Académique Documents

Professionnel Documents

Culture Documents

Steel Box Girder Bridges - Design and Construction

Transféré par

Anonymous Gd0PTUQDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Steel Box Girder Bridges - Design and Construction

Transféré par

Anonymous Gd0PTUQDroits d'auteur :

Formats disponibles

CT5125: Steel bridges – file <design-box-girder>

20. Box Girder Bridge

20.1 Introduction

IThe nomenclature of the structural elements in a steel box girder is given in figure 1 which shows, as an

example, a single cell box girder with a composite concrete deck.

Until 1940 the structural possibilities for box girders were

limited; structures had to be assembled from rolled sections,

plates and riveted connections.

Fig. 1.

Box girder bridge with composite

concrete deck: nomenclaturen

Notwithstanding these limitations, the first steel box girder, the

Conway bridge with a single span of 125.5 m and the Britannia

Bridge (1850) with main spans 152 m, figure 2, served as a model

of what could be achieved with innovative design.

Fig. 2. Left: The Conway bridge (tubular bridge).

Middle and right: The Britannia bridge.

The basic concept of using hollow sections was only occasionally repeated with riveted construction.

• The Britannia Bridge was duplicated only once; in America. A box girder is more material consuming

than a truss girder, and material was much more expensive than labor in those days.

• The tubular members of the Firth of Forth Bridge (1890) were a second exception.

• The railway bridge across the Oude Maas, Dordrecht, The Netherlands, has tubular riveted

diagonals. Here a corrosion problem arose. Riveted boxes are not completely watertight.

Humid airs sucked in, condensed and water collected at the bottom.

With the development of electric welding and precision flame

cutting, the structural possibilities increased enormously. It is

now possible to design large welded units in a more

economical way, e.g. box girders, using the techniques similar

to those of shipbuilding.

A box girder consists of:

• a concrete deck or an orthotropic steel deck as the

top flange, and sometimes a combination of the two

• a stiffened plate or a bracing as a bottom flange

• web vertical or inclcined

• stiff diaphragms or bracing’s at the supports and

lighter cross bracing’s between the supports at

distances of about 2,5 times the construction depth,

Fig. 3. Section of a steel box girder bridge.

Nowadays, the basic cross-section can be found in many bridges.

20. Design of a steel box girder 301

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

The great torsion rigidity makes a box girder a particularly appropriate solution where the bridge is curved in the

horizontal plane, figure 4. Many bridges over European highways may serve as examples. Launching as an

erection method is then still possible as long as the curvature is constant.

Fig. 4.

Left: Plate girder bridge.

Right: Box girder bridge.

In wide cross-sections the box is sometimes subdivided

into cells, figure 5.

Fig. 5. Types of cross section (concrete – composite concrete / steel – steel).

Nowadays, composite steel-concrete box girder bridges are commonly used in (curved) bridges. They generally

consist of one or more U-girders attached to a concrete deck through shear connectors. Diaphragms connect

individual steel U-girders periodically along the length to ensure that the bridge system behaves as a unit. The

cross section of a steel box is flexible (i.e. can distort) in the cross-wise direction and must be stiffened with

cross-frames that are installed in between the diaphragms to prevent distortion. Web and bottom plates stiffeners

are required to improve stability of the relatively thin steel plates that make up the steel box. During construction,

overall use of top bracing members enhances stability and torsional rigidity of the girder. These bracing members

become unimportant once the concrete deck hardens, but is left in place anyway.

20. Design of a steel box girder 302

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Fig. 6.

Example composite steel-concrete bridge using diaphragms connecting

individual steel U-girders.

Fig. 7. Left: Transportation of box section with stiffened flange.

Right: Welded connection on site.

Fig. 8.

Hybrid box girder: concrete at support region and steel at

mid-span.

20. Design of a steel box girder 303

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Fig. 9. Hemboog: railway viaduct Zaandam – Amsterdam, total length

2.2 km.

Fig. 10. Silent bridge technology (Holland Railconsult).

20.2 General Design Principles

Span

Box girders are suitable for longer spans than I-girders and allow larger span to depth ratios. The limits for

competitiveness may vary due to local market conditions.

Steel or steel-concrete composite box girders are usually more expensive than plate girders because they require

more fabrication time. They have, however, several advantages over plate girders which make their use

attractive:

• very high torsional rigidity: In closed box girders, torque is resisted mainly by Saint Venant shear

stresses because the Saint Venant torsional stiffness is normally much greater than the torsional

warping stiffness. For highly curved spans, this stiffness of the box girders is virtually essential during

their construction, as well as under service loads. All steel box girders provide torsional stiffness during

20. Design of a steel box girder 304

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

their erection. Composite box girders only achieve their torsional rigidity after concreting. During

erection and concreting they may require expensive temporary bracing, which can also interfere with

the execution of the concrete slab.

• very wide flanges allow large span-to-depth ratios

• a neater appearance, since the stiffening can remain invisible in the box

• very good aerodynamic shape, which is equally important for large suspension or cable-stayed bridges

as is the torsional stiffness

• a very good adaptability to the most difficult conditions. Box girders are able to cross greater torsional

spans than flexural spans using piers with a single bearing as shown in Figure 4.

• low noise emission and reduction on costs for corrosion protection

• easy handling

Table 1 shows an indication of economic span limits for road bridges.

Table 1. Span range for box girder bridges.

Composite concrete deck (m) Orthotropic deck (m)

Simple span 20 - 100 70 - 120

Interior span of continuous 30 - 140 100 - 250

girder

The longest span so far is 300 m achieved in 1974 by the Costa e Silva bridge in Rio de Janeiro, figure 11. It is

always probable that the longest span existing has passed the limit of best economy.

Fig. 11. Rio-Niteroi bridge.

Span-to-depth ratio

The span-to-depth ratio will normally be around 20 to 25 for simple girders and around 25 to 35 for continuous

girders. It is possible to reduce the depth, if necessary, without violating deflection limitations, at the expense of

additional steel. The above ratios are valid for road bridges. For rail bridges the ratios should be smaller, say 15

and 20. It is advisable to check the most favorable span-to-depth ratio by trial designs.

Cross-section

A box girder may have vertical or inclined webs. It is cheaper to manufacture a girder with vertical webs. This

section shape may be the best solution for a narrow road or a single-track railroad. A single narrow closed box

girder can be positioned on the bridge centre line and completed with cantilever brackets. A combination of a

wide deck on a short or medium span bridge favors inclined webs, Figure 1. For instance, a 13 m wide concrete

deck without transverse prestressing requires a width of the box of 6 m at the top. If it were made with vertical

webs, the bottom flange would be

much too wide to be efficient.

Inclined webs reduce the width in a

favorable way.

Fig. 12.

Use of concrete as a lower flange

in case of hogging moment.

20. Design of a steel box girder 305

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Normally the webs are inclined 20 - 35 degrees from the vertical. In many cases inclined webs are chosen for

aesthetic reasons. There are several effects that make wide flanges inefficient. One is shear lag and another is

local buckling of areas in compression. Further, the minimum thickness specified in codes may often make the

flange area excessive. Plate widths of 3,3 m are readily available and some French or German mills produce

wider plates, up to 5 m. (Greater widths are available with thinner plates.). If still wider plates are needed, a

longitudinal weld increases the costs. It is generally preferable to adopt the maximum available width and avoid

the longitudinal weld even if a slightly thicker plate would lead to less stiffening. This advice is valid for the

bottom plate as well as the webs. The best economy is achieved if sections can be fabricated in the full width at

the shop. If the sections can be delivered by boat, the only limitation is the handling equipment. Composite box

girders will frequently be small enough to be shipped in one piece, also by road. Local restrictions for road

transport should be checked. The normal width limit, 2,5 m, may be exceeded if special permits are requested.

The cost of the escort should be checked.

Fig. 13.

Use of corrugated web plates; effective concrete

prestressing.

20.3 Structural Details

Longitudinal stiffeners

Stiffeners are needed on the bottom flange at least at the piers where it is in compression and sometimes also on

the webs. In designing an economical girder, the cost of handling and welding the stiffeners has to be taken into

account. With increasing labor costs the tendency is to have fewer stiffeners and thicker plates. In most cases, the

bottom flange will have a very small effective area if it is not stiffened at the support. An efficient profile is the

cold-formed trapezoidal stiffener. One to two will be sufficient if they are made big enough. If the bridge is to be

erected by launching or cantilevering, it is often necessary to stiffen the bottom flange along the whole girder in

order to resist the hogging moments during erection.

Pier Diaphragms and Intermediate Cross Frames

At the supports, considerable forces from torque and shear have to be transmitted to the bearings. The

recommended solution at piers is a diaphragm, i.e. a steel plate transverse to the girder. The plate is designed to

carry the shear from the torque and is strengthened locally in order to carry the support reactions. The diaphragm

at the pier sections prevents deformation of the section (distortion of the box cross-section). If the bottom flange

is narrow, it may be necessary to put the bearings outside the flange and to provide the webs with external

stiffeners.

In order to prevent cross-section distortion, the girder is provided with intermediate cross frames (see Figure 1).

The webs and bottom flange have transverse stiffeners at these sections. The intermediate transverse stiffeners

are made of flats or strips of plate when cross bracing’s are used. For the intermediate frames, the bracing’s can

be omitted if the rigidity of the cross frames constituted by web and flange stiffeners is enough. The intermediate

transverse stiffeners are made of a T section when bracing’s are not used. To be considered effective against

distortion, cross frames must comply with the stiffness and strength requirements. The stiffness is expressed in

terms of a minimum value for the dimensionless parameter S. This parameter is in effect a ratio between the

distortional stiffness of the box and the distortional stiffness of the cross frame. It may be that the distortional

stresses calculated neglecting all intermediate frames are acceptable, in which case none of the frames need meet

the stiffness criteria.

For the purpose of analysis, box girders may be divided into two groups according to their behavior under

torsional loads. The first group contains girders assumed to have a rigid cross-section, which do not change their

20. Design of a steel box girder 306

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

cross sectional shape when rotated about their longitudinal axis. This might be the case for concrete box girders

with relatively thick walls. In other cases, closely spaced diaphragms or bracing’s may be required to satisfy this

condition, like mostly is the case for steel box girders.

Intermediate Transverse Elements between Boxes

The design of the transverse elements

between two longitudinal box girders are

generally subject to important stress

variations under eccentric live loads. Their

design is generally governed by fatigue

considerations. Large, widely spaced

diaphragms may be adapted, figure 14a.

Alternatively, cross girders at 3 to 4m

spacing may be adopted that support a

concrete or orthotropic steel deck as shown

in figure 14b.

Fig. 14. Intermediate transverse elements

between boxes.

Bearings

As a box girder is torsionally rigid, it is possible to use a single bearing at one or more supports and to transmit

the torque to where the foundations are suitable to resist it. This is particularly common if the bridge is highly

curved. Slender columns may support the single bearings.

At each end of the bridge, there are generally two bearings if the bridge consists of a single box girder. In this

case, special attention has to be paid to ensure sufficient distance between the two bearings.

Another consequence of the torsional rigidity is that extra care has to be taken to get the correct support reactions

when there are two bearings at each support. One way of doing this is to let the box rest on jacks with

predetermined loads and to fix the permanent bearing when the jack loads are correct.

If the bearings on the pier are under the diaphragm, care must be taken to ensure that thermal moments do not

lead to longitudinal eccentricity occurring at the bearings. Additional stiffeners may need to be provided.

Corrosion protection

The interior of a box girder is exposed to far less risk of corrosion than the outside. Hence, the interior corrosion

protection can be made simpler or even omitted completely. There is always a possibility of water leaking into

the box, especially if the deck is made of concrete. For this reason, the box should be equipped with a

dehumidifier to keep the air dry. This is an inexpensive precaution.

White painting or very light colors should be used for the interior to facilitate future inspections.

Access holes in diaphragms

Access is usually required through diaphragms, during construction and during service. A manhole 600 mm high

is usually considered as a minimum. Tight corner radii should be avoided; if they are necessary, stress

concentration effects must be carefully considered.

Access into the box (for maintenance) should be either through the end diaphragm or through a hole in the

bottom flange or web. Access through the deck should be avoided, as it is difficult to achieve permanently seals.

Holes in the bottom flange can significantly reduce the flexural strength of the cross section and the entire

structure, especially if they are placed in the vicinity of continuous supports in the effective width region where

high negative moments develop, or in high positive moment regions. Away from high moment regions, normal

stresses due to flexure are small and adding a hole in the bottom flange may be possible (mostly with extra

strengthening because of fatigue criteria).Web access holes can greatly reduce the shear resistance of the web,

which is made of relatively thin steel plates. Therefore, this alternative should only be considered around mid-

span, where low shear forces and torsional moments exist.

20.4 Erection Methods

Box girders may be erected with normal methods such as launching or cantilevering. If the bridge is curved in a

circle, launching works without complication. If the box has an orthotropic deck, it is rigid enough even for

20. Design of a steel box girder 307

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

highly curved bridges. However, boxes with composite concrete slabs are normally erected as an open trough.

This open shape is torsionally very soft. The shear centre is unusually far under the centre of gravity, so that the

section will deflect substantially, vertically as well as horizontally, under self-weight, complicating the

launching. Further, the casting of the concrete slab creates additional eccentric load and further deformations and

stresses if the box is curved and open. One solution is to provide the box with horizontal bracing between the top

flanges. The bracing must be designed to avoid interference with the casting of the concrete slab. These

diagonals may be temporary if it is deemed worthwhile to remove them after casting the slab. Some examples of

erection methods are shown.

Fig. 15. Replacement of Moerdijk bridge, 1975-1978.

Box girder parts (22m length) constructed at both

starting points road bridge, transported and lifted by

crane. Temporary supports are used.

Fig. 16. Neckar Vally viaduct , Weitingen,

Germany.

Fig. 17.

Dumbarton bridge.

20. Design of a steel box girder 308

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Fig. 18. Storrow Drive Connector brige.

20.5 Analysis

20.5.1 General

A box girder may be analyzed as a beam subjected to bending, shear and torsion. However, simple beam theory

is not an adequate tool and additional considerations are required, e.g. shear lag, warping and distortion of the

cross-section. The additional stresses caused by cross-section distortion depend largely on the distance between

the cross braces. With a sufficiently small distance, these stresses may be

neglected. National practice varies on this point. The general case of an

eccentric load applied to a box girder is in effect a combination of three

main components: bending, torsion and distortion, figure 20. Warping out

of plane and distortion compromises an internal set of forces, statically in

equilibrium, whose effects depend on the behaviour of the structure

between the point of application and the nearest positions where the box

section is restrained against distortion.

Fig. 19. Normal stress distribution under warping for an I-section beam.

Between points of support, intermediate transverse web stiffeners (intermediate diaphragms or cross frames) may

be provided to develop sufficient shear resistance in a thin web. The cross bracing’s act to restrain cross-section

deformation.

20. Design of a steel box girder 309

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

bending

torsion distortion

deformation

warping rotation warping distortion

out of plane in plane out of plane in plane

Fig. 20.

Bending, torsion and distortion components in case of eccentric loading of a boxed girder.

Fig. 21.

Torsion: Typical cross sectional distributions of (a) pure St. Venant’s shear flow, (b) axial stress due to the

restraint of warping, (c) corresponding shear flow.

Fig. 22.

Distortion: Typical cross sectional distributions of (a) distortional axial warping stress, (b) corresponding

distortional shear flow, (c)transverse distortional moment per unit length.

As shown in figures 21 and 22, a state of forces is developed in a (curved) box girder when loaded. The forces

that are developed included bending moments, shear forces, pure (i.e. St. Venant) torsion, warping (i.e. non

uniform) torsional moments, and bi-moments. Torsional moments and bi-moments due to cross-section

distortion also developed. However, providing an adequate number of cross frames can easily reduce distortion-

related effects. When intermediate bracing’s are omitted, special attention should be paid to the design of the

corners of the unbraced cross frames, which should resist the bending moment in the plane of the cross frame.

(The steel box girder works in the same way as pre-stressed concrete box girders). In this case, web and flange T

20. Design of a steel box girder 310

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

stiffeners are designed for this purpose. The design of the corners is generally governed by fatigue

considerations. When the intermediate cross frames do not support traffic load directly, they are in general lightly

stressed. The out-of-plane deformation of cross sections subjected to torsion violates the main assumption of the

Bernoulli’s Beam Theory: plane sections remain plane.

If restrained, these out-of-plane deformations create additional normal and shear stresses, which when integrated

over the cross-section yield the bi-moment and warping torsional moment respectively.

Stress calculations

Normal stresses – including the effect of warping – are calculated as follows:

Mx My M M

σ exact = y+ x + ω ω = σ approx + ω ω

Ix Iy Iω Iω

This equation shows that the exact normal stress is generated by the bending moments (M x, M y ) and bi-moment

(M ω) which causes warping. The sum of the first two terms is from classical beam theory, which does not

account for warping, and is frequently referred to as σapprox. The third term is a function of the warping constant,

Iω, and the warping function ω.

Shear stresses - including the effect of warping - are calculated as follows:

Vy V T T T

τ exact = Sx ( s) + x S y ( s) + s + ω Sω ( s ) = τ approx + ω Sω ( s)

tI x tI y 2tAc tI ω tI ω

One important issue is to know the effect of warping on both normal and shear stress. This is achieved by

investigating the ratio between approximate stresses calculated using classical beam theory (i.e. ignoring

warping) and exact stresses, which include the effect of warping.

σ exact − σ approch

WSR − N =

σ approch

τ exact − τ approch

WSR − S =

τ approch

Fig. 23.

Key-points considered for stress calculations.

For most of the bridges constructed (cross-frames

used) for combined loading, total stresses (normal stresses and shear stresses) are underestimated if warping is

not taken into account by an average less than 5% [6]. However, it is recommended that for each bridge a

(global)study on warping stresses be included.

Shear center

Consider the figure below showing a cantilever beam with a transverse force at the tip. Under the action of this

load, the beam may twist as it bends. It is the line of action of the lateral force that is responsible for this bend-

twist coupling. If the line of action of the force passes through the

Shear Center of the beam section, then the beam will only bend

without any twist. Otherwise, twist will accompany bending.

The shear center is in fact the centroid of the internal shear force

system. Depending on the beam's cross-sectional shape along its

length, the location of shear center may vary from section to section.

20. Design of a steel box girder 311

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

A line connecting all the shear centers is called the elastic axis of the beam. When a beam is under the action of

a more general lateral load system, then to prevent the beam from twisting, the load must be centered along the

elastic axis of the beam. The two following points facilitate the determination of the shear center location.

1. The shear center always falls on a cross-sectional axis of symmetry.

2. If the cross section contains two axes of symmetry, then the shear center is located at their intersection.

Notice that this is the only case where shear center and centroid coincide

If the cross section contains no axis of symmetry or only one

axis of symmetry, the determination of the exact location of

shear center requires a more detailed analysis.

If the applied shear force does not pass

through the shear center, it will force the beam

to twist as it bends. This eccentricity produces

a torque, that will cause an additional shear

flow and shear stress.

20.5.2 Bending

According to the elementary beam theory, when a box girder is loaded, the longitudinal normal stresses induced

in the flanges are assumed to be uniformly distributed across the flange width. However, in most cases,

particularly in a wide flange, these stresses are non-uniformly distributed due to shear deformations of the flange

plates. This phenomenon, characterized by the fact

that the longitudinal stress on a flange near the web is

much larger than that far from the web, is known as

shear lag.

Fig. 24.

Left: stress distribution without shear deformation.

Right: stress distribution with shear deformation.

The procedure commonly adopted in design is to replace the actual width of flange by an effective breadth

which, when used in conjunction with simple beam theory, leads to a correct estimate of the maximum flange

stress or deflection as required. The effective breadth factor for a (stiffened) flange depends on the geometry of

the box girder, the ratio of stiffener area to plate area, support conditions and loading distribution. Detailed

information on shear leg effects in member design like box girders, is given in prEN 1993-1-5 (Eurocode 1:

Design of steel structures, Part 1-5: Plated structural elements). Some information given by the Eurocode is listed

below.

20. Design of a steel box girder 312

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

20. Design of a steel box girder 313

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

The distribution of shear stresses in case of a vertical loading is given.

qb,0 = 0

Qy b Q b

qb,1' = qb,0 + ⋅ ⋅( h − hc ) ⋅ tu = y ⋅ ⋅ ( h − hc ) ⋅ tu

Ix 2 Ix 2

qb,2 = 0

Qy Qy

qb,1'' = qb,2 − ⋅ a ⋅ ( h − hc ) ⋅ t u = − ⋅ a ⋅ ( h − hc ) ⋅ tu

Ix Ix

Qy b

qb,1''' = qb ,1' − qb,1'' = ⋅ + a ⋅ ( h − hc ) ⋅ tu

Ix 2

Q 1

qb,3 = qb ,1''' + y ⋅ ( h − hc ) 2 ⋅ ⋅ t w

Ix 2

b

= y ⋅ (h − hc ) ⋅ + a ⋅ tu + ⋅t w ⋅( h −hc )

Q 1

Ix 2 2

Q b Q b

qb,4 = qb,5 + y ⋅ hc ⋅ ⋅ tl = y ⋅ hc ⋅ ⋅ tl

Ix 2 Ix 2

qb,5 = 0

20.5.3 Torsion

If the deflected shape caused by warping is not restricted, only St. Venant shear stresses exist.

If the deflected shape caused by warping is restricted, for example caused by:

20. Design of a steel box girder 314

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

- the presence of intermediate supports

- existence of intermediate diaphragms at end supports

- change in torsion along bridge length

additional warping stresses exist.

In general for static analyses the torsional warping stresses in box girders are neglected. However, some care

should be taken with this assumption.

A characteristic feature of thin-walled cross sections is

the large out-of-plane warping displacement that may

occur as a result of torsional (and distortional) loading.

In the absence of any longitudinal restraint, the

distribution of free warping due to constant torque is

identical at every cross section.

Fig. 25.

(a) Free warping.

(b) Restrained warping in a single-cell box section.

In addition to rigid-body rotation, each wall element undergoes a degree of shear deformation.

Pure torsion

The theoretical behavior of a thin walled box section subject to pure torsion is dealt with in many textbooks. For

a single cell box, the torque is resisted by a shear flow (St. Venant), which is constant around the box

b

Ts = 4 ⋅ P ⋅ = 2 ⋅ P ⋅ b

2

Ts = H ⋅ h +V ⋅ b = q s ⋅ b ⋅ h + q s ⋅ h ⋅ b = 2 ⋅ qs ⋅ h ⋅ b

Ts

qs =

2 ⋅ b⋅ h

Ts

q s = τ s ⋅ t ( s) =

2⋅F

Ts = ∫ qs ⋅ rS ( s) ⋅ ds where, rs (s) is distance of shear centre.

Rotation in plane

The shear flow produces shear stresses and strains in the walls and gives rise to a twist per unit length, which is

given by the general expression:

dθ dθ Ts

Ts = G ⋅K s ⋅ or (Bartho – equation) ϑ= =

dz dz G ⋅ K s

with

4 ⋅b2 ⋅ h2

Ks = (torsion constant)

b h b

+ 2⋅ +

tu t w tl

20. Design of a steel box girder 315

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Unrestrained warping out of plane

Pure torsion of a thin walled section will also produce a warping of the cross section, resulting in a torsional

warping displacement.

The general expression for the distribution of a sectorial

coordinate is expressed by:

τs

s s

ws ( s) = ws= 0 ( s ) − ϑ ⋅ ∫ rs ⋅ ds + ∫ ⋅ ds

0 0

G

The first integral determines the level of warping around

the equivalent open section formed by making an

imaginary cut in the closed box at s = 0. It is therefore

evaluated around the entire section.

Fig. 26. Distribution of sectorial coordinate.

The second integral, which applies only to the closed part of the section, takes account of shear deformation in

the various wall elements necessary to restore compatibility of warping displacement around the perimeter.

Restrained warping out of plane

If warping is in any way restrained, axial displacements at each section have the same cross-sectional

distribution, as is shown for pure torsion, but with a varying magnitude along the length of the girder.

A warping stress resultant is formed, generally referred to as a bi-moment (B). This warping torsional moment is

expressed by:

d 2θ

M ω = − E ⋅ Iω ⋅ 2

dz

d 2θ M ω

σ ω = E ⋅ω s ⋅ = ⋅ ωs

dz 2 Iω

This permits the familiar equation for longitudional stress in simple beam theory to be extended to include

torsional warping effects in thin walled sections.

Some practical information on stresses caused by restrained warping out of plane is given in e.g. the Dutch code

NEN 6788. A short summary is given.

3 ⋅ ∆M t

σw =

It ⋅ A

A = 2 ⋅ h ⋅ t3 + 2⋅ b ⋅ t

with b⋅t = b 1 ⋅t1 als b 2 ⋅t2 > b 1 ⋅t1

b⋅t = b 2 ⋅t2 als b 2 ⋅t2 < b 1 ⋅t1

and ∆M t change of torsion moment, in Nmm.

It moment of inertia in mm4

A cross-section area (without stiffeners), in mm2

h girder height, in mm

b girder width, in mm

t plate thickness in mm.

20. Design of a steel box girder 316

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

20.5.4 Distortion

Distorsion of box girders occurs when the torsional loads are not distributed to the plates of the cross section in

proportion to a uniform St. Venant shear flow. While torsional warping stresses in box girders may be relatively

small, without proper bracing (cross frames), distortional warping stresses can be quite significant. The

distortional behaviour of box girders can be understood by examining how the transverse force components in

the distortional loads are resisted in the girder. Figure 27 (a) shows the typical distorted shape that results in out-

of-plane bending of the plate components. Figure 27 (b) shows the shears that develop in the through-thickness

direction as a result of the distortion. The distortional loads on the flanges and webs are partially resisted by the

shears that develop in the plates. Out-of-plate bending stresses are induced with the corresponding moments

shown in figure 27 (c).

Fig. 27.

Out-of-plane distortional stresses in

a box girder.

Distortional loads are also partially resisted by the in-plane shears that develop on the cross sections of the

individual plated, as shown in figure 28. The large arrows represent the in-plane shears that resist the distortional

loads that are represented by the small arrows on the girder plates.

Fig. 28.

In-plane distortional warping stresses in

box girders.

The individual plates will experience in-plane bending from these shears, and longitudinal bending stresses may

be induced on the cross section. The longitudinal bending stresses are known as the distortional warping stresses,

and a typical distribution of the warping stress in a box girder is shown in figure 28. Providing internal cross

frames that are spaced along the girder length can significantly reduce cross-sectional distortion. To be effective,

these cross frames must possess sufficient stiffness.

20. Design of a steel box girder 317

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

The most common type of internal cross

frame in modern box girder bridges is the K-

frame. Figure 29 shows an internal K- frame

subjected to a concentrated load represented

by the forces H and V.

Fig. 29. Brace forces in cross frame under

distortional loads.

Since no torsional moment result from the

components of the distortional load, V and H must satisfy the equilibium: V(a+b) = 2Hh.

Once V and H are determined, the brace forces can be derived from static equilibrium of the K-frame.

Equilibrium of the K-frame in the horizontal direction leads to S = Dh .

The relationship between the horizontal and vertical components of the diagonal must satisfy the equilibrium of

DH h=DV(a/2), which results in an axial strut force of

a a 2a

S = DH = DV = V = H

2h h a +b

Thus, the axial force in a diagonal of the K-frame is

D= D +D =

2V F aI

+G J

2

=

2 LDK

H 2K

2 2 2

V H h V

h h

Following figure 30, the pure torsional and distortional

components in a vertical and horizontal couple is as

follows:

Fig. 30.

Pure torsional and distortional components in a

vertical and horizontal couple.

External torques generated by horizontal forces acting on the top and bottom plates of the box usually result from

curvature of the girder. The effect of the axial ending stress on the top flange can be modeled as an axial force

that is approx. equal to M/h, where M is the

bending moment and h is the girder depth. The

force M/h acts on the curved segment in the

longitudinal direction as shown in figure 31.

Fig. 31.

Approximation of effect of curvature on girder

flange.

20. Design of a steel box girder 318

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Due to the curvature of the segment, the force resultant of (M/h)dθ is developed on the flange in the lateral

direction. Dividing the lateral force by the length of the segment, ds, a distributed load equal to M.(Rh) is

derived. Due to the nature of bending stresses, the

bottom flange is subjected to the same magnitude of

the lateral load in the opposite direction. As a result,

these two horizontal components form a distributed

torsional load equal to M/R acting on the girder.

Fig. 32. Equivalent torsional loads on a curved box

girder.

Therefore, the effect of the curvature can be approx. analyzed by a straight model in which the flange segments

are subjected to longitudinal forces of M/h as well as external load of M/(Rh) in the lateral direction.

In general the distortional behavior depends on interaction between the two sorts of behavior, the warping and

the transverse distortional bending. The behavior has been demonstrated to be analogous to that of a beam on an

elastic foundation (BEF), with the beam stiffness representing the warping resistance and the elastic foundation

representing the transverse distortional bending resistance.

The differential equation is

d 4κ m

E ⋅ I Dω ⋅ 4

+ K Dω ⋅ κ = T

dz 2

The equation for the distortion stiffness of a box girder is

12 ⋅ (b ⋅ I w ⋅ Iu + b ⋅ Il ⋅ I w + 6 ⋅ h ⋅Iu ⋅ Il ) ⋅ E ⋅ Iw

KDω =

(b 2

⋅ I w2 + 2 ⋅ h ⋅I l ⋅ Iw ⋅ b + 2⋅ b ⋅ I w ⋅ h ⋅ Iu + 3 ⋅ h 2 ⋅ Iu ⋅ Il )

with

E ⋅ tu3

12 ⋅ (1 − µ 2 )

EIu = bending stiffness upper flange =

E ⋅ tw3

12 ⋅ (1 − µ 2 )

EIw = bending stiffness web =

E ⋅ tl3

12 ⋅ (1 − µ 2 )

EIl = bending stiffness lower flange =

For alternative cross-frames, as an example some equations are given.

Intermediate Kd

diaphragms

Plate KD = G ⋅ td ⋅b ⋅ h

Frame 12 ⋅ (b * ⋅ I w ⋅ I u + b* ⋅ I l ⋅ I w + 6 ⋅ h* ⋅ Iu ⋅ Il )⋅ E⋅ I w

KD =

(b *2 2

⋅ I w2 + 2 ⋅ h * ⋅ Il ⋅ Iw ⋅ b + 2 ⋅ b* ⋅ Iw ⋅ h * ⋅ Iu + 3 ⋅ h* ⋅ I u ⋅ I l )

X-shape 2 ⋅ E ⋅ Av ⋅ h2 ⋅ b2

KD = 3

lv

V-shape E ⋅ Av ⋅ h2 ⋅ b2

KD =

2 ⋅ lv

3

20. Design of a steel box girder 319

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Plate

H H

γH = =

G ⋅ A G ⋅ b ⋅ td

V V

γV = =

G ⋅ A G ⋅ h ⋅ td

H H H ⋅h

κ= = = or

G ⋅ A G ⋅ b ⋅td G ⋅ b ⋅td ⋅h

V V V ⋅b

κ= = =

G ⋅ A G ⋅ h ⋅ td G ⋅ h ⋅ t d ⋅ b

TDω

κ=

G ⋅ b ⋅ td ⋅ h

KD = G ⋅ t d ⋅ b ⋅ h

Frame

12 ⋅ (b * ⋅ I w ⋅ I u + b* ⋅ I l ⋅ I w + 6 ⋅ h* ⋅ Iu ⋅ Il )⋅ E⋅ I w

KD =

(b *2 2

⋅ I w2 + 2 ⋅ h * ⋅ Il ⋅ Iw ⋅ b + 2 ⋅ b* ⋅ Iw ⋅ h * ⋅ Iu + 3 ⋅ h* ⋅ I u ⋅ I l )

1

Iu = ⋅ t d ⋅ hu3

12

1

I w = ⋅ t d ⋅ hw3

12

1

I l = ⋅ td ⋅ hl3

12

X-shape

1 1 H 2 ⋅ h2 V 2 ⋅b2

Qv = ⋅ H + V = ⋅

2 2

+

2 2 h2 b2

1 TDω ⋅ ( b + h )

2 2 2 2 2

1 TDω TDω

Qv = ⋅ + 2 = ⋅

2 h2 b 2 h2 ⋅ b 2

⋅ ( b 2 + h2 ) = D ω ⋅ b

T 1 T l

= Dω ⋅

2 b⋅h 2 b⋅h

Qv

uv = ⋅ lb

E ⋅ Av

b Q ⋅b

uv , x = uv ⋅ = v

lb E ⋅ Av

h Qv ⋅ h

uv , x = uv ⋅ =

lb E ⋅ Av

20. Design of a steel box girder 320

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

b h Qv b 2 + h 2 Qv

2

uv , x u v, y l Q

κ= + = + ⋅ = ⋅ = b ⋅ v

h b h b E ⋅ Av h ⋅ b E ⋅ Av h ⋅ b E ⋅ Av

3

l 1 TDω

κ = 2b 2 ⋅ ⋅

h ⋅ b E ⋅ Av 2

2 ⋅ E ⋅ Av ⋅ h2 ⋅ b2

KD = 3

lb

V-shape

H 2 ⋅ h 2 V 2 ⋅ b2

2

H

Qv = + V 2 = +

2 4⋅ h

2 2

b

TDω

2

TDω

2

TDω 2 ⋅ ( b2 + 4 ⋅ h2 )

Qv = + 2 =

4 ⋅ h2 b 4 ⋅ h 2 ⋅ b2

⋅ ( b 2 + 4 ⋅ h 2 ) = TDω ⋅ b

T 1 l

= Dω ⋅

2 b⋅h b⋅h

Qv

uv = ⋅ lb

E ⋅ Av

b Qv ⋅ b

uv , x = uv ⋅ =

2 ⋅ lb 2 ⋅ E ⋅ Av

h 2 ⋅ Qv ⋅ h

uv , x = 2 ⋅uv ⋅ =

lb E ⋅ Av

b 2 ⋅ h Qv b2 + 4 ⋅ h 2 Qv 2 ⋅ lb

2

uv , x u v, y Q

κ= + = + ⋅ = ⋅ = ⋅ v

h b 2⋅h b E ⋅ Av 2 ⋅ h ⋅ b E ⋅ Av h ⋅ b E ⋅ Av

2 ⋅ lb

3

T

κ= ⋅ Dω

h ⋅ b E ⋅ Av

2 2

E ⋅ Av ⋅ h2 ⋅ b2

KD =

2 ⋅ lb

3

20. Design of a steel box girder 321

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Example: Brace forces due to distortion of quasi-closed straight box girder

Fig. 33.

Eccentric concrete load on box girder.

Open boxes will require some plane bracing on the open side, to provide torsional stiffness during construction.

It is usual for the deck slab to be concreted in stages and for the steel girders to be unpropped between supports

during this process. Part of the load is thus carried by the steel beam sections alone, part by the composite

sections. A number of separate analyses are therefore required, each representing a different stage.Typically

there are about twice as many stages as spans, since concrete is usually placed alternately in midspan regions and

over supports. Distortional effects should be considered carefully when concreting open sections in stages.

Explanation is given on the following.

A simple span quasi-closed box girder subjected to

distribute top flange loads, as shown in figure 34 (a).

The load is equivalent to an eccentric distributed vertical

load w = 48.2 kN/m with an offset of 0.53m to the

centerline of the girder (shear center vertically). This

loading condition arises in girders with an

unsymmetrical bridge deck, which frequently occurs in

the fascia of bridges. The girder dimensions as well as

the bracing member sizes are shown in figure 34 (b).

Fig. 34.

Quasi-closed straight box girder subjected to eccentric

vertical loading.

The girder length is divided into 16 bracing panels,

each with a length of 3.1 m. K-frames are provided at

every other lateral strut and are spaced at s K = 6.1 m.

Fig. 35.

Quasi-closed box girder (a) cross section and (b)

plan view of truss type.

Solid diaphragms are used at each of the end supports. Other dimensions for the box girder can be obtained from

figure 34, including a = 2.03 m, b = 3.18 m and R = ¥ (straight girder). The corresponding diagonal length is LDK

= 2.50 m.

Substituting these values into results in D = 20.9 kN and S = 8.5 kN respectively.

Predicted values and FEA-results for the K-frame forces in the straight girder with the X-type top lateral truss are

given in figure 36. Only the tensile components of the diagonals and the lateral struts are shown.

20. Design of a steel box girder 322

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Fig. 36. K-frame forces due to eccentric vertical loads.

Example: Brace forces due to distortion of quasi-closed curved continuous box girder

The following case is explained.

A three span curved continuos girder with

concentric loading, as shown in figure 37.

Using the bending moments at the K-frame

locations, the brace forces are calculated with the

equations as given in the previous example with e

= 0. The axial forces in the struts and diagonals at

the interior side of the K-frames are shown in

figure 38 (web inclination is ignored).

Fig. 37.

Curved continuos box girder.

A good agreement exists between FEA results and forces predicted by equations given.

Figure 38 demonstrates that relatively large forces can be generated due to distortion.

When superimposed on forces from bending and torsion,

these forces can become even larger and problems can

develop in these critical bracing’s members since

“typical” sizes are often used in lieu of actual design. In

many situations, relatively small angles that may be

structurally inadequate are used for these bracing

members.

Fig. 38. K-frame forces in curved continuous box

girder.

20. Design of a steel box girder 323

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

20.6 Learning from Failures

Structural failures occur as a result of human failures. Moreover, human failures have the inclination to repeat

themselves. During the period 1969-1971, several accidents happened with box girder bridges, all during the

erection stage:

• 1969: bridge across the Danube, Vienna

• 1970: bridge across the Cleddau, Milford Haven, Wales

• 1970: bridge across the Lower Yarra, Melbourne, Australia

• 1971: bridge across the Rhine, Koblenz, Germany.

• 1977: bridge connecting Koror – Babaldaob – New Guinea

These five cases are briefly discussed below.

Vienna

The erection of this bridge proceeded without problems by cantilevering from both sides. The final gap was

closed on a hot summer day. The deformations of the bridge due to temperature expansion are shown in figure

39. During the night an evenly distributed temperature was restored. The bridge straightened, leading to plate

buckling. The buckling was corrected and no collapse occurred.

Fig. 39. Bridge across Danuble 1969 Vienna; buckling of lower flange under compression.

Milford Haven

The midspan of this bridge was erected by cantilevering. With this

method of erection the cross frame above a pier suffers extra loading

due to the cantilevering part. This load causes no problem, provided

that the diaphragm is designed to carry it. This was not the case. The

bridge collapsed, figure 40.

Fig. 40. Cleddau Bridge in Milford, Wales 1970.

20. Design of a steel box girder 324

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Melbourne

The stiffening girder of this cable-stayed bridge consisted of three cells. For erection, the box was divided into

two parts longitudinally, figure 41. On each side of a pier one part of the box was assembled, hoisted to the

correct level and shifted into the correct position to be connected.

Some complications:

• Both parts were asymmetric. Vertical and horizontal deflection

were to be expected due to dead load.

• It is practically impossible to assemble both parts independently in

such a way that the sag is exactly the same. An actual difference of

120 mm was measured.

• The laterally cantilevering top flange is strongly inclined to buckle.

Putting ballast on top of the bridge solved the latter two problems. The

difference in overall deflection disappeared, but buckling of the cantilevering

top flange increased. To solve the problem of the final buckle, some high

strength friction grip bolts were taken out to remove the incompatibility in

flange length, with the disastrous result of passing the ultimate load carrying

resistance. The bridge yielded and collapsed 50 minutes later.

Fig. 41. West Gate Bridge, Melbourne 1970.

Koblenz

Cantilevering was used as the erection method and again a collapse occurred. The failure was due to the

coincidence of three unfavorable aspects, each of which separately would, most probably, not have caused the

collapse.

• Due to welding of the cross weld, a deformation was introduced, increasing the eccentricity of the

compressive stress, Figure 43a.

• A gap of about 460 mm was kept free between the longitudinal stiffeners, so that automatic welding

equipment could pass the stiffeners without stopping, Figure 10b. The buckling length was taken as 460

mm. The effective buckling length was larger, Figure 10c.

• The effect of effective width on the locally unstiffened plate was not taken into account.

20. Design of a steel box girder 325

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Fig. 43.

Rhine River Bridge, Kobelnz 1971.

The accidents in the United Kingdom particularly led to a rigorous investigation program. In 1974, the `Merrison

Rules' were issued, a code giving recommendations on calculation and erection of box girders.

Zeulenroda bridge, East-Germany

Buckling of the lower flange.

Fig. 44. Stausee-Zeulenroda bridge, Germany, 1973.

20. Design of a steel box girder 326

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

Koro-Babaldaob bridge

Without any warning, the bridge collapsed. Several explanations have been developed, however, a clear

conclusion about the exact reason doesn’t exist.

Fig. 45. Koror-Baaldaob bridge, Paulau 1977.

REFERENCES

[1] Distortional Loads and Brace Forces in Steel Box Girders, Journal of Strucutral Engineering / Juni 2002.

[2] Distorsie van kokerliggerbruggen, Msc-work M. Oomen, 2003.

[3] Design Guide for Composite Box Girder Bridges, SCI-P-140.

[4] Behaviour of concrete box girder bridges of deformable cross-section, Proc. Instn Civ. Engrs Structs &

Bldgs, 1993, 99 May, 109-122

[5] http://www.ae/msstate.edu/~masoud/Teaching/SA2/

[6] Behavior and design of curved composite box girder bridges, Report Oct. 2002, University of Central

Florida, Orlando, FL 32816-2450.

APPENDIX Examples: analysis

20. Design of a steel box girder 327

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

1. Torsion

Opposite torsion moments at fully free girder ends. Box girder dimension: b · h · l = 1950 · 1950 · 10000 mm,

d = 50 mm, E = 210000 N/mm2 and ? = 0,3. Torsion moment: 3,8025 · E+8 Nmm.

4 ⋅ b2 ⋅h 2 4 ⋅ 1950 2 ⋅ 1950 2

Ks = = = 3,7 ⋅ 1011 mm 3

b h b 1950 1950 1950

+ 2⋅ + + 2⋅ +

tu t w tl 50 50 50

dθ Ts 3,8025 ⋅ 108

ϑ= = = = 1,27 ⋅ 10 −8

dz G ⋅ K s 210000

⋅ 3,7 ⋅ 1011

2,6

Rotation girder

dθ 1 1

θ= ⋅ L ⋅ = 1,27 ⋅ 10 −8 ⋅ 10000 ⋅ = 6,35 ⋅ 10−5

dz 2 2

FE-results.

displacement

normal stress (in longitudinal direction)

Because of the unrestrained warping out of plane the normal stresses are negligible (as shown).

2. Torsion

Opposite torsion moments at girder ends. Left end fully clamped and right end fully free.

Girder dimensions identical to first example.

normal stress (in longitudinal direction)

displacement

Because of the restrained warping out of plane, stresses occur (as shown).

20. Design of a steel box girder 328

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

3. Torsion

Torsion moment positioned half girder length. Both girder ends pin ended supported and girder dimensions

identical to first example.

displacement

normal stress (in longitudinal direction).

Because of the restrained warping out of plane, mainly stresses occur (as shown) at supports and load input

3. Torsion

Torsion moment uniformly along the whole girder length. Girder pin ended supported at 0 –50 – 100% girder

length and girder dimensions identical to first example.

displacement normal stress (in longitudinal direction)

Because of the restrained warping out of plane, stresses occur (as shown) along the whole girder length

20. Design of a steel box girder 329

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

4. Distortion: cross-frame, plate structure

Plate dimension: b · h · t d = 100 · 100 · 10 mm, E = 210000 N/mm2 and ? = 0,3.

Each plate edge loaded uniformly by shear: total edge load F = 1000 N.

Distortion moment: TD? = F · h = F · b = 1000 N · 100 mm. = 100.000 Nmm

load input frame deformation

210000

K D = G ⋅ t d ⋅ b ⋅h = ⋅ 10 ⋅ 100 ⋅ 100 = 8,0769 ⋅ 109 Nmm

2,6

TDω

κ= = = 1,238 · 10-5

G ⋅ b ⋅ td ⋅ h

5. Distortion: cross-frame, frame structure

Frame dimensions: b · h · t d = 100 · 100 · 50 mm, h u = h l = h w = 5 mm, E = 210000 N/mm2 en ? = 0,3. Edge

loading: 750 N.

TD? = F · h = F · b = 750 N · 100 mm. = 75.000 Nmm.

load input. frame deformation

KD =

( )

12 ⋅ b * ⋅ I w ⋅ Iu + b * ⋅ I l ⋅ I w + 6 ⋅ h * ⋅ I u ⋅ Il ⋅ E ⋅ I w

(b *2

⋅ I w + 2 ⋅ h ⋅ I l ⋅ I w ⋅ b + 2 ⋅ b ⋅ Iw ⋅ h ⋅ I u + 3 ⋅ h *2 ⋅ I u ⋅ I l

2 * * *

)

K D = 1,603 ⋅ 107 Nmm

TDω → κ = 4,076 · 10-3

KD =

κ

20. Design of a steel box girder 330

Dr. A. Romeijn

CT5125: Steel bridges – file <design-box-girder>

6. Distortion: girder

Girder pin ended supported at both ends (each end, two bearings) and girder ends stiffened by cross frames

(stiffness 1,696*1013 Nmm).

h= 1875 mm.

b= 2450 mm.

a= 1000 mm.

tu = 150 mm.

tw = 50 mm.

tl = 100 mm.

L= 12700 mm.

E= 210000 N/mm2

?= 0,3

EID? = 3,164·1022 N·mm4 .

7

KD? = 2,970·10 N·mm / mm’.

Mt / 2 = 4800000 N·mm / mm’.

qt = 7680 N / mm’.

girder input as eccentric loading

normal stress displacements

5. Distortion: girder

Identical to example 6, however cross frames located at 0 – 50 – 100% girder length.

normal stress displacements

As an indication:

• the influence of distortion stiffness on stresses is relatively small

• increasing the number of frames by a factor 2 results into a decrease of normal stress by a factor 4.

20. Design of a steel box girder 331

Dr. A. Romeijn

Vous aimerez peut-être aussi

- Super T StandardsDocument16 pagesSuper T Standardschithirai10Pas encore d'évaluation

- Bridge Deck With Link-SlabDocument31 pagesBridge Deck With Link-Slabquithanqui100% (1)

- Cable Supported Bridges: Concept and DesignD'EverandCable Supported Bridges: Concept and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Integral Bridge Midas SeminarDocument36 pagesIntegral Bridge Midas Seminarlamkinpark3373100% (1)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesD'EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesPas encore d'évaluation

- Substructures - Solutions - MidasbridgeDocument14 pagesSubstructures - Solutions - Midasbridgechao liuPas encore d'évaluation

- Integral Bridge Design ExampleDocument33 pagesIntegral Bridge Design ExampleRussel Odendaal100% (1)

- Analysis of Box Girder Bridge PresentationDocument32 pagesAnalysis of Box Girder Bridge PresentationVineel Kumar Bapatla100% (3)

- Integral Bridges: What Is An Integral Bridge?Document20 pagesIntegral Bridges: What Is An Integral Bridge?Akhilesh Goje100% (1)

- Post Tensioned Box Girder Design Manual (3) (200-374)Document175 pagesPost Tensioned Box Girder Design Manual (3) (200-374)Saputra ErwanPas encore d'évaluation

- IRC 112 Creep Shrinkage Manual Calculation Vs Midas Civil ValuesDocument5 pagesIRC 112 Creep Shrinkage Manual Calculation Vs Midas Civil ValuesDhimas Surya NegaraPas encore d'évaluation

- mIDAS Civil 2020 v11 UPDATES PDFDocument27 pagesmIDAS Civil 2020 v11 UPDATES PDFani4576Pas encore d'évaluation

- Grillage Modelling ExampleDocument14 pagesGrillage Modelling Examplewanjailani100% (1)

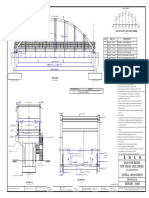

- PSC Box Girder Bridge With Abutment & Pier Design in AASHTO-LRFDDocument197 pagesPSC Box Girder Bridge With Abutment & Pier Design in AASHTO-LRFDSANDIPPas encore d'évaluation

- Midas Civil - Advanced - Prestressed Box Girder Design (FCM, FSM)Document77 pagesMidas Civil - Advanced - Prestressed Box Girder Design (FCM, FSM)mdkmlPas encore d'évaluation

- LARSA 4D Advanced Training Manual For Bridge ProjectsDocument61 pagesLARSA 4D Advanced Training Manual For Bridge ProjectsDyarPas encore d'évaluation

- Advantages of Prestressed Concrete BridgesDocument44 pagesAdvantages of Prestressed Concrete BridgesVivek PremjiPas encore d'évaluation

- 5377 68 23Document8 pages5377 68 23JamesPas encore d'évaluation

- Integral Bridge DesignDocument24 pagesIntegral Bridge DesignMaitrabarun Karjee100% (2)

- 4 - Steel Composite BridgeDocument31 pages4 - Steel Composite BridgeNabeel Ahmad100% (1)

- RC-Pier LRFD 3 Column Frame Pier ExampleDocument160 pagesRC-Pier LRFD 3 Column Frame Pier ExampleMTCLS100% (2)

- SEO-Optimized TitleDocument14 pagesSEO-Optimized TitleMarekPas encore d'évaluation

- Elastomeric Bearing Design ExampleDocument14 pagesElastomeric Bearing Design ExampleTan Nguyen Cong100% (2)

- Detail Design of Bridge Abutment 1Document4 pagesDetail Design of Bridge Abutment 1mohammad azimPas encore d'évaluation

- Computer Aided Design of An Integral Bridge Super Structure Using Excel Spread SheetsDocument9 pagesComputer Aided Design of An Integral Bridge Super Structure Using Excel Spread SheetsNuruddeen MuhammadPas encore d'évaluation

- Design Balanced Cantilever BridgesDocument26 pagesDesign Balanced Cantilever BridgesShijo AntonyPas encore d'évaluation

- Arch BridgeDocument133 pagesArch BridgeLau Kim Hwa100% (2)

- Everything You Need to Know About Integral BridgesDocument21 pagesEverything You Need to Know About Integral BridgesshardasiddhPas encore d'évaluation

- PC Composite and PSC Box Girder Bridge Design Modeling FeaturesDocument58 pagesPC Composite and PSC Box Girder Bridge Design Modeling FeaturesRamon Gutierrez100% (1)

- MIDAS 2013 Indonesia Workshop - Cable Stayed BridgeDocument85 pagesMIDAS 2013 Indonesia Workshop - Cable Stayed BridgeDanang Rahadian100% (1)

- Extended-Design and Analysis of A Network Arch BridgeDocument10 pagesExtended-Design and Analysis of A Network Arch BridgehansPas encore d'évaluation

- Integral Abutment Bridge Design (Modjeski and Masters) PDFDocument56 pagesIntegral Abutment Bridge Design (Modjeski and Masters) PDFAnderson UrreaPas encore d'évaluation

- Csi Bridge Key Features and TerminologyDocument64 pagesCsi Bridge Key Features and TerminologyGmo010% (1)

- Cable Stayed BackwardDocument69 pagesCable Stayed BackwardIonut FalcescuPas encore d'évaluation

- Integral Abutments For Prestressed Beam BridgesDocument89 pagesIntegral Abutments For Prestressed Beam BridgesBridgy mcbridge100% (5)

- 2016 FAQ Midas CivilDocument67 pages2016 FAQ Midas Civillamkinpark3373Pas encore d'évaluation

- Pilar JembatanDocument37 pagesPilar JembatanMAWAR08100% (4)

- Modeling of Post-Tensioned Segmental Box GirdersDocument63 pagesModeling of Post-Tensioned Segmental Box GirdersUlissipo1955100% (1)

- Skew Bridges Calculation MethodsDocument9 pagesSkew Bridges Calculation MethodsIsidro P. BuquironPas encore d'évaluation

- Tendon Template PDFDocument27 pagesTendon Template PDFGeorge LazarPas encore d'évaluation

- Complete Design Report of Bridge Using CSiBridgeDocument60 pagesComplete Design Report of Bridge Using CSiBridgeKS Lee75% (4)

- M54 Unit 10 Skew Deck & Intergral BridgesDocument25 pagesM54 Unit 10 Skew Deck & Intergral BridgesPhilip YapPas encore d'évaluation

- Midas Civil Training - 0220-Edit-Final PDFDocument48 pagesMidas Civil Training - 0220-Edit-Final PDFgundulp100% (2)

- Vibration Analysis of Steel Pedestrian BridgesDocument35 pagesVibration Analysis of Steel Pedestrian BridgesYasela100% (1)

- ASCE - Transverse Analysis of A PSC Wide Box Girder+ribsDocument10 pagesASCE - Transverse Analysis of A PSC Wide Box Girder+ribsMananPas encore d'évaluation

- Design of Dingley Bypass Integral Bridges: Dr. Kabir Patoary - Principal Engineer - Bridges - GHDDocument32 pagesDesign of Dingley Bypass Integral Bridges: Dr. Kabir Patoary - Principal Engineer - Bridges - GHDkevin_au18Pas encore d'évaluation

- Modeling Statement-Super TDocument20 pagesModeling Statement-Super Talden cayagaPas encore d'évaluation

- Design of Elastomeric Bearings For Steel BridgesDocument66 pagesDesign of Elastomeric Bearings For Steel BridgesMaha Moddather Hassan100% (4)

- Notes - Bridge Design - Box Girder BridgesDocument20 pagesNotes - Bridge Design - Box Girder BridgesBobby Wong100% (4)

- Box Girder Bridges Design GuideDocument20 pagesBox Girder Bridges Design Guidefaraday99Pas encore d'évaluation

- Chapter 7: Box Girder BridgesDocument26 pagesChapter 7: Box Girder BridgesPacha Khan KhogyaniPas encore d'évaluation

- UNIT-2 (Lecture-3) Types of BridgesDocument41 pagesUNIT-2 (Lecture-3) Types of BridgesMd Sabbir HossainPas encore d'évaluation

- Span PDFDocument15 pagesSpan PDFeddyzevallosPas encore d'évaluation

- Composite Floors PDFDocument17 pagesComposite Floors PDFmuru0105Pas encore d'évaluation

- Steel As A Structural MaterialDocument10 pagesSteel As A Structural MaterialFaisal ShahzadPas encore d'évaluation

- Numerical Modelling of Continuous Box GirderDocument38 pagesNumerical Modelling of Continuous Box GirderAnonymous Gd0PTUQPas encore d'évaluation

- Dissertation CDN PDFDocument271 pagesDissertation CDN PDFAnonymous Gd0PTUQPas encore d'évaluation

- Segmental Post-Tensioned BridgesDocument7 pagesSegmental Post-Tensioned BridgesAnonymous Gd0PTUQPas encore d'évaluation

- Article On Calculation of Time Dependent Losses (April-June'14)Document16 pagesArticle On Calculation of Time Dependent Losses (April-June'14)Anonymous Gd0PTUQPas encore d'évaluation

- Construction Stage Analysis of Segmental Cantilever BridgeDocument10 pagesConstruction Stage Analysis of Segmental Cantilever BridgeIAEME PublicationPas encore d'évaluation

- Prestressed Concrete Beam Design To BS 5400 Part 4Document8 pagesPrestressed Concrete Beam Design To BS 5400 Part 4Anonymous Gd0PTUQPas encore d'évaluation

- Segmental Post-Tensioned BridgesDocument7 pagesSegmental Post-Tensioned BridgesAnonymous Gd0PTUQPas encore d'évaluation

- Computerised Box Bridge DesignDocument14 pagesComputerised Box Bridge DesignTeo Peng KeatPas encore d'évaluation

- Section2 1 PDFDocument14 pagesSection2 1 PDFRavi ShankarPas encore d'évaluation

- Time-Dependent Prestress Losses in Pretensioned Concrete ConstructionDocument196 pagesTime-Dependent Prestress Losses in Pretensioned Concrete ConstructionAnonymous Gd0PTUQPas encore d'évaluation

- Lecture 24 - Prestressed ConcreteDocument12 pagesLecture 24 - Prestressed ConcretejeovanPas encore d'évaluation

- Chapter 14 ADocument18 pagesChapter 14 AWalid ThohariPas encore d'évaluation

- Reinforced Concrete Design-Krishnaraju PDFDocument318 pagesReinforced Concrete Design-Krishnaraju PDFcbecdm81% (37)

- Dowel ActionDocument6 pagesDowel ActionAnonymous Gd0PTUQPas encore d'évaluation

- 7 1Document69 pages7 1Ardian Rizardhi SatyagrahaPas encore d'évaluation

- FHWA-NHI-00-043 - Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design and Construction GuidelinesDocument418 pagesFHWA-NHI-00-043 - Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design and Construction Guidelinestenkken1504100% (2)

- Behaviour of Box Girder Bridges PDFDocument9 pagesBehaviour of Box Girder Bridges PDFAnonymous Gd0PTUQPas encore d'évaluation

- A Critical Analysis of The Vicaria Arch Bridge Yeste, Albacete, SpainDocument11 pagesA Critical Analysis of The Vicaria Arch Bridge Yeste, Albacete, SpainAnonymous Gd0PTUQPas encore d'évaluation

- Recommended Practice For Precast Prestressed Concrete Composite Bridge Deck PanelsDocument43 pagesRecommended Practice For Precast Prestressed Concrete Composite Bridge Deck PanelsAnonymous Gd0PTUQPas encore d'évaluation

- 42m BowStringDocument1 page42m BowStringsorowarePas encore d'évaluation

- EnHanced4 WB KeyDocument293 pagesEnHanced4 WB Keyezzeldin3khater100% (2)

- Rancangan Pengajaran Harian Sepanjang PKPP Tahun 1Document13 pagesRancangan Pengajaran Harian Sepanjang PKPP Tahun 1Jamuna BatumalaiPas encore d'évaluation

- Ageli Software DevelopmentDocument112 pagesAgeli Software DevelopmentRyan Adrian100% (2)

- DefenseDocument20 pagesDefenseManny De MesaPas encore d'évaluation

- CS3C Mover Practice 2Document4 pagesCS3C Mover Practice 2Nguyễn Lê Hà ViPas encore d'évaluation

- WS 1.6 IvtDocument2 pagesWS 1.6 IvtAN NGUYENPas encore d'évaluation

- ID Rekonstruksi Sistem Birokrasi PertanahanDocument24 pagesID Rekonstruksi Sistem Birokrasi PertanahanMuhammad FakhriPas encore d'évaluation

- MARGA-Quick Guide enDocument11 pagesMARGA-Quick Guide enKaran TibdewalPas encore d'évaluation

- Reactions of Hydrocarbons and HaloalkanesDocument6 pagesReactions of Hydrocarbons and HaloalkanesGwynethAdrienneLeighVillapandoPas encore d'évaluation

- Mod 1 1 Concepts of Everyday LeadershipDocument26 pagesMod 1 1 Concepts of Everyday LeadershipSaifuzzaman AntorPas encore d'évaluation

- Contracts-Nature and TerminologyDocument19 pagesContracts-Nature and TerminologyNguyễn Trần HoàngPas encore d'évaluation

- An ISO 9001Document3 pagesAn ISO 9001Prasad IngolePas encore d'évaluation

- TQM 2 MARKSDocument12 pagesTQM 2 MARKSMARIYAPPANPas encore d'évaluation

- 4.3-Euler's Equation PDFDocument6 pages4.3-Euler's Equation PDFRonald Cario SeguinPas encore d'évaluation

- A Practice Teaching Narrative of Experience in Off Campus InternshipDocument84 pagesA Practice Teaching Narrative of Experience in Off Campus InternshipClarenz Jade Magdoboy MonseratePas encore d'évaluation

- Affidavit of DesistanceDocument6 pagesAffidavit of Desistancesalasvictor319Pas encore d'évaluation

- BBFH107 - Business Statistics II Assignment IIDocument2 pagesBBFH107 - Business Statistics II Assignment IIPeter TomboPas encore d'évaluation

- The National Artists of The Philippines For Music and TheaterDocument29 pagesThe National Artists of The Philippines For Music and Theaterleeahna cyra villanuevaPas encore d'évaluation

- 1201 CCP Literature ReviewDocument5 pages1201 CCP Literature Reviewapi-548148057Pas encore d'évaluation

- Research Planning: Content, Steps, and Structural ComponentsDocument18 pagesResearch Planning: Content, Steps, and Structural ComponentsAndrei GS ZapshaPas encore d'évaluation

- CSEC English B June 2013 P2Document7 pagesCSEC English B June 2013 P2Jhanett RobinsonPas encore d'évaluation

- English Proficiency Test (EPT) Reviewer With Answers - Part 1 - Online E LearnDocument4 pagesEnglish Proficiency Test (EPT) Reviewer With Answers - Part 1 - Online E LearnMary Joy OlitoquitPas encore d'évaluation

- 2339321 16 pf test reportDocument15 pages2339321 16 pf test reportIndrashis MandalPas encore d'évaluation

- Bellak Tat Sheet2pdfDocument17 pagesBellak Tat Sheet2pdfTalala Usman100% (3)

- Laertes' Temper: Definition of DiacopeDocument27 pagesLaertes' Temper: Definition of DiacopeAhmad Abdellah ElsheemiPas encore d'évaluation

- Matrix Software User ManuelDocument45 pagesMatrix Software User ManuelHema SantoshPas encore d'évaluation

- Case Study Analysis of Six Sigma Implementation Inservice OrganisationsDocument30 pagesCase Study Analysis of Six Sigma Implementation Inservice OrganisationsMohammed AwolPas encore d'évaluation

- Homemade Water PurifierDocument13 pagesHomemade Water PurifierSherazPas encore d'évaluation

- Belief MatrixDocument1 pageBelief Matrixapi-384108912Pas encore d'évaluation

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (137)

- Advanced Modelling Techniques in Structural DesignD'EverandAdvanced Modelling Techniques in Structural DesignÉvaluation : 5 sur 5 étoiles5/5 (3)

- Building Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareD'EverandBuilding Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareÉvaluation : 4.5 sur 5 étoiles4.5/5 (15)

- Marine Structural Design CalculationsD'EverandMarine Structural Design CalculationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (13)

- Transmission Pipeline Calculations and Simulations ManualD'EverandTransmission Pipeline Calculations and Simulations ManualÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsD'EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsPas encore d'évaluation

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Built: The Hidden Stories Behind Our StructuresD'EverandBuilt: The Hidden Stories Behind Our StructuresÉvaluation : 4 sur 5 étoiles4/5 (27)

- Design and Construction of Soil Anchor PlatesD'EverandDesign and Construction of Soil Anchor PlatesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Pile Design and Construction Rules of ThumbD'EverandPile Design and Construction Rules of ThumbÉvaluation : 4.5 sur 5 étoiles4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingD'EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingPas encore d'évaluation

- Advanced Design Examples of Seismic Retrofit of StructuresD'EverandAdvanced Design Examples of Seismic Retrofit of StructuresÉvaluation : 1 sur 5 étoiles1/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- Structural Analysis: In Theory and PracticeD'EverandStructural Analysis: In Theory and PracticeÉvaluation : 4.5 sur 5 étoiles4.5/5 (24)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsD'EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsÉvaluation : 4 sur 5 étoiles4/5 (16)

- Experiment and Calculation of Reinforced Concrete at Elevated TemperaturesD'EverandExperiment and Calculation of Reinforced Concrete at Elevated TemperaturesÉvaluation : 5 sur 5 étoiles5/5 (2)

- Matrix Methods for Advanced Structural AnalysisD'EverandMatrix Methods for Advanced Structural AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- Pipeline Planning and Construction Field ManualD'EverandPipeline Planning and Construction Field ManualÉvaluation : 5 sur 5 étoiles5/5 (3)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresD'EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresÉvaluation : 1 sur 5 étoiles1/5 (2)

- Offshore Pipelines: Design, Installation, and MaintenanceD'EverandOffshore Pipelines: Design, Installation, and MaintenanceÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)