Académique Documents

Professionnel Documents

Culture Documents

Customer Training Schedule: Quality at Its Best

Transféré par

Max Durán ParraguezTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Customer Training Schedule: Quality at Its Best

Transféré par

Max Durán ParraguezDroits d'auteur :

Formats disponibles

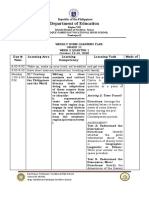

Customer Training

Schedule

Quality at its best

Effective:

Jun - Dec 2004

1-800-47-ROBOT

www.fanucrobotics.com

FANUC ROBOTICS PROVIDES THE TRAINING YOU NEED, WHEN YOU NEED IT!

FANUC Robotics American, Inc

3900 West Hamlin Road

Rochester Hills, MI 48309-3253

1-800-47-ROBOT

Dear Colleague:

Automation today is shifting towards utilizing PC’s to program

robots. With the release of our PalletPRO offline programming

package, we are prepared to help you gain practical skills to

successfully utilize this software. Be sure to see the course

description for PalletTool Features & Options on page 11.

Our instructors are utilizing the ROBOGUIDE family of offline

robot simulation software to enhance the learning experience of

our students during classroom instruction. This method has

proven to be an effective tool when delivering complex material.

In response to customers’ requests, we are now offering a

variety of new courses, including ServoGun Operations &

Programming and advanced courses in PalletTool (pg. 11) and

Teach Pendant Programming (4th quarter, pg 10).

In addition to training at FRA Home Office, we also provide

dedicated training at the customer’s site and at our regional

facilities:

FANUC Central - Mason, Ohio

FANUC Midwest - Chicago, Illinois

FANUC West - Lake Forest, California

FANUC Canada - Mississauga, Ontario

Once you have found the courses you need, call 1-800-47-

ROBOT or visit www.fanucrobotics.com today to enroll.

Regards

Michael C. Basso

Training Manager

2 automation • innovation • dedication

General Information and Guidelines for

Training, Scheduling and Certifications

Certifications: Method of Delivery for Our

Courses:

All of the courses described in this brochure

consist of lectures, demonstrations and a series

of lab exercises designed to reinforce what the

students have learned, including all required

FANUC Robotics’ certification achievements and recommended safety procedures.

represent major milestones in our journey

In addition to these lab exercises, a pre-test and

towards total quality management and

post-test are used to measure mastery of

meeting our customers’ needs. These ratings

objectives.

indicate that FANUC Robotics has developed

the proper infrastructure for the design, Records and Transcripts:

manufacture and integration of robotics process

solutions at our Rochester Hills, Michigan All records are kept for at least two years.

headquarters. Training records may be obtained by sending a

letter or e-mail to our address, which includes

Authorized IACET Provider: the following information: Student Name,

Address, Company, Course Name and Course

The Training Department is a member and

Dates. A $10 processing fee must accompany

authorized CEU (Certified Continuing Education

the request. Make checks payable to FANUC

Units) provider of the International Association

Robotics America.

for Continuing Education and Training (IACET).

This is one more reason why FANUC Robotics Confidentiality:

training is your best training solution.

Records are kept strictly confidential and will

Continuing Education Units: only be issued to those parties inquiring by the

expressed written request of the student

For CEUs, no partial credit will be issued if a enrolled. No records will be released to a third

student fails to complete the party or to employers unless accompanied by

course, pre-tests, post-tests the expressed written request of the student.

(where applicable), participate

in group exercises (where Critique sheets may be shared with employers

applicable) and complete the and with auditors to ensure course quality and

Post Course Survey. for resolution of any course issues.

Credits will be issued on the basis of one CEU Prerequisites:

per 10 contact hours (10 hours of training). See FANUC Robotics recommends attendance in

individual course descriptions for award prerequisite classes prior to attending our

references. specialized and advanced classes. Experi-

enced students who may have worked for many

Location: years with our robots but who have not had

FANUC Robotics America, Inc. Training formal training may feel they do not need to

Department is located in our Rochester Hills, attend a basic class. FANUC Robotics will

Michigan headquarters. Our company also has accept registrations from such students with the

facilities in Chicago, Illinois; Los Angeles, understanding that the FANUC instructor in an

California; Charlotte, North Carolina; Cincinnati advanced class will follow the published class

and Toledo, Ohio; Toronto, Ontario. Contact schedule and will not be able to coach individual

your local facility to explore possibilities of students on basic concepts that may be

local training! required for the class.

Please review this brochure carefully or visit our

website at www.fanucrobotics.com to review

prerequisites for selected classes.

To Register Call 1-800-47-ROBOT Or Contact Us At www.fanucrobotics.com 3

FANUC ROBOTICS PROVIDES THE TRAINING YOU NEED, WHEN YOU NEED IT!

Training Cancellations: Development Charges:

Cancellation of a registration is done at no Execution of on-site training programs may

charge if FANUC Robotics is notified in writing involve developmental charges. Please review

at least two weeks before start of class. this brochure carefully or go to our website at

Cancellation is subject to a fee equal to 100% www.fanucrobotics.com to review whether

of the course tuition if notice is received with these charges are applicable to your on-site

less than two weeks notice. selection.

Training Rescheduling: Yes, Older Product Training Is

Rescheduling of a registration is done at no Available!

charge if FANUC Robotics is notified in writing Just contact our registrar for more information.

at least two weeks before start of class. A 30%

fee will be charged for notice of less than two Need Robot Training in a Foreign

weeks. A training voucher will be issued upon Language?

cancellation that must be used within a period

of six months of issue. Unused vouchers will Class dates indicate when it will be taught in a

not be subject to a refund. The full fee will be different language. Just contact our registrar for

charged for students who fail to attend the class more information.

without any advance notice.

Training Documentation

Training Class Payment: All documentation is issued only during the

Payment may be made by check, credit card or course. Any work material issued and used in

purchase order and must be received prior to courses may not be reproduced either in whole

attendance in any training class. or in part. All software used in courses is the

property of FANUC Robotics and may not be

Please remit all monies to: copied or reproduced. If this stipulation is

FANUC Robotics America, Inc. infringed, we reserve the right to exclude the

Drawer #5739 person concerned from the course and to take

PO Box 79001 further legal action. The documentation issued

Detroit, MI 48279-5739 serves informative purposes; it is based on the

current state of technical development and does

not include documentaiton updates.

Liability

FANUC Robotics America is not liable for loss

or theft of property brought into the training

rooms, especially clothing and valuables.

4 automation • innovation • dedication

Computer Based Training

Web Based Robot Operations

Training: Benefits:

• Self-paced learning when you need it

FANUC Robotics’ Web Based Training (WBT)

• Offers instant feedback, letting students

Program, “Robot Operations”, is an introductory

know about areas that may need review

robotics course that includes basic robot

• Use as a primer to instructor-led courses

terminology and operational skills. The CBT is

held at FANUC Robotics America Rochester

a self-paced learning tool that allows users to

Hills facility

access information and move through material

• Diminishes the time users spend away from

based on a person’s specific interest or need.

their primary job function for training

The course content and structure is based on

• Reduces travel expenses to attend basic

an assessment of concepts and skills taught at

operations training

the FANUC Robotics America’s training facility

• Can also be used as a refresher course, due

in the course named, “Robot Operations.”

to constant personnel changes

FANUC Robotics Robot Operation WBT is,

• Provides customers the latest in Instruc-

“Training you need, when you need it!”

tional Design

Ordering Information: • CEU accreditation available

To view a demo or for in-depth information on Objectives:

this training product, call 1-800-47-ROBOT or

Upon completion of the course the student will

email: traininginfo@fanucrobotics.com.

be able to:

Features: • Demonstrate or explain how to safely cycle

• Easy-to-use interface for simple navigation power from the Standard Operator Panel

• Access to specific content through modules observing recommended safety practices

that target specific areas of interest or need • Describe how to move the robot in the

• Provides self-assessment through Progress JOINT and WORLD jog modes, anticipating

Check and Mastery Challenge testing the robot’s direction and speed, using the

• Automatically bookmarks progress through Teach Pendant

the course based on username logon and • Describe or demonstrate creating and

password identification, making identification making changes to Teach Pendant programs

of completed modules easily recognizable • Describe or demonstrate how to access,

• Provides printable Quick Reference Guides test, abort or run a program in a production

for step-by-step instructions to accomplish environment

specific tasks for future reference.

• On-demand detailed reporting of student's

progress and completion

To Register Call 1-800-47-ROBOT Or Contact Us At www.fanucrobotics.com 5

FANUC ROBOTICS PROVIDES THE TRAINING YOU NEED, WHEN YOU NEED IT!

Operations and Programming Classes

Robot Operations KAREL Operation & Introduction

24 Hours, Class Code: J2P0305 to Programming

Course Description: 40 Hours, Class Code: J2P0315

This course is intended for the person who Course Description:

operates or may be required to perform mainte- This course covers operation of the SYSTEMS

nance on a system R-J to R-J3iB Controller with R-J to R-J3iB Controller and fundamentals of

standard application software package. It covers the KAREL language. Instruction includes

the tasks and procedures needed to reach the material contained in the “Robot Operations”

course goals with both classroom instruction and course in addition to fundamental programming

hands-on training. The course does not address techniques using the KAREL language. The

the set-up and operation of specific software course is not an in-depth programming course

features and options. and is focused on the interpretation of existing

Course Objectives: code rather than development of application

• Power up and Jog the Robot programs.

• Recover from common program and robot Course Objectives:

faults • Perform startup and shutdown procedures

• Execute production operations • Jog the robot

• Create, modify and execute a teach pendant • Teach positional data

program • Perform error recovery procedures

• Backup and restore individual programs and • Write, enter, debug and test simple KAREL

files and teach pendant programs

Prerequisites: None Prerequisites: None

Michigan C an ad a Michigan

Ma y 1 0 Ma y 2 5 Ma y 1 4

J un 1 J ul 1 3 A ug 2 0

J ul 6 No v 2 Sep 24

A ug 2 Dec 14 O c t 2 2 - R H C o nt r o l l e r

A ug 1 6 Oh io No v 1 9

Sep 7 A ug 3 1

Sep 27 No v 9

Oc t 1 8 Illin o is

No v 8 Sep 21

No v 2 2 No v 1 6

Dec 14

6 automation • innovation • dedication

Operations and Programming Classes (Cont.)

KAREL Operation & Accelerated Course Note:

Language Programming The following programming courses are

80 Hours, Class Code: J2P0320

intended for an operator, technician, engineer or

Course Description: programmer who must setup and record a

This is an accelerated course for engineers and program on a System R-J to R-J3iB controlled

technicians with prior programming experience robot with a specific application software such

on a high level such as ‘C’, ‘PASCAL’, or as ArcTool, DispenseTool, HandlingTool,

‘FORTRAN’. The students will create, write, PaintTool, PalletTool or SpotTool. The courses

and modify application programs using KAREL cover the Robot Operations outline intermixed

language. This course covers the KAREL with the tasks required to set up the specific

Operations and Introduction to Programming application, test, run and refine the program and

class outline as well as concepts that explain production setup.

fundamental programming techniques using the

KAREL language, language syntax, system ArcTool Operation and

variables and the I/O structure. Advanced Programming

topics of multi-tasking, file handling and serial 32 Hours, Class Code: J2P0410

communications are covered. Course Objectives:

Course Objectives: • Safely power up the robot from a complete

• Perform startup and shutdown procedures shutdown

• Jog the Robot • Manipulate the robot using the teach

• Teach positional data pendant

• Perform error recovery procedures • Setup and test robot movement parameters

• Write, enter, debug and test KAREL and for a given work cell and torch

HandlingTool (TPP+) programs. • Setup ArcTool for specific weld applications

• Create and test weld programs for a given

Prerequisites: Prior programming weld task

experience on a high level language such • Edit weld programs in teach mode

as “C”, PASCAL, or FORTRAN. • Setup and save to file management devices

Michigan • Manipulate I/O in program logic and real

J un 1 8 logic

A ug 6 Prerequisites: None

Dec 17 Michigan

May 10

Jul 6

S ep 13

Nov 8

D ec 6

To Register Call 1-800-47-ROBOT Or Contact Us At www.fanucrobotics.com 7

FANUC ROBOTICS PROVIDES THE TRAINING YOU NEED, WHEN YOU NEED IT!

Operations and Programming Classes (Cont.)

DispenseTool Operation & HandlingTool Operation &

Programming Programming

32 Hours, Class Code: J2P0210 32 Hours, Class Code: J2P0310

Course Objectives: Course Objectives:

• Power up and Jog the Robot • Power up and Jog the Robot

• Recover from common program and robot • Recover from common program and robot

faults faults

• Execute production operations • Execute production operations

• Create, modify and execute a dispensing • Create, modify and execute a material

program handling program

• Backup and restore individual programs and • Create and execute MACROs

files • Monitor, force and simulate input and output

signals

Prerequisites: None • Backup and restore individual programs and

Michigan files

J un 1 4

J ul 1 2 Prerequisites: None

A ug 1 6 Michigan C an ad a

Oc t 4 Ma y 2 4 J un 8

Oc t 2 5 J un 1 4 Sep 14

Dec 13 J un 2 8 Dec 7

J ul 1 2 California

PaintTool Operation & J ul 2 6 Ma y 4

Programming A ug 9 J un 2 2

32 Hours, Class Code: J2P0510 A ug 2 3 Oc t 2 5

Sep 7 Dec 14

Course Objectives: Sep 20 Ohio

• Power up and Jog the Robot Oc t 4 Ma y 1 8

• Recover from common program and robot Oc t 1 8 J ul 2 7

faults Oc t 2 5 Oc t 1 9

• Execute production operations No v 1 Illinois

• Setup paint parameters (FF,AA,FA,ES) No v 8 J un 2 9

• Create, modify and execute a teach pendant No v 2 9 A ug 2 4

process Dec 13 Oc t 2 6

Prerequisites: None Dec 20

Michigan

Ma y 3

J un 7

J un 2 1

J ul 1 9

A ug 1 6

Sep 13

Oc t 1 8

No v 8

Dec 13

8 automation • innovation • dedication

Operations and Programming Classes (Cont.)

PalletTool Operation & SpotTool Operation & Programming

Programming with Servo Gun

32 Hours, Class Code: J3P0710 40 Hours, Class Code: J20610SG

Course Objectives: Course Objectives:

• Power up and Jog the Robot • Power up and Jog the Robot

• Recover from common program and robot • Recover from common program and robot

faults faults

• Setup the Pallet System • Execute production operations

• Setup the Gripper Signals and Sensors • Create, modify and execute a teach pendant

• Teach the Infeed and Pallet Stations and program

Station I/O • Backup and restore individual programs and

• Create the Unit Loads and Optimal Path and files

Download • Setup SpotTool and all related I/O

• Execute production operations • Setup and test auxiliary axis settings needed

• Create, modify and execute a palletizing for Servo Gun operation

teach pendant program • Setup SpotTool for Servo Gun welding

• Backup and restore individual programs and • Create and test weld programs using the Servo

files Gun

• Development charges will be added to • Setup Servo Gun pressure schedules including

any on-site training request. the Weld Stroke

Prerequisites: None • Manipulate the Servo Gun using Teach

Pendant keys

Michigan

J ul 6 Prerequisites: None

J ul 1 9 - up t o V 5 . 11 Michigan

A ug 2 Ma y 2 4

Sep 27 A ug 2

Oc t 2 5 Sep 20

Dec 6 Oc t 1 8

No v 8

SpotTool Operation &

Programming

32 Hours, Class Code: J2P0610

Course Objectives:

• Power up and Jog the Robot

• Recover from common program and robot

faults

• Execute production operations

• Create, modify and execute a teach pendant

program

• Backup and restore individual programs and

files

• Setup SpotTool and all related I/O

Prerequisites: None

Michigan

Ma y 3

J un 7

J un 2 8

J ul 2 6

A ug 2 3

To Register Call 1-800-47-ROBOT Or Contact Us At www.fanucrobotics.com 9

FANUC ROBOTICS PROVIDES THE TRAINING YOU NEED, WHEN YOU NEED IT!

Specialized Training Classes

Course Notes: HandlingTool Features and Options

40 Hours, Class Code: ADV0310

These courses cover additional functionality and

are designed for experienced students who Course Objectives:

have taken our standard applications • Create multi-tasking TP programs

courses. They do not cover basic Robot • Write condition handler TP programs for

Operations or programming. Features and unexpected interrupts – global and local

Options Courses do not cover advanced • Setup Payload Schedules and code their use

programming topics, but focus on the set up • Setup Collision Guard sensitivities and code

and execution of both standard and optional their use

features which lie outside the scope of normal • Perform Background Editing of a TP program

day-to-day operation. • Address Coordinate Offsets within a TP

program

ArcTool Features and Options • Setup and use the TP Menus and Prompts

40 Hours, Class Code: ADV0410 Feature

• Setup the PassWord Feature

Course Objectives: • Backup and restore individual programs and

• Write multi-tasking programs files

• Setup payload schedules, Collision Guard

sensitivities and use them in a program Prerequisites: Completion of

• Setup and use the Torchmate option HandlingTool Operations and

• Setup and use Touch Sensing Programming.

• Use Rapid Fault Recovery

• Setup and use TAST

Michigan

Ma y 3

Prerequisites: Completion of ArcTool J un 2 1

Operations and Programming. J ul 1 9

No v 1 5

Michigan

Ma y 2 4

A ug 1 6 Advanced TPP Programming

Dec 13 40 Hours, Class Code: ADVTPP

SpotTool Features and Options Course Description

40 Hours, Class Code: ADV0610 Advanced programming is the next step after an

Course Objectives: Operation and Programming class. Topics from

• Shift Function the previous classes will be used in this class to

• Tool Frame Adjust option develop a more complex scenario. Students will

• Coordinates Offset function be given the task of creating all the necessary

• Remote Tool Center Point option programs to integrate robots into a cell.

• Error Recovery option Course Objectives:

• Collision Guard option • Define cell requirements

• DeviceNet I/O option • Develop programs with a language

• Backup and restore individual programs and independent model

files • Coding of programs using advanced

• SpotTool+ Advanced Functions option programming techniques

• Program Toolbox option • Cell Interface

Prerequisites: Completion of SpotTool • Error Trapping / Recovery

Operations and Programming. Prerequisites: Completion of an

Michigan “Operation & Programming” class.

A ug 3 0 Please call the FANUC Robotics Training Registrar

for course availability.

10 automation • innovation • dedication

Specialized Training Classes (Cont.)

PalletTool Feature & Options • Setup single view process (robot mtd. camera)

40 Hours, Class Code: ADV0710T • Set up multi-view process (robot mtd. camera)

• Load, save, and backup projects

Course Description: • TPP programming using robot server

This course makes use of FANUC Robotics • Troubleshooting

PalletPRO 3D robot palletizing simulation Prerequisites: Completion of HandlingTool

software. The instructional activities included in

Programming, HandlingTool Features and

this course provide procedures for creating a

PalletPRO virtual workcell and downloading data Options or KAREL Operations &

to the robot. PalletTool Turbo, a variant of Programming

PalletTool, will be used for high speed palletizing.

Michigan

This course does not cover basic robot opera- Aug 30

May 17

tions or HandlingTool programming.

Jun 1 S ep 27

Course Objectives: Jun 28 Oct 11

• Create a new workcell using PalletPRO Jul 6 Nov 1

• Edit the virtual robot properties Aug 2 Nov 22

• Add palletizing instruction to TP programs

• Specify and fine tune the best path for your visLOC 3D Operation &

robot to take when palletizing Programming

• Modify Utool values for various grippers Please call the FANUC Robotics Training Registrar

• Use pallet offset information for course availability.

• Enable alternate return paths ( clear/diag Servo Gun Operation & Programming

return) 16 Hours, Class Code: SERVOGUN

• Stack with labels out and flipped layers

• Set up Ethernet communications between the Course Description:

robot and a PC This course covers the features that an operator,

Prerequisites: Completion of PalletTool technician, engineer or programmer needs to set up

and operate a Servo Gun using FANUC Robotics

Operations and Programming.

SpotTool+ Software with the Servo Gun option. It is

Michigan designed for those who are familiar with SpotTool+

Ma y 1 7 using Air Gun but have not previously worked with

A ug 9 Servo Gun. It does not cover any basic operation,

O c t 11 set up, or programming of the robot.

No v 1 5 Course Objectives:

• Setup and test auxiliary axis settings needed for

visLOC 2D Operation & Servo Gun operation

Programming • Setup SpotTool+ for Servo Gun welding

24 Hours, Class Code: VISLOC1 • Create and test weld programs using the Servo

Gun

Course Description:

• Set up Servo Gun pressure schedules including

This course covers the basic tasks and proce- the Weld Stroke menu

dures required for an operator, technician, • Manipulate the Servo Gun using Teach Pendant

engineer or programmer to setup, teach, test and keys

modify vision applications in production using an

R-J3/R-J3iB controller equipped with visLOC

Prerequisites: Completion of SpotTool

software. Operations and Programming.

Course Objectives: Michigan

• Power up and jog the robot J ul 7

• Set Robot TCP/IP Parameters Sep 8

• Setup Ethernet parameters in VisLOC No v 2 2

• Setup and calibrate the camera

• Setup single view process (fix mtd. camera)

To Register Call 1-800-47-ROBOT Or Contact Us At www.fanucrobotics.com 11

FANUC ROBOTICS PROVIDES THE TRAINING YOU NEED, WHEN YOU NEED IT!

Specialized Training Classes (Cont.)

visTRAC Operation & Programming PaintPRO Robotic Workcell

32 Hours, Class Code: visTRAC Simulation

Course Description: 8 Hours, Class Code: PntPRO

This course covers the basic tasks and proce- Course Description:

dures required for an operator, technician, This class demonstrates how to use PaintPRO

engineer or programmer to setup, teach, test and simulation software to program FANUC’s new

modify vision applications in production using an P-500 paint robots. Upon completion of this

R-J3/R-J3iB controller equipped with visLOC class, students will know how to setup a multi-

software. arm workcell and add a new style utilizing the

Course Objectives: Cad Generator program.

• Power up and jog the robot Course Objectives:

• Set Robot TCP/IP Parameters " Create a Virtual WorkCell

• Setup Ethernet parameters in VisLOC " Jogging Robots using the Virtual Teach

• Setup and calibrate the camera Pendant & Teach Tool

• Setup single view process (fix mtd. camera) " Creating a Program

• Setup single view process (robot mtd. " Editing a Program

camera) " Calibrating the Virtual & Real World

• Setup Line Tracking WorkCells (overview only)

• Develop a visTRAC application " Create a Style using the Cad Generator

• Hardware/Software overview program

• Set up multi-view process (robot mtd.

camera)

Prerequisites: Previous experience or

• Load, save, and backup projects training in a related field involving the

• TPP programming using robot server application of paint materials using

• Troubleshooting automation would be helpful to the

Prerequisites: Completion of student.

HandlingTool Programming, Please call the FANUC Robotics Training

HandlingTool Features and Options or Registrar for course availability.

KAREL Operations & Programming

Please call the FANUC Robotics Training

Registrar for course availability.

12 automation • innovation • dedication

Specialized Training Classes (Cont.)

HandlingWorks Operations PC Developer’s Kit

24 Hours, Class Code: JWP0310 24 Hours, Class Code: J3P0320

Course Description: Course Description:

This course is intended for the person who sets This course introduces programmers and

up or operates an R-J3 controller using the system analysts to the features and functions of

HandlingWorks system package and a FANUC the PC Developers Kit. You will develop stand

Robot equipped with a standard Material alone robot interactive PC application programs

Handling application software package. and graphical user interfaces which communi-

Course Objectives: cate information and instructions between a PC

and a FANUC RJ3 controller.

• Describe the Main Menu Screens

• Setup the workcell layout on the Graphical Course Objectives:

Interface • Install, setup, and verify Ethernet communi-

• Monitor the Robot and/or specific workcell cation between the PC and the robot system

items • State the function of the TPP macro

• Troubleshoot alarms and recover programs provided to support PCDK

• Force, simulate and monitor I/O Signals • State the function of the KAREL built-in

• Define other specific user defined data needs routines provided to support PCDK

• Manipulate files between the HOST and each • Write an independent PC program which will

individual Robot respond to an event initiated by a TPP or

Prerequisites: Completion of KAREL program

• Write a PC program that reads and changes

HandlingTool or KAREL Operations & positional and numeric data from a KAREL

Programming. and TPP program

Please call the FANUC Robotics Training • Write a PC program that monitors and

Registrar for course availability. responds in changes to the status of specific

digital, analog or grouped I/O

Prerequisites: Completion of

HandlingTool Programming or KAREL

Operations & Programming.

Please call the FANUC Robotics Training

Registrar for course availability.

To Register Call 1-800-47-ROBOT Or Contact Us At www.fanucrobotics.com 13

FANUC ROBOTICS PROVIDES THE TRAINING YOU NEED, WHEN YOU NEED IT!

Electrical Maintenance Classes

Course Notes: Electrical Maintenance w/R-J3iB

LR Mate Controller

Electrical courses are designed for mainte- 32 Hours, Class Code: J3iBME0250

nance personnel responsible for installing and

maintaining the System RS1 configured, R-J2,

Michigan

Oc t 2 5

R-J3 or R-J3iB controller. Although Robot

Operations is not a prerequisite for these Electrical Maintenance w/R-J2

courses, the operational aspects covered in

these courses are minimal. A review of the

Controller

32 Hours, Class Code: J2E0250

functions that the student will be required to

perform when back in the workplace is advised. Michigan

J un 2 1

Note: If a student is required to set up and

J ul 2 6

program the robot, the Robot Operations or

A ug 2 3

application programming class is also

No v 1

recommended.

Course Objectives (the following Electrical Maintenance w/R-J2

Objectives apply to ALL Electrical LR Mate Controller

Maintenance Courses): 32 Hours, Class Code: J2ELR01

• Safely power up the robot from complete Michigan

shutdown Oc t 1 8

• Manipulate the robot using the teach

pendant

• Recognize and describe major robot Electrical Maintenance

components w/R-J3 Controller

• Troubleshoot Class 1, 2 and 3 faults 32 Hours, Class Code: J3E0250

• Master the robot Michigan

• Manipulate I/O for the robot Ma y 2 4

J un 2 8

J ul 1 2

Electrical Maintenance w/R-H A ug 1 6

Controller Sep 13

Oc t 4

Electrical Maintenance w/ RS1-4 No v 2 9

Configured w/RJ-2 Controller

M-410i Robot Electrical Electrical Maintenance w/RS1-4

Maintenance w/ R-J2 Controller Configured or RIA R-J3 Control

Please call the FANUC Robotics Training Reliable Controller

Registrar for course availability for these 32 Hours, Class Code: J3ERS1

classes. Michigan

Ma y 1 0

J un 7

A ug 2

No v 8

14 automation • innovation • dedication

Electrical Maintenance Classes (Cont.)

Electrical Maintenance Paint Electrical Maintenance

w/R-J3iB Controller w/R-J3 Controller

32 Hours, Class Code: J3iBE0250 32 Hours, Class Code: J3EP550

Michigan C an ad a Michigan

Ma y 3 A ug 1 0 Ma y 2 4

Ma y 1 7 Oc t 1 9 J ul 2 6

J un 7 California No v 1

J un 2 1 A ug 3

J ul 1 9 No v 3 0 Paint Electrical Maintenance

A ug 9 Ohio

A ug 3 0

w/RIA R-J3 Control Reliable

J un 1 5 Controller

Sep 27 A ug 1 7

O c t 11 32 Hours, Class Code: J3EP550CR

Dec 7

No v 1 6 Illinois Michigan

Dec 6 M a y 11 Sep 20

Dec 20 J ul 1 3

Oc t 1 2 Paint Electrical Maintenance

w/R-J3iB Controller

32 Hours, Class Code: J3iBEP550

Paint Electrical Maintenance

w/R-J2 Controller Michigan

32 Hours, Class Code: J2EP550 Ma y 1 7

J un 1 4

Michigan J ul 6

J un 2 1 A ug 2

Sep 27 Sep 7

Dec 20 O c t 11

No v 2 9

Dec 6

To Register Call 1-800-47-ROBOT Or Contact Us At www.fanucrobotics.com 15

FANUC ROBOTICS PROVIDES THE TRAINING YOU NEED, WHEN YOU NEED IT!

Mechanical Maintenance Classes

Course Notes: M-410i Robot Disassembly/

These courses are recommended for

Reassembly

32 Hours, Class Code: MTD410i

mechanical technicians or other persons

responsible for mechanical troubleshooting, Michigan

maintenance and repair of the robot. We Ma y 3

require some previous mechanical knowledge J ul 2 6

of repair and assembly of robots or machine Sep 20

tools. These courses provide detailed M-410iB Robot Disassembly/

instruction and procedures necessary for

complete disassembly, inspection and

Reassembly

32 Hours, Class Code: MTD410iB

reassembly of the FANUC mechanical unit.

Michigan

Course Objectives (the following J un 7

Objectives apply to ALL Mechanical J un 2 1

Maintenance Courses): A ug 2 3

• Diagnose robot mechanical problems to Oc t 1 8

the component level No v 2 9

• Replace all mechanical components on the M-420 Robot Disassembly/

robot Reassembly

• Perform adjustments to the robot

32 Hours, Class Code: MTD420i

• Perform periodic maintenance on the

mechanical unit Michigan

Dec 8

M-6i or AM100i Robot Disassembly/ Feb 23

Reassembly Ma y 1 0

20 Hours, Class Code: MTDM6i

Michigan M-710i/M710iB Robot Disassembly/

Sep 7 Reassembly

Oc t 4 28 Hours, Class Code: MTDM710i

No v 1 5 Michigan

M-6iB or AM100iB Robot A ug 2

No v 1

Disassembly/Reassembly Dec 20

24 Hours, Class Code: MTDM6iB

Michigan P-50 Robot Disassembly/

A ug 9 Reassembly

No v 2 2 32 Hours, Class Code: MTDP145

M-16i or AM120i Robot Michigan

Disassembly/Reassembly Sep 13

20 Hours, Class Code: MTDM16i P-145 Robot Disassembly/

Michigan Reassembly

J un 1 32 Hours, Class Code: MTDP145

J ul 6 Michigan

Oc t 6 J un 1 4

No v 1 7 J ul 6

M-16iB or AM120iB Robot O c t 11

Disassembly/Reassembly P-155 Robot Disassembly/

24 Hours, Class Code: MTDM16iB Reassembly

Michigan 32 Hours, Class Code: MTDP155

A ug 9 Michigan

No v 2 2 Ma y 1 7

Dec 20

16 automation • innovation • dedication

Mechanical Maintenance Classes (Cont.)

P-200 Robot Disassembly/ S-500 Robot Disassembly/

Reassembly Reassembly

32 Hours, Class Code: MTDP200 32 Hours, Class Code: MTDS500

Michigan Michigan

J un 1 Ma y 1 7

A ug 2 3 J ul 1 9

No v 1 6 Sep 7

P-200E Robot Disassembly/ S-500iB Robot Disassembly/

Reassembly Reassembly

32 Hours, Class Code: MTDP200E 32 Hours, Class Code: MTDS500iB

Michigan Michigan

j ul 1 2 Sep 27

A ug 9 No v 8

Sep 20 R-J3iB LR Mate Mechanical

Oc t 2 5 Maintnenance

8 Hours

R-2000i Robot Disassembly/ Course Description:

Reassembly

32 Hours, Class Code: MTDR2000i This one day lecture course provides a

mechanical overview of the FANUC robot in a

Michigan

classroom environment. Also covered are the

Ma y 1 0

adjustment and maintenance procedures.

J un 1 4

J un 2 8 Course Objectives:

J ul 1 2 This course covers the basic mechanical

J ul 2 6 structure of the robot. This will enable the

A ug 1 6 student to perform adjustments and mainte-

Sep 13 nance on the mechanical unit. More specifically,

Oc t 4 students completing this course will have an

No v 1 understanding of:

No v 2 9 • Mechanical adjustments to the robot.

Dec 20 • Periodic maintenance on the mechanical

S-420i Robot Disassembly/ unit.

Reassembly Michigan

32 Hours, Class Code: MTDS42i Oc t 2 9

Michigan

Ma y 2 4

J un 2 8

A ug 3 0

Oc t 2 5

Dec 6

S-430i Robot Disassembly/

Reassembly

32 Hours, Class Code: MTDS43i

Michigan

J un 2 1

J ul 1 9

A ug 2 3

O c t 11

Dec 13

To Register Call 1-800-47-ROBOT Or Contact Us At www.fanucrobotics.com 17

FANUC ROBOTICS PROVIDES THE TRAINING YOU NEED, WHEN YOU NEED IT!

Reservation Information

Things you should know before calling to make a class reservation:

1) Know the Controller model you require for 3) Know the Application Software (ArcTool,

training. This can be found on the upper right HandlingTool, KAREL, etc.). The Teach

side of the Controller. Pendant will display this when you power-up

the Controller.

2) Know the Robot Model. This can be found

on all robot arms.

4) Know how many students will be attending

and on which dates.

5) Where would you like to attend the training?

At FANUC Robotics’ site or your location?

6) If you would like training on-site, do you

have dedicated robot(s) for training?

Where to make the Reservation:

1) PHONE: You can call 1-800-47-ROBOT

(1-800-477-6268) at anytime between the

hours of 8:00 am - 4:30 pm EST.

2) WEB: www.fanucrobotics.com - Select

“Training” then “Course Registration”

18 automation • innovation • dedication

Rochester Hills, MI Facility Map

FANUC Robotics America

N

3900 W. Hamlin Road Rochester Hills

Rochester Hills, MI 48309-3253

Tienken Rd.

Oakland Pontia c

Airport University

Pontiac

Featherstone

M5 Hamlin Rd.

Updyke Rd

FANUC Robotics

M59

Rochester Rd.

Squirrel Rd

Featherstone

Front Lobby Mt. C lemens

Troy

Hamlin West Birmingham

Big Beaver

To I75 Hamlin East

M59 West

59

Squirrel Rd

Adams Rd

M59 East

N I696 Warren

Highland

Park

I96

Te legraph Rd. - M24

Dearborn

I94 Windsor

I75 CANADA

401

Detroit Metro

Airport

From Oakland Pontiac Airport:

M59 East to North Squirrel. Take Hamlin Road East. Go past Adams traffic light, take first

Boulevard turn around. FANUC Robotics on north side of Hamlin.

From Detroit Metro Airport:

I-94 East to I-75 North to Adams Road Exit. Turn Left, north on Adams Road, go approxi-

mately 3 miles. Turn right on Hamlin, take first Boulevard turn around. FANUC Robotics on

north side of Hamlin.

From Detroit City Airport:

Outer Drive North to VanDyke North, to I-696 West, to I-75 North, to M-59 East, to North Squirrel

Exit. Right on Hamlin Rd. Go past Adams Road traffic light. Take first Boulevard turn around.

FANUC Robotics on north side of Hamlin Rd.

To Register Call 1-800-47-ROBOT Or Contact Us At www.fanucrobotics.com 19

FANUC ROBOTICS PROVIDES THE TRAINING YOU NEED, WHEN YOU NEED IT!

FANUC Robotics America, Inc.

Rochester Hills, MI 48309-3253

3900 West Hamlin Road

1-800-47-ROBOT

20 automation • innovation • dedication

Vous aimerez peut-être aussi

- Roboguide Training Manual (FRDE) (Z KAE TRN Roboguide 1 01 En)Document95 pagesRoboguide Training Manual (FRDE) (Z KAE TRN Roboguide 1 01 En)Brian Lee93% (29)

- Pmi-Acp Exam Prep Study Guide: Extra Preparation for Pmi-Acp Certification ExaminationD'EverandPmi-Acp Exam Prep Study Guide: Extra Preparation for Pmi-Acp Certification ExaminationPas encore d'évaluation

- Wipro Ucf FaqDocument10 pagesWipro Ucf FaqChinmay N KumarPas encore d'évaluation

- FMI Submission Review Scoring - IFMA FMP PM Update 11.13.14 (For Public Comment) - 0Document5 pagesFMI Submission Review Scoring - IFMA FMP PM Update 11.13.14 (For Public Comment) - 0MHDPas encore d'évaluation

- TECHNOLOGY PLAN AND INFRASTRUCTURE SUPPORT SYSTEM FbsDocument4 pagesTECHNOLOGY PLAN AND INFRASTRUCTURE SUPPORT SYSTEM FbsMacKru NauTics100% (3)

- ACC 406 Spring 2021 Q and SDocument7 pagesACC 406 Spring 2021 Q and S许之晟Pas encore d'évaluation

- Basic 6 CBLM-Use-Relevant-Technologies-HK-NCIIIDocument33 pagesBasic 6 CBLM-Use-Relevant-Technologies-HK-NCIIIMylina Fabi50% (2)

- SCO-01E ELearnReq Rev0Document2 pagesSCO-01E ELearnReq Rev0Adolfo AnguloPas encore d'évaluation

- Annexure VT-JIF - Virtual Training - Joining Instruction Form I2 Rev00 16042021Document4 pagesAnnexure VT-JIF - Virtual Training - Joining Instruction Form I2 Rev00 16042021mohamed fawzanPas encore d'évaluation

- Fanuc Training Catalog & Course ScheduleDocument38 pagesFanuc Training Catalog & Course ScheduleAutoman IntertradePas encore d'évaluation

- Annexure VT-JIF - Virtual Training - Joining Instruction Form I1 Rev04 14052020Document4 pagesAnnexure VT-JIF - Virtual Training - Joining Instruction Form I1 Rev04 14052020Aqdas SajjadPas encore d'évaluation

- Syllabus MKT 425 Spring 2021 SLN 10643Document7 pagesSyllabus MKT 425 Spring 2021 SLN 10643siddhanth masagoniPas encore d'évaluation

- CIIA Programme Information BookletDocument6 pagesCIIA Programme Information BookletCarl RossPas encore d'évaluation

- Guidelines and Policies For The School of I.T. and I.S. Ojt/Internship CoursesDocument18 pagesGuidelines and Policies For The School of I.T. and I.S. Ojt/Internship Coursesedwardgarcia333Pas encore d'évaluation

- Bering Practicum Journal 2023 For SoftboundDocument48 pagesBering Practicum Journal 2023 For SoftboundCarlo Ford YonsonPas encore d'évaluation

- Course Number Course Title Term: (Alternatively)Document11 pagesCourse Number Course Title Term: (Alternatively)Yousef MeguidPas encore d'évaluation

- Training Catalog & Course ScheduleDocument38 pagesTraining Catalog & Course Scheduleamir65esfPas encore d'évaluation

- OUTPUT - Technology PlanDocument6 pagesOUTPUT - Technology PlanEdward RaagasPas encore d'évaluation

- T2232-370-01 SG-Edu Lec ENDocument713 pagesT2232-370-01 SG-Edu Lec ENStelian OlaruPas encore d'évaluation

- Computing System and InfrastructureDocument13 pagesComputing System and InfrastructurekanikaPas encore d'évaluation

- Exemption Accreditation Application PackDocument21 pagesExemption Accreditation Application PackstaticknifePas encore d'évaluation

- Exemption Accreditation Application PackDocument21 pagesExemption Accreditation Application Packnimodi lankaPas encore d'évaluation

- T3904-390-02 SG-Ins Lec EN PDFDocument383 pagesT3904-390-02 SG-Ins Lec EN PDFBrunoPanuto100% (1)

- BAFI1026 Risk Management Course Guide S2 2010Document17 pagesBAFI1026 Risk Management Course Guide S2 2010shaharhr1Pas encore d'évaluation

- BUS 421 Winter 2022 SD1 Course OutlineDocument9 pagesBUS 421 Winter 2022 SD1 Course OutlineRithik KhannaPas encore d'évaluation

- Sector-11, Jankipuram Extension, Lucknow E-Mail: Vineetkansal@ietlucknow - Ac.inDocument8 pagesSector-11, Jankipuram Extension, Lucknow E-Mail: Vineetkansal@ietlucknow - Ac.insumitPas encore d'évaluation

- Technology Plan and Infrastruture Support SystemDocument5 pagesTechnology Plan and Infrastruture Support SystemRyanM.PradelPas encore d'évaluation

- CS240 SyllabusDocument3 pagesCS240 SyllabusDidarul AlamPas encore d'évaluation

- ACCG340Document11 pagesACCG340Dung Tran0% (1)

- Course Booking Form - QMS-VILT - CR - 06-2022Document3 pagesCourse Booking Form - QMS-VILT - CR - 06-2022Laltu DuttaPas encore d'évaluation

- Training Management GuidelinesDocument6 pagesTraining Management Guidelineskabayo_rudyPas encore d'évaluation

- CTP BrochureDocument3 pagesCTP BrochurescribdXIIIPas encore d'évaluation

- LMS Requirements DocumentDocument13 pagesLMS Requirements DocumentMs WilliamsPas encore d'évaluation

- Advanced Financial Modeler Accreditation From The Financial Modeling Institute FaqsDocument9 pagesAdvanced Financial Modeler Accreditation From The Financial Modeling Institute FaqsOCTANE PLANT ENGINEERINGPas encore d'évaluation

- A Memorandum of UnderstandingDocument5 pagesA Memorandum of Understandingfeezy11Pas encore d'évaluation

- OBA335H Operations Management: Instructor and Class InformationDocument10 pagesOBA335H Operations Management: Instructor and Class InformationNicPas encore d'évaluation

- 1.technology Plan and Infrastruture Support SystemDocument5 pages1.technology Plan and Infrastruture Support SystemBhong BertePas encore d'évaluation

- Anyalezu Guthlac Syllabus ECO561 ApprovedDocument23 pagesAnyalezu Guthlac Syllabus ECO561 ApprovedAlireza ManaiPas encore d'évaluation

- 4551 Fall 2020 Course Outline Detailed Sept 29Document20 pages4551 Fall 2020 Course Outline Detailed Sept 29GFGSHSPas encore d'évaluation

- Guidelines For Local ChaptersDocument8 pagesGuidelines For Local ChaptersBalaji VenkataramanPas encore d'évaluation

- Organizer / Faculty Coordinator's (FC) RoleDocument4 pagesOrganizer / Faculty Coordinator's (FC) RoleJeevan GaikwadPas encore d'évaluation

- For Educational Use Only: Milling Using Pro/ENGINEER Wildfire 5.0Document0 pageFor Educational Use Only: Milling Using Pro/ENGINEER Wildfire 5.0kavadarci14Pas encore d'évaluation

- Script..Demo Achilles AdlawanDocument3 pagesScript..Demo Achilles AdlawanAchilles Gem J. AdlawanPas encore d'évaluation

- CFM Exam Study Course - FAQDocument5 pagesCFM Exam Study Course - FAQfranz delgadilloPas encore d'évaluation

- P2 P Training Guide v2.0.3Document6 pagesP2 P Training Guide v2.0.3Timothy MunhengaPas encore d'évaluation

- Ccfa Certification Exam Guide: Crowdstrike UniversityDocument9 pagesCcfa Certification Exam Guide: Crowdstrike UniversityneoaltPas encore d'évaluation

- Palalay Practicum Journal-2023Document39 pagesPalalay Practicum Journal-2023MaAngelicaElimancoPas encore d'évaluation

- Email Correspondence: To Protect Your Privacy, Your Business With Blue Ridge CommunityDocument11 pagesEmail Correspondence: To Protect Your Privacy, Your Business With Blue Ridge CommunitycarlPas encore d'évaluation

- 1 Course Materials 2 Prerequisites 3 Course Outline 4 Computer Setup 6 Instructor-Led Practices and Labs 7 Instructor-Led Practice: Using Virtual PC 10 Facilities 12Document18 pages1 Course Materials 2 Prerequisites 3 Course Outline 4 Computer Setup 6 Instructor-Led Practices and Labs 7 Instructor-Led Practice: Using Virtual PC 10 Facilities 12José MarquesPas encore d'évaluation

- t2174-360-03 SG-Ins Lec ENDocument318 pagest2174-360-03 SG-Ins Lec ENTaru LucianPas encore d'évaluation

- CSCI 359.0SB & 7RB CSCI359 - Systems Analysis and Design: PrerequisiteDocument13 pagesCSCI 359.0SB & 7RB CSCI359 - Systems Analysis and Design: Prerequisiteeric yuulPas encore d'évaluation

- PEOs Curriculum and CO PO Mapping 21 May 2016Document3 pagesPEOs Curriculum and CO PO Mapping 21 May 2016Binesh KannothPas encore d'évaluation

- T2166-360-01 SG-Edu Exc ENDocument0 pageT2166-360-01 SG-Edu Exc ENmetalservis2009Pas encore d'évaluation

- MAN 3240 - Applied Organizational Behavior (New/Master) - CoronelDocument9 pagesMAN 3240 - Applied Organizational Behavior (New/Master) - CoronelEng MatanaPas encore d'évaluation

- CS4443 XTIA - TSU Web-Based Software Development (Xiaoli Huan)Document7 pagesCS4443 XTIA - TSU Web-Based Software Development (Xiaoli Huan)canadaspiritPas encore d'évaluation

- MKT571 R4 Syllabus SK8Document17 pagesMKT571 R4 Syllabus SK8Alireza ManaiPas encore d'évaluation

- Training Course - Certified Professional For Requirements Engineering - Foundation Level (CPRE-FL)Document2 pagesTraining Course - Certified Professional For Requirements Engineering - Foundation Level (CPRE-FL)harshscribd007Pas encore d'évaluation

- OJT PoliciesDocument22 pagesOJT PoliciesChristopher OaresPas encore d'évaluation

- C F P S: Ertified Unction Oint PecialistDocument5 pagesC F P S: Ertified Unction Oint Pecialistmarilena2003Pas encore d'évaluation

- C F P S: Ertified Unction Oint PecialistDocument4 pagesC F P S: Ertified Unction Oint PecialistaprasooninPas encore d'évaluation

- APC BR1000 Datasheet PDFDocument2 pagesAPC BR1000 Datasheet PDFMax Durán ParraguezPas encore d'évaluation

- SC PMX82 User ManualDocument16 pagesSC PMX82 User ManualdavidspyPas encore d'évaluation

- Datasheet R 2000ic 165RDocument1 pageDatasheet R 2000ic 165RMax Durán ParraguezPas encore d'évaluation

- 40150EDocument2 pages40150EMax Durán ParraguezPas encore d'évaluation

- Mechanical Switches: Precision Switching With Unmatched DurabilityDocument129 pagesMechanical Switches: Precision Switching With Unmatched DurabilityMax Durán Parraguez100% (1)

- 70vauto SWDocument9 pages70vauto SWMax Durán ParraguezPas encore d'évaluation

- DDR4 CompatibilityDocument9 pagesDDR4 CompatibilityMax Durán ParraguezPas encore d'évaluation

- Past Simple: Mixed Regular & Irregular: Infinitive Past Infinitive PastDocument2 pagesPast Simple: Mixed Regular & Irregular: Infinitive Past Infinitive Pastlitalomp05Pas encore d'évaluation

- Unit II. 2.5DESIGNING LESSON PLANS AND UNIT PLANDocument15 pagesUnit II. 2.5DESIGNING LESSON PLANS AND UNIT PLANSugar Rey Rumart RemotiguePas encore d'évaluation

- The Good Generation: Lingua House Lingua HouseDocument4 pagesThe Good Generation: Lingua House Lingua HousecooladillaPas encore d'évaluation

- A Primer in BERTologyDocument15 pagesA Primer in BERTologyzhang EmmttPas encore d'évaluation

- Hogue WDocument6 pagesHogue WRyan RobisonPas encore d'évaluation

- Subjunctive 1 4Document5 pagesSubjunctive 1 4Arizendy Dewi FortunaPas encore d'évaluation

- Department of Education: Republic of The PhilippinesDocument9 pagesDepartment of Education: Republic of The PhilippinesAmelyn Goco MañosoPas encore d'évaluation

- Questioned Documents TimelineDocument23 pagesQuestioned Documents TimelineAli Zafrullah Daud BinudinPas encore d'évaluation

- 3 - PLC Configuration PDFDocument80 pages3 - PLC Configuration PDFJose67% (3)

- Automotive Software Engineering Master EnglDocument4 pagesAutomotive Software Engineering Master EnglJasmin YadavPas encore d'évaluation

- Englis Discoveries NIVEL 4Document55 pagesEnglis Discoveries NIVEL 4sandra garciaPas encore d'évaluation

- Assessment Tests - OryaDocument7 pagesAssessment Tests - OryaOrya AkkadPas encore d'évaluation

- COBOL Hage PDFDocument8 pagesCOBOL Hage PDFykabach87Pas encore d'évaluation

- Fundamentals of PoroelasticityDocument96 pagesFundamentals of PoroelasticitySimon-Nicolas RothPas encore d'évaluation

- 1st Class Activity Human BingoDocument1 page1st Class Activity Human BingoRita SarmentoPas encore d'évaluation

- TEA Catalogue 2018 PDFDocument90 pagesTEA Catalogue 2018 PDFamoyil422Pas encore d'évaluation

- Book of Dzyan - WikipediaDocument3 pagesBook of Dzyan - WikipediaAnonymous PqxjViUtDtPas encore d'évaluation

- CCS 1203 Introduction To Computer Programming CATDocument2 pagesCCS 1203 Introduction To Computer Programming CATIsaac OgolaPas encore d'évaluation

- Art AppreciationDocument8 pagesArt AppreciationJoshua AyensaPas encore d'évaluation

- Tugas Week 8 Task 6 Muhammad Afuza AKbar 22323111Document4 pagesTugas Week 8 Task 6 Muhammad Afuza AKbar 22323111Muhammad Afuza AkbarPas encore d'évaluation

- T. Romer The Problem of The Hexateuch in PDFDocument26 pagesT. Romer The Problem of The Hexateuch in PDFJorge Yecid Triana RodriguezPas encore d'évaluation

- Dogme Lesson - Sussex UniversityDocument8 pagesDogme Lesson - Sussex Universitywhistleblower100% (1)

- Luce Irigaray and The Female Imaginary: Speaking As A WomanDocument6 pagesLuce Irigaray and The Female Imaginary: Speaking As A WomanVictoria BluePas encore d'évaluation

- Annallene Marielle F. Riano: SY. 2020-2021 Modular Distance Learning September 13,2020 2:00 PMDocument14 pagesAnnallene Marielle F. Riano: SY. 2020-2021 Modular Distance Learning September 13,2020 2:00 PMANNALLENE MARIELLE FARISCALPas encore d'évaluation

- G.Prathibha: Career ObjectiveDocument3 pagesG.Prathibha: Career ObjectivePrathibha GandhamPas encore d'évaluation

- Review Unit 1 - Version A XDocument7 pagesReview Unit 1 - Version A Xherfan andersonPas encore d'évaluation

- U2000 Fundamental Configuratin GuideDocument60 pagesU2000 Fundamental Configuratin Guideshwemoeko34Pas encore d'évaluation

- English World Teachers Book Unit 1 Level 6 PDFDocument14 pagesEnglish World Teachers Book Unit 1 Level 6 PDFmaram alhusbanPas encore d'évaluation

- Workflow Performance Configuration in 12th ReleaseDocument67 pagesWorkflow Performance Configuration in 12th Releasesaloni pansePas encore d'évaluation

- Muestra Eyes Open 4 WBDocument7 pagesMuestra Eyes Open 4 WBclau aPas encore d'évaluation