Académique Documents

Professionnel Documents

Culture Documents

Utility

Transféré par

Amit JainDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Utility

Transféré par

Amit JainDroits d'auteur :

Formats disponibles

8.

ENERGY PERFORMANCE ASSESSMENT

OF COMPRESSORS

8.1 Introduction

The compressed air system is not only an energy intensive utility but also one of the least ener-

gy efficient. Over a period of time, both performance of compressors and compressed air sys-

tem reduces drastically. The causes are many such as poor maintenance, wear and tear etc. All

these lead to additional compressors installations leading to more inefficiencies. A periodic per-

formance assessment is essential to minimize the cost of compressed air.

8.2 Purpose of the Performance Test

To find out:

• Actual Free Air Delivery (FAD) of the compressor

• Isothermal power required

• Volumetric efficiency

• Specific power requirement

The actual performance of the plant is to be compared with design / standard values for

assessing the plant energy efficiency.

8.3 Performance Terms and Definitions

8.4 Field Testing

8.4.1 Measurement of Free Air Delivery (FAD) by Nozzle method

Principle: If specially shaped nozzle discharge air to the atmosphere from a receiver getting

its supply from a compressor, sonic flow conditions sets in at the nozzle throat for a particular

Bureau of Energy Efficiency 107

8. Energy Performance Assessment of Compressors

ratio of upstream pressure (receiver) to the downstream pressure (atmospheric) i.e. Mach num-

ber equals one.

When the pressure in the receiver is kept constant for a reasonable intervals of time, the air-

flow output of the compressor is equal to that of the nozzle and can be calculated from the

known characteristic of the nozzle.

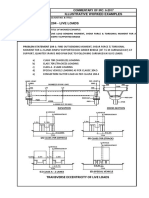

8.4.2 Arrangement of test equipment

The arrangement of test equipment and measuring device shall confirm to Figure 8.1.

8.4.3 Nozzle Sizes

The following sizes of nozzles are recommended for the range of capacities indicated below:

Flow Nozzle: Flow nozzle with profile as desired in IS 10431:1994 and dimensions

Nozzle size (mm) Capacity (m3/hr)

6 3–9

10 9 – 30

16 27 – 90

22 60 – 170

33 130 – 375

50 300 – 450

80 750 – 2000

125 1800 – 5500

165 3500 – 10000

8.4.4 Measurements and duration of the test.

The compressor is started with the air from the receiver discharging to the atmosphere through

the flow nozzle. It should be ensured that the pressure drop through the throttle valve should be

equal to or twice the pressure beyond the throttle. After the system is stabilized the following

measurements are carried out:

• Receiver pressure

• Pressure and temperature before the nozzle

• Pressure drop across the nozzle

• Speed of the compressor

• kW, kWh and amps drawn by the compressor

The above readings are taken for the 40%, 60%, 100% and 110% of discharge pressure values.

Measuring instruments required for test

• Thermometers or Thermocouple

• Pressure gauges or Manometers

• Differential pressure gauges or Manometers

• Standard Nozzle

Bureau of Energy Efficiency 108

8. Energy Performance Assessment of Compressors

• Psychrometer

• Tachometer/stroboscope

• Electrical demand analyser

8.5 Calculation Procedure for Nozzle Method

k : Flow coefficient – as per IS

d : Nozzle diameter M

T1 : Absolute inlet temperature °K

P1 : Absolute inlet pressure kg/cm2

P3 : Absolute Pressure before nozzle kg/cm2

T3 : Absolute temperature before nozzle °K

Ra : Gas constant for air 287.1 J/kg k

P3–P4 : Differential pressure across the nozzle kg/cm2

Bureau of Energy Efficiency 109

8. Energy Performance Assessment of Compressors

II. Isothermal Efficiency = Isothermal power/Input power

Isothermal power(kW) = P1 x Qf x loger

36.7

P1 = Absolute intake pressure kg/ cm2

Qf = Free air delivered m3/hr.

r = Pressure ratio P2/P1

III. Specific power consumption = Power consumption ,kW

at rated discharge pressure Free Air Delivered, m3/hr

IV. Volumetric efficiency = Free air delivered m3/min x 100

Compressor displacement, m3/min

Compressor Displacement = π

x D2 x L x S x χ x n

4

D = Cylinder bore, metre

L = Cylinder stroke, metre

S = Compressor speed rpm

χ = 1 for single acting and

2 for double acting cylinders

n = No. of cylinders

8.6 Example

Calculation of Isothermal Efficiency for a Reciprocating Air Compressor.

Step – 1 : Calculate Volumetric Flow Rate

k : Flow coefficient (Assumed as 1)

d : Nozzle diameter : 0.08 metre

P2 : Receiver Pressure – 3.5 kg / cm2 (a)

P1 : Inlet Pressure – 1.04 kg / cm2(a)

T1 : Inlet air temperature 30°C or 303°K

P3 : Pressure before nozzle – 1.08 kg / cm2

T3 : Temperature before the nozzle 40°C or 313°K

P3 – P4 : Pressure drop across the nozzle = 0.036 kg / cm2

Ra : Gas constant : 287 Joules / kg K

Bureau of Energy Efficiency 110

8. Energy Performance Assessment of Compressors

Step – 2 : Calculate Isothermal Power Requirement

Isothermal Power (kW) = P1 x Qf x loger

36.7

P1 - Absolute intake pressure = 1.04 kg / cm2 (a)

Qf - Free Air Delivered = 1407.6 m3 / h.

Compression ratio r = 3.51 = 3.36

1.04

Isothermal Power = 1.04 x 1407.6 x loge3.36 = 48.34 kW

36.7

Step – 3 : Calculate Isothermal Efficiency

Motor input power = 100 kW

Motor and drive efficiency = 86 %

Compressor input power = 86 kW

Isothermal efficiency = Isothermal Power x 100

Compressor input Power

= 48.34 x 100 = 56%

86.0

8.7 Assessment of Specific Power requirement

Specific power consumption = Actual power consumed by the compressor

Measured Free Air Delivery

In the above example the measured flow is 1407.6 m3/hr and actual power consumption is

100 kW.

Specific power requirement = 100

1407.6

= 0.071 kW/m3/hr

8.8 Measurement of FAD by Pump Up Method

(Note: The following section is a repeat of material provided in the chapter-3 on Compressed

Air System in Book-3.)

Bureau of Energy Efficiency 111

8. Energy Performance Assessment of Compressors

Another way of determining the Free Air Delivery of the compressor is by Pump Up

Method - also known as receiver filling method. Although this is less accurate, this can be

adopted where the elaborate nozzle method is difficult to be deployed.

Simple method of Capacity Assessment in Shop floor

• Isolate the compressor along with its individual receiver being taken for test from main

compressed air system by tightly closing the isolation valve or blanking it, thus closing

the receiver outlet.

• Open water drain valve and drain out water fully and empty the receiver and the pipeline.

Make sure that water trap line is tightly closed once again to start the test.

• Start the compressor and activate the stopwatch.

• Note the time taken to attain the normal operational pressure P2 (in the receiver) from ini-

tial pressure P1.

• Calculate the capacity as per the formulae given below:

Actual Free air discharge

P2 – P1 V

Q = X Nm3/Minute

P0 T

Where

P2 = Final pressure after filling (kg/cm2 a)

P1 = Initial pressure (kg/cm2a) after bleeding

P0 = Atmospheric Pressure (kg/cm2 a)

V = Storage volume in m3 which includes receiver,

after cooler, and delivery piping

T = Time take to build up pressure to P2 in minutes

The above equation is relevant where the compressed air temperature is same as the ambi-

ent air temperature, i.e., perfect isothermal compression. In case the actual compressed air tem-

perature at discharge, say t2°C is higher than ambient air temperature say t1°C (as is usual case),

the FAD is to be corrected by a factor (273 + t1) / (273 + t2).

EXAMPLE

An instrument air compressor capacity test gave the following results (assume the final com-

pressed air temperature is same as the ambient temperature) - Comment?

Piston displacement : 16.88 m3/minute

Theoretical compressor capacity : 14.75 m3/minute @ 7 kg/cm2

Compressor rated rpm 750 : Motor rated rpm : 1445

Receiver Volume : 7.79 m3

Additional hold up volume,

i.e., pipe / water cooler, etc., is : 0.4974 m3

Total volume : 8.322 m3

Bureau of Energy Efficiency 112

8. Energy Performance Assessment of Compressors

Initial pressure P1 : 0.5 kg/cm2

Final pressure P2 : 7.03 kg/cm2

Atmospheric pressure P0 : 1.026 kg/cm2,a

Time taken to buildup pressure

from P1 to P2 : 4.021 minutes

(P2 – P1) × Total Volume

Compressor output m3/minute :

Atm. Pressure × Pumpup time

(7.03 – 0.5) × 8.322

: = 13.17 m3/minute

1.026 × 4.021

Capacity shortfall with respect to 14.75 m3/minute rating is 1.577 m3/minute i.e.,

10.69 %, which indicates compressor performance needs to be investigated further.

Bureau of Energy Efficiency 113

8. Energy Performance Assessment of Compressors

QUESTIONS

1) What is meant by Free Air Delivery?

2) Describe the method of estimating flow by nozzle method.

3) Describe the method of estimating flow by pump up method.

4) Define the term isothermal efficiency and explain its significance.

5) Define the term volumetric efficiency and explain its significance.

6) How is specific power requirement calculated?

REFERENCES

1. IS 10431:1994: Measurement of airflow of compressors and exhausters by nozzles.

2. IS 5456:1985 code of practice for testing of positive displacement type air compressors

and exhausters

3. Compressor performance – Aerodynamics for the user by M Theodore Gresh-

Butterworth Heinemann.

Bureau of Energy Efficiency 114

Vous aimerez peut-être aussi

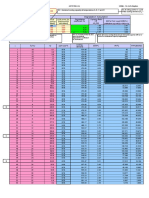

- Final Design Values of PHE C-510 CoolersDocument4 pagesFinal Design Values of PHE C-510 CoolersRamji MishraPas encore d'évaluation

- 07/06/2019 427071582.xls Chiller - Fix CAP+Stepless: Degradation CalculationDocument7 pages07/06/2019 427071582.xls Chiller - Fix CAP+Stepless: Degradation CalculationselisenPas encore d'évaluation

- Ahu 6 Alternate ArrangementDocument4 pagesAhu 6 Alternate Arrangementnaresh100% (1)

- Stacks: Ammonia Injection: A Route To CleanDocument8 pagesStacks: Ammonia Injection: A Route To CleanZEN MA100% (1)

- Cooling Tower Data Sheet REV-00Document12 pagesCooling Tower Data Sheet REV-00Anonymous ZnuMEWN1Pas encore d'évaluation

- Calculating Expansion Tank VolumeDocument5 pagesCalculating Expansion Tank VolumeAhmed AliPas encore d'évaluation

- Hood Design Data - Range of Capture VelocitiesDocument3 pagesHood Design Data - Range of Capture VelocitieszshehadehPas encore d'évaluation

- Fabrication and Working of a Cooling Tower ThesisDocument21 pagesFabrication and Working of a Cooling Tower ThesisNoorul BabaPas encore d'évaluation

- Pump power and sizing calculationDocument1 pagePump power and sizing calculationVIVEKZI0Pas encore d'évaluation

- Equations: Hvac Equations, Data, and Rules of ThumbDocument21 pagesEquations: Hvac Equations, Data, and Rules of ThumbzodedPas encore d'évaluation

- Comprehensive analysis of salt composition and propertiesDocument188 pagesComprehensive analysis of salt composition and propertiesBurhanudin MuizPas encore d'évaluation

- Chiller Size CalculatorDocument4 pagesChiller Size CalculatormpokePas encore d'évaluation

- Cooling Tower UtilitasDocument32 pagesCooling Tower UtilitasVlany DorisPas encore d'évaluation

- Boiler Feed Water Treatment & BlowdownDocument6 pagesBoiler Feed Water Treatment & BlowdownnurulPas encore d'évaluation

- Coil Selection For 38 TR Ahu r0 18.12.2006Document2 pagesCoil Selection For 38 TR Ahu r0 18.12.2006Mohsin ShaikhPas encore d'évaluation

- Psychrometric CalculatorDocument4 pagesPsychrometric CalculatorArie Emmanuel ListonPas encore d'évaluation

- Cal. Dew PointDocument1 pageCal. Dew PointJuan Pablo ApazaPas encore d'évaluation

- Pump Technical Data SheetDocument3 pagesPump Technical Data SheetAnggara PangestuPas encore d'évaluation

- Specifition-Sheet For Evaporator 1. Customer Details A. B. C. D. E. 2. Data Required For EvaporatorDocument2 pagesSpecifition-Sheet For Evaporator 1. Customer Details A. B. C. D. E. 2. Data Required For EvaporatorTowfiq Hossain TaskuPas encore d'évaluation

- Total Head Calculation of Pipe Line and Pump StationDocument7 pagesTotal Head Calculation of Pipe Line and Pump Stationthakur_raghabPas encore d'évaluation

- Energy Optimization in Parallel or Cross Feed Multiple-Effect EvaporatorDocument12 pagesEnergy Optimization in Parallel or Cross Feed Multiple-Effect Evaporatorkishna009Pas encore d'évaluation

- Design of Reactor 1Document13 pagesDesign of Reactor 1Nelykah Rianne MartijaPas encore d'évaluation

- Cooling Tower Calc Efficiency Under 40Document4 pagesCooling Tower Calc Efficiency Under 40Maman HakimPas encore d'évaluation

- Cations PPM As Caco3 Anions PPMDocument9 pagesCations PPM As Caco3 Anions PPMkpranjal15Pas encore d'évaluation

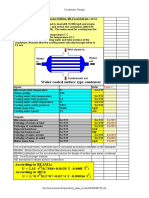

- Condenser DesignDocument2 pagesCondenser DesignRahul ChandrawarPas encore d'évaluation

- Spreadsheet Heat Loss from a PipeDocument1 pageSpreadsheet Heat Loss from a PipeJogender DhayalPas encore d'évaluation

- FAD CALCULATION FOR AIR DELIVERYDocument4 pagesFAD CALCULATION FOR AIR DELIVERYAnonymous JZK84WzfKPas encore d'évaluation

- 1 - Blow-Thru Vs Draw-ThruxDocument2 pages1 - Blow-Thru Vs Draw-ThruxtehtehtehPas encore d'évaluation

- AB&CO Electrical Process Air Heaters: Preliminary Calculation of Prices & DimensionsDocument2 pagesAB&CO Electrical Process Air Heaters: Preliminary Calculation of Prices & DimensionsGeorge ConstantinePas encore d'évaluation

- Ozone Treatment of Cooling Tower WaterDocument26 pagesOzone Treatment of Cooling Tower WaterLh KooPas encore d'évaluation

- Scale-Up Chemical Engineering ProcessesDocument12 pagesScale-Up Chemical Engineering ProcesseskayePas encore d'évaluation

- RTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsDocument2 pagesRTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsJhon LewisPas encore d'évaluation

- Delivery Pipe: System CurvesDocument3 pagesDelivery Pipe: System CurvestankimsinPas encore d'évaluation

- Lindab PascalDocument20 pagesLindab PascalruisengoPas encore d'évaluation

- FD Fan Sizing CalculationDocument3 pagesFD Fan Sizing CalculationkumarananyarupeshPas encore d'évaluation

- Chemical Plant Utility - Nitrogen System DesignDocument10 pagesChemical Plant Utility - Nitrogen System DesignIJRASETPublicationsPas encore d'évaluation

- Waste Heat Recovery (Mech-31)Document18 pagesWaste Heat Recovery (Mech-31)shammiPas encore d'évaluation

- Z-16-412 R0 CB20SG X 1 No Boiler SupplyDocument15 pagesZ-16-412 R0 CB20SG X 1 No Boiler SupplyBashir AliPas encore d'évaluation

- Mechanical Vapor Recompression (MVR) Evaporation Process - ENCON EvaporatorsDocument2 pagesMechanical Vapor Recompression (MVR) Evaporation Process - ENCON EvaporatorsGabriela UrdanetaPas encore d'évaluation

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetraifaisalPas encore d'évaluation

- Prs CatalogueDocument4 pagesPrs CatalogueDylan RamasamyPas encore d'évaluation

- Pack Calculation Pro PDFDocument90 pagesPack Calculation Pro PDFhoangpalestinePas encore d'évaluation

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraPas encore d'évaluation

- EKC316 - Humidification Process Design and Psychrometric AnalysisDocument95 pagesEKC316 - Humidification Process Design and Psychrometric AnalysisSathiswaran SelvamPas encore d'évaluation

- Condensate Line SizingDocument2 pagesCondensate Line SizingWade ColemanPas encore d'évaluation

- AtfdDocument4 pagesAtfdDarshan PatelPas encore d'évaluation

- Kalyani Steels Ltd. Media Consumption ListDocument14 pagesKalyani Steels Ltd. Media Consumption Listmadhusri002Pas encore d'évaluation

- Cooling Tower. Application - TreybalDocument81 pagesCooling Tower. Application - TreybalMarx CesarPas encore d'évaluation

- Humidification Load Calculation Armstrong PDFDocument3 pagesHumidification Load Calculation Armstrong PDFsyedPas encore d'évaluation

- Horizontal KO PotDocument4 pagesHorizontal KO Pothk168Pas encore d'évaluation

- Thermal Conductivity of FRP CompositesDocument69 pagesThermal Conductivity of FRP Compositesjppmj100% (1)

- Air Pollution: Fabric FiltersDocument34 pagesAir Pollution: Fabric FiltersfatimaPas encore d'évaluation

- Return Air Square: Ceiling DiffuserDocument1 pageReturn Air Square: Ceiling DiffuserEnak Cenir100% (1)

- Humidity and Cooling Tower FundamentalsDocument11 pagesHumidity and Cooling Tower FundamentalsMuhammed AfnazPas encore d'évaluation

- Achieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015Document25 pagesAchieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015ansarPas encore d'évaluation

- 08-Electric Water HeaterDocument3 pages08-Electric Water Heatermohamed IbrahemPas encore d'évaluation

- Air Pollution ControlDocument35 pagesAir Pollution ControlPraveen YadavPas encore d'évaluation

- Pharmaceutical Facility DesignDocument27 pagesPharmaceutical Facility Designmdalt9180Pas encore d'évaluation

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsD'EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsPas encore d'évaluation

- Adsorption from Solutions of Non-ElectrolytesD'EverandAdsorption from Solutions of Non-ElectrolytesÉvaluation : 5 sur 5 étoiles5/5 (1)

- System of Compressed Air For Electrofilter in Thermal Power PlantDocument4 pagesSystem of Compressed Air For Electrofilter in Thermal Power PlantAmit JainPas encore d'évaluation

- 1 Matrix Workings - Case Study - Blank Matrix Sheet - SW - Account StatementDocument2 pages1 Matrix Workings - Case Study - Blank Matrix Sheet - SW - Account StatementAmit JainPas encore d'évaluation

- Nokia 710 UG enDocument90 pagesNokia 710 UG enAmit JainPas encore d'évaluation

- Air Piping ManualDocument125 pagesAir Piping ManualAmit JainPas encore d'évaluation

- Nokia 710 UG enDocument90 pagesNokia 710 UG enAmit JainPas encore d'évaluation

- Price List Shri Sumati EnclaveDocument2 pagesPrice List Shri Sumati EnclaveAmit JainPas encore d'évaluation

- L88 enDocument12 pagesL88 enibayraktar775208Pas encore d'évaluation

- Illustrative Worked Examples: Commentary of Irc: 6-2017Document4 pagesIllustrative Worked Examples: Commentary of Irc: 6-2017jatin singla100% (1)

- Davey Dewatering AEMDocument2 pagesDavey Dewatering AEMJohan TanPas encore d'évaluation

- Weekly Physical Science Learning PlanDocument1 pageWeekly Physical Science Learning PlanLea Mae MimayPas encore d'évaluation

- Hydraulic Circuit DesignDocument17 pagesHydraulic Circuit DesignansarALLAAH100% (1)

- 0192 IP PracticeExamDocument32 pages0192 IP PracticeExamlisahunPas encore d'évaluation

- Fire Test Report: ANSI/API Standard 607, 6th Edition, 2010 ISO 10497: 2010Document16 pagesFire Test Report: ANSI/API Standard 607, 6th Edition, 2010 ISO 10497: 2010jamil voraPas encore d'évaluation

- Two Rotor CDocument3 pagesTwo Rotor CmuralidharanPas encore d'évaluation

- "View" "Slide Show.": Resources Chapter MenuDocument62 pages"View" "Slide Show.": Resources Chapter Menuelty TanPas encore d'évaluation

- 9991013Document16 pages9991013dsn_sarmaPas encore d'évaluation

- Guide Rings: Fcs Fluoro Carbon Seals PVT LTDDocument2 pagesGuide Rings: Fcs Fluoro Carbon Seals PVT LTDvikram velayuthamPas encore d'évaluation

- BMQ 30m-Min - 1500mm (SK92172.1AD-IEC71-71LP)Document2 pagesBMQ 30m-Min - 1500mm (SK92172.1AD-IEC71-71LP)YeisonPas encore d'évaluation

- AVK Dams - Reservoirs - HydroPower BrochureDocument15 pagesAVK Dams - Reservoirs - HydroPower Brochureindra putraPas encore d'évaluation

- Remover e Instalar Camisas de CilindrosDocument4 pagesRemover e Instalar Camisas de CilindrosAlejandro ValenzuelaPas encore d'évaluation

- Lg956l&Lg958l&Lg959 Service ManualDocument367 pagesLg956l&Lg958l&Lg959 Service ManualAimHigh100% (1)

- 3039exq Week 11 Session 1 Notes Example The Design of Slender RC ColumnsDocument8 pages3039exq Week 11 Session 1 Notes Example The Design of Slender RC ColumnsengkjPas encore d'évaluation

- Winters FluidpowerDocument8 pagesWinters FluidpowerJOSE DEL CARMEN TOLEDOPas encore d'évaluation

- A Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993 PDFDocument7 pagesA Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993 PDFShiva ShankarPas encore d'évaluation

- Farm Electrification Guide for Efficient Irrigation and MechanizationDocument23 pagesFarm Electrification Guide for Efficient Irrigation and MechanizationSushant YadavPas encore d'évaluation

- Earthquake DescriptorsDocument13 pagesEarthquake DescriptorsDiane Demariano Torcuator60% (5)

- Dytran Reference ManualDocument866 pagesDytran Reference ManualDon100% (2)

- Module 5 DC MachinesDocument94 pagesModule 5 DC MachinesABC XYZPas encore d'évaluation

- Experiment 4 (Physics For Eng)Document9 pagesExperiment 4 (Physics For Eng)RESI-AURIN, JK L.Pas encore d'évaluation

- The Manual of Fastening EN 8100 PDFDocument106 pagesThe Manual of Fastening EN 8100 PDFOleh SmolovyiPas encore d'évaluation

- Training System DS4Document164 pagesTraining System DS4Henrry Roberto Amaya BazánPas encore d'évaluation

- Gas Turb 10Document224 pagesGas Turb 10Mohammad Ali AkhtardaneshPas encore d'évaluation

- Catalog Ecodan - ATW - 2017 PDFDocument32 pagesCatalog Ecodan - ATW - 2017 PDFDamian OvidiuPas encore d'évaluation

- Condenser Hot Vapor Bypass Control: PetrocontrolDocument6 pagesCondenser Hot Vapor Bypass Control: Petrocontrolonizuka-t2263Pas encore d'évaluation

- United States Patent (19) : Ogle 11 4,177,779Document11 pagesUnited States Patent (19) : Ogle 11 4,177,779Zavorra ZavorratoPas encore d'évaluation

- TheArtofAviation 10016620 PDFDocument270 pagesTheArtofAviation 10016620 PDFangelo dosramosPas encore d'évaluation

- Boiler Furnace DefectsDocument4 pagesBoiler Furnace DefectskrishnaPas encore d'évaluation