Académique Documents

Professionnel Documents

Culture Documents

30 V, 26 A, 6.9 m Ω Low R N ch Trench Power MOSFET: DS (ON)

Transféré par

ytnateTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

30 V, 26 A, 6.9 m Ω Low R N ch Trench Power MOSFET: DS (ON)

Transféré par

ytnateDroits d'auteur :

Formats disponibles

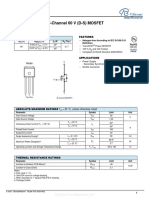

30 V, 26 A, 6.

9 mΩ Low RDS(ON)

N ch Trench Power MOSFET

GKI03080

Features Package

V(BR)DSS --------------------------------- 30 V (ID = 100 µA)

ID ---------------------------------------------------------- 26 A DFN 5 × 6

RDS(ON) ---------- 8.5 mΩ max. (VGS = 10 V, ID = 25.0 A) 8pin 8pin

Qg ------- 7.1 nC (VGS = 4.5 V, VDS = 15 V, ID = 31.5 A) D D D D D D D D

Low Total Gate Charge

High Speed Switching

Low On-Resistance

Capable of 4.5 V Gate Drive

100 % UIL Tested S S S G G S S S

1pin

RoHS Compliant 1pin

Not to scale

Applications

DC-DC converters Equivalent circuit

Synchronous Rectification

D(5)(6)(7)(8)

Power Supplies

G(4)

S(1)(2)(3)

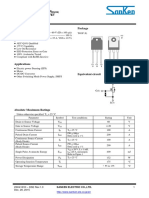

Absolute Maximum Ratings

Unless otherwise specified, TA = 25 °C

Parameter Symbol Test conditions Rating Unit

Drain to Source Voltage VDS 30 V

Gate to Source Voltage VGS ± 20 V

TC = 25 °C,

with infinite heatsink

26 A

Continuous Drain Current ID

TA = 25 °C,

mounted on PCB*

12 A

PW ≤ 100µs

Pulsed Drain Current IDM Duty cycle ≤ 1 %

51 A

Continuous Source Current

IS 26 A

(Body Diode)

Pulsed Source Current PW ≤ 100µs

ISM Duty cycle ≤ 1 %

51 A

(Body Diode)

VDD = 20 V, L = 1 mH,

IAS = 3.4 A, unclamped,

Single Pulse Avalanche Energy EAS RG = 4.7 Ω,

18 mJ

Refer to Figure 1

Avalanche Current IAS 10 A

TC = 25 °C,

with infinite heatsink

40 W

Power Dissipation PD

TA = 25 °C,

mounted on PCB*

3.1 W

Operating Junction Temperature TJ 150 °C

Storage Temperature Range TSTG − 55 to 150 °C

* 1 inch square 2 oz copper pad on 1.5 × 1.5 inch PCB.

GKI03080-DS Rev.1.6 SANKEN ELECTRIC CO.,LTD. 1

Mar. 11, 2015 http://www.sanken-ele.co.jp

GKI03080

Thermal Characteristics

Unless otherwise specified, TA = 25 °C

Parameter Symbol Test Conditions Min. Typ. Max. Unit

Thermal Resistance

RθJC − − 3.1 °C/W

(Junction to Case)

Thermal Resistance

RθJA Mounted on PCB* − − 40.3 °C/W

(Junction to Ambient)

* 1 inch square 2 oz copper pad on 1.5 × 1.5 inch PCB.

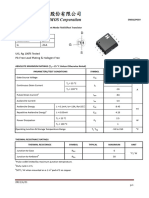

Electrical Characteristics

Unless otherwise specified, TA = 25 °C

Parameter Symbol Test Conditions Min. Typ. Max. Unit

Drain to Source Breakdown

V(BR)DSS ID = 100 μA, VGS = 0 V 30 − − V

Voltage

Drain to Source Leakage Current IDSS VDS = 30 V, VGS = 0 V − − 100 µA

Gate to Source Leakage Current IGSS VGS = ± 20 V − − ± 100 nA

Gate Threshold Voltage VGS(th) VDS = VGS, ID = 250 µA 1.0 2.0 2.5 V

Static Drain to Source ID = 25.0 A, VGS = 10 V − 6.9 8.5 mΩ

RDS(ON)

On-Resistance ID = 12.5 A, VGS = 4.5 V − 9.8 13.0 mΩ

Gate Resistance RG f = 1 MHz − 3.0 − Ω

Input Capacitance Ciss − 1030 −

VDS = 15 V

Output Capacitance Coss VGS = 0 V − 265 − pF

f = 1 MHz

Reverse Transfer Capacitance Crss − 120 −

Total Gate Charge (VGS = 10 V) Qg1 − 16.0 −

Total Gate Charge (VGS = 4.5 V) Qg2 VDS = 15 V − 7.1 −

ID = 31.5 A

nC

Gate to Source Charge Qgs − 2.3 −

Gate to Drain Charge Qgd − 3.1 −

Turn-On Delay Time td(on) − 2.0 −

VDD = 15 V

Rise Time tr ID = 31.5 A − 3.5 −

VGS = 10 V, RG = 4.7 Ω

ns

Turn-Off Delay Time td(off) − 10.9 −

Refer to Figure 2

Fall Time tf − 7.5 −

Source to Drain Diode Forward

VSD IS = 25.0 A, VGS = 0 V − 0.9 1.5 V

Voltage

Source to Drain Diode Reverse

trr IF = 31.5 A − 25.1 − ns

Recovery Time

di/dt = 100 A/µs

Source to Drain Diode Reverse

Qrr Refer to Figure 3 − 21.6 − nC

Recovery Charge

GKI03080-DS Rev.1.6 SANKEN ELECTRIC CO.,LTD. 2

Mar. 11, 2015

GKI03080

Test Circuits and Waveforms

1 V(BR)DSS

E AS L I AS

2

L

2 V(BR)DSS VDD V(BR)DSS

ID

VDS

IAS

RG VDD

VGS VDS VDD

0V ID

(a) Test Circuit (b) Waveform

Figure 1 Unclamped Inductive Switching

RL

90%

VGS

VDS 10%

RG VDD

VGS 90%

VDS

0V 10%

td(on) tr td(off) tf

P.W. = 10 μs

Duty cycle ≤ 1 % ton toff

(a) Test Circuit (b) Waveform

Figure 2 Switching Time

D.U.T.

IF L

IF

VDD trr

RG 0V

IRM × 90 %

VGS di/dt

0V

IRM

(a) Test Circuit (b) Waveform

Figure 3 Diode Reverse Recovery Time

GKI03080-DS Rev.1.6 SANKEN ELECTRIC CO.,LTD. 3

Mar. 11, 2015

GKI03080

RDS(ON)-ID characteristics (typical) RDS(ON)-ID characteristics (typical) ID-VGS characteristics (typical)

VGS=10V VGS=4.5V VDS=5V

16 28 60

14 24 50

12

Tc = 125℃ 20

40

RDS(ON) (mΩ )

RDS(ON) (mΩ )

10

75℃ Tc = 125℃

16

ID (A)

8 25℃ 30

75℃

12

6 25℃

20 Tc =125℃

8

4

75℃

2 4 10 25℃

0 0 0

0 10 20 30 40 50 60 0 10 20 30 40 50 60 0 1 2 3 4 5

ID (A) ID (A) VGS (V)

IDR-VSD characteristics (typical) IDR-VSD characteristics (typical)

VDS-VGS characteristics (typical)

Tc=25℃ VDS=0V

Tc=25℃ 60

0.5 60

VGS=10V

50 50

0.4

40 40

IDR (A)

0.3

VDS (V)

IDR (A)

VGS=4.5V

30 30

Tc =125℃

0.2 3V

ID=25.0A 75℃

20 20

ID=15.8A 0V 25℃

0.1

ID=12.5A 10 10

0.0

0 0

0 5 10 15

0 0.5 1 1.5 0 0.5 1 1.5

VGS (V) VSD (V) VSD (V)

Capacitance-VDS characteristics (typical) VGS - Qg characteristics (typical) Vth-Tc characteristics (typical)

15

10000 3

Ciss

10

1000 2

Vth (V)

Capacitance (pF)

VGS (V)

Coss

5 1

100

Crss Tc=25℃ ID=250uA

Ta=25℃ VDS=15V VGS=VDS

VGS=0V ID=31.5A

f =1MHz

0 0

10

0 10 20 30 0 5 10 15 20 25 50 75 100 125 150

Qg (nC) Tc (℃)

VDS (V)

RDS(ON)-Tc characteristics (typical) RDS(ON)-Tc characteristics (typical) BVDSS-Tc characteristics (typical)

18 24 40

16 39

20

14 38

12 16 37

RDS(ON) (mΩ)

RDS(ON) (mΩ)

BVDSS (V)

36

10

12 35

8

34

6 8

33 ID=1mA

4 VGS=0V

ID=25A 4 32

ID=12.5A

2 VGS=10V

VGS=4.5V 31

0 0

30

25 50 75 100 125 150 25 50 75 100 125 150

25 50 75 100 125 150

Tc (℃) Tc (℃) Tc (℃)

GKI03080-DS Rev.1.6 SANKEN ELECTRIC CO.,LTD. 4

Mar. 11, 2015

GKI03080

PD-Ta Derating SAFE OPERATING AREA

50 100

ID(pulse) MAX

PT=100μs

40

10

30

ID (A)

PT=1ms

PD (W)

20

1

10

1 shot

Tc=25℃

0 0.1

0 50 100 150 0.1 1 10 100

VDS (V)

Ta (℃)

TRANSIENT THERMAL RESISTANCE - PULSE WIDTH

1.E+01

Rth j-c (℃/W)

1.E+00

1.E-01

Tc = 25℃

1shot

VDS < 10V

1.E-02

1.E-04 1.E-03 1.E-02 1.E-01 1.E+00 1.E+01 1.E+02

P.T. (sec)

GKI03080-DS Rev.1.6 SANKEN ELECTRIC CO.,LTD. 5

Mar. 11, 2015

GKI03080

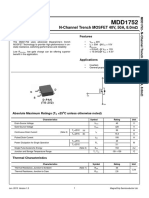

Package Outline

DFN 5 × 6

Symbol Min. Max.

A 1.03 1.17

b 0.34 0.48

C 0.824 0.970

D 4.80 5.40

D1 4.11 4.31

D2 4.80 5.00

E 5.95 6.15

E1 5.65 5.85

E2 1.60 --

e 1.27

L 0.05 0.25

L1 0.38 0.50

L2 0.38 0.50

H 3.30 3.50

I -- 0.18

NOTES:

1) Dimension is in millimeters

2) Pb-free. Device composition compliant with the RoHS directive

Marking Diagram

SK

GKI×××××

Part Number

YMDDXXXB

Lot Number

Y is the Last digit of the year (0 to 9)

M is the Month (1 to 9, O, N or D)

DD is the Date (two digit of 01 to 31)

XXX is the suffix No.

B expresses Pb free pins

GKI03080-DS Rev.1.6 SANKEN ELECTRIC CO.,LTD. 6

Mar. 11, 2015

GKI03080

OPERATING PRECAUTIONS

In the case that you use Sanken products or design your products by using Sanken products, the reliability largely

depends on the degree of derating to be made to the rated values. Derating may be interpreted as a case that an operation

range is set by derating the load from each rated value or surge voltage or noise is considered for derating in order to

assure or improve the reliability. In general, derating factors include electric stresses such as electric voltage, electric

current, electric power etc., environmental stresses such as ambient temperature, humidity etc. and thermal stress caused

due to self-heating of semiconductor products. For these stresses, instantaneous values, maximum values and minimum

values must be taken into consideration. In addition, it should be noted that since power devices or IC’s including power

devices have large self-heating value, the degree of derating of junction temperature affects the reliability significantly.

Because reliability can be affected adversely by improper storage environments and handling methods, please

observe the following cautions.

Cautions for Storage

Ensure that storage conditions comply with the standard temperature (5 to 35°C) and the standard relative humidity

(around 40 to 75%); avoid storage locations that experience extreme changes in temperature or humidity.

Avoid locations where dust or harmful gases are present and avoid direct sunlight.

Reinspect for rust on leads and solderability of the products that have been stored for a long time.

Cautions for Testing and Handling

When tests are carried out during inspection testing and other standard test periods, protect the products from power

surges from the testing device, shorts between the product pins, and wrong connections. Ensure all test parameters are

within the ratings specified by Sanken for the products.

Remarks About Using Thermal Silicone Grease

When thermal silicone grease is used, it shall be applied evenly and thinly. If more silicone grease than required is

applied, it may produce excess stress.

The thermal silicone grease that has been stored for a long period of time may cause cracks of the greases, and it

cause low radiation performance. In addition, the old grease may cause cracks in the resin mold when screwing the

products to a heatsink.

Fully consider preventing foreign materials from entering into the thermal silicone grease. When foreign material

is immixed, radiation performance may be degraded or an insulation failure may occur due to a damaged insulating

plate.

The thermal silicone greases that are recommended for the resin molded semiconductor should be used.

Our recommended thermal silicone grease is the following, and equivalent of these.

Type Suppliers

G746 Shin-Etsu Chemical Co., Ltd.

YG6260 Momentive Performance Materials Japan LLC

SC102 Dow Corning Toray Co., Ltd.

Soldering

When soldering the products, please be sure to minimize the working time, within the following limits:

・Reflow Preheat ; 180 °C / 90 ± 30 s

Solder heating ; 250 °C / 10 ± 1s (260 °C peak, 2 times)

・Soldering iron ; 380 ± 10 °C / 3.5 ± 0.5s (1 time)

Electrostatic Discharge

When handling the products, the operator must be grounded. Grounded wrist straps worn should have at least 1MΩ

of resistance from the operator to ground to prevent shock hazard, and it should be placed near the operator.

Workbenches where the products are handled should be grounded and be provided with conductive table and floor

mats.

When using measuring equipment such as a curve tracer, the equipment should be grounded.

When soldering the products, the head of soldering irons or the solder bath must be grounded in order to prevent

leak voltages generated by them from being applied to the products.

The products should always be stored and transported in Sanken shipping containers or conductive containers, or

be wrapped in aluminum foil.

GKI03080-DS Rev.1.6 SANKEN ELECTRIC CO.,LTD. 7

Mar. 11, 2015

GKI03080

IMPORTANT NOTES

The contents in this document are subject to changes, for improvement and other purposes, without notice. Make

sure that this is the latest revision of the document before use.

Application examples, operation examples and recommended examples described in this document are quoted for

the sole purpose of reference for the use of the products herein and Sanken can assume no responsibility for any

infringement of industrial property rights, intellectual property rights, life, body, property or any other rights of

Sanken or any third party which may result from its use.

Unless otherwise agreed in writing by Sanken, Sanken makes no warranties of any kind, whether express or

implied, as to the products, including product merchantability, and fitness for a particular purpose and special

environment, and the information, including its accuracy, usefulness, and reliability, included in this document.

Although Sanken undertakes to enhance the quality and reliability of its products, the occurrence of failure and

defect of semiconductor products at a certain rate is inevitable. Users of Sanken products are requested to take, at

their own risk, preventative measures including safety design of the equipment or systems against any possible

injury, death, fires or damages to the society due to device failure or malfunction.

Sanken products listed in this document are designed and intended for the use as components in general purpose

electronic equipment or apparatus (home appliances, office equipment, telecommunication equipment, measuring

equipment, etc.).

When considering the use of Sanken products in the applications where higher reliability is required (transportation

equipment and its control systems, traffic signal control systems or equipment, fire/crime alarm systems, various

safety devices, etc.), and whenever long life expectancy is required even in general purpose electronic equipment

or apparatus, please contact your nearest Sanken sales representative to discuss, prior to the use of the products

herein.

The use of Sanken products without the written consent of Sanken in the applications where extremely high

reliability is required (aerospace equipment, nuclear power control systems, life support systems, etc.) is strictly

prohibited.

When using the products specified herein by either (i) combining other products or materials therewith or (ii)

physically, chemically or otherwise processing or treating the products, please duly consider all possible risks that

may result from all such uses in advance and proceed therewith at your own responsibility.

Anti radioactive ray design is not considered for the products listed herein.

Sanken assumes no responsibility for any troubles, such as dropping products caused during transportation out of

Sanken’s distribution network.

The contents in this document must not be transcribed or copied without Sanken’s written consent.

GKI03080-DS Rev.1.6 SANKEN ELECTRIC CO.,LTD. 8

Mar. 11, 2015

Vous aimerez peut-être aussi

- Samsung Bn44-00517c Pslf790d04a Parts InfoDocument15 pagesSamsung Bn44-00517c Pslf790d04a Parts InfoDodi Gak DodolPas encore d'évaluation

- 30 V, 40 A, 2.2 m Ω Low R N ch Trench Power MOSFET: DS (ON)Document8 pages30 V, 40 A, 2.2 m Ω Low R N ch Trench Power MOSFET: DS (ON)ytnatePas encore d'évaluation

- 30V 48A 3.4mΩ Low RDS(ON) N-Channel Power MOSFETDocument8 pages30V 48A 3.4mΩ Low RDS(ON) N-Channel Power MOSFETytnatePas encore d'évaluation

- 60 V, 69 A, 3.9 m Ω Low R N ch Trench Power MOSFET: DS (ON)Document9 pages60 V, 69 A, 3.9 m Ω Low R N ch Trench Power MOSFET: DS (ON)ytnatePas encore d'évaluation

- 40 V, 85 A, 2.6 m Ω Low R N ch Trench Power MOSFET: DS (ON)Document9 pages40 V, 85 A, 2.6 m Ω Low R N ch Trench Power MOSFET: DS (ON)ytnatePas encore d'évaluation

- Pk6H6Ba Niko-Sem: N-Channel Enhancement Mode Field Effect TransistorDocument5 pagesPk6H6Ba Niko-Sem: N-Channel Enhancement Mode Field Effect TransistorSetiawan BurhanPas encore d'évaluation

- N-Channel 60 V (D-S) MOSFET: Features Product SummaryDocument7 pagesN-Channel 60 V (D-S) MOSFET: Features Product SummaryPuti Benny LakraPas encore d'évaluation

- AONR21357 ReemplazoDocument6 pagesAONR21357 ReemplazoDavid Enrique Rivero CahuichPas encore d'évaluation

- 15T15GH HFDocument9 pages15T15GH HFNathan ScorsesePas encore d'évaluation

- NIKO-SEM N-Channel Enhancement Mode Field Effect TransistorDocument4 pagesNIKO-SEM N-Channel Enhancement Mode Field Effect Transistoralan segundo garcia chotaPas encore d'évaluation

- 30V P-Channel MOSFET Product SummaryDocument6 pages30V P-Channel MOSFET Product SummaryStoica VictorPas encore d'évaluation

- Sija58Adp: Vishay SiliconixDocument9 pagesSija58Adp: Vishay SiliconixReza RezaPas encore d'évaluation

- EMB09A03HP ExcellianceMOSDocument9 pagesEMB09A03HP ExcellianceMOSЕвгений ТокаревPas encore d'évaluation

- P2610ADG Niko-Sem: N-Channel Enhancement Mode Field Effect TransistorDocument6 pagesP2610ADG Niko-Sem: N-Channel Enhancement Mode Field Effect Transistormhmd193Pas encore d'évaluation

- General Description Product Summary: 30V N-Channel SRFETDocument6 pagesGeneral Description Product Summary: 30V N-Channel SRFETwillys borjaPas encore d'évaluation

- AM4825PDocument5 pagesAM4825PAlejandroVCMXPas encore d'évaluation

- Aon 7702 ADocument6 pagesAon 7702 AXlabs MedanPas encore d'évaluation

- 2 SK 4161Document9 pages2 SK 4161ytnatePas encore d'évaluation

- DS Am4410n F1 PDFDocument5 pagesDS Am4410n F1 PDFmad saniPas encore d'évaluation

- AOD4 04 / MCD4 04 Freescale: V (V) R M ( ) I (A) Product SummaryDocument3 pagesAOD4 04 / MCD4 04 Freescale: V (V) R M ( ) I (A) Product SummaryLudmila MilaPas encore d'évaluation

- PK616BA: N-Channel Enhancement Mode MOSFETDocument5 pagesPK616BA: N-Channel Enhancement Mode MOSFETGaraShop TecnologiaPas encore d'évaluation

- AONR32320CDocument6 pagesAONR32320CJalu JajangkarPas encore d'évaluation

- General Description Product Summary: 30V P-Channel MOSFETDocument5 pagesGeneral Description Product Summary: 30V P-Channel MOSFETteranet tbtPas encore d'évaluation

- N-Channel Enhancement Mode Field Effect Transistor AOD484Document5 pagesN-Channel Enhancement Mode Field Effect Transistor AOD484kalanghoPas encore d'évaluation

- TSM060NB06CZ: Taiwan SemiconductorDocument6 pagesTSM060NB06CZ: Taiwan Semiconductorn tanevarPas encore d'évaluation

- EMB12P03VDocument5 pagesEMB12P03VBình NguyễnPas encore d'évaluation

- AOD452 N-Channel Enhancement Mode Field Effect Transistor: Features General DescriptionDocument5 pagesAOD452 N-Channel Enhancement Mode Field Effect Transistor: Features General DescriptionDimitri FrancoPas encore d'évaluation

- EMB12N03VDocument5 pagesEMB12N03VChiapin LeePas encore d'évaluation

- Mosfet Substituto 13n03laDocument8 pagesMosfet Substituto 13n03laRisoSilvaPas encore d'évaluation

- Srfet: General Description Product SummaryDocument7 pagesSrfet: General Description Product SummaryRafael SantosPas encore d'évaluation

- Aon 7702Document6 pagesAon 7702Agung HaryantoPas encore d'évaluation

- AM4512C Analog Power P & N-Channel 30-V (D-S) MOSFET: V (V) R M ( ) I (A) Product SummaryDocument8 pagesAM4512C Analog Power P & N-Channel 30-V (D-S) MOSFET: V (V) R M ( ) I (A) Product SummaryAtlantis GuadalupePas encore d'évaluation

- MDD1752 N-Channel MOSFET DatasheetDocument7 pagesMDD1752 N-Channel MOSFET DatasheetHomer Sadych Henao MarinPas encore d'évaluation

- 30V N-Channel AlphaMOS Power MOSFETDocument6 pages30V N-Channel AlphaMOS Power MOSFETFernando TessadriPas encore d'évaluation

- NTD4810N, NVD4810N Power MOSFET: 30 V, 54 A, Single N Channel, DPAK/IPAKDocument8 pagesNTD4810N, NVD4810N Power MOSFET: 30 V, 54 A, Single N Channel, DPAK/IPAKBelkis Amion AlbonigaPas encore d'évaluation

- AOTF4126Document7 pagesAOTF4126José Mauro Costa MacedoPas encore d'évaluation

- N-Ch 30V Fast Switching MOSFETs technical summaryDocument4 pagesN-Ch 30V Fast Switching MOSFETs technical summaryFranklin JimenezPas encore d'évaluation

- AON6908A: General Description Product SummaryDocument11 pagesAON6908A: General Description Product SummaryLuis SantosPas encore d'évaluation

- N-Channel MOSFET Technical SpecificationsDocument3 pagesN-Channel MOSFET Technical SpecificationsRisoSilvaPas encore d'évaluation

- Pk632ba NikosemDocument4 pagesPk632ba NikosemAlien AwePas encore d'évaluation

- AOD452A N-Channel SDMOS POWER Transistor: General Description FeaturesDocument7 pagesAOD452A N-Channel SDMOS POWER Transistor: General Description FeaturesAlexsandro TorezinPas encore d'évaluation

- General Description Product Summary: 30V N-Channel AlphamosDocument6 pagesGeneral Description Product Summary: 30V N-Channel AlphamosDenis DenisovPas encore d'évaluation

- Aon6978 PDFDocument10 pagesAon6978 PDFKakang NggaPas encore d'évaluation

- SUD50N10-18P: Vishay SiliconixDocument10 pagesSUD50N10-18P: Vishay SiliconixWalter CzyzyniewskiPas encore d'évaluation

- VBsemi-Elec-FR120N C879050Document7 pagesVBsemi-Elec-FR120N C879050Truong Dang VinhPas encore d'évaluation

- AON6372Document6 pagesAON6372Akhmad MukhsinPas encore d'évaluation

- D452 AlphaOmegaSemiconductorsDocument5 pagesD452 AlphaOmegaSemiconductorsamerican cutePas encore d'évaluation

- AM4835P Analog Power P-Channel 30-V (D-S) MOSFET: 19 at V - 10V - 9.5 30 at V - 4.5V - 7.5 - 30Document6 pagesAM4835P Analog Power P-Channel 30-V (D-S) MOSFET: 19 at V - 10V - 9.5 30 at V - 4.5V - 7.5 - 30kevin XmxPas encore d'évaluation

- AOD472 N-Channel Enhancement Mode Field Effect Transistor: Features General DescriptionDocument5 pagesAOD472 N-Channel Enhancement Mode Field Effect Transistor: Features General DescriptionAlexsandro TorezinPas encore d'évaluation

- High-efficiency 30V P-channel MOSFETDocument6 pagesHigh-efficiency 30V P-channel MOSFETmagentaPas encore d'évaluation

- P1203BV Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorDocument5 pagesP1203BV Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorMalith UdayangaPas encore d'évaluation

- N-Channel 60 V (D-S) MOSFET: Features Product SummaryDocument7 pagesN-Channel 60 V (D-S) MOSFET: Features Product SummaryOde TtePas encore d'évaluation

- EMB07N03HRDocument6 pagesEMB07N03HRChiapin LeePas encore d'évaluation

- Srfet: Product Summary General DescriptionDocument5 pagesSrfet: Product Summary General DescriptionShamim DhaliPas encore d'évaluation

- Datasheet 4Document4 pagesDatasheet 4Andrey RossiPas encore d'évaluation

- General Description Product Summary: 30V N-Channel AlphamosDocument6 pagesGeneral Description Product Summary: 30V N-Channel AlphamosDavid SimonPas encore d'évaluation

- AOD4184A: General Description Product SummaryDocument6 pagesAOD4184A: General Description Product SummaryAriel dajaoPas encore d'évaluation

- 2SK2837 Series: N-Channel Power MOSFET (20A, 500volts) DescriptionDocument7 pages2SK2837 Series: N-Channel Power MOSFET (20A, 500volts) Descriptionyugewui linPas encore d'évaluation

- N-Channel SDMOSTM POWER Transistor AOD452A Features 55A, 8mΩDocument7 pagesN-Channel SDMOSTM POWER Transistor AOD452A Features 55A, 8mΩFacundo GarcesPas encore d'évaluation

- Ssc1s311a Ds enDocument26 pagesSsc1s311a Ds enGerman DfrPas encore d'évaluation

- DJR 0417Document9 pagesDJR 0417ytnatePas encore d'évaluation

- SSC3S927L Data Sheet: LLC Current-Resonant Off-Line Switching ControllerDocument28 pagesSSC3S927L Data Sheet: LLC Current-Resonant Off-Line Switching ControllerytnatePas encore d'évaluation

- SSC3S931 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerDocument23 pagesSSC3S931 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerytnatePas encore d'évaluation

- 2 SK 3801Document1 page2 SK 3801ytnatePas encore d'évaluation

- fkv460s Ds en PDFDocument1 pagefkv460s Ds en PDFytnatePas encore d'évaluation

- SSC3S900 Series Data Sheet: LLC Current-Resonant Off-Line Switching ControllerDocument32 pagesSSC3S900 Series Data Sheet: LLC Current-Resonant Off-Line Switching ControllerytnatePas encore d'évaluation

- Ssc1s311a Ds enDocument26 pagesSsc1s311a Ds enGerman DfrPas encore d'évaluation

- SSC3S921 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerDocument28 pagesSSC3S921 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerytnatePas encore d'évaluation

- FKP300A: N-Channel MOS FETDocument9 pagesFKP300A: N-Channel MOS FETytnatePas encore d'évaluation

- FKV550T: External Dimensions 1 ...... FM20Document1 pageFKV550T: External Dimensions 1 ...... FM20ytnatePas encore d'évaluation

- MOS FET 2SK3800 maximum ratings and electrical characteristicsDocument1 pageMOS FET 2SK3800 maximum ratings and electrical characteristicsytnatePas encore d'évaluation

- SSC3S910 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerDocument31 pagesSSC3S910 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerytnatePas encore d'évaluation

- Fkv550n Ds enDocument8 pagesFkv550n Ds enytnatePas encore d'évaluation

- FKP300A: N-Channel MOS FETDocument9 pagesFKP300A: N-Channel MOS FETytnatePas encore d'évaluation

- Mosfet: Features PackageDocument9 pagesMosfet: Features PackageytnatePas encore d'évaluation

- 2 SK 3004Document2 pages2 SK 3004ytnatePas encore d'évaluation

- FKP300A: N-Channel MOS FETDocument9 pagesFKP300A: N-Channel MOS FETytnatePas encore d'évaluation

- External Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsDocument2 pagesExternal Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsytnatePas encore d'évaluation

- External Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsDocument2 pagesExternal Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsytnatePas encore d'évaluation

- Sanken Electric : Low On-State Resistance Built-In Gate Protection Diode SMD PKGDocument6 pagesSanken Electric : Low On-State Resistance Built-In Gate Protection Diode SMD PKGytnatePas encore d'évaluation

- 60V N - CH Mosfet: Features Package-TO3PDocument9 pages60V N - CH Mosfet: Features Package-TO3PytnatePas encore d'évaluation

- External Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsDocument2 pagesExternal Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsytnatePas encore d'évaluation

- Specifications List by Part Number: 2-2 Mos FetsDocument3 pagesSpecifications List by Part Number: 2-2 Mos FetsytnatePas encore d'évaluation

- External Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsDocument2 pagesExternal Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsytnatePas encore d'évaluation

- External Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsDocument2 pagesExternal Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsytnatePas encore d'évaluation

- External Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsDocument2 pagesExternal Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsytnatePas encore d'évaluation

- AB01B Data Sheet: V 800 V, I 0.5 A, T 200 Ns Fast Recovery DiodeDocument5 pagesAB01B Data Sheet: V 800 V, I 0.5 A, T 200 Ns Fast Recovery DiodeytnatePas encore d'évaluation

- External Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsDocument2 pagesExternal Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsytnatePas encore d'évaluation

- Had 48Document2 pagesHad 48ytnatePas encore d'évaluation

- This Is Brochure-Trafo-Auto-Centrado-type-DryDocument1 pageThis Is Brochure-Trafo-Auto-Centrado-type-DryfendynovapamelaPas encore d'évaluation

- 24MP48HQ Spec SheetDocument1 page24MP48HQ Spec SheetmaxthiPas encore d'évaluation

- Ka3882/3/4/5 Smps Controller: Current Mode PWM ControllerDocument6 pagesKa3882/3/4/5 Smps Controller: Current Mode PWM Controllerjoil alvesPas encore d'évaluation

- Summative Assessment - I, 202-13: Class - III Subject:-ComputerDocument2 pagesSummative Assessment - I, 202-13: Class - III Subject:-ComputerSavithri MurthyPas encore d'évaluation

- Altera Cyclone III 3C120 Dev KitDocument90 pagesAltera Cyclone III 3C120 Dev KitNguyen Minh ToanPas encore d'évaluation

- User's Guide: TMS320C5515/14/05/04 DSP Inter-IC Sound (I2S) BusDocument38 pagesUser's Guide: TMS320C5515/14/05/04 DSP Inter-IC Sound (I2S) BusDiana MaldonadoPas encore d'évaluation

- Paper 13-Design of An Intelligent Combat Robot For War FieldDocument7 pagesPaper 13-Design of An Intelligent Combat Robot For War FieldDhruv DalwadiPas encore d'évaluation

- Topic#1 Introduction To Semiconductors IndustryDocument28 pagesTopic#1 Introduction To Semiconductors IndustryRio PerezPas encore d'évaluation

- Basic Concepts in Computer Systems ServicingDocument20 pagesBasic Concepts in Computer Systems ServicingMary Jane CenizalPas encore d'évaluation

- Aec AssignmentDocument14 pagesAec AssignmentAnnu YadavPas encore d'évaluation

- Atmel 11121S 32 Bit Cortex A5 Microcontroller SAMA5D3 Summary DatasheetDocument22 pagesAtmel 11121S 32 Bit Cortex A5 Microcontroller SAMA5D3 Summary DatasheetbibloiPas encore d'évaluation

- Pixtend v2 L Connection Planner ExcelDocument1 pagePixtend v2 L Connection Planner ExcelFlorian BichPas encore d'évaluation

- TZX-Series: Vishay SemiconductorsDocument7 pagesTZX-Series: Vishay SemiconductorsFABIAN FIGUEROAPas encore d'évaluation

- 2500 VA 230V safety isolation transformerDocument1 page2500 VA 230V safety isolation transformerpadminittPas encore d'évaluation

- Ict NotesDocument4 pagesIct Noteschelsea nelsonPas encore d'évaluation

- RSRP Vs RSRQ Vs SinrDocument15 pagesRSRP Vs RSRQ Vs SinrmohamedPas encore d'évaluation

- The Veloce Emulator: Laurent VUILLEMIN Platform Compile Software Manager Emulation DivisionDocument36 pagesThe Veloce Emulator: Laurent VUILLEMIN Platform Compile Software Manager Emulation DivisionPhil UrichPas encore d'évaluation

- Final Poster PDFDocument1 pageFinal Poster PDFj4everPas encore d'évaluation

- c2236 TransistorDocument4 pagesc2236 Transistorsekar27Pas encore d'évaluation

- Ideacentre AIO 520-22IKU: F0D50094LDDocument3 pagesIdeacentre AIO 520-22IKU: F0D50094LDklaus82Pas encore d'évaluation

- The Triode ValveDocument6 pagesThe Triode ValveAhmedPas encore d'évaluation

- Profibus Introduction Aug2005 PDFDocument9 pagesProfibus Introduction Aug2005 PDFMohamed IyadPas encore d'évaluation

- Motherboard Vcore VRM Tier ListDocument3 pagesMotherboard Vcore VRM Tier Listmghg100% (1)

- DC Motor Direction Control ReportDocument6 pagesDC Motor Direction Control ReportEngr Farhanullah SarkiPas encore d'évaluation

- 10W Single Output Industrial DIN Rail Power Supply: SeriesDocument2 pages10W Single Output Industrial DIN Rail Power Supply: SeriesCiprian BalcanPas encore d'évaluation

- EMI FIlter DesignDocument27 pagesEMI FIlter DesignankurmalviyaPas encore d'évaluation

- EmulatorDocument2 pagesEmulatorRoger RojasPas encore d'évaluation

- MESH-2100 User ManualDocument2 pagesMESH-2100 User ManualCarlos Daniel CruzPas encore d'évaluation

- KAMC Nurse Call and Infant Protection System CommissioningDocument12 pagesKAMC Nurse Call and Infant Protection System Commissioningmohammed naseer uddinPas encore d'évaluation

- Parallel Operation of DC Generators Homework ProblemsDocument2 pagesParallel Operation of DC Generators Homework ProblemsRyan De GuzmanPas encore d'évaluation