Académique Documents

Professionnel Documents

Culture Documents

Cold Tuff Fittings: Master Links

Transféré par

YOGESH GOPAL0 évaluation0% ont trouvé ce document utile (0 vote)

32 vues1 pageki8um

Titre original

164

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentki8um

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

32 vues1 pageCold Tuff Fittings: Master Links

Transféré par

YOGESH GOPALki8um

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

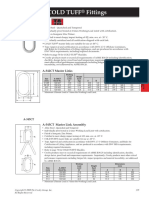

RIGGING ACCESSORIES COLD TUFF® Fittings

• Alloy Steel - Quenched and Tempered

• Individually proof tested at 2 times Working Load Limit with certification.

• Finish is Inorganic Zinc Primer.

• Certified to meet charpy impact testing of 31 ft-lbs. min. avg. at - 4° F.

• Individually serialized and all certification shipped with each link.

• COLD TUFF® master links are suitable for use at -50° F.

• Type Approval and certification in accordance with DNV 2.7-1 Offshore Containers,

DNV-OS-E101, and Rules for Certification of Lifting Appliances, and are produced

in accordance with DNV MSA requirements, including required documents.

• Refer to page 88 for COLD TUFF® Shackles.

A-342CT

Master Links • Meets or exceeds all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, these

fittings meet other critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

A-342CT Master Links

Dimensions (in.)

Working Load

Size A-342CT Limit Weight Each Deformation

(in.) Stock No. (lbs.)* (lbs.) A B C D E Indicator

7/8W 1261392 15200 3.3 0.88 3.75 6.38 5.51 8.14 4.50

1-1/4W 1261407 39100 12.0 1.33 5.50 9.50 8.16 12.16 7.00

1-1/2W 1261418 61100 18.6 1.61 5.90 10.50 9.12 13.72 7.50

1-3/4 1261423 62520 25.2 1.75 6.00 12.00 9.50 15.50 7.50

2 1261433 97680 37.0 2.00 7.00 14.00 11.00 18.00 9.00

*Minimum Ultimate Load is 5 times the Working Load Limit.

• Alloy Steel - Quenched and Tempered

• Individually proof tested at 2 times Working Load Limit with certification.

• Finish is Inorganic Zinc Primer.

• Certified to meet charpy impact testing of 31 ft-lbs. min. avg. at -4° F.

• COLD TUFF® master links are suitable for use at -50° F.

• Type Approval and certification in accordance with DNV 2.7-1 Offshore

Containers, DNV-OS-E101, and Rules for Certification of Lifting Appliances,

and are produced in accordance with DNV MSA requirements, including

required documents.

• Refer to page 88 for COLD TUFF® Shackles.

A-345CT

Master Links • Meets or exceeds all requirements of ASME B30.26 including identification,

Assembly ductility, design factor, proof load and temperature requirements. Importantly,

these fittings meet other critical performance requirements including fatigue life,

impact properties and material traceability, not addressed by ASME B30.26.

A-345CT Master Link Assembly

Dimensions

(in.)

Size Working Load Limit Weight Each

(in.) A-345CT Stock No. (lbs.)* (lbs.) A B C

1-1/4 1261609 35160 30.0 1.25 4.38 8.75

1-1/2 1261620 47880 51.0 1.50 5.25 10.50

1-3/4 1261631 62520 78.0 1.75 6.00 12.00

2 1261642 97680 123.0 2.00 7.00 14.00

*Minimum Ultimate Load is 5 times the Working Load Limit.

164 Copyright © 2017 The Crosby Group LLC All Rights Reserved

Vous aimerez peut-être aussi

- Vickers General Hydraulic BookDocument29 pagesVickers General Hydraulic BookKarthik Sarang100% (15)

- Spline Program Ver 1.1Document10 pagesSpline Program Ver 1.1VivekPas encore d'évaluation

- (Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesDocument7 pages(Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesSasan AbbasiPas encore d'évaluation

- H02 Hydraulic CylinderDocument21 pagesH02 Hydraulic CylinderYOGESH GOPALPas encore d'évaluation

- Through Bolt Connection PDFDocument197 pagesThrough Bolt Connection PDFAkhil VNPas encore d'évaluation

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantD'EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- CommunityHall RBNagar WEDocument245 pagesCommunityHall RBNagar WEyadagirireddy bolluPas encore d'évaluation

- ITP For Painting WorksDocument27 pagesITP For Painting Workssree50% (2)

- Ta-30 Manual MaintenanceDocument29 pagesTa-30 Manual MaintenanceAntonio Carrion100% (1)

- FWEFJLNIY4QKLQXDocument13 pagesFWEFJLNIY4QKLQXSoldan MihaiPas encore d'évaluation

- Case Study of Sri-Lankan HousingDocument56 pagesCase Study of Sri-Lankan HousingdixitprabidhiPas encore d'évaluation

- VW Gol 2005 Gearbox Listado de PartesDocument16 pagesVW Gol 2005 Gearbox Listado de Partesl_aguilar_mPas encore d'évaluation

- Crude and Refinery CalculationsDocument4 pagesCrude and Refinery Calculationsbakhtyar21100% (1)

- Master Pro VOA DjouiniDocument68 pagesMaster Pro VOA DjouinitoufikPas encore d'évaluation

- CAT DisplayDocument12 pagesCAT Displayharikrishnanpd3327Pas encore d'évaluation

- 51 CR V4Document4 pages51 CR V4armin_kunosic9871Pas encore d'évaluation

- Cold Tuff Master LinkDocument1 pageCold Tuff Master LinkSelamet MirantoPas encore d'évaluation

- Crosby Bolt Type Shackles: Testing The LimitsDocument1 pageCrosby Bolt Type Shackles: Testing The LimitsStephen KokoPas encore d'évaluation

- Manilhas Crosby G2130Document1 pageManilhas Crosby G2130Álamo NatividadePas encore d'évaluation

- 2019 Crosby Catalog Metric-Rigging-Accessories-Master Link A-342Document1 page2019 Crosby Catalog Metric-Rigging-Accessories-Master Link A-342I-SignPas encore d'évaluation

- Dmn66D0Ldw Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetDocument6 pagesDmn66D0Ldw Product Summary Features and Benefits: Dual N-Channel Enhancement Mode Mosfetzigmund zigmundPas encore d'évaluation

- FT Eslabon Maestro A342Document1 pageFT Eslabon Maestro A342fernando.solarPas encore d'évaluation

- AMDLA4530SDocument3 pagesAMDLA4530SJorge LealPas encore d'évaluation

- Kopr Kote Oilfield TdsDocument1 pageKopr Kote Oilfield Tdsbob smithPas encore d'évaluation

- Crosby G-2150Document1 pageCrosby G-2150jdpardoPas encore d'évaluation

- Silicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388BDocument5 pagesSilicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388Bameer_jaburPas encore d'évaluation

- XLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeDocument1 pageXLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeLEMAGA GROUPPas encore d'évaluation

- B1545G MBRB1545CTG Schottky 2x 15A 45VDocument5 pagesB1545G MBRB1545CTG Schottky 2x 15A 45VRuslanPas encore d'évaluation

- StartersDocument2 pagesStartersmaniiscribdPas encore d'évaluation

- G-2140 / S-2140 Crosby Alloy Bolt Type Anchor ShacklesDocument1 pageG-2140 / S-2140 Crosby Alloy Bolt Type Anchor ShacklessaurabhsubhuPas encore d'évaluation

- AMDLA4530QDocument3 pagesAMDLA4530QJorge LealPas encore d'évaluation

- Avx Flexiterm MLCC DSDocument5 pagesAvx Flexiterm MLCC DSguest guestPas encore d'évaluation

- 2N7002DWQ Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetDocument5 pages2N7002DWQ Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetErkanPas encore d'évaluation

- Kopr-Kote TDS 2Document1 pageKopr-Kote TDS 2jesusPas encore d'évaluation

- Siemens Eg Type Circuit BreakerDocument15 pagesSiemens Eg Type Circuit BreakerAna Hernández MonterrubioPas encore d'évaluation

- Dual N Channel Mosfet DiodesDocument6 pagesDual N Channel Mosfet DiodesrameshPas encore d'évaluation

- Lds 0287Document8 pagesLds 0287asif.binance1988Pas encore d'évaluation

- Primacorelw 81ni1h enDocument2 pagesPrimacorelw 81ni1h enedwinPas encore d'évaluation

- CPE5-013 MA4 ProductSheetDocument4 pagesCPE5-013 MA4 ProductSheetAjmal ArshadPas encore d'évaluation

- Sidactor Series - Do-15: Baseband Protection (Voice-Ds1)Document3 pagesSidactor Series - Do-15: Baseband Protection (Voice-Ds1)ALFONZO DANIELPas encore d'évaluation

- Type 55b Ds Feb18Document3 pagesType 55b Ds Feb18Suresh KumarPas encore d'évaluation

- Swing Check ValveDocument2 pagesSwing Check ValveHardik ShahPas encore d'évaluation

- Crosby 2130 2150Document1 pageCrosby 2130 2150Sumner TingPas encore d'évaluation

- SS26T3G, NRVBSS26T3G Surface Mount Schottky Power RectifierDocument5 pagesSS26T3G, NRVBSS26T3G Surface Mount Schottky Power RectifierMirley ValeraPas encore d'évaluation

- LDS 0159Document6 pagesLDS 0159aliabPas encore d'évaluation

- Divinycell HCP IMP Technical Data SheetDocument2 pagesDivinycell HCP IMP Technical Data SheetSolomon PasulaPas encore d'évaluation

- Corod SWR High Strength 29feb12Document3 pagesCorod SWR High Strength 29feb12Ronald LlerenaPas encore d'évaluation

- For Lifting and Transferring Concrete Pipe Sections and WellsDocument1 pageFor Lifting and Transferring Concrete Pipe Sections and Wellsjunyang liPas encore d'évaluation

- PZT2222AT1 NPN Silicon Planar Epitaxial TransistorDocument3 pagesPZT2222AT1 NPN Silicon Planar Epitaxial TransistorCapitanSalamiPas encore d'évaluation

- 2N7002 Product Summary Features and Benefits: N-Channel Enhancement Mode Field Effect TransistorDocument6 pages2N7002 Product Summary Features and Benefits: N-Channel Enhancement Mode Field Effect TransistorErkanPas encore d'évaluation

- Features/Benefits Typical Applications: Specification ElectricalDocument2 pagesFeatures/Benefits Typical Applications: Specification Electricalpaula09Pas encore d'évaluation

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoPas encore d'évaluation

- 1 Watt Glass Case Zener Diodes: 1N3016B-1 - 1N3045B-1Document5 pages1 Watt Glass Case Zener Diodes: 1N3016B-1 - 1N3045B-1Otto AndradePas encore d'évaluation

- Codes For Vessels/Heat ExchangersDocument23 pagesCodes For Vessels/Heat ExchangersiFROG ChannelPas encore d'évaluation

- Tyco Grinnell Grooved CouplingDocument4 pagesTyco Grinnell Grooved Couplingprvns0074377Pas encore d'évaluation

- HarshEnvironment SeriesA R1 EF8320A512Document2 pagesHarshEnvironment SeriesA R1 EF8320A512Enrique Arellano HidalgoPas encore d'évaluation

- Er 0262Document7 pagesEr 0262CarlosFeLipeReinosoPas encore d'évaluation

- GRINNEL Figure 577 Acoplamiento Rig RanDocument4 pagesGRINNEL Figure 577 Acoplamiento Rig RanFIRE RL SYSTEMSPas encore d'évaluation

- HB CLS6B FKWDocument11 pagesHB CLS6B FKWkrishPas encore d'évaluation

- Castrol Tribol GR 4020 220-460 PD Tds-EnDocument3 pagesCastrol Tribol GR 4020 220-460 PD Tds-EnIulian BarbuPas encore d'évaluation

- Sd103aw, SD103BW, SD103CWDocument4 pagesSd103aw, SD103BW, SD103CWВиктор АгарковPas encore d'évaluation

- Ficha Técnica - FRAYÖL GEAR S 2 EP - 680Document2 pagesFicha Técnica - FRAYÖL GEAR S 2 EP - 680Julio Oliveira Goncalves JuniorPas encore d'évaluation

- JST NV ConnectorDocument2 pagesJST NV ConnectorRicky CapascoPas encore d'évaluation

- TDCDocument6 pagesTDCalex hutaurukPas encore d'évaluation

- Kaiser Aluminum 7075 Rod and BarDocument2 pagesKaiser Aluminum 7075 Rod and BarH VPas encore d'évaluation

- MURD620CT Switchmode Power Rectifier: DPAK Surface Mount PackageDocument5 pagesMURD620CT Switchmode Power Rectifier: DPAK Surface Mount Packagetecnicogato27Pas encore d'évaluation

- Esr 2907Document4 pagesEsr 2907محمد الدعجةPas encore d'évaluation

- Fasson 0828 DatasheetDocument2 pagesFasson 0828 DatasheetGregory Alan Francisco IIPas encore d'évaluation

- Catalog Threaded Enlargers Nipples o Z Gedney en 588940Document3 pagesCatalog Threaded Enlargers Nipples o Z Gedney en 588940Alexis Rodrigo Tapia EstrellaPas encore d'évaluation

- Connector: 2.0mm Pitch/crimp Style Wire-To-Wire ConnectorsDocument2 pagesConnector: 2.0mm Pitch/crimp Style Wire-To-Wire ConnectorsMr. TPas encore d'évaluation

- PCI Express Gen 4 and Gen 5 Card Edge ConnectorsDocument4 pagesPCI Express Gen 4 and Gen 5 Card Edge ConnectorsAlejandro JimenezPas encore d'évaluation

- Unit No. HTM 009: DimensionsDocument1 pageUnit No. HTM 009: DimensionsYOGESH GOPALPas encore d'évaluation

- Fs5 Our - STE5 SPS - of - Pros5 Gre 5 S5ssive - Pis5 s5 Gging - Q3 - s5 S s552014Document1 pageFs5 Our - STE5 SPS - of - Pros5 Gre 5 S5ssive - Pis5 s5 Gging - Q3 - s5 S s552014YOGESH GOPALPas encore d'évaluation

- Integramf rktedPiggmingFundae5nmentals - PapersDocument1 pageIntegramf rktedPiggmingFundae5nmentals - PapersYOGESH GOPALPas encore d'évaluation

- Mathcad Prime 4 Keyboard ShortcutsDocument15 pagesMathcad Prime 4 Keyboard Shortcutshonghainhi0806Pas encore d'évaluation

- OMT315 - 151B3009 (Selection)Document1 pageOMT315 - 151B3009 (Selection)YOGESH GOPALPas encore d'évaluation

- Unit No. HTM 001: DimensionsDocument1 pageUnit No. HTM 001: DimensionsYOGESH GOPALPas encore d'évaluation

- OMT315 - 151B3003 (Technical Data)Document1 pageOMT315 - 151B3003 (Technical Data)YOGESH GOPALPas encore d'évaluation

- JHGVHDocument14 pagesJHGVHYOGESH GOPALPas encore d'évaluation

- OMT315 - 151B3009 (Selection)Document1 pageOMT315 - 151B3009 (Selection)YOGESH GOPALPas encore d'évaluation

- Flange Thickness Calculation - SKDocument3 pagesFlange Thickness Calculation - SKYOGESH GOPALPas encore d'évaluation

- Flange Thickness Calculation - SKDocument3 pagesFlange Thickness Calculation - SKYOGESH GOPALPas encore d'évaluation

- 6213 20200228Document4 pages6213 20200228Damian DNPas encore d'évaluation

- Parallel and Series Connection of Two Hydraulic Motors: Saving Time During UnloadingDocument2 pagesParallel and Series Connection of Two Hydraulic Motors: Saving Time During UnloadingYOGESH GOPALPas encore d'évaluation

- BV3D BV3DZDocument4 pagesBV3D BV3DZYOGESH GOPALPas encore d'évaluation

- Pump FormulaDocument3 pagesPump FormulaViwek MertiyaPas encore d'évaluation

- Lessons Learned Checklist WordDocument2 pagesLessons Learned Checklist WordYOGESH GOPALPas encore d'évaluation

- Cold Tuff Fittings: Master LinksDocument1 pageCold Tuff Fittings: Master LinksYOGESH GOPALPas encore d'évaluation

- Hydraulic Motors: Single Direction MotorDocument14 pagesHydraulic Motors: Single Direction MotorYOGESH GOPALPas encore d'évaluation

- Radicon Product Brochure Metric EngDocument8 pagesRadicon Product Brochure Metric EngYOGESH GOPALPas encore d'évaluation

- Container DimensionsDocument7 pagesContainer DimensionsYOGESH GOPALPas encore d'évaluation

- Combining StressesDocument31 pagesCombining StressesYOGESH GOPALPas encore d'évaluation

- 7 Unrestrained Beams HandoutDocument3 pages7 Unrestrained Beams HandoutKenaia AdeleyePas encore d'évaluation

- Compatibility of S-N and Crack Growth Curves in The Fatigue Reliability Assessment of A Welded Steel JointDocument9 pagesCompatibility of S-N and Crack Growth Curves in The Fatigue Reliability Assessment of A Welded Steel JointYOGESH GOPALPas encore d'évaluation

- Crosby Grade 100 Clevis Sling Hooks: J AA R LDocument1 pageCrosby Grade 100 Clevis Sling Hooks: J AA R LYOGESH GOPALPas encore d'évaluation

- Container Dimensions PDFDocument3 pagesContainer Dimensions PDFHassan Muhammad TundePas encore d'évaluation

- Ii-Ii ResultsDocument62 pagesIi-Ii ResultssandeepkiranvPas encore d'évaluation

- Lauire Baker and Other Architects PDFDocument8 pagesLauire Baker and Other Architects PDFmoni_john_1Pas encore d'évaluation

- LS3 Maintenance Manual PDFDocument134 pagesLS3 Maintenance Manual PDFIzhar Dhiya Ul HayyanPas encore d'évaluation

- A Report On Summer Training: Submitted by Submitted ToDocument43 pagesA Report On Summer Training: Submitted by Submitted Toedu4 uPas encore d'évaluation

- Sun - Power VRM en PDFDocument2 pagesSun - Power VRM en PDFFaly RalisonPas encore d'évaluation

- Pure VDocument2 pagesPure VMorris MorrisonPas encore d'évaluation

- Wap-7 Drawing DrequiredDocument8 pagesWap-7 Drawing DrequiredM PankajPas encore d'évaluation

- Lsis Air Circuit BreakersDocument3 pagesLsis Air Circuit BreakersECATOnlinePas encore d'évaluation

- PNGRB T4SDocument52 pagesPNGRB T4SC D JOSHIPas encore d'évaluation

- Metrology Unit 3 PPT 3Document34 pagesMetrology Unit 3 PPT 3Punith RajPas encore d'évaluation

- Cabcode PDFDocument3 pagesCabcode PDFSunil SinghPas encore d'évaluation

- Hotronix Clam Hover Press Operators ManualDocument12 pagesHotronix Clam Hover Press Operators ManualJavi BuenoPas encore d'évaluation

- Hydac Eds 601Document4 pagesHydac Eds 601AlphaPas encore d'évaluation

- BD9215AFVDocument5 pagesBD9215AFVYusuf Agustaf SatrianiPas encore d'évaluation

- Mobil Cross RefDocument2 pagesMobil Cross RefpaniyaPas encore d'évaluation

- Ijsart 150101771Document4 pagesIjsart 150101771SujuddinPas encore d'évaluation

- Hoover hnd315 80 PDFDocument39 pagesHoover hnd315 80 PDFtrutleptPas encore d'évaluation

- Datasheet DSE8610Document2 pagesDatasheet DSE8610Jose GutierrezPas encore d'évaluation

- Synthetic Fibers and PlasticsDocument36 pagesSynthetic Fibers and Plasticssanjayagrawal70-1100% (2)

- Life Cycle Inventory Data For CottonDocument31 pagesLife Cycle Inventory Data For CottonAbhas GargPas encore d'évaluation