Académique Documents

Professionnel Documents

Culture Documents

Welder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)

Transféré par

mahendraDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Welder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)

Transféré par

mahendraDroits d'auteur :

Formats disponibles

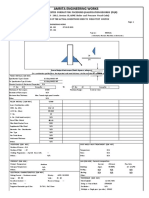

SEW INFRASTRUCTURES LIMITED

WELDER PERFORMANCE QUALIFICATIONS (WPQ)

(See QW-301, Section IX,

ASME Boiler and Pressure Vessel Code)

Welder's Name: P. THIRUPATHI NAIDU Identification No: W-009

Identification of WPS followed: SEW/NMDC/WPS-001 Test Coupon Production weld

Specification of base metal(s): IS 2062 BR Thickness: 16 MM

Testing Conditions and Qualification Limits

Welding Variables(QW-350) Actual Values Range Qualified

Welding Process(es) SMAW SMAW

Type (i.e., manual, semi automatic) used MANUAL MANUAL

Backing metal, weld metal, doube welded etc.,) WITHOUT WITHOUT

Plate Pipe PLATE PLATE

Base metal P- or S- Number P 1 P 1

Base metal of electrode specification(s) (SFA) AWS SFA 5.1 AWS SFA 5.1

Filler metal of electrode classification(s) E 7018 E 7018

Filler metal F- Number(s) F4 F4

Consumable insert(GTAW or PAW) NA NA

Filler type (solid/metal or flux cored/powder) (GTAW or PAW) SOLID SOLID

Deposit thickness for each process

Process 1____________ 3 layers minimum Yes No YES(16 mm) MAX .TO BE WELDED

Process 2____________ 3 layers minimum Yes No

Position Qualified 3G F,V

Vertical Progression (uphill or downhill) UP HILL UP HILL

Type of fuel gas(OFW) NA NA

Insert gas backing(GTAW, PAW,GMAW) NA NA

Transfer mode(spray/globular or pulse to short circuit-GMAW) SPRAY SPRAY

GTAW current type/polarity(AC,DCEP,DCEN) DCEP DCEP

RESULTS:

Visual examination of completed weld(QW-302.4)__________________

Bend Test Transverse root and face

Side Longutudinal root and face

Plate bend specimen, corrosion-resistant overlay Macro test for fusion

Type Result Type Result Result

Alternative radiographic examination results Report No:__7781_______________

Fillet weld fracture test___________ NA Length and percent of defects____________________

Macro examination_____ NA Fillet size________X___________

Other tests_____________________ NA

Film or specimens evaluated by____ PRABHAKAR Company___ISO TECH SERVICES

Mechanical tests conducted by_____________________________________ Lab test no________________________

Welding supervised by______________________________________________

We certify that the statements in this record are correct and the test coupons were prepared by, welded and tested in

accordance with the requirements of section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Organization_M/S. RALCO STEELS PVT LTD.______________

Date___20/04/2013_________ By__________________________

RALCO STEELS PVT LTD (QA/QC) SEW LTD MECON

Signature

Name

Date

Format No: NMDC/SEW/RSPL/STRL/003

._________________

SEW INFRASTRUCTURES LIMITED

WELDER PERFORMANCE QUALIFICATIONS (WPQ)

(See QW-301,

Section IX, ASME Boiler and Pressure Vessel Code)

Welder's Name: B.SHANKAR RAO Identification No: W-001

Test Description

Identification of WPS followed: NMDC/SEW/WPS-001 Test Coupon Production weld

Specification of base metal(s): IS 2062 BR Thickness: 16 MM

Testing Conditions and Qualification Limits

Welding Variables(QW-350) Actual Values Range Qualified

Welding Process(es) SMAW SMAW

Type (i.e., manual, semi automatic) used MANUAL MANUAL

Backing metal, weld metal, doube welded etc.,) WITHOUT WITHOUT

Plate Pipe PLATE PLATE

Base metal P- or S- Number P 1 P 1

Base metal of electrode specification(s) (SFA) AWS SFA 5.1 AWS SFA 5.1

Filler metal of electrode classification(s) E 7018 E 7018

Filler metal F- Number(s) F4 F4

Consumable insert(GTAW or PAW) NA NA

Filler type (solid/metal or flux cored/powder) (GTAW or PAW) SOLID SOLID

Deposit thickness for each process

Process 1____________ 3 layers minimum Yes No YES(16mm) MAX .TO BE WELDED

Process 2____________ 3 layers minimum Yes No

Position Qualified 3G F,V

Vertical Progression (uphill or downhill) UP HILL UP HILL

Type of fuel gas(OFW) NA NA

Insert gas backing(GTAW, PAW,GMAW) NA NA

Transfer mode(spray/globular or pulse to short circuit-GMAW) SPRAY SPRAY

GTAW current type/polarity(AC,DCEP,DCEN) DCEP DCEP

RESULTS:

Visual examination of completed weld(QW-302.4)__________________

Bend Test Transverse root and face

Side Longutudinal root and face

Plate bend specimen, corrosion-resistant overlay Macro test for fusion

Type Result Type Result Result

Alternative radiographic examination results Report No:__7781_______________

Fillet weld fracture test___________ NA Length and percent of defects____________________

Macro examination_____ NA Fillet size________X___________

Other tests_____________________ NA

Film or specimens evaluated by____ PRABHAKAR Company___ISO TECH SERVICES

Mechanical tests conducted by_____________________________________ Lab test no________________________

Welding supervised by______________________________________________

We certify that the statements in this record are correct and the test coupons were prepared by, welded and tested in

accordance with the requirements of section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Organization_M/S. RALCO STEELS PVT LTD._______________

Date___20/04/2013_________ By__________________________

RALCO STEELS PVT LTD (QA/QC) SEW LTD MECON

Signature

Name

Date

Format No: NMDC/SEW/RSPL/STRL/003

._________________

SEW INFRASTRUCTURES LIMITED

WELDER PERFORMANCE QUALIFICATIONS (WPQ)

(See QW-301,

Section IX, ASME Boiler and Pressure Vessel Code)

Welder's Name: K. RAJESH Identification No: W-010

Test Description

Identification of WPS followed: SEW/NMDC/WPS-001 Test Coupon Production weld

Specification of base metal(s): IS 2062 BR Thickness: 16 MM

Testing Conditions and Qualification Limits

Welding Variables(QW-350) Actual Values Range Qualified

Welding Process(es) SMAW SMAW

Type (i.e., manual, semi automatic) used MANUAL MANUAL

Backing metal, weld metal, doube welded etc.,) WITHOUT WITHOUT

Plate Pipe PLATE PLATE

Base metal P- or S- Number P 1 P 1

Base metal of electrode specification(s) (SFA) AWS SFA 5.1 AWS SFA 5.1

Filler metal of electrode classification(s) E 7018 E 7018

Filler metal F- Number(s) F4 F4

Consumable insert(GTAW or PAW) NA NA

Filler type (solid/metal or flux cored/powder) (GTAW or PAW) SOLID SOLID

Deposit thickness for each process

Process 1____________ 3 layers minimum Yes No YES(16mm) MAX .TO BE WELDED

Process 2____________ 3 layers minimum Yes No

Position Qualified 3G F,V

Vertical Progression (uphill or downhill) UP HILL UP HILL

Type of fuel gas(OFW) NA NA

Insert gas backing(GTAW, PAW,GMAW) NA NA

Transfer mode(spray/globular or pulse to short circuit-GMAW) SPRAY SPRAY

GTAW current type/polarity(AC,DCEP,DCEN) DCEP DCEP

RESULTS:

Visual examination of completed weld(QW-302.4)__________________

Bend Test Transverse root and face

Side Longutudinal root and face

Plate bend specimen, corrosion-resistant overlay Macro test for fusion

Type Result Type Result Result

Alternative radiographic examination results Report No:__7781_______________

Fillet weld fracture test___________ NA Length and percent of defects____________________

Macro examination_____ NA Fillet size________X___________

Other tests_____________________ NA

Film or specimens evaluated by____ PRABHAKAR Company___ISO TECH SERVICES

Mechanical tests conducted by_____________________________________ Lab test no________________________

Welding supervised by______________________________________________

We certify that the statements in this record are correct and the test coupons were prepared by, welded and tested in

accordance with the requirements of section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Organization_M/S. RALCO STEELS PVT LTD._______________

Date___20/04/2013_________ By__________________________

RALCO STEELS PVT LTD (QA/QC) SEW LTD MECON

Signature

Name

Date

Format No: NMDC/SEW/RSPL/STRL/003

._________________

SEW INFRASTRUCTURES LIMITED

WELDER PERFORMANCE QUALIFICATIONS (WPQ)

(See QW-301,

Section IX, ASME Boiler and Pressure Vessel Code)

Welder's Name: K. SURESH KUMAR Identification No: W-011

Test Description

Identification of WPS followed: SEW/NMDC/WPS-001 Test Coupon Production weld

Specification of base metal(s): IS 2062 BR Thickness: 16 MM

Testing Conditions and Qualification Limits

Welding Variables(QW-350) Actual Values Range Qualified

Welding Process(es) SMAW SMAW

Type (i.e., manual, semi automatic) used MANUAL MANUAL

Backing metal, weld metal, doube welded etc.,) WITHOUT WITHOUT

Plate Pipe PLATE PLATE

Base metal P- or S- Number P 1 P 1

Base metal of electrode specification(s) (SFA) AWS SFA 5.1 AWS SFA 5.1

Filler metal of electrode classification(s) E 7018 E 7018

Filler metal F- Number(s) F4 F4

Consumable insert(GTAW or PAW) NA NA

Filler type (solid/metal or flux cored/powder) (GTAW or PAW) SOLID SOLID

Deposit thickness for each process

Process 1____________ 3 layers minimum Yes No YES(16mm) MAX .TO BE WELDED

Process 2____________ 3 layers minimum Yes No

Position Qualified 3G F,V

Vertical Progression (uphill or downhill) UP HILL UP HILL

Type of fuel gas(OFW) NA NA

Insert gas backing(GTAW, PAW,GMAW) NA NA

Transfer mode(spray/globular or pulse to short circuit-GMAW) SPRAY SPRAY

GTAW current type/polarity(AC,DCEP,DCEN) DCEP DCEP

RESULTS:

Visual examination of completed weld(QW-302.4)__________________

Bend Test Transverse root and face

Side Longutudinal root and face

Plate bend specimen, corrosion-resistant overlay Macro test for fusion

Type Result Type Result Result

Alternative radiographic examination results Report No:__7781_______________

Fillet weld fracture test___________ NA Length and percent of defects____________________

Macro examination_____ NA Fillet size________X___________

Other tests_____________________ NA

Film or specimens evaluated by____ PRABHAKAR Company___ISO TECH SERVICES

Mechanical tests conducted by_____________________________________ Lab test no________________________

Welding supervised by______________________________________________

We certify that the statements in this record are correct and the test coupons were prepared by, welded and tested in

accordance with the requirements of section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Organization_M/S. RALCO STEELS PVT LTD._______________

Date___20/04/2013_________ By__________________________

RALCO STEELS PVT LTD (QA/QC) SEW LTD MECON

Signature

Name

Date

Format No: NMDC/SEW/RSPL/STRL/003

._________________

SEW INFRASTRUCTURES LIMITED

WELDER PERFORMANCE QUALIFICATIONS (WPQ)

(See QW-301,

Section IX, ASME Boiler and Pressure Vessel Code)

Welder's Name: V. KANNAMA NAIDU Identification No: W-012

Test Description

Identification of WPS followed: SEW/NMDC/WPS-001 Test Coupon Production weld

Specification of base metal(s): IS 2062 BR Thickness: 16 MM

Testing Conditions and Qualification Limits

Welding Variables(QW-350) Actual Values Range Qualified

Welding Process(es) SMAW SMAW

Type (i.e., manual, semi automatic) used MANUAL MANUAL

Backing metal, weld metal, doube welded etc.,) WITHOUT WITHOUT

Plate Pipe PLATE PLATE

Base metal P- or S- Number P 1 P 1

Base metal of electrode specification(s) (SFA) AWS SFA 5.1 AWS SFA 5.1

Filler metal of electrode classification(s) E 7018 E 7018

Filler metal F- Number(s) F4 F4

Consumable insert(GTAW or PAW) NA NA

Filler type (solid/metal or flux cored/powder) (GTAW or PAW) SOLID SOLID

Deposit thickness for each process

Process 1____________ 3 layers minimum Yes No YES(16mm) MAX .TO BE WELDED

Process 2____________ 3 layers minimum Yes No

Position Qualified 3G F,V

Vertical Progression (uphill or downhill) UP HILL UP HILL

Type of fuel gas(OFW) NA NA

Insert gas backing(GTAW, PAW,GMAW) NA NA

Transfer mode(spray/globular or pulse to short circuit-GMAW) SPRAY SPRAY

GTAW current type/polarity(AC,DCEP,DCEN) DCEP DCEP

RESULTS:

Visual examination of completed weld(QW-302.4)__________________

Bend Test Transverse root and face

Side Longutudinal root and face

Plate bend specimen, corrosion-resistant overlay Macro test for fusion

Type Result Type Result Result

Alternative radiographic examination results Report No:__7781_______________

Fillet weld fracture test___________ NA Length and percent of defects____________________

Macro examination_____ NA Fillet size________X___________

Other tests_____________________ NA

Film or specimens evaluated by____ PRABHAKAR Company___ISO TECH SERVICES

Mechanical tests conducted by_____________________________________ Lab test no________________________

Welding supervised by______________________________________________

We certify that the statements in this record are correct and the test coupons were prepared by, welded and tested in

accordance with the requirements of section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Organization_M/S. RALCO STEELS PVT LTD._______________

Date___20/04/2013_________ By__________________________

RALCO STEELS PVT LTD (QA/QC) SEW LTD MECON

Signature

Name

Date

Format No: NMDC/SEW/RSPL/STRL/003

._________________

SEW INFRASTRUCTURES LIMITED

WELDER PERFORMANCE QUALIFICATIONS (WPQ)

(See QW-301,

Section IX, ASME Boiler and Pressure Vessel Code)

Welder's Name: G. SIMHA CHALAM Identification No: W-013

Test Description

Identification of WPS followed: SEW/NMDC/WPS-001 Test Coupon Production weld

Specification of base metal(s): IS 2062 BR Thickness: 16 MM

Testing Conditions and Qualification Limits

Welding Variables(QW-350) Actual Values Range Qualified

Welding Process(es) SMAW SMAW

Type (i.e., manual, semi automatic) used MANUAL MANUAL

Backing metal, weld metal, doube welded etc.,) WITHOUT WITHOUT

Plate Pipe PLATE PLATE

Base metal P- or S- Number P 1 P 1

Base metal of electrode specification(s) (SFA) AWS SFA 5.1 AWS SFA 5.1

Filler metal of electrode classification(s) E 7018 E 7018

Filler metal F- Number(s) F4 F4

Consumable insert(GTAW or PAW) NA NA

Filler type (solid/metal or flux cored/powder) (GTAW or PAW) SOLID SOLID

Deposit thickness for each process

Process 1____________ 3 layers minimum Yes No YES(16mm) MAX .TO BE WELDED

Process 2____________ 3 layers minimum Yes No

Position Qualified 3G F,V

Vertical Progression (uphill or downhill) UP HILL UP HILL

Type of fuel gas(OFW) NA NA

Insert gas backing(GTAW, PAW,GMAW) NA NA

Transfer mode(spray/globular or pulse to short circuit-GMAW) SPRAY SPRAY

GTAW current type/polarity(AC,DCEP,DCEN) DCEP DCEP

RESULTS:

Visual examination of completed weld(QW-302.4)__________________

Bend Test Transverse root and face

Side Longutudinal root and face

Plate bend specimen, corrosion-resistant overlay Macro test for fusion

Type Result Type Result Result

Alternative radiographic examination results Report No:__7781_______________

Fillet weld fracture test___________ NA Length and percent of defects____________________

Macro examination_____ NA Fillet size________X___________

Other tests_____________________ NA

Film or specimens evaluated by____ PRABHAKAR Company___ISO TECH SERVICES

Mechanical tests conducted by_____________________________________ Lab test no________________________

Welding supervised by______________________________________________

We certify that the statements in this record are correct and the test coupons were prepared by, welded and tested in

accordance with the requirements of section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Organization_M/S. RALCO STEELS PVT LTD._______________

Date___20/04/2013_________ By__________________________

RALCO STEELS PVT LTD (QA/QC) SEW LTD MECON

Signature

Name

Date

Format No: NMDC/SEW/RSPL/STRL/003

._________________

Vous aimerez peut-être aussi

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocument1 pagePQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraPas encore d'évaluation

- John Lear UFO Coverup RevelationsDocument30 pagesJohn Lear UFO Coverup RevelationscorneliusgummerichPas encore d'évaluation

- Attachment X - Specifications For Prefabrication PipingDocument25 pagesAttachment X - Specifications For Prefabrication PipingmahendraPas encore d'évaluation

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavPas encore d'évaluation

- WPSDocument6 pagesWPSYASH BARDHAN SinghPas encore d'évaluation

- 10 Ideas For ConversationDocument116 pages10 Ideas For ConversationGreenLake36100% (1)

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYPas encore d'évaluation

- Sec A - Group 9 - When A New Manager StumblesDocument13 pagesSec A - Group 9 - When A New Manager StumblesVijay Krishnan100% (3)

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikPas encore d'évaluation

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepPas encore d'évaluation

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanPas encore d'évaluation

- KWU Recruit Select Online DISC Val Guide v3.2 PDFDocument10 pagesKWU Recruit Select Online DISC Val Guide v3.2 PDFAntonio AlbieroPas encore d'évaluation

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaPas encore d'évaluation

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuPas encore d'évaluation

- Steel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditDocument2 pagesSteel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditmahendraPas encore d'évaluation

- WPS SumDocument61 pagesWPS SumA. ΒρατσισταPas encore d'évaluation

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyPas encore d'évaluation

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191Pas encore d'évaluation

- Evidence Case DigestDocument55 pagesEvidence Case DigestMae TrabajoPas encore d'évaluation

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelPas encore d'évaluation

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityPas encore d'évaluation

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasPas encore d'évaluation

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 pagePt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RPas encore d'évaluation

- Untitled PresentationDocument23 pagesUntitled Presentationapi-543394268Pas encore d'évaluation

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- QC - 08 PTCDocument5 pagesQC - 08 PTCmahendraPas encore d'évaluation

- PWPS Fillet WeldDocument2 pagesPWPS Fillet WeldUgonnaPas encore d'évaluation

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviPas encore d'évaluation

- Aws 001Document1 pageAws 001akshay sarfarePas encore d'évaluation

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- Work Instruction For Macro ExaminationDocument4 pagesWork Instruction For Macro Examinationmahendra50% (2)

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyPas encore d'évaluation

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajPas encore d'évaluation

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranPas encore d'évaluation

- WPS - 023Document10 pagesWPS - 023MAT-LION0% (1)

- Work Instruction FOR: Charpy Impact TestDocument4 pagesWork Instruction FOR: Charpy Impact TestmahendraPas encore d'évaluation

- Work Instruction FOR: Tensile TestDocument4 pagesWork Instruction FOR: Tensile TestmahendraPas encore d'évaluation

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriPas encore d'évaluation

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Grid / Hippodamian Model: Hippodamus of MiletusDocument34 pagesGrid / Hippodamian Model: Hippodamus of MiletusVriti SachdevaPas encore d'évaluation

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaPas encore d'évaluation

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Document21 pagesTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarPas encore d'évaluation

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksPas encore d'évaluation

- QC - 06 Surface Preparation & Painting 2Document6 pagesQC - 06 Surface Preparation & Painting 2mahendraPas encore d'évaluation

- Steel Konnect (India) Pvt. Ltd. Procedure Manual: Skipl /QC/P - 13: 1 OF 2 Revision: 00 Date: 01.02.2013Document2 pagesSteel Konnect (India) Pvt. Ltd. Procedure Manual: Skipl /QC/P - 13: 1 OF 2 Revision: 00 Date: 01.02.2013mahendraPas encore d'évaluation

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouPas encore d'évaluation

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiPas encore d'évaluation

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipPas encore d'évaluation

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielPas encore d'évaluation

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaPas encore d'évaluation

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocument4 pages170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyPas encore d'évaluation

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniPas encore d'évaluation

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityPas encore d'évaluation

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaPas encore d'évaluation

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityPas encore d'évaluation

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaPas encore d'évaluation

- P. WpsDocument14 pagesP. WpsIsmiArdyPas encore d'évaluation

- Welding Procedure Specification According To EN ISO 15609, 2004Document2 pagesWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouPas encore d'évaluation

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023Pas encore d'évaluation

- PDF Created With Pdffactory Trial VersionDocument8 pagesPDF Created With Pdffactory Trial VersionmahendraPas encore d'évaluation

- Arc Welding PPT FinishDocument50 pagesArc Welding PPT FinishmahendraPas encore d'évaluation

- 3.0 Mtpa NMDC Integrated Steel Plant (Nisp), Nagarnar, Chattisgarh Steel Melting Shop - Pkg-06Document1 page3.0 Mtpa NMDC Integrated Steel Plant (Nisp), Nagarnar, Chattisgarh Steel Melting Shop - Pkg-06mahendraPas encore d'évaluation

- 3.0 Mtpa NMDC Integrated Steel Plant (Nisp), Nagarnar, Chattisgarh Steel Melting Shop - Pkg-06Document1 page3.0 Mtpa NMDC Integrated Steel Plant (Nisp), Nagarnar, Chattisgarh Steel Melting Shop - Pkg-06mahendraPas encore d'évaluation

- Work Instruction FOR: Calibration of Pressure Gauge by Dead Weight TesterDocument3 pagesWork Instruction FOR: Calibration of Pressure Gauge by Dead Weight TestermahendraPas encore d'évaluation

- Wps Requirement As Per Aws d1.1-1Document2 pagesWps Requirement As Per Aws d1.1-1mahendraPas encore d'évaluation

- Mild Steel Electrodes: Brand Aws A/Sfa 5.1 IS 814 DIN 1913 BS 639 EN 499Document5 pagesMild Steel Electrodes: Brand Aws A/Sfa 5.1 IS 814 DIN 1913 BS 639 EN 499mahendraPas encore d'évaluation

- Work Instruction FOR: Spectro AnalysisDocument3 pagesWork Instruction FOR: Spectro AnalysismahendraPas encore d'évaluation

- Steel Konnect India PVT Ltd. Procedure Manual: Procedure For Production PlanningDocument1 pageSteel Konnect India PVT Ltd. Procedure Manual: Procedure For Production PlanningmahendraPas encore d'évaluation

- QC - 16 Guided Bend Test.Document3 pagesQC - 16 Guided Bend Test.mahendra100% (1)

- Purpose: Steel Konnect (India) Pvt. Ltd. Procedure ManualDocument3 pagesPurpose: Steel Konnect (India) Pvt. Ltd. Procedure ManualmahendraPas encore d'évaluation

- Steel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Final Inspection of PipesDocument7 pagesSteel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Final Inspection of PipesmahendraPas encore d'évaluation

- Steel Konnect (India) PVT LTD: Raw Material Inspection / Identification ReportDocument2 pagesSteel Konnect (India) PVT LTD: Raw Material Inspection / Identification ReportmahendraPas encore d'évaluation

- Preheating N BackWear FacingDocument2 pagesPreheating N BackWear FacingmahendraPas encore d'évaluation

- DistortionDocument2 pagesDistortionmahendraPas encore d'évaluation

- SAmple Format (Police Report)Document3 pagesSAmple Format (Police Report)Johnpatrick DejesusPas encore d'évaluation

- Closing Ceremony PresentationDocument79 pagesClosing Ceremony Presentationapi-335718710Pas encore d'évaluation

- Effect of Intrinsic and Extrinsic Motivation On Academic PerformanceDocument11 pagesEffect of Intrinsic and Extrinsic Motivation On Academic Performancefarah ablayPas encore d'évaluation

- Fashion Designer Research Paper ThesisDocument4 pagesFashion Designer Research Paper Thesisafbteyrma100% (2)

- PWC Taxavvy 18 2020 Mco PDFDocument12 pagesPWC Taxavvy 18 2020 Mco PDFMichael YapPas encore d'évaluation

- Whether To Use Their GPS To Find Their Way To The New Cool Teen HangoutDocument3 pagesWhether To Use Their GPS To Find Their Way To The New Cool Teen HangoutCarpovici Victor100% (1)

- Agricultural LocationDocument26 pagesAgricultural LocationPrince MpofuPas encore d'évaluation

- Mindfulness of Breathing and The Four Elements MeditationDocument98 pagesMindfulness of Breathing and The Four Elements Meditationulrich_ehrenbergerPas encore d'évaluation

- EDDS StuttgartDocument21 pagesEDDS Stuttgartdaniel.namendorfPas encore d'évaluation

- 7999 Cswdo Day CareDocument3 pages7999 Cswdo Day CareCharles D. FloresPas encore d'évaluation

- Kenya's Top 10 Tourist SpotsDocument23 pagesKenya's Top 10 Tourist SpotsAaron LopezPas encore d'évaluation

- Adverbial Phrases 3Document21 pagesAdverbial Phrases 3Jobelle VergaraPas encore d'évaluation

- Natural Wonders of The World: I:GrammarDocument8 pagesNatural Wonders of The World: I:GrammarNhị NguyễnPas encore d'évaluation

- Grade 5 DLL ENGLISH 5 Q3 Week 2Document7 pagesGrade 5 DLL ENGLISH 5 Q3 Week 2Armie Joimie ValdezPas encore d'évaluation

- JBL Tune 115TWS HeadphoneDocument2 pagesJBL Tune 115TWS HeadphoneTimiPas encore d'évaluation

- Righeimer ComplaintDocument45 pagesRigheimer ComplaintSarah BatchaPas encore d'évaluation

- Igice Cya Kabiri: 2.0. Intambwe Zitandukanye Z'Imikorere Ya Mariyamu KinyamaruraDocument7 pagesIgice Cya Kabiri: 2.0. Intambwe Zitandukanye Z'Imikorere Ya Mariyamu KinyamaruraJacques Abimanikunda BarahirwaPas encore d'évaluation

- Flex Li3 21 VAADocument1 pageFlex Li3 21 VAAAyman Al-YafeaiPas encore d'évaluation

- CHC40221 Workplace LogbookDocument14 pagesCHC40221 Workplace LogbookKarla GiaPas encore d'évaluation

- COT Cott Aug 2017Document30 pagesCOT Cott Aug 2017Ala BasterPas encore d'évaluation

- Dolomite in Manila Bay A Big HitDocument3 pagesDolomite in Manila Bay A Big HitJoanaPauline FloresPas encore d'évaluation

- Material Safety Data Sheet Visco WelDocument4 pagesMaterial Safety Data Sheet Visco Welfs1640Pas encore d'évaluation

- PGY2 SummaryDocument3 pagesPGY2 SummarySean GreenPas encore d'évaluation