Académique Documents

Professionnel Documents

Culture Documents

Integrity SOPs For Vein

Transféré par

ziadddDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Integrity SOPs For Vein

Transféré par

ziadddDroits d'auteur :

Formats disponibles

MACTER INTERNATIONAL (Pvt.) LTD.

STERILE PRODUCTS DEPARTMENT

EYE & EAR DROPS SECTION

STANDARD OPERATING PROCEDURE

Title: S.O.P OF INTEGRITY TESTING OF STERILISATION Doc. No.: E/E /3/ EE-020

GRADE LIQUID FILTERS.

Prepared By: AM Issue No.:1

Reviewed By: QAM Issue Date: 12-2-2001

Approved By: DQO DP Page: 1 of 2

1.0 INTRODUCTION

The Bubble Point is the direct measure of the pore size and Integrity of the finest filter

in the system and is a nondestructive test procedure for membrane filter system.

The bubble point pressure is dependent upon:

a) The pore size of the finest filter in the system, with typical values are,

>3 bar for 0.2 um pore size.

>2 bar for 0.45 um pore size. Etc.

b) The wetting liquid.

c) The material of which the filter is made ( 0.2 µm cellulose acetate filter about 4

bar ).

D) The temperature ( a bubble point at 80 oC may be about 60 % less, one at 60o C

about 20 % less than at 20 oC.

2.0 PURPOSE

In critical filtration the user must be able to check that the filtration system is inn

perfect working condition. A nondestructive test must be able to show that the system

is correctly assembled, without leaks, and confirm the integrity of the filter itself.

3.0 FREQUENCY

Compliance with CGMP guidelines requires such integrity testing (BUBBLE POINT)

before and after filtration.

4.0 PROCEDURE

4.1 Confirm that the equipment is labeled correctly and that, for product the details on the

aseptic area section of the batch records are the same as those on the manufacturing

area.

4.2 The filter in the cartridge filtration is thoroughly wetted (e.g. by the standard distill

water rinse ), and the system drained on the inlet side.

4.3 Connect the filter to the pressure vessel.

MACTER INTERNATIONAL (Pvt.) LTD.

STERILE PRODUCTS DEPARTMENT

EYE & EAR DROPS SECTION

STANDARD OPERATING PROCEDURE

Title: S.O.P OF INTEGRITY TESTING OF STERILISATION Doc. No.: E/E /3/ EE-020

GRADE LIQUID FILTERS.

Issue No: 1 Issue Date: 12-2-2001 Page: 2 of 2

4.4 A piece of narrow tubing is attached to the outlet – side valve, and free end of this

dipped in a bowel of water.

4.5 With inlet – side vent valve closed, the outlet valve is opened and a pressure of about

70 % of the minimum expected bubble point applied at the inlet.

4.6 The pressure is slowly increased ( at the rate of about 0.1 bar every 5 seconds ) until a

continuous stream of bubbles is visible in the bowel. This is the bubble point ( should a

few bubbles appear irregularly as pressure as pressure is first applied, these can be

neglected, they are due to setting within the system ).

4.7 On completion of the integrity test, remove piece of narrow tubing from the outlet side

of the valve and filter the bulk solution using nitrogen pressure. Assist the aseptic area

operator in ensuring that all air is bled from the system.

N.B. The personnel performing the cleanings / maintenance and The personnel

checking those works must sign along with the date the time started and time

when work was completed on the respective log sheets.

FILTER INTEGRITY TEST

(Bubble Point Test)

Date______________

Batch No ____________ Batch Size ______________ Department ________________

Pore Size Actual Bubble Point

No Remarks

(µm) Pressure (Bar) (Bar)

__________________

Microbiologist

Vous aimerez peut-être aussi

- Clean Room Classification SOPDocument5 pagesClean Room Classification SOPNoor Javed100% (1)

- LVC 4A1TestReportDocument4 pagesLVC 4A1TestReportMarisol ZamudioPas encore d'évaluation

- Cleaning Validation Protocol TemplateDocument3 pagesCleaning Validation Protocol Templatemuhammad asifPas encore d'évaluation

- Operation of A Submerged Hollow Fiber Membrane Bioreactor For Wastewater Treatment On Meeting Reclamation Criteria PDFDocument19 pagesOperation of A Submerged Hollow Fiber Membrane Bioreactor For Wastewater Treatment On Meeting Reclamation Criteria PDFShiva Kumar S MPas encore d'évaluation

- 27-The Importance of The ContaminationDocument11 pages27-The Importance of The ContaminationDiango Alaín Zacarias CarretoPas encore d'évaluation

- SOP (Nylon BP)Document1 pageSOP (Nylon BP)Sudhanshu ShekharPas encore d'évaluation

- Soluble Salt Meter Product DatasheetDocument8 pagesSoluble Salt Meter Product DatasheetRajeev KhanPas encore d'évaluation

- GMP in Aseptic Process PresentationDocument18 pagesGMP in Aseptic Process PresentationRew IshPas encore d'évaluation

- Dye Penetrant Inspection Procedure GuideDocument7 pagesDye Penetrant Inspection Procedure GuideNDTInstructor100% (1)

- Model 4010lx Operator ManualDocument68 pagesModel 4010lx Operator ManualLakshman tangellaPas encore d'évaluation

- Ti01f07a05 01enDocument5 pagesTi01f07a05 01enSiva ShankarPas encore d'évaluation

- Risk Management To Performing Quality Test For Waving Some User PointsDocument3 pagesRisk Management To Performing Quality Test For Waving Some User PointsIrshadAlamPas encore d'évaluation

- _seat-tightness-of-pressure-relief-valves-api-standard-527-fourth-edition-november-2014-pdf-freeDocument15 pages_seat-tightness-of-pressure-relief-valves-api-standard-527-fourth-edition-november-2014-pdf-freestudentmgmPas encore d'évaluation

- EUROVENT 4/10 - 2005: in Situ Determination of Fractional Efficiency OF General Ventilation FiltersDocument32 pagesEUROVENT 4/10 - 2005: in Situ Determination of Fractional Efficiency OF General Ventilation FiltersLBPas encore d'évaluation

- GMW16037Document4 pagesGMW16037Anonymous 7ZTcBn100% (1)

- Measurement of Residual Particulate Contamination On ComponentsDocument20 pagesMeasurement of Residual Particulate Contamination On Componentsdivyesh khuntPas encore d'évaluation

- Filter Integrity Test MachineDocument4 pagesFilter Integrity Test MachineAtul SharmaPas encore d'évaluation

- Chinese GMP 2010Document115 pagesChinese GMP 2010Atul SharmaPas encore d'évaluation

- CharnDocument28 pagesCharnsksingh82Pas encore d'évaluation

- Filter Selection Guide-EDocument78 pagesFilter Selection Guide-ENuñez JesusPas encore d'évaluation

- Sterile FiltrationDocument37 pagesSterile FiltrationVaruni Chowdary100% (1)

- BPC BioSED srl KUADRO Automatic Analyzer User's ManualDocument42 pagesBPC BioSED srl KUADRO Automatic Analyzer User's Manualmarcosoag100% (2)

- Ipc - TM-650 Test Methods Manual PDFDocument3 pagesIpc - TM-650 Test Methods Manual PDFmagrafsoluciones100% (1)

- Flow Cell Cleaner: Verification Report For Humalyzer PhotometerDocument3 pagesFlow Cell Cleaner: Verification Report For Humalyzer PhotometerMaherPas encore d'évaluation

- Validation of Laminar Air Flow SOPDocument2 pagesValidation of Laminar Air Flow SOPRahul Patil100% (5)

- BW-200 Service ManualDocument17 pagesBW-200 Service ManualngovantienPas encore d'évaluation

- Filmtec™ Fiberglassed Elements For Light Industrial Systems: Product Data SheetDocument4 pagesFilmtec™ Fiberglassed Elements For Light Industrial Systems: Product Data SheetfasihulPas encore d'évaluation

- Sysmex CA-1500 - PMI - ProDocument2 pagesSysmex CA-1500 - PMI - ProBakhrom KasimovPas encore d'évaluation

- Elastic Recovery, Consistency and Stiffness of Polymer Modified Binders (ARRB Elastometer)Document13 pagesElastic Recovery, Consistency and Stiffness of Polymer Modified Binders (ARRB Elastometer)तिप्लोकाची तिरुनचिपल्ली केरकेट्टाPas encore d'évaluation

- Sample Cleaning Validation ProtocolDocument9 pagesSample Cleaning Validation ProtocolSolomonPas encore d'évaluation

- thể tích lấy mẫu đánh giá cấp sạch-TRS961-ANNEX6Document1 pagethể tích lấy mẫu đánh giá cấp sạch-TRS961-ANNEX6phu DuongPas encore d'évaluation

- EU GMP Annex 1 Update 2008 Particle CountingDocument8 pagesEU GMP Annex 1 Update 2008 Particle CountingpokermarmotaPas encore d'évaluation

- Barometric Column Filtration V/s Filtrate Pump Filtration Comparison: Case StudyDocument8 pagesBarometric Column Filtration V/s Filtrate Pump Filtration Comparison: Case StudyEusebio Castillo MejiaPas encore d'évaluation

- GMP 2Document18 pagesGMP 2j.k.kumar100% (3)

- User Guide: Bod Auto-Stir DO ProbeDocument15 pagesUser Guide: Bod Auto-Stir DO ProbeDispetrocarb S.A.S.Pas encore d'évaluation

- NAS Doc. E7605-2-05-08 - Partikelmesstechnik PDFDocument22 pagesNAS Doc. E7605-2-05-08 - Partikelmesstechnik PDFer_sanjaypatel100% (1)

- US Environmental Protection Agency Office of Pesticide ProgramsDocument20 pagesUS Environmental Protection Agency Office of Pesticide Programsanandhra2010Pas encore d'évaluation

- TSG C 003 Membrane Cleaning Guide Food Dairy RO NF ElementsDocument3 pagesTSG C 003 Membrane Cleaning Guide Food Dairy RO NF ElementsOmid LarkiPas encore d'évaluation

- COD Analysis Method - 0Document5 pagesCOD Analysis Method - 0Ricardo GallegosPas encore d'évaluation

- Thermo Scientific Two Stage Viable, Andersen Cascade ImpactorDocument2 pagesThermo Scientific Two Stage Viable, Andersen Cascade Impactorसुनिल बाबु खत्रीPas encore d'évaluation

- Manual - Filter Oil Test Rig -ISO 1 & 3Document5 pagesManual - Filter Oil Test Rig -ISO 1 & 3Rudra QMS SolutionPas encore d'évaluation

- PT-Liquid Penetrant Testing Procedure R01 - 2 2Document12 pagesPT-Liquid Penetrant Testing Procedure R01 - 2 2George Ogbeche100% (1)

- Source Water STP 31-05-2019Document11 pagesSource Water STP 31-05-2019saptaksamadder4Pas encore d'évaluation

- O&M Manual: BALLOKI 1223MW Combined Cycle Power PlantDocument28 pagesO&M Manual: BALLOKI 1223MW Combined Cycle Power PlantMehtab AhmedPas encore d'évaluation

- Xpress 500 Changeover TimeDocument3 pagesXpress 500 Changeover Timeltrevino100Pas encore d'évaluation

- SOP For Serial Dilutions of Microbial CultureDocument5 pagesSOP For Serial Dilutions of Microbial CultureranerxPas encore d'évaluation

- MICLAB 060 SampleDocument7 pagesMICLAB 060 SampleVizit31Pas encore d'évaluation

- GU-486 Screening & Monitoring Bacteria GuidelineDocument8 pagesGU-486 Screening & Monitoring Bacteria GuidelineRaj MalhotraPas encore d'évaluation

- WCMBR-20(U) Marine Membrane Sewage Treatment Plant InstructionsDocument19 pagesWCMBR-20(U) Marine Membrane Sewage Treatment Plant InstructionsAshitoshPas encore d'évaluation

- In Situ Determination of Fractional Efficiency of General Ventilation FiltersDocument32 pagesIn Situ Determination of Fractional Efficiency of General Ventilation FiltersMichaelPas encore d'évaluation

- Bioreactor URS A1Document30 pagesBioreactor URS A1Badar RizwanPas encore d'évaluation

- Filmtec™ Soar 7000I Element: Product Data SheetDocument3 pagesFilmtec™ Soar 7000I Element: Product Data Sheetali jafPas encore d'évaluation

- Guide to Choosing the Right Particle Counter for Cleanroom CertificationDocument2 pagesGuide to Choosing the Right Particle Counter for Cleanroom CertificationsombatsePas encore d'évaluation

- Chemical Plant III Assignment - 1-2023Document4 pagesChemical Plant III Assignment - 1-2023winnie FikilePas encore d'évaluation

- Physical Pharmaceutics-II Lab Manual as per the PCI SyllabusD'EverandPhysical Pharmaceutics-II Lab Manual as per the PCI SyllabusPas encore d'évaluation

- Water Treatment Plant Performance Evaluations and OperationsD'EverandWater Treatment Plant Performance Evaluations and OperationsPas encore d'évaluation

- Automotive Actuators and EVAP System TestingD'EverandAutomotive Actuators and EVAP System TestingÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Gas-Liquid And Liquid-Liquid SeparatorsD'EverandGas-Liquid And Liquid-Liquid SeparatorsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Solid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityD'EverandSolid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityÉvaluation : 5 sur 5 étoiles5/5 (2)

- The Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsD'EverandThe Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsPas encore d'évaluation

- Acceptance Criteria: A. For Visual Inspection CriteriaDocument9 pagesAcceptance Criteria: A. For Visual Inspection CriteriaziadddPas encore d'évaluation

- My uPLODocument10 pagesMy uPLOziadddPas encore d'évaluation

- Protocol 1 Cease Itm Are 4Document4 pagesProtocol 1 Cease Itm Are 4ziadddPas encore d'évaluation

- List Cap IletDocument4 pagesList Cap IletziadddPas encore d'évaluation

- B) - For Rinse Sampling:: Through Whatman No. 2 Filter PaperDocument6 pagesB) - For Rinse Sampling:: Through Whatman No. 2 Filter PaperziadddPas encore d'évaluation

- Equipment List QCDocument1 pageEquipment List QCziadddPas encore d'évaluation

- Protocol 1 Cease Itm Are 2Document6 pagesProtocol 1 Cease Itm Are 2ziadddPas encore d'évaluation

- Sampling Procedures & Sampling Plan: I. Sampling Procedure: A) - For Swab SamplingDocument7 pagesSampling Procedures & Sampling Plan: I. Sampling Procedure: A) - For Swab SamplingziadddPas encore d'évaluation

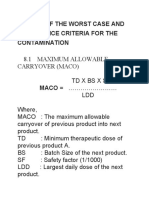

- Selection of The Worst Case and Acceptance Criteria For The ContaminationDocument11 pagesSelection of The Worst Case and Acceptance Criteria For The ContaminationziadddPas encore d'évaluation

- Protocol 1 Cease Itm Are 1Document7 pagesProtocol 1 Cease Itm Are 1ziadddPas encore d'évaluation

- DRUG FORMULATION COMPOSITIONDocument12 pagesDRUG FORMULATION COMPOSITIONziadddPas encore d'évaluation

- Protocol 1 Cease Itm AreDocument3 pagesProtocol 1 Cease Itm AreziadddPas encore d'évaluation

- Reference Regulatory AuthoritiesDocument2 pagesReference Regulatory AuthoritiesziadddPas encore d'évaluation

- Cream HvacDocument3 pagesCream HvacziadddPas encore d'évaluation

- SopsDocument35 pagesSopsziaddd86% (14)

- Work Experience Sample2Document7 pagesWork Experience Sample2ziadddPas encore d'évaluation

- CleanRoom TechnologyDocument109 pagesCleanRoom TechnologysarathsreekumarPas encore d'évaluation

- Aseptic Process Validation (By Media Fill Trial)Document19 pagesAseptic Process Validation (By Media Fill Trial)ziaddd100% (2)

- PS W 01 2011 Questionnaire For AssessmentDocument13 pagesPS W 01 2011 Questionnaire For AssessmentsfgvsdfrbhPas encore d'évaluation

- Cleanroom Users Manual: Georgia Tech Microelectronics Research CenterDocument43 pagesCleanroom Users Manual: Georgia Tech Microelectronics Research Centeromayoral100% (1)

- Hold Time 1Document11 pagesHold Time 1ziadddPas encore d'évaluation

- Observational Cam DiSP July 02Document29 pagesObservational Cam DiSP July 02ziadddPas encore d'évaluation

- Mycophenolate Mofetil: A New Therapeutic Option in DermatologyDocument7 pagesMycophenolate Mofetil: A New Therapeutic Option in DermatologyziadddPas encore d'évaluation

- 62 Vol. 5 Issue 5 May 2014IJPSR RA 3367 Paper 62Document10 pages62 Vol. 5 Issue 5 May 2014IJPSR RA 3367 Paper 62ziadddPas encore d'évaluation

- Mycophenolate Mofetil: A New Therapeutic Option in DermatologyDocument7 pagesMycophenolate Mofetil: A New Therapeutic Option in DermatologyziadddPas encore d'évaluation

- 4파키스탄 Korea (Pakintan)Document45 pages4파키스탄 Korea (Pakintan)ziadddPas encore d'évaluation

- 37163893-1c1d-44b9-ac25-3c467ed44cbfDocument10 pages37163893-1c1d-44b9-ac25-3c467ed44cbfziadddPas encore d'évaluation

- 124 Vol. 5 Issue 8 IJPSR 2014 RA 3721 Paper 14Document4 pages124 Vol. 5 Issue 8 IJPSR 2014 RA 3721 Paper 14ziadddPas encore d'évaluation

- Good StorageDocument20 pagesGood Storageziaddd100% (1)

- Introduction To R.T.P.P: 1.1 GeneralDocument12 pagesIntroduction To R.T.P.P: 1.1 GeneralSairam Kumar ChowdaryPas encore d'évaluation

- FINALSDocument8 pagesFINALSSeenpai23Pas encore d'évaluation

- Qcs 2010 'Part 8.04 Pipeline InstallationDocument29 pagesQcs 2010 'Part 8.04 Pipeline InstallationRotsapNayrb100% (2)

- 810-701 CRSeals Handbook PRESSURE Apr-2018Document4 pages810-701 CRSeals Handbook PRESSURE Apr-2018Anonymous VNu3ODGavPas encore d'évaluation

- Epoxidation of Castor Oil With Peracetic Acid Formed in Situ in The Presence of An Ion Exchange ResinDocument8 pagesEpoxidation of Castor Oil With Peracetic Acid Formed in Situ in The Presence of An Ion Exchange ResinSölangs QüntellaPas encore d'évaluation

- Rigaku Nex QCDocument12 pagesRigaku Nex QCLuis ReyesPas encore d'évaluation

- S1XBIG58 M500 4 Tech InfoDocument15 pagesS1XBIG58 M500 4 Tech InfoFredy DanielPas encore d'évaluation

- 2 - Cleaning and Shaping in EndodonticsDocument299 pages2 - Cleaning and Shaping in EndodonticsElisabeth MarofPas encore d'évaluation

- Lightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiDocument6 pagesLightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiAfzalPas encore d'évaluation

- Fosroc Solvent 102 resin cleaning solventDocument2 pagesFosroc Solvent 102 resin cleaning solventShaikhRizwanPas encore d'évaluation

- C.02 - Gas-Freeing and Cleaning of TanksDocument7 pagesC.02 - Gas-Freeing and Cleaning of TanksmkkamarajPas encore d'évaluation

- ASPHALT METHOD STATEMENTDocument7 pagesASPHALT METHOD STATEMENTBasem Donia100% (1)

- Calculation Dilute Phase Pressure Drop Rhodes MethodDocument3 pagesCalculation Dilute Phase Pressure Drop Rhodes MethodBTEPas encore d'évaluation

- Commiphora Myrrh A Phytochemical and Pharmacologic PDFDocument17 pagesCommiphora Myrrh A Phytochemical and Pharmacologic PDFWaterfall ShapelessPas encore d'évaluation

- ASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire ApparatusDocument3 pagesASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire Apparatusalin2005Pas encore d'évaluation

- Galvanic Series: Why Metals Corrode?Document7 pagesGalvanic Series: Why Metals Corrode?Rey Francis FamulaganPas encore d'évaluation

- Nucleic Acids BrochureDocument2 pagesNucleic Acids BrochureCring-cring NavarroPas encore d'évaluation

- QUERCETANUSDocument64 pagesQUERCETANUSganyesod100% (2)

- General Characteristics of Bacteria and MollicutesDocument13 pagesGeneral Characteristics of Bacteria and MollicutesPrincess Mehra0% (1)

- ANSWER A. Diesel Cycle Has Lower Efficiency Than Otto CycleDocument12 pagesANSWER A. Diesel Cycle Has Lower Efficiency Than Otto CycleParmeshwarPaulPas encore d'évaluation

- FlexEJ Brochure Elaflex 10 2011Document41 pagesFlexEJ Brochure Elaflex 10 2011harlyganPas encore d'évaluation

- Ips e PR 850 PDFDocument73 pagesIps e PR 850 PDFdeyanshu7Pas encore d'évaluation

- E Booklet Feeding The ChakrasDocument20 pagesE Booklet Feeding The ChakrasVibrating PicklePas encore d'évaluation

- Unit 1 - Construction Materials - WWW - Rgpvnotes.inDocument21 pagesUnit 1 - Construction Materials - WWW - Rgpvnotes.inmadhavi likharPas encore d'évaluation

- RN FDocument52 pagesRN Fhassan SardarPas encore d'évaluation

- Computational Models For Drug Design and DelivDocument235 pagesComputational Models For Drug Design and DelivIbrahim Al SharabiPas encore d'évaluation

- Preslia 68 - MSDSDocument12 pagesPreslia 68 - MSDSFraPas encore d'évaluation

- DESN 10041 - Exam-2020-MainDocument4 pagesDESN 10041 - Exam-2020-MainZikani NyirendaPas encore d'évaluation

- 12 Biology Notes Ch06 Molecular Basis of InheritanceDocument14 pages12 Biology Notes Ch06 Molecular Basis of Inheritancehimanshu kumarPas encore d'évaluation

- LCGC Europe 2001Document4 pagesLCGC Europe 2001Jhonattan BaezPas encore d'évaluation