Académique Documents

Professionnel Documents

Culture Documents

HAZOP Table Week 8

Transféré par

Lavender Man100%(2)100% ont trouvé ce document utile (2 votes)

74 vues2 pagesTitre original

HAZOP Table Week 8.docx

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

100%(2)100% ont trouvé ce document utile (2 votes)

74 vues2 pagesHAZOP Table Week 8

Transféré par

Lavender ManDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

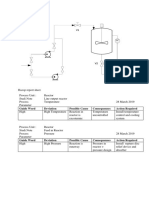

System/Project: Heat Exchanger 818C Facilitator: SAHIL HARIRAMANI

Group members SAHIL HARIRAMANI, JOEL SHAH, JORDAN WILSON, JOSHUA

Date: 4th May 2018 present: VARDY, JACKY CHEW, MUNIB JAVED

P&ID No: P2-62-D1 Line No:

Scope HX818C Line description:

Parameter Deviation Possible causes Consequences Safeguards Action Responsible

Pressure vessel might Relief Valve (Vent Perform regular Maintenance

PRESSURE High Overheating of naptha rupture 25) maintenance checks Operators

Blockage in shell side pipe Increased likelihood of Relief Valve (Vent Perform regular Maintenance

PRESSURE High outlet (naptha) explosion 25) maintenance checks Operators

Increased flowrate of the Increased likelihood of Relief Valve (Vent Perform regular Maintenance

PRESSURE High tube side (kerosene) explosion 25) maintenance checks Operators

Decreased flowrate of the Potential of structural Perform regular Maintenance

PRESSURE Low tube side (kerosene) damage Flow Controller 8204 maintenance checks Operators

Potential of structural Perform regular Maintenance

PRESSURE Low Spurious failure of valve damage None available maintenance checks Operators

Increased damage to pipes

Increased flowrate of the as hot vapour will be Control

TEMPERATURE High tube side (kerosene) flowing through it None in place Flow Controllers Engineer

Decreased flow rate of Failure of shell side inlet Perform regular Maintenance

TEMPERATURE High shell side inlet (naptha) valve None in place maintenance checks Operators

Perform regular Maintenance

TEMPERATURE Low Fouling on HX818C tubes Flooding of the HX818C None in place maintenance checks Operators

Increased flowrate of the Control

TEMPERATURE Low shell side (Naptha) Flooding of the HX818C None in place Flow Controllers Engineer

Decreased flowrate of the Temperature Perform regular Maintenance

TEMPERATURE Low tube side (kerosene) Flooding of the HX818C Controller 8208 maintenance checks Operators

Low Temperature of tube-

side inlet causing low HT

causing more liquid to be Control

LEVEL High retained in HX818C Flooding of the HX818C None in Place Level Controller Engineer

High Temperature of tube-

side inlet causing low HT

causing little (or no) liquid Damaging of HX818C Control

LEVEL Low to be retained in HX818C tubes None in Place Level Controller Engineer

Damaging of HX818C Control

LEVEL None Blockage of shell-side inlet tubes None in Place Flow Controller Engineer

Overheating of shell side Control

FLOW Low Pipe Leakage (Inlet) liquid None in Place Flow Sensor Engineer

Incorrect valve positioning Decreased temperature of Control

FLOW High (shell-side inlet) shell-side outlet None in Place Flow Sensor Engineer

Failure of shell-side outlet Control

FLOW Reverse valve Damage to HX818C None in Place Flow Controller Engineer

Product specifications not Perform regular Maintenance

COMPOSITION As well as Pipe rupture met None in Place maintenance checks Operators

Perform regular Maintenance

CORROSION High Contaminants High Flow None in Place maintenance checks Operators

Pipe rupture (in extreme Perform regular Maintenance

CORROSION High Contaminants cases) None in Place maintenance checks Operators

Decreased heat transfer in Perform regular Maintenance

CORROSION High Contaminants HX818C None in Place maintenance checks Operators

Vous aimerez peut-être aussi

- HAZOP Studies On Distillation ColumnDocument3 pagesHAZOP Studies On Distillation ColumnHaneen HamamPas encore d'évaluation

- Distillation Column HAZOPDocument6 pagesDistillation Column HAZOPAhmer SohailPas encore d'évaluation

- HAzopDocument2 pagesHAzopMehran IsgandarliPas encore d'évaluation

- Hazop For ReactorDocument2 pagesHazop For ReactorHuda100% (1)

- HAZOP Neautralization ReactorDocument4 pagesHAZOP Neautralization ReactorIssyahira Ernie100% (1)

- Methanol Production Plant Feed Inlet Into Reformer, R-01 Supply Heat To FeedDocument12 pagesMethanol Production Plant Feed Inlet Into Reformer, R-01 Supply Heat To FeedAin SyuhadaPas encore d'évaluation

- Hazop For CSTRDocument3 pagesHazop For CSTRRomel Leo100% (1)

- Hazard and Operability StudyDocument43 pagesHazard and Operability Studyhell oPas encore d'évaluation

- Bottom Outet Sliding Gate OperationDocument29 pagesBottom Outet Sliding Gate OperationLovewater RainingPas encore d'évaluation

- Case Study 2Document2 pagesCase Study 2SyafiyatulMunawarahPas encore d'évaluation

- Final AssignmentDocument14 pagesFinal Assignmentquik silvaPas encore d'évaluation

- Standard Operating Procedure For Hy-Lp Bypass System: ObjectiveDocument8 pagesStandard Operating Procedure For Hy-Lp Bypass System: ObjectiveSonratPas encore d'évaluation

- Tutorial Hazop: Node Guide Word Deviation Possible Cause Consequences Action RequiredDocument3 pagesTutorial Hazop: Node Guide Word Deviation Possible Cause Consequences Action RequiredSyafiyatulMunawarahPas encore d'évaluation

- Control Valve Selection Guide - Valve Selection - Valve HandbookDocument21 pagesControl Valve Selection Guide - Valve Selection - Valve Handbook2g2qscbv5pPas encore d'évaluation

- Training Module THINKTANKcontrol Valve PDFDocument90 pagesTraining Module THINKTANKcontrol Valve PDFkam.kimou16Pas encore d'évaluation

- I - Process-ControlDocument79 pagesI - Process-Controlenge.aqeelPas encore d'évaluation

- 5 Process ControlDocument79 pages5 Process ControlGurunath EpiliPas encore d'évaluation

- sm-ts3 p1-6 Errorcode PDFDocument6 pagessm-ts3 p1-6 Errorcode PDFslumber_86Pas encore d'évaluation

- Process Instrumentation and Control SystemDocument78 pagesProcess Instrumentation and Control SystemMorgen Mukamwi100% (1)

- Preliminary - MITTEN HPU Only Rev DDocument120 pagesPreliminary - MITTEN HPU Only Rev DFabyano BrittoPas encore d'évaluation

- Group AssignmentDocument30 pagesGroup AssignmentmiexaraPas encore d'évaluation

- 4W04 Slides HAZOPDocument16 pages4W04 Slides HAZOPharveyPas encore d'évaluation

- 970 Series Hydraulic Test Stand: With Computer Monitoring and Data Acquisition (Apd )Document5 pages970 Series Hydraulic Test Stand: With Computer Monitoring and Data Acquisition (Apd )Sajad KarimiPas encore d'évaluation

- Guide Word Deviation Possible Cause Consequenses Action RequiredDocument2 pagesGuide Word Deviation Possible Cause Consequenses Action RequiredMuhamad FajarPas encore d'évaluation

- Hazard and Operability Study (Hazop)Document16 pagesHazard and Operability Study (Hazop)Usman KhalidPas encore d'évaluation

- I. Brief On Process Unit Description Including Design Intents.Document6 pagesI. Brief On Process Unit Description Including Design Intents.izzhamizmPas encore d'évaluation

- Please Give Me Your Comment in This Presentation 1639101925Document79 pagesPlease Give Me Your Comment in This Presentation 1639101925Adith Wiendar P PutraPas encore d'évaluation

- 1 Turbine ProtectionDocument16 pages1 Turbine ProtectionAnonymous 0lB7qDRMbO100% (1)

- SQX62UDocument12 pagesSQX62UboroumandPas encore d'évaluation

- Control SystemDocument52 pagesControl SystemRana KashifPas encore d'évaluation

- Hazard and Operability Studies (HAZOP) 2Document15 pagesHazard and Operability Studies (HAZOP) 2jeevanantham 5846Pas encore d'évaluation

- Control Valves P&I DiagramDocument27 pagesControl Valves P&I DiagramSudarshan NavalePas encore d'évaluation

- HAZOP Write UpDocument3 pagesHAZOP Write UpGlacier RamkissoonPas encore d'évaluation

- Maintenance ApproachDocument4 pagesMaintenance ApproachBarathPas encore d'évaluation

- CPE 664 Design Project 2 Design ProjectDocument120 pagesCPE 664 Design Project 2 Design Projectsuhel ahmadPas encore d'évaluation

- HAZOP Worksheet: Node: 11 Type: Drawing: Design Conditions/parametersDocument3 pagesHAZOP Worksheet: Node: 11 Type: Drawing: Design Conditions/parametersAminPas encore d'évaluation

- Technical Submittal 1000kVA PAECDocument9 pagesTechnical Submittal 1000kVA PAECGhilman HabibPas encore d'évaluation

- Presentation Rev02Document41 pagesPresentation Rev02Yu HuiPas encore d'évaluation

- R - Set 2 HazopDocument2 pagesR - Set 2 HazopSynthia RashidPas encore d'évaluation

- What Is PID ControlDocument52 pagesWhat Is PID ControlShivaji Thube100% (1)

- Balance of Plant - IntroductionDocument20 pagesBalance of Plant - IntroductionSwapanbasuPas encore d'évaluation

- Single-Phase Step Voltage RegulatorDocument12 pagesSingle-Phase Step Voltage Regulatorbdrepublicadominicana2020Pas encore d'évaluation

- 01 PendahuluanDocument47 pages01 PendahuluanMUHAMMAD LUQMAN HAKIMI MOHD ZAMRIPas encore d'évaluation

- Performa CV Logix 764 Manual PDFDocument40 pagesPerforma CV Logix 764 Manual PDFLuisiño DueñasPas encore d'évaluation

- Performa CV Logix 764 ManualDocument40 pagesPerforma CV Logix 764 ManualLuisiño DueñasPas encore d'évaluation

- The Ultra Quiet High Pressure Fan Coil: CRSL Crsl-EcmDocument72 pagesThe Ultra Quiet High Pressure Fan Coil: CRSL Crsl-EcmJustin ReyesPas encore d'évaluation

- Control Valves Training Material 2Document103 pagesControl Valves Training Material 2Marcelo Fabián PurrettaPas encore d'évaluation

- Hydraulic Test Stand: 952 SeriesDocument4 pagesHydraulic Test Stand: 952 SeriesSajad KarimiPas encore d'évaluation

- Control ValveDocument35 pagesControl Valveshivani DubeyPas encore d'évaluation

- HAZOP For Scrub ColumnDocument5 pagesHAZOP For Scrub ColumnCiXian Teoh100% (1)

- STERIS - Finn Aqua T Series Pure Steam Generator - TDS - SD791Document8 pagesSTERIS - Finn Aqua T Series Pure Steam Generator - TDS - SD791Anderson BaziaPas encore d'évaluation

- PLC Pak Dheka Kajian Desain Retrofit Governor Control System Di PLTU Nii Tanasa Unit 1Document20 pagesPLC Pak Dheka Kajian Desain Retrofit Governor Control System Di PLTU Nii Tanasa Unit 1Yassar atha100% (1)

- Styrene Manufacture: University of Khartoum Faculty of Engineering Chemical DepartmentDocument28 pagesStyrene Manufacture: University of Khartoum Faculty of Engineering Chemical Departmentindrajit majumderPas encore d'évaluation

- K & T Style Hydraulic System Test Analysers - ManualDocument16 pagesK & T Style Hydraulic System Test Analysers - Manualpravesh bhartiPas encore d'évaluation

- MS 111 Hydraulic System Manual - 02Document216 pagesMS 111 Hydraulic System Manual - 02Juan Sebastian Diaz CuadrosPas encore d'évaluation

- Process Control Fundamentals - ADDDocument115 pagesProcess Control Fundamentals - ADDAsifPas encore d'évaluation

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesD'EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesÉvaluation : 1 sur 5 étoiles1/5 (2)

- Golf Course Irrigation: Environmental Design and Management PracticesD'EverandGolf Course Irrigation: Environmental Design and Management PracticesPas encore d'évaluation

- Week 9Document1 pageWeek 9Lavender ManPas encore d'évaluation

- Gavin Towler, R K Sinnott-Chemical Engineering Design Principles Practice and Economics of Plant and ProceDocument1 pageGavin Towler, R K Sinnott-Chemical Engineering Design Principles Practice and Economics of Plant and ProceLavender ManPas encore d'évaluation

- Week 5Document2 pagesWeek 5Lavender ManPas encore d'évaluation

- Questions:: Main Ideas/FindingsDocument2 pagesQuestions:: Main Ideas/FindingsLavender ManPas encore d'évaluation

- Week 8Document2 pagesWeek 8Lavender ManPas encore d'évaluation

- Week 10Document1 pageWeek 10Lavender ManPas encore d'évaluation

- Week 4Document2 pagesWeek 4Lavender Man100% (1)

- Pcs0911a Skyair Nu Series Co PDFDocument24 pagesPcs0911a Skyair Nu Series Co PDFVietHienPas encore d'évaluation

- Physics Perfect Score Module Form 4Document52 pagesPhysics Perfect Score Module Form 4Muhammad Nur Hafiz Bin Ali75% (4)

- Experiment Name - Determination of Calorific ValueDocument6 pagesExperiment Name - Determination of Calorific ValueJay RanjanPas encore d'évaluation

- ThermodynamicsDocument15 pagesThermodynamicsJimmy OrajayPas encore d'évaluation

- Marcet Boiler ExperimentDocument3 pagesMarcet Boiler ExperimentGarfield SmithPas encore d'évaluation

- MDL Bhel Rev 03 28 07 14Document276 pagesMDL Bhel Rev 03 28 07 14Santoshkumar GuptaPas encore d'évaluation

- Domekt R 700 VDocument1 pageDomekt R 700 VdanielPas encore d'évaluation

- Specification Comparison Sheet: Royal Primary Site Development of Mardumah, Phase - 1 Contract No.: 725-C03Document34 pagesSpecification Comparison Sheet: Royal Primary Site Development of Mardumah, Phase - 1 Contract No.: 725-C03Savad AlwyePas encore d'évaluation

- 1234-ENG - Behavior in Heat 060906Document5 pages1234-ENG - Behavior in Heat 060906Uday SharmaPas encore d'évaluation

- Topic 3 Past Paper: MarkschemeDocument10 pagesTopic 3 Past Paper: MarkschemeGajendra100% (1)

- Heat TransferDocument292 pagesHeat TransferahmedalishPas encore d'évaluation

- 303-03A Engine Cooling - 1.5L EcoBoostDocument71 pages303-03A Engine Cooling - 1.5L EcoBoostMohamed AdelPas encore d'évaluation

- Hku PHD Thesis LengthDocument6 pagesHku PHD Thesis Lengthbsr22d1d100% (2)

- BS Iso TR 05925-2-1997 (1999)Document16 pagesBS Iso TR 05925-2-1997 (1999)Олег СоловьевPas encore d'évaluation

- Thrust BearingsDocument112 pagesThrust BearingsMohammad Ali ZamanPas encore d'évaluation

- 10.FABRICATION OF GEO THERMAL HEATING AND COOLING SYSTEM 1st REVIEWDocument13 pages10.FABRICATION OF GEO THERMAL HEATING AND COOLING SYSTEM 1st REVIEWAnonymous Clyy9NPas encore d'évaluation

- Draft SystemDocument5 pagesDraft Systemmkchy12Pas encore d'évaluation

- Application Guide Masterflow Cementitious GroutDocument16 pagesApplication Guide Masterflow Cementitious GroutVinayPas encore d'évaluation

- Parts Catalog: Outdoor UnitDocument4 pagesParts Catalog: Outdoor UnitZulkipli MarasabessyPas encore d'évaluation

- Fan Coil - HFCFDocument12 pagesFan Coil - HFCFdanielcarreteroPas encore d'évaluation

- Semi Empirical Equation For The Calculation of The Track Diameter of Alpha Particles in CR-39 As A Function of Etching TemperatureDocument7 pagesSemi Empirical Equation For The Calculation of The Track Diameter of Alpha Particles in CR-39 As A Function of Etching Temperaturemido ghalbanPas encore d'évaluation

- Cooling Heating HandbookDocument170 pagesCooling Heating Handbookhmz_engineering87100% (2)

- Heat and WorkDocument36 pagesHeat and WorkJan Ice100% (1)

- Diesel Particle Filter Emergency RegenerationDocument6 pagesDiesel Particle Filter Emergency RegenerationgheorgheovidiuPas encore d'évaluation

- HPX2 X 12Document1 pageHPX2 X 12dzukaPas encore d'évaluation

- 38LZA&40LZADocument2 pages38LZA&40LZAMohd Azizul AzamPas encore d'évaluation

- Spec Wall Mounted LGDocument17 pagesSpec Wall Mounted LGTASDIKPas encore d'évaluation

- EGVUSE09-07C - A VRV Basic Operation Guide PDFDocument40 pagesEGVUSE09-07C - A VRV Basic Operation Guide PDFShaikhMazharAhmed100% (1)

- Assignment 16 The Ideal GasDocument8 pagesAssignment 16 The Ideal Gasbob jizzlePas encore d'évaluation

- LCR-600 Opps ManualDocument68 pagesLCR-600 Opps ManualJoseph BossePas encore d'évaluation