7101 PDFDavid PomaPas encore d'évaluation

- Overview of Mitsubishi Services: Download All Pages PDFDocument27 pagesOverview of Mitsubishi Services: Download All Pages PDFiswandyPas encore d'évaluation

- ISO & DIN Specs - Greases - FinalDocument1 pageISO & DIN Specs - Greases - FinalDavid PomaPas encore d'évaluation

- Gulf TEC Plus 10W-40 (06.2012)Document1 pageGulf TEC Plus 10W-40 (06.2012)David PomaPas encore d'évaluation

- Brochure HouillonDocument2 pagesBrochure HouillonDavid PomaPas encore d'évaluation

- Viscosidad Tablas de Conversiones - ASTM D2161-05 PDFDocument26 pagesViscosidad Tablas de Conversiones - ASTM D2161-05 PDFEdwin GarzónPas encore d'évaluation

- Wärtsila App Lube 34 50 SG Data SpecsDocument6 pagesWärtsila App Lube 34 50 SG Data SpecsDavid Poma100% (2)

- TD Operators ManualDocument2 pagesTD Operators ManualDavid PomaPas encore d'évaluation

- ISO & DIN Specs - Hydraulic - FinalDocument3 pagesISO & DIN Specs - Hydraulic - FinalDavid PomaPas encore d'évaluation

- GLXXNuto H SeriesDocument2 pagesGLXXNuto H SeriesDavid PomaPas encore d'évaluation

- Gulf Oil Lub PDFDocument25 pagesGulf Oil Lub PDFDavid Poma100% (2)

- ISO & DIN Specs - Hydraulic - Final PDFDocument3 pagesISO & DIN Specs - Hydraulic - Final PDFDavid Poma100% (2)

- TD Operators ManualDocument84 pagesTD Operators Manualsivan_sg1800Pas encore d'évaluation

- API Spec S Petrol Engine FinalDocument1 pageAPI Spec S Petrol Engine FinalDavid PomaPas encore d'évaluation

- Lube Points in Automobiles - Final PDFDocument1 pageLube Points in Automobiles - Final PDFDavid PomaPas encore d'évaluation

- Turbine Oil Oxidation Stability Test PDFDocument2 pagesTurbine Oil Oxidation Stability Test PDFDavid PomaPas encore d'évaluation

- Gulf Powertrac 4T Oct16 - 20161005040210Document1 pageGulf Powertrac 4T Oct16 - 20161005040210David PomaPas encore d'évaluation

- TDS - G-Profi - SGE 40 NAB - All Lubricating Oil For Type 2, 3, 4 and 6 Jenbacher Gas EnginesDocument1 pageTDS - G-Profi - SGE 40 NAB - All Lubricating Oil For Type 2, 3, 4 and 6 Jenbacher Gas EnginesDavid PomaPas encore d'évaluation

- 'Documents - MX - Oil Anlaysis Techn For HHP Diesel Enginescummins 2 PDFDocument5 pages'Documents - MX - Oil Anlaysis Techn For HHP Diesel Enginescummins 2 PDFDavid PomaPas encore d'évaluation

- ACEA Specs FinalDocument3 pagesACEA Specs FinalDavid PomaPas encore d'évaluation

- Lube Points in Automobiles - FinalDocument2 pagesLube Points in Automobiles - FinalDavid PomaPas encore d'évaluation

- ISO & DIN Specs - Hydraulic - FinalDocument3 pagesISO & DIN Specs - Hydraulic - FinalDavid Poma100% (1)

- Lube Points in Automobiles - Final PDFDocument1 pageLube Points in Automobiles - Final PDFDavid PomaPas encore d'évaluation

- Bosch Spare Parts Price List 2016Document113 pagesBosch Spare Parts Price List 2016David PomaPas encore d'évaluation

- Overview of Mitsubishi Services: Download All Pages PDFDocument27 pagesOverview of Mitsubishi Services: Download All Pages PDFiswandyPas encore d'évaluation

- Overview of Mitsubishi Services: Download All Pages PDFDocument27 pagesOverview of Mitsubishi Services: Download All Pages PDFiswandyPas encore d'évaluation

- 2013 Chevrolet Captiva Sport Owners PDFDocument374 pages2013 Chevrolet Captiva Sport Owners PDFDavid PomaPas encore d'évaluation

- Gulf-Syngear-Fe-75w-80 - 20-Dec-16 - 20161222052228Document1 pageGulf-Syngear-Fe-75w-80 - 20-Dec-16 - 20161222052228David PomaPas encore d'évaluation

- Iso11500 PDFDocument13 pagesIso11500 PDFDavid PomaPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- MM 540 DPDocument3 pagesMM 540 DPapi-27077834100% (1)

- Operation Manual XMQ6130C 1Document161 pagesOperation Manual XMQ6130C 1Bobby AldPas encore d'évaluation

- Sprinter 2.7 Liter Diesel Fuel Injection DiagnosisSprinterDocument150 pagesSprinter 2.7 Liter Diesel Fuel Injection DiagnosisSprinterMiguel Ángel Gil Pérez100% (13)

- CSIA Aftermarket Components and Fireplace SystemsDocument58 pagesCSIA Aftermarket Components and Fireplace SystemsCSIA MarketingPas encore d'évaluation

- No. of Patents US4013428 - Lurgi Gasification ProcessDocument8 pagesNo. of Patents US4013428 - Lurgi Gasification ProcessChristian ImanuelPas encore d'évaluation

- Compressor SurgeDocument3 pagesCompressor SurgeajaysapruPas encore d'évaluation

- Submitted in Partial Fulfilment For The Award of The Degree ofDocument27 pagesSubmitted in Partial Fulfilment For The Award of The Degree ofJaymit PatelPas encore d'évaluation

- Oxygen Sensor Certification ManualDocument20 pagesOxygen Sensor Certification ManualSR BangashPas encore d'évaluation

- Industrial Burners, Combustion Equipment - Maxon CorporationDocument2 pagesIndustrial Burners, Combustion Equipment - Maxon CorporationJose CencičPas encore d'évaluation

- Catalogo de Peças H40-H70FT - Sub Serie L177Document970 pagesCatalogo de Peças H40-H70FT - Sub Serie L177Suziane Sousa Victor80% (5)

- ShovelDocument17 pagesShovelAr Dheeraj MauryaPas encore d'évaluation

- TM 10-3930-669-20 Forklift Truck 6K Drexel R60SL-DC Part 1Document408 pagesTM 10-3930-669-20 Forklift Truck 6K Drexel R60SL-DC Part 1Advocate100% (1)

- Ethylene BalanceDocument29 pagesEthylene BalanceCraigUnderwood100% (2)

- A974 (01-2012)Document340 pagesA974 (01-2012)Felipe Melo89% (9)

- Function, Structure, Operation of Engine Null (4JK1)Document36 pagesFunction, Structure, Operation of Engine Null (4JK1)jonathan100% (3)

- Autogreider Hidromek HMK MG 330Document2 pagesAutogreider Hidromek HMK MG 330dicon100% (1)

- Riot Control Vehicle RCV 3500Document5 pagesRiot Control Vehicle RCV 3500Lico Peliciolli100% (1)

- Types of FuelsDocument19 pagesTypes of FuelsSumeet KhachanePas encore d'évaluation

- Khu 10 Ye - Efe Ea - 000Document51 pagesKhu 10 Ye - Efe Ea - 000Parag AhsanPas encore d'évaluation

- Bayliner Owner's Manual Supplement 1787653Document60 pagesBayliner Owner's Manual Supplement 1787653Jose Fascini FilhoPas encore d'évaluation

- PC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineDocument12 pagesPC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineJohn MkCito KIPas encore d'évaluation

- Wind Energy (ENER 412)Document60 pagesWind Energy (ENER 412)Bruktawit MekonenPas encore d'évaluation

- Liners InspectionDocument9 pagesLiners Inspectiong arv100% (1)

- RPM Tech LM220 Snow Blower BrochureDocument4 pagesRPM Tech LM220 Snow Blower BrochurePhil B.Pas encore d'évaluation

- ElectrolysisDocument300 pagesElectrolysisberbouPas encore d'évaluation

- Bfe2218 Lazourdy 500gpm@6bar PDFDocument117 pagesBfe2218 Lazourdy 500gpm@6bar PDFYazan Tamimi50% (2)

- Set 05Document13 pagesSet 05Wak TunPas encore d'évaluation

- Automatic Versus Manual Transmissions: Mtcars Dataset AnalysisDocument4 pagesAutomatic Versus Manual Transmissions: Mtcars Dataset AnalysisdsasasPas encore d'évaluation

- Mars Series Tech SpecificationsDocument4 pagesMars Series Tech Specificationsviorel0% (1)

- EME4096 Assignment 2 PDFDocument5 pagesEME4096 Assignment 2 PDFmikeyPas encore d'évaluation