Académique Documents

Professionnel Documents

Culture Documents

ASME VIII Div.1 PWHT Requirements

Transféré par

venu0 évaluation0% ont trouvé ce document utile (0 vote)

46 vues8 pagesTitre original

asmeviii-general-ppt-140604183648-phpapp01.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

46 vues8 pagesASME VIII Div.1 PWHT Requirements

Transféré par

venuDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 8

General Reading

ASME VIII Div.1- Charlie Chong/ Fion Zhang/ He Jungang / Li Xueliang

ASME VIII Div.1- Charlie Chong/ Fion Zhang/ He Jungang / Li Xueliang

When and where PWHT is mandatory by

code requirement?

ASME VIII Div.1- Charlie Chong/ Fion Zhang/ He Jungang / Li Xueliang

a) UW-2(a) when our service is lethal and our material is carbon steel or low

alloy steel.

b) UW-2(c) when our pressure vessel is unfired steam boiler and our material

is carbon steel or low alloy steel.

c) UW-2(d) when our pressure vessel is subjected to direct firing and our

material is carbon steel or low alloy steel.

d) UCS-56 when our nominal thickness exceeds a specific value, for instance

38 mm for P No.1 material or 0 mm for P No.3 material.UCS-56 also

gives min.

e) UCS-56, the same apply for other martial groups i.e. UNF-56, UHA-32,

UHT-56 and etc.

f) UCS-68(b) when our MDMT (Minimum Design Metal Temperature) is

below -55 Degree F

1. UW-2(a), when service is lethal and material is carbon steel or low

alloy steel.

2. UW-2(c), when pressure vessel is unfired steam boiler and material is

carbon steel or low alloy steel.

3. UW-2(d), when pressure vessel is subjected to direct firing and

material is carbon steel or low alloy steel.

4. UCS-56, when nominal thickness exceeds a specific value, for instance

38 mm for P No.1 material or 0 mm for P No.3 material.

5. UCS-56, the same apply for other martial groups i.e. UNF-56, UHA-

32, UHT-56 and etc.

6. UCS-68(b), when MDMT (Minimum Design Metal Temperature) is

below -55 Degree F.

How PWHT must be done when it is

mandatory?

ASME VIII Div.1- Charlie Chong/ Fion Zhang/ He Jungang / Li Xueliang

When one of above requirement applies to us, then we must do PWHT

based the requirement of UW-40 / UCS-56, which detailed to us the

PWHT procedure. Some important requirements in this clause are;

1. For Furnace PWHT;

a) Loading Temperature shall not exceed 800ºF,

b) Heating rate 800ºF /hr /inch of thickness,

c) During heating period the temperature variation shall be smaller

than 250ºF within 15ft interval length.

d) Above 800ºF, cooling rate 500ºF /hr /inch of thickness.

e) Still air cooling permitted below 800ºF.

f) During soaking period, temperature difference between hottest and

coldest part shall not exceed 150ºF.

g) Minimum overlap for PWHT in multiple heats is 5 ft.

ASME VIII Div.1- Charlie Chong/ Fion Zhang/ He Jungang / Li Xueliang

ASME VIII Div.1- Charlie Chong/ Fion Zhang/ He Jungang / Li Xueliang

Vous aimerez peut-être aussi

- 4 Heat TreatmentokDocument22 pages4 Heat TreatmentokPramod AthiyarathuPas encore d'évaluation

- Table UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EDocument5 pagesTable UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EMechanicalPas encore d'évaluation

- Table UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EDocument6 pagesTable UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EMechanicalPas encore d'évaluation

- Asme Sec Viii Ucs PWHTDocument35 pagesAsme Sec Viii Ucs PWHTMahesh KumarPas encore d'évaluation

- ASME VIII and API 510 Heat TreatmentDocument9 pagesASME VIII and API 510 Heat Treatmentphan hoang diepPas encore d'évaluation

- API 510 PWHT RequirementsDocument30 pagesAPI 510 PWHT RequirementsKandregula Mohan BabuPas encore d'évaluation

- PWHTDocument30 pagesPWHT9490233523Pas encore d'évaluation

- 01 ASME Sec VIII Div 1 - GEN PresentationDocument112 pages01 ASME Sec VIII Div 1 - GEN Presentationinatt101Pas encore d'évaluation

- API 570 Authorized Piping Inspector Preparatory Program Mock Exam QuestionsDocument13 pagesAPI 570 Authorized Piping Inspector Preparatory Program Mock Exam QuestionsShanawas Abdul Razak80% (5)

- PWHT, HT, Igc, MawpDocument40 pagesPWHT, HT, Igc, Mawpsachinshirnath100% (1)

- Iiw 1693 05Document19 pagesIiw 1693 05Pradip Goswami100% (1)

- Uha 32-2Document1 pageUha 32-2Lipika GayenPas encore d'évaluation

- Table Ucs 56 3 (P.no.4)Document1 pageTable Ucs 56 3 (P.no.4)Anonymous AyDvqgPas encore d'évaluation

- DIN-PS00-De0001 PAT Tower Standard Design Criteria and Requirement (Rev3...Document8 pagesDIN-PS00-De0001 PAT Tower Standard Design Criteria and Requirement (Rev3...Abhishek ChappaPas encore d'évaluation

- PWHT Requirements for Pressure Parts MaterialsDocument2 pagesPWHT Requirements for Pressure Parts MaterialsManuel Alejandro González MarcanoPas encore d'évaluation

- ASME BPVC.VIII.1-2019 Postweld Heat Treatment RequirementsDocument1 pageASME BPVC.VIII.1-2019 Postweld Heat Treatment RequirementsCITRIXPas encore d'évaluation

- ASME Section VIII Div. 1 Pressure Vessel Inspection GuideDocument47 pagesASME Section VIII Div. 1 Pressure Vessel Inspection GuideTayfunwPas encore d'évaluation

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariableschowhkPas encore d'évaluation

- ASME Guides WeldCanadaDocument3 pagesASME Guides WeldCanadaSubhan50Pas encore d'évaluation

- Cold Drawn Seamless For Heat Exchangers and BoilersDocument12 pagesCold Drawn Seamless For Heat Exchangers and BoilersmuhammadsaliPas encore d'évaluation

- Ma App 23Document2 pagesMa App 23ahmedPas encore d'évaluation

- Table UCS-56-4 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-Nos. 5A, 5B, and 5CDocument3 pagesTable UCS-56-4 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-Nos. 5A, 5B, and 5CMechanicalPas encore d'évaluation

- Asme Section Ii A Sa-179 Sa-179m PDFDocument4 pagesAsme Section Ii A Sa-179 Sa-179m PDFHyunjong MoonPas encore d'évaluation

- Asme Section II A Sa-358 Sa-358mDocument10 pagesAsme Section II A Sa-358 Sa-358mAnonymous GhPzn1xPas encore d'évaluation

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariablesAnonymous rYZyQQot55Pas encore d'évaluation

- Astm A269Document6 pagesAstm A269Leonardo Borsari SixelPas encore d'évaluation

- Comparative Study Summary 07 2004 enDocument32 pagesComparative Study Summary 07 2004 enthmaraishriPas encore d'évaluation

- UCS-79 - ASME VIII Div 1 (Fiber Elongation)Document2 pagesUCS-79 - ASME VIII Div 1 (Fiber Elongation)Asep Darojat0% (1)

- Lesson 19 - API-510 - New2Document56 pagesLesson 19 - API-510 - New2Fahim MarwatPas encore d'évaluation

- Asme PWHT PreheatDocument135 pagesAsme PWHT PreheatWaqas WaqasPas encore d'évaluation

- Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3Document7 pagesTable UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3MechanicalPas encore d'évaluation

- IBR DetailsDocument10 pagesIBR Detailsreach_arindomPas encore d'évaluation

- Vessel Nozzle PDFDocument30 pagesVessel Nozzle PDFEugenia LorenzaPas encore d'évaluation

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniPas encore d'évaluation

- A 607 PDFDocument4 pagesA 607 PDFGustavo Suarez100% (1)

- Wps Gt-9b-Cvn90 Rev 1Document6 pagesWps Gt-9b-Cvn90 Rev 1HAKANPas encore d'évaluation

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniPas encore d'évaluation

- ABS RulesDocument7 pagesABS RulessmithworkPas encore d'évaluation

- Asme CCase 1996-2Document2 pagesAsme CCase 1996-2ADAMJSRAOPas encore d'évaluation

- Astm A765Document5 pagesAstm A765Mostafa HalawaPas encore d'évaluation

- Astm A 333Document9 pagesAstm A 333rogersampaiocosta100% (1)

- Code of Structural Transmission Line TowerDocument13 pagesCode of Structural Transmission Line TowerYogeshGuptaPas encore d'évaluation

- A508Document8 pagesA508doshi78Pas encore d'évaluation

- Heat treatment of welded joints - Part 2: Tempering, PWHT application and monitoringDocument3 pagesHeat treatment of welded joints - Part 2: Tempering, PWHT application and monitoringJlkKumarPas encore d'évaluation

- Asme Viii D Table 2aDocument16 pagesAsme Viii D Table 2aJohakim974100% (1)

- 1876 3Document4 pages1876 3hogoyoPas encore d'évaluation

- Modern Armour Configurations Against 14.5 MM AP LASS 1999Document31 pagesModern Armour Configurations Against 14.5 MM AP LASS 1999spartha_bePas encore d'évaluation

- Sa 193Document18 pagesSa 193Haridev MoorthyPas encore d'évaluation

- ASME VIII Lethal Service Requirements GuideDocument3 pagesASME VIII Lethal Service Requirements GuideNasir Khan Jadoon0% (1)

- ASME Sec VIII - AwarenessDocument33 pagesASME Sec VIII - AwarenessNirmal100% (4)

- U.S. Army Explosives and Demolitions HandbookD'EverandU.S. Army Explosives and Demolitions HandbookPas encore d'évaluation

- Counter Sniper Manual - The Official US Army ManualD'EverandCounter Sniper Manual - The Official US Army ManualPas encore d'évaluation

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985D'EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Pas encore d'évaluation

- SSB Northern RailwayDocument3 pagesSSB Northern Railwaytarlok chandPas encore d'évaluation

- Make & Take: Rockler SeriesDocument3 pagesMake & Take: Rockler SeriescajemarPas encore d'évaluation

- Synthesis Gas 2019 Part 1 - 2 PDFDocument71 pagesSynthesis Gas 2019 Part 1 - 2 PDFcap n3moPas encore d'évaluation

- Stuktur SVM Tek Kimpalan 2017Document1 pageStuktur SVM Tek Kimpalan 2017Cikgu Azry Azeem PetronessaPas encore d'évaluation

- Cement: M. E. (Construction Engineering & Management) Year - I (Semester - Ii)Document27 pagesCement: M. E. (Construction Engineering & Management) Year - I (Semester - Ii)Tarun PatelPas encore d'évaluation

- Hempadur Primer 1530yDocument4 pagesHempadur Primer 1530yRodrigo CondorettyPas encore d'évaluation

- Defects in Brick Masonry - Causes & RemediesDocument2 pagesDefects in Brick Masonry - Causes & Remediessuryakantame100% (1)

- Vertical Roller Mill IntroductionDocument2 pagesVertical Roller Mill Introductionemad sabriPas encore d'évaluation

- Aniti Vibration ProductsDocument2 pagesAniti Vibration ProductsAbbas Al MisbahPas encore d'évaluation

- POSHS Metal Industries PVT - LTDDocument12 pagesPOSHS Metal Industries PVT - LTDSafety DeptPas encore d'évaluation

- Manpower List Can LineDocument12 pagesManpower List Can LineSafety OfficerPas encore d'évaluation

- List of TESDA Acc Assessment Centers PDFDocument119 pagesList of TESDA Acc Assessment Centers PDFSollee Montaño FerrerPas encore d'évaluation

- Astm A351-A351mDocument5 pagesAstm A351-A351mLuRobert100% (3)

- Metal Extrusion and Drawing Processes GuideDocument35 pagesMetal Extrusion and Drawing Processes GuideGRAHAM KUNDAI DENGEZAPas encore d'évaluation

- AWS D1.1 - Type of Qualification Tests Required - Welder and Welding Operator Performance Qualification - Welding and InspectionDocument1 pageAWS D1.1 - Type of Qualification Tests Required - Welder and Welding Operator Performance Qualification - Welding and Inspectionjyzjz6sr65Pas encore d'évaluation

- AbrasivesDocument3 pagesAbrasivesSaranya PandiarajPas encore d'évaluation

- WhizCut 2022Document88 pagesWhizCut 2022Mann Sales & MarketingPas encore d'évaluation

- Application Instructions for HEMPADUR MASTIC 45880/45881Document6 pagesApplication Instructions for HEMPADUR MASTIC 45880/45881Mohamed NouzerPas encore d'évaluation

- Tage Frid Teaches Woodworking PDFDocument232 pagesTage Frid Teaches Woodworking PDFjhfm_xxi88% (8)

- M50-NF High Speed Steel Metaux-SolutionsDocument2 pagesM50-NF High Speed Steel Metaux-SolutionsLaurent MorgePas encore d'évaluation

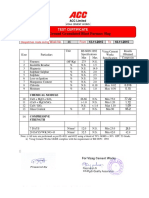

- Ground Granulated Blast Furnace Slag: Test CertificateDocument2 pagesGround Granulated Blast Furnace Slag: Test CertificatenoumanPas encore d'évaluation

- Carboflam eDocument8 pagesCarboflam eVan SotPas encore d'évaluation

- TDS Nitoproof Damp Protect India2Document2 pagesTDS Nitoproof Damp Protect India2hitesh315Pas encore d'évaluation

- Elements of Gating SystemDocument21 pagesElements of Gating SystemsudhirPas encore d'évaluation

- Nes D2242Document6 pagesNes D2242prasannaPas encore d'évaluation

- Carpentry Workshop ManualDocument73 pagesCarpentry Workshop ManualRaj NaikPas encore d'évaluation

- Mig Welding JSADocument2 pagesMig Welding JSANoval Febri100% (1)

- Ball Check Valves FlangedDocument1 pageBall Check Valves FlangedeliiiiiiPas encore d'évaluation

- Gating System in CastingDocument28 pagesGating System in CastingPrashantParashar100% (1)

- Materials, Processes and DefectsDocument28 pagesMaterials, Processes and DefectsmangsureshPas encore d'évaluation