Académique Documents

Professionnel Documents

Culture Documents

PCM70140 Primer Epoxi PPG

Transféré par

MisaelTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PCM70140 Primer Epoxi PPG

Transféré par

MisaelDroits d'auteur :

Formats disponibles

ENVIROCRON® XZR Powder Coat

PCM70140

PRODUCT DATA

HIGHLIGHTS

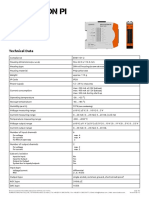

TECHNICAL PROPERTIES

PPG’s Enviracryl® and

Envirocron® powder coatings are

aesthetically pleasing, produce a Property Test Method Value

durable uniform finish and can be

custom formulated with finishes Color __________ Zinc Primer Gray

from high gloss to low gloss, and Gloss ASTM D-523 55 - 70 @ 60°

in a variety of textures.

Adhesion ASTM D-3359 100% (5B Pass)

PPG’s “World Class” Epoxy

Powder Coatings provide a Hardness ASTM D-3363 H - 2H Pencil (Eagle)

combination of good physical and Impact Resistance ASTM D-2794 80 In.-lbs. Direct

chemical resistance properties. 80 In.-lbs. Reverse

This extensive line of Epoxy Conical Mandrel ASTM D-522 1/8" Mandrel

Powders is antiseptically - No Cracking

manufactured to meet the Salt Spray ASTM B-117 4000 Hrs. Pass

increasing requirement demands

<1/8'' Scribe Creep

of the automotive and industrial

- No Blisters

markets. These sophisticated

Epoxies are the solution to your Humidity ASTM D-1735 1000 Hrs. Pass

smoothness, low-bake, durability <1/16'' Scribe Creep

and physical property - No Blisters

requirements. An unsurpassed

application development program Film Properties were determined using 2.0 - 3.0 mils powder film over iron

enables consistently friendly use phosphated, chrome rinse pretreated, 22 gauge, unpolished cold rolled steel test

on a variety of substrates. panels. Impact resistance was determined at 2.0 mils.

PRODUCT FEATURES

This product contains heavy APPLICATION DATA

metals. Please refer to the MSDS

for handling. Application Type: Electrostatic Spray

Excellent corrosion resistance Recommended Bake: 20 Minutes at 325 °F Metal Temperature

Good chemical resistance

See Cure Curve PCM-014

VOCs are essentially zero

VOC: Essentially Zero

Specific Gravity: 3.59 ± .05

Theoretical Coverage: 54 Sq. Ft. per pound at 1.0 mil

Shelf Life from Date of 80 °F Maximum - 12 Months

Manufacture:

PPG recommends that all material be used in FIFO order (first in - first out).

Materials that exceed the recommended shelf life should be tested prior to use.

PPG Industries, Inc. * Statements and methods described herein are based upon the best information and practices known to PPG Industries, Inc. (“PPG”). Any statements or methods

19699 Progress Drive mentioned herein are general suggestions only and are not to be construed as representations or warranties as to safety, performance, or results. Since the suitability

and performance of the product is highly dependent on the product user’s processes, operations, and numerous other user-determined conditions, the user is solely

Strongsville, OH 44149 responsible for, and assumes all responsibility, risk and liability arising from, the determination of whether the product is suitable for the user’s purposes, including

800-450-2652 without limitation substrate, application process, pasteurization and/or processing, and end use. No testing, suggestions or data offered by PPG to the user shall

www.industrial-coatings.com relieve the user of this responsibility. PPG does not warrant freedom from patent infringement in the use of any formula or process set forth herein. Continuous

improvements in coatings technology may cause future technical data to vary from what is in this bulletin. Contact your PPG representative for the most up to date

powder@ppg.com information.

ENVIROCRON and the PPG logo are registered trademarks of PPG Industries, Inc. 12/23/2009

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Valvulas Sherwood PDFDocument8 pagesValvulas Sherwood PDFMisaelPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- CuZn40 01 2019 PDFDocument7 pagesCuZn40 01 2019 PDFMisaelPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Copper Alloy C37700 PDFDocument10 pagesCopper Alloy C37700 PDFMisaelPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Copper Alloy C37700 PDFDocument10 pagesCopper Alloy C37700 PDFMisaelPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 09 - 06 - 2020 Listado para La Toma de Longitudes 35075Document3 pages09 - 06 - 2020 Listado para La Toma de Longitudes 35075MisaelPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Dark Waters: Advance ScreeningsDocument1 pageDark Waters: Advance ScreeningsMisaelPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- I.003 8 BlastingDocument1 pageI.003 8 BlastingMisaelPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Mill Test Certificate: Yong Metal Co.,LimitedDocument2 pagesMill Test Certificate: Yong Metal Co.,LimitedMisael100% (1)

- Emer Solenoid Cylinder Valves Solenoid Cylinder ValveDocument3 pagesEmer Solenoid Cylinder Valves Solenoid Cylinder ValveMisaelPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Valve MoonDocument1 pageValve MoonMisaelPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Radio Frequency Identification TechnologDocument10 pagesRadio Frequency Identification TechnologMisaelPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Handbook H-28 1957 Part-IIDocument126 pagesHandbook H-28 1957 Part-IIMisaelPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- PCM70140 Primer Epoxi PPGDocument1 pagePCM70140 Primer Epoxi PPGMisaelPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Lalmonirhat Social Services Office - 26 - 09 - 19 - LegendDocument1 pageLalmonirhat Social Services Office - 26 - 09 - 19 - LegendTauhid RahmanPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- HBN PVC Free Alternatives ChartDocument24 pagesHBN PVC Free Alternatives ChartaggibudimanPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- EEP - 8 Steps To Begin Circuit DesignDocument3 pagesEEP - 8 Steps To Begin Circuit DesignSugeng SumarnoPas encore d'évaluation

- A Comparison of BS en 287 Part 1 and ISO 9606Document3 pagesA Comparison of BS en 287 Part 1 and ISO 9606Joe ClarkePas encore d'évaluation

- Valve Catalogue General Imsubs Pvt. Ltd.Document20 pagesValve Catalogue General Imsubs Pvt. Ltd.Spark MeditechPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Datasheet RevPi AIODocument2 pagesDatasheet RevPi AIOsebadansPas encore d'évaluation

- BibliographyDocument5 pagesBibliographyMonal ParekhPas encore d'évaluation

- Fxe-400s Control PC: ApparatusDocument2 pagesFxe-400s Control PC: ApparatusCristian Gabriel CordaryPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Two Hand Relays: SpecificationsDocument2 pagesTwo Hand Relays: SpecificationsticojfsPas encore d'évaluation

- Experiment # 3 Conservation of EnergyDocument5 pagesExperiment # 3 Conservation of EnergyellatsPas encore d'évaluation

- Inventory Database - All Parts Inc (8/20/20)Document2 835 pagesInventory Database - All Parts Inc (8/20/20)All Parts Inc.Pas encore d'évaluation

- MEISER Grating PDFDocument136 pagesMEISER Grating PDFEngr Qaisar NazeerPas encore d'évaluation

- Sue's Rendezvous Illegal Certificate of OccupancyDocument3 pagesSue's Rendezvous Illegal Certificate of OccupancySamuel L. RiversPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- 1465914490CL June 2016 PDFDocument48 pages1465914490CL June 2016 PDFCoolerAdsPas encore d'évaluation

- Display Nec NL6448BC33 74 PreDocument30 pagesDisplay Nec NL6448BC33 74 PrehenryvyperPas encore d'évaluation

- GA-I (H) D 1000 Series ROBOTDocument1 pageGA-I (H) D 1000 Series ROBOTmfarrukhkPas encore d'évaluation

- AENG 24a - Environmental Engineering EEDocument6 pagesAENG 24a - Environmental Engineering EEMichael Pantonilla100% (1)

- BMS-HSS-F-113 - Lift Plan Rev 03Document11 pagesBMS-HSS-F-113 - Lift Plan Rev 03Fariz SafarullaPas encore d'évaluation

- Signaling in RE AreaDocument30 pagesSignaling in RE AreaVikas Srivastav93% (15)

- Using Oracle Database Vault With Oracle Database 12c - D86597GC10 - 1080544 - USDocument3 pagesUsing Oracle Database Vault With Oracle Database 12c - D86597GC10 - 1080544 - USJinendraabhi0% (1)

- 2 - WCDMA Power ControlDocument50 pages2 - WCDMA Power ControlSabrine Chahbi100% (1)

- Intake Manifold Air Temperature Is High: TroubleshootingDocument3 pagesIntake Manifold Air Temperature Is High: TroubleshootingPutra JawaPas encore d'évaluation

- Getting Started With Openfoam: Eric PatersonDocument41 pagesGetting Started With Openfoam: Eric PatersonReza Nazari0% (1)

- Dimethylamine PDFDocument2 pagesDimethylamine PDFangelofgloryPas encore d'évaluation

- Mhi (Humicool Industrial) : Industrial Evaporative Cooler / HumidifierDocument2 pagesMhi (Humicool Industrial) : Industrial Evaporative Cooler / HumidifierGraham GunnerPas encore d'évaluation

- Utmost TFT Training Part1Document96 pagesUtmost TFT Training Part1gideontargrave7Pas encore d'évaluation

- Harman-Kardon Hk-3490 SM 1Document70 pagesHarman-Kardon Hk-3490 SM 1ymitevPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Rigging Guide 2008Document222 pagesRigging Guide 2008Alex1Pas encore d'évaluation

- Unix Important QuestionsDocument3 pagesUnix Important QuestionsNeo DragonPas encore d'évaluation

- CONTENTSDocument9 pagesCONTENTSESRAPas encore d'évaluation

- The Fabric of Civilization: How Textiles Made the WorldD'EverandThe Fabric of Civilization: How Textiles Made the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (58)