Académique Documents

Professionnel Documents

Culture Documents

C93 310bkW Spec Sheet HEX

Transféré par

Hammad AneesCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

C93 310bkW Spec Sheet HEX

Transféré par

Hammad AneesDroits d'auteur :

Formats disponibles

C9 ACERT™

Industrial Engine

Tier 3/Stage IIIA

280 bkW/375 bhp @ 2200 rpm

CAT® ENGINE SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore......................................................112.0 mm (4.41 in)

Stroke...................................................149.0 mm (5.87 in)

Displacement.......................................... 8.8 L (537.01 in3)

Aspiration...............................Turbocharged Aftercooled

Compression Ratio...................................................16.1:1

Rotation (from flywheel end).............. Counterclockwise

Cooling System............................. 13.9 liters, 3.7 gallons

Lube Oil System (refill)................. 32.0 liters, 8.5 gallons

Weight, Net Dry (approximate kg, lb)..... 776 kg, 1711 lb

Image shown may not reflect

actual engine

FEATURES

Emissions Full Range of Attachments

Meets U.S. EPA Tier 3, EU Stage IIIA emission Wide range of bolt-on system expansion

requirements. attachments, factory designed and tested.

Worldwide Supplier Capability Unmatched Product Support Offered Through

Caterpillar Worldwide Caterpillar Dealer Network

- Casts engine blocks, heads, and cylinder liners More than 1,500 dealer outlets

- Machines critical components Caterpillar factory-trained dealer technicians service

- Assembles complete engine every aspect of your industrial engine

- Factory-designed systems built at Caterpillar ISO 99.7% of parts orders filled within 24 hours

9001:2000 certified facilities worldwide

-Ownership of these manufacturing processes Caterpillar parts and labor warranty

enables Caterpillar to produce high quality, Preventive maintenance agreements available for

dependable product. repair before failure options

Testing Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to

Prototype testing on every model: determine:

- proves computer design - internal engine component condition

- verifies system torsional stability - presence of unwanted fluids

- functionality tests every model - presence of combustion by-products

Every Caterpillar engine is dynamometer tested

under full load to ensure proper engine Web Site

performance. For all your industrial power requirements, visit

www.cat-industrial.com.

16 April 2012 11:09 AM

C9 ACERT™

Industrial Engine

Tier 3/Stage IIIA

STANDARD ENGINE EQUIPMENT 280 bkW/375 bhp @ 2200 rpm

Air Inlet System Fuel System

Air to air aftercooled (ATAAC) HEUI injection

Turbocharged Fuel filter, secondary (2 micron high performance)

Fuel transfer pump

Control System Fuel priming pump

ACERT™ Technology

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation Lube System

Power compensation for fuel temperature Crankcase breather

Programmable low and high idle and total engine Oil cooler

limit Oil filler

Electronic diagnostics and fault logging Oil filter

Engine monitoring system Oil pan front sump

J1939 Broadcast (diagnostic and engine status) Oil dipstick

ADEM™ A4 Oil pump (gear driven)

Cooling System General

Thermostats and housing, vertical outlet Paint, Caterpillar Yellow

Jacket water pump, centrifugal Vibration damper

Water pump, inlet Lifting eyes

Exhaust System

Exhaust manifold, dry

Optional exhaust outlet

Flywheels and Flywheel Housing

SAE No. 1 Flywheel housing

2 16 April 2012 11:09 AM

C9 ACERT™

Industrial Engine

Tier 3/Stage IIIA

PERFORMANCE CURVES 280 bkW/375 bhp @ 2200 rpm

IND - D - DM8120-00

Torque Metric

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Engine Speed Engine Power Torque N•m BSFC g/kW-hr Fuel Rate L/hr

rpm kW

2200 280 1215 228 76.1

2100 280 1273 225.9 75.4

2000 280 1337 222.8 74.4

1900 280 1407 219.7 73.3

1800 280 1485 217.1 72.5

1700 274 1537 216.3 70.6

1600 266 1589 216.5 68.7

1500 257 1638 217.3 66.6

1400 245 1668 219.8 64.0

1300 215 1580 225.3 57.8

1200 160 1270 231.2 44.0

1100 115 1000 236.8 32.5

3 16 April 2012 11:09 AM

C9 ACERT™

Industrial Engine

Tier 3/Stage IIIA

PERFORMANCE CURVES 280 bkW/375 bhp @ 2200 rpm

IND - D - DM8120-00

Engine English

Torque

lb•ft

Engine

Power bhp

BSFC

lb/bhp-hr

Engine Speed rpm

Engine Speed Engine Power Engine Torque BSFC lb/bhp-hr Fuel Rate

rpm bhp lb•ft gal/hr

2200 375 896 .375 20.1

2100 375 939 .371 19.9

2000 375 986 .366 19.7

1900 375 1038 .361 19.4

1800 375 1095 .357 19.2

1700 367 1134 .356 18.7

1600 357 1172 .356 18.1

1500 345 1208 .357 17.6

1400 328 1230 .361 16.9

1300 288 1165 .370 15.3

1200 214 937 .380 11.6

1100 154 738 .389 8.6

4 16 April 2012 11:09 AM

C9 ACERT™

Industrial Engine

Tier 3/Stage IIIA

RATINGS AND CONDITIONS 280 bkW/375 bhp @ 2200 rpm

IND - D For service where maximum power is Engine Performance Diesel Engines — 7 liter and

required for periodic overloads. higher All rating conditions are based on SAE J1995,

inlet air standard conditions of 99 kPa (29.31 in. Hg)

dry barometer and 25ºC (77ºF) temperature.

Performance measured using a standard fuel with

fuel gravity of 35º API having a lower heating value

of 42,780 kJ/kg (18,390 btu/lb) when used at 29º C

(84.2º F) with a density of 838.9 g/L.

Engine Dimensions

(1) Length 1091.4 mm (42.97 in) Note: Do not use for installation design.

See general dimension drawings for

(2) Width 827.2 mm (32.57 in) detail (Drawing # 2651026 ).

(3) Height 1022.8 mm (40.27 in)

Performance Number: DM8120-00 © 2012 Caterpillar

Feature Code: C09DI14 Arr. Number: 2524433 All rights reserved.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

16289399 CAT, CATERPILLAR, their respective logos, "Caterpillar Yellow," the

"Power Edge" trade dress, as well as corporate and product identity

used herein, are trademarks of Caterpillar and may not be used

without permission.

Vous aimerez peut-être aussi

- C9 ACERT 224bkWDocument5 pagesC9 ACERT 224bkWAlief FadilPas encore d'évaluation

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesD'EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesPas encore d'évaluation

- C7 Acert EspecificaciónDocument5 pagesC7 Acert EspecificaciónFabrizio Jesus Morales Salirrosas100% (1)

- Designing and Tuning High-Performance Fuel Injection SystemsD'EverandDesigning and Tuning High-Performance Fuel Injection SystemsÉvaluation : 3.5 sur 5 étoiles3.5/5 (7)

- Motor CAT C9Document4 pagesMotor CAT C9avictoras100% (2)

- C7 ACERT 205bkWDocument5 pagesC7 ACERT 205bkWsheronPas encore d'évaluation

- 03 Engine Specification Sheet - C9Document5 pages03 Engine Specification Sheet - C9avinash_1229Pas encore d'évaluation

- Cat® Engine Specifications: C18 Acert Industrial EngineDocument5 pagesCat® Engine Specifications: C18 Acert Industrial EngineAsif MehmoodPas encore d'évaluation

- C18 ACERT 470bkWDocument5 pagesC18 ACERT 470bkWAlief FadilPas encore d'évaluation

- CAT-C15 ACERT-Ind - EngineDocument5 pagesCAT-C15 ACERT-Ind - EngineRakesh DoshiPas encore d'évaluation

- C11 ACERT 261bkWDocument5 pagesC11 ACERT 261bkWJulio huanriPas encore d'évaluation

- Cat® Engine Specifications: C13 Acert Industrial EngineDocument5 pagesCat® Engine Specifications: C13 Acert Industrial EngineالمهندسوليدالطويلPas encore d'évaluation

- C18-Rating ADocument5 pagesC18-Rating AFirzan Yudhistira PutraPas encore d'évaluation

- Especificaciones Motor CatDocument5 pagesEspecificaciones Motor CatWalter TaucherPas encore d'évaluation

- Cat® Engine Specifications: C18 Acert Industrial EngineDocument5 pagesCat® Engine Specifications: C18 Acert Industrial Enginevo phuongPas encore d'évaluation

- Caterpillar Engine Specifications: C15 Acert Industrial Power UnitDocument5 pagesCaterpillar Engine Specifications: C15 Acert Industrial Power UnitGoran MatovicPas encore d'évaluation

- Cat c9 300 HP Spec SheetDocument7 pagesCat c9 300 HP Spec SheetDennis K ThomasPas encore d'évaluation

- SS-003484 Industrial-C9 Dita-2200 RPM-224 KW-DM8117-01Document5 pagesSS-003484 Industrial-C9 Dita-2200 RPM-224 KW-DM8117-01Agung TriyonoPas encore d'évaluation

- CAT C9 ACERT Engine PDFDocument4 pagesCAT C9 ACERT Engine PDFettoscar100% (1)

- c7 168 KW Spec Sheet Abby PDFDocument4 pagesc7 168 KW Spec Sheet Abby PDFAlfonzo PerezPas encore d'évaluation

- C15 Acert: Industrial Caterpillar Engine SpecificationsDocument4 pagesC15 Acert: Industrial Caterpillar Engine Specificationsyash singhPas encore d'évaluation

- CaterpillarDocument29 pagesCaterpillarrobert_candra_tarunaPas encore d'évaluation

- Lehh0541 00Document3 pagesLehh0541 00Dedi MaryadiPas encore d'évaluation

- Cat 3406 Fuel ConsumptionDocument5 pagesCat 3406 Fuel Consumptionayman akrab100% (2)

- CAT 3406 C Heavy Duty Truck EngineDocument5 pagesCAT 3406 C Heavy Duty Truck EngineAS_865025438100% (1)

- Caterpillar 3408Document5 pagesCaterpillar 3408Fernando Padilla100% (3)

- C9.3 Acert Industrial Power Unit: Tier 4 Final, Stage Iv Technology 224-298 Bkw/300-400 BHP at 1800-2200 RPMDocument4 pagesC9.3 Acert Industrial Power Unit: Tier 4 Final, Stage Iv Technology 224-298 Bkw/300-400 BHP at 1800-2200 RPMAditi DasPas encore d'évaluation

- Lehh0025-00 C6.6 Acert Power Unit For Irrigation & Ind PumpDocument2 pagesLehh0025-00 C6.6 Acert Power Unit For Irrigation & Ind PumpAgung TriyonoPas encore d'évaluation

- Engine Brochure Industrial-3406c Dita-2000 Rpm-328 Kw-dm0346-01Document5 pagesEngine Brochure Industrial-3406c Dita-2000 Rpm-328 Kw-dm0346-01maekel abdul HakimPas encore d'évaluation

- 3508 Ind C A 1800 RPMDocument5 pages3508 Ind C A 1800 RPMJeinnerCastroPas encore d'évaluation

- C2.2NA Fire Pump HX 2022Document6 pagesC2.2NA Fire Pump HX 2022dfheardPas encore d'évaluation

- C15 ACERT 354bkWDocument5 pagesC15 ACERT 354bkWrodizianoPas encore d'évaluation

- Spec Sheet Industry 170HP Tot 450HPDocument34 pagesSpec Sheet Industry 170HP Tot 450HPJonh BladerPas encore d'évaluation

- CAT Engine Specifications: 3516B Offshore Generator SetDocument6 pagesCAT Engine Specifications: 3516B Offshore Generator SetKarel GómezPas encore d'évaluation

- Cat 3412e PDFDocument4 pagesCat 3412e PDFCristina CoceasuPas encore d'évaluation

- Lehw0053 00Document4 pagesLehw0053 00kumarraghuPas encore d'évaluation

- Cat® Engine SpecificationsDocument5 pagesCat® Engine SpecificationsadelabostatPas encore d'évaluation

- Cat 3516Document4 pagesCat 3516Muhammad IshfaqPas encore d'évaluation

- CaterpillarDocument4 pagesCaterpillarrobert_candra_tarunaPas encore d'évaluation

- Motores Industriales Diesel Cat c7 AcertDocument2 pagesMotores Industriales Diesel Cat c7 AcertMirko Alejandro Garcia SilvaPas encore d'évaluation

- CAT Engine Specifications: 3508B Land Mechanical EngineDocument4 pagesCAT Engine Specifications: 3508B Land Mechanical Enginemehdi kamaliPas encore d'évaluation

- Lehw0258 02Document4 pagesLehw0258 02Robel KebedePas encore d'évaluation

- C7 Petroleum EngineDocument4 pagesC7 Petroleum Engineavinash_1229Pas encore d'évaluation

- Cat® Engine Specifications: C32 Acert Industrial EngineDocument5 pagesCat® Engine Specifications: C32 Acert Industrial EnginerodizianoPas encore d'évaluation

- Industrial Caterpillar Engine Specifications: V12, 4-Stroke-Cycle DieselDocument5 pagesIndustrial Caterpillar Engine Specifications: V12, 4-Stroke-Cycle DieselLuis Eduardo Albarracin RugelesPas encore d'évaluation

- Lehh0022 Cat 6.6 PDFDocument4 pagesLehh0022 Cat 6.6 PDFRobinson GuanemePas encore d'évaluation

- Mss-Ind-18429639-013 C7 Iopu SpecsheetDocument3 pagesMss-Ind-18429639-013 C7 Iopu SpecsheetJoko SusiloPas encore d'évaluation

- Specifi Cations: C32 Acert™ Locomotive EngineDocument5 pagesSpecifi Cations: C32 Acert™ Locomotive EngineIssa DRAMANEPas encore d'évaluation

- LEHW0175Document4 pagesLEHW0175حسين عبدالهاديPas encore d'évaluation

- Lehw0124 01Document6 pagesLehw0124 01Hosam HamdyPas encore d'évaluation

- Lehw0013 01Document4 pagesLehw0013 01ingcalderonPas encore d'évaluation

- Manual 3306 CaterpillarDocument5 pagesManual 3306 CaterpillarCRISTOBAL HUMBERTO AGUILAR ROSENDOPas encore d'évaluation

- m20 C18 FIRE PUMP 448 BKW 600 BHP 1750 RPMDocument5 pagesm20 C18 FIRE PUMP 448 BKW 600 BHP 1750 RPMStalinTelmoPas encore d'évaluation

- CAT Engine Specifications: 3508B Offshore Emergency Generator SetDocument6 pagesCAT Engine Specifications: 3508B Offshore Emergency Generator SetGazPas encore d'évaluation

- Motores Industriales Diesel Cat c9 AcertDocument2 pagesMotores Industriales Diesel Cat c9 AcertpillueloingPas encore d'évaluation

- CAT Engine Specifications: C32 Acert Petroleum EngineDocument4 pagesCAT Engine Specifications: C32 Acert Petroleum EngineArvind HarryPas encore d'évaluation

- Manual 3306 Caterpillar PDFDocument4 pagesManual 3306 Caterpillar PDFmuhammad aliPas encore d'évaluation

- Lecture c4 System IdentificationDocument93 pagesLecture c4 System IdentificationHammad AneesPas encore d'évaluation

- Tensions When Innovating Circular EconomyDocument11 pagesTensions When Innovating Circular EconomyHammad AneesPas encore d'évaluation

- Control Theory - : C3. Linearization of Nonlinear SystemsDocument21 pagesControl Theory - : C3. Linearization of Nonlinear SystemsHammad AneesPas encore d'évaluation

- 55 6520 PDFDocument1 page55 6520 PDFHammad AneesPas encore d'évaluation

- MECH 300: Summer PracticeDocument30 pagesMECH 300: Summer PracticeHammad AneesPas encore d'évaluation

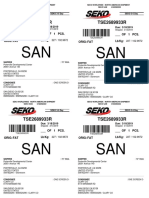

- San San: Tse2689933r Tse2689933rDocument1 pageSan San: Tse2689933r Tse2689933rHammad AneesPas encore d'évaluation

- RMA100876 Return Label PDFDocument1 pageRMA100876 Return Label PDFHammad AneesPas encore d'évaluation

- RMA100867 Return LabelDocument1 pageRMA100867 Return LabelHammad AneesPas encore d'évaluation

- RMA100889 Return Label PDFDocument3 pagesRMA100889 Return Label PDFHammad AneesPas encore d'évaluation

- RMA100868 Return Label PDFDocument2 pagesRMA100868 Return Label PDFHammad AneesPas encore d'évaluation

- Manual Motor Cat c9Document3 pagesManual Motor Cat c9Hammad AneesPas encore d'évaluation

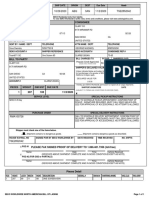

- Rma100726 Bol PDFDocument1 pageRma100726 Bol PDFHammad AneesPas encore d'évaluation

- Documents - MX - Caterpillar c9 Schematic PDFDocument4 pagesDocuments - MX - Caterpillar c9 Schematic PDFLuis Emilio Santana DiazPas encore d'évaluation

- Documents - MX - Caterpillar c9 Schematic PDFDocument4 pagesDocuments - MX - Caterpillar c9 Schematic PDFLuis Emilio Santana DiazPas encore d'évaluation

- C93 310bkW Spec Sheet HEXDocument4 pagesC93 310bkW Spec Sheet HEXHammad AneesPas encore d'évaluation

- TPMS - 021709 LR5Document88 pagesTPMS - 021709 LR5juanPas encore d'évaluation

- A6000 Digital Motor Electronics Control Unit: Connector Location ViewsDocument5 pagesA6000 Digital Motor Electronics Control Unit: Connector Location ViewsHugo Gear100% (2)

- Sea-Doo Stock Carb SettingsDocument4 pagesSea-Doo Stock Carb SettingsvalkosavovPas encore d'évaluation

- Engine Electrical SystemDocument79 pagesEngine Electrical SystemCristian MirandaPas encore d'évaluation

- Autonomous CarDocument41 pagesAutonomous CarZia AzamPas encore d'évaluation

- Ducati Diavel 1200 Carbon, ABS '11 Service ManualDocument875 pagesDucati Diavel 1200 Carbon, ABS '11 Service ManualNikolas Karrer100% (7)

- MoT Issue 31 - Apr 2006Document8 pagesMoT Issue 31 - Apr 2006m_eves5314Pas encore d'évaluation

- Bomag BW177D-3 BW177DH-3 BW177PDH-3 PDFDocument4 pagesBomag BW177D-3 BW177DH-3 BW177PDH-3 PDFMahmoud Emam100% (1)

- Techincal SeminarDocument16 pagesTechincal SeminarVenukanth S-2019Pas encore d'évaluation

- GM Gen. 1 6T70/75 GM Gen. 2 6T70/75/80Document10 pagesGM Gen. 1 6T70/75 GM Gen. 2 6T70/75/80fabricio0svs0liraPas encore d'évaluation

- Spirax s5 Atf XDocument3 pagesSpirax s5 Atf XElectro killPas encore d'évaluation

- Review of Engine Cycles: Lecture #7 - Week3Document24 pagesReview of Engine Cycles: Lecture #7 - Week3Isyraf FitriPas encore d'évaluation

- GSF150 BanditDocument163 pagesGSF150 BanditDar Sono SuPas encore d'évaluation

- 4 F 27 eDocument122 pages4 F 27 eApple MiseryPas encore d'évaluation

- The Vito: Panel Van, Dualiner and TravelinerDocument24 pagesThe Vito: Panel Van, Dualiner and TravelinerGeir Markussen100% (1)

- Timing Belt Installation PDFDocument7 pagesTiming Belt Installation PDFHadeka PainoPas encore d'évaluation

- Design of Radial Engine With Different Metals Using AnsysDocument74 pagesDesign of Radial Engine With Different Metals Using Ansysibrahim67% (3)

- KbxPrice List W e F 1st July 2017Document17 pagesKbxPrice List W e F 1st July 2017Jaydeep KachchhavaPas encore d'évaluation

- Simone Mola - Fundamentals of Vehicle DynamicsDocument353 pagesSimone Mola - Fundamentals of Vehicle DynamicsWagner AbreuPas encore d'évaluation

- 89n303 The Touareg V10-TDI EngineDocument50 pages89n303 The Touareg V10-TDI Engineeduardorojas007100% (3)

- Motore - Engine Moteur - Moto R DY 36Document25 pagesMotore - Engine Moteur - Moto R DY 36DOMINGOS VELHO100% (1)

- Filter Catalog 4-2017Document81 pagesFilter Catalog 4-2017Ramses Hernandez100% (1)

- Wa320 5Document228 pagesWa320 5Felipe Naxo Becerra Arriagada50% (2)

- 125 and 160kva Material Cost For 3 YearDocument1 page125 and 160kva Material Cost For 3 Yearnirav patelPas encore d'évaluation

- Warehouse Report JuliDocument983 pagesWarehouse Report Julishubham sahuPas encore d'évaluation

- Hatlapa L220, L270, L350Document2 pagesHatlapa L220, L270, L350hao0% (1)

- PIDS Other Attached DocumentsDocument13 pagesPIDS Other Attached DocumentsAtty. Lynn ElevadoPas encore d'évaluation

- Linea de Monta CargasDocument14 pagesLinea de Monta CargasAlvin Smith Buelvas Barandica100% (1)

- ME 530 Project Report 42F152F14Document12 pagesME 530 Project Report 42F152F14Anonymous JhK8arPas encore d'évaluation