Académique Documents

Professionnel Documents

Culture Documents

MT Report

Transféré par

BauyrzhanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MT Report

Transféré par

BauyrzhanDroits d'auteur :

Formats disponibles

MT Report

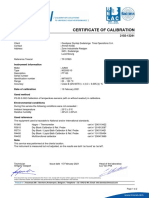

CI568932-31871.doc

Conveyed confidentially as trade secret

MT Report Page 1/2

Period of exam. / Date Technician (Init.) Certificate no. Assistant 1 (Init.) Cert. no. Assist. 1 Assistant 2 (Init.) Cert. no. Assist. 2

09.09.2010 Bogachenko 4321.MT.2/10 Krachun 3778.MT.2/09

Assistant 3 (Init.) Cert. no. Assist. 3 Assistant 4 (Init.) Cert. no. Assist. 4 Examination organization / Inspection authority

PE"DDP"

Client Contractor Location

Wadan Yards Okean 1.Zavodskay Sqyare.Mykolaiv.Ukraine 54050

Object Section ID-no. Drawing no. ECN. no.

door frame 177 1004720 30991

Examination procedure Acceptance criteria Technician equipment type Registrations no.

CI 568932-31871 CI 568932-31871 Parker 16596

Supplementary information (without liability)

Weld preparation Other Heat-treated Time of examination

X Y U V K I Fillet Yes No Hours after weld. 24

Welding process 121 131 135 136 141 Other

Man.elec. 111 Sub. arc Mic Mac Fluxcored wire TIG

Surface condition Reinforcement

Fine Smooth General Primer coated As welded Ground

Examination procedure Other

EN 1290 ASME V BS 6072

Current magnetizing Yoke Coil magnetizing Test bench Permanent magnet

Current Number of turns S = mm

Longit. Amp.

S max.= mm Type DA400S

AC = Lifting Power:

Circular N S

I eff.= Amp. S S max.=165mm S

S Amp. x turns N

S DC I = Amp

Reg. No. Reg. No. 16596 Reg. No. Reg. No.

Type of prods Other Arc burns ground out De-magnetized after examination

Steel Copper Yes No Yes No

Fluid Background

White Ground Non-treated

Magnetic ink Water/black Kerosine/black Water/fluo. Kerosine//fluo.

Field strength <5 kA/m Other Lighting

Oerstedm. value Oe White UV-lamp No.

Magnetized for Object temperature Other

Longitudinal indications Transverse indications Indications in any direction Ambient

Acceptance criteria Incl. visual exam. Other

EN 1291, level 2x EN ISO 5817, Weld class

Extent of examination

100 % of weld no.1 100 % of weld no.2

100 % of weld no3. 100 % of weld no.4

100 % of weld no.5 100 % of weld no.6

100 % of weld no.7 100 % of weld no.8

100 % of all non-specified welding

Results of examination

accepteble

Repairs Enclosures Technician (Date/Signature)

09.09.2010

Marked on object Marked on sketch Checked after grinding 1 sheets

Bogachenko

Siemens Wind Power A/S 1/1

© All Rights Reserved 2006

Vous aimerez peut-être aussi

- ASNT Magnetic Particle Testing Level - II Questions and AnswersDocument6 pagesASNT Magnetic Particle Testing Level - II Questions and AnswersBauyrzhan100% (5)

- 8.1 ASNT Ultrasonic Testing Level - II Questions and AnswersDocument6 pages8.1 ASNT Ultrasonic Testing Level - II Questions and AnswersGururaja G86% (21)

- Electronic Ticket Receipt, November 03 For MR ARAYA GEBRESLASSIE BERHEDocument2 pagesElectronic Ticket Receipt, November 03 For MR ARAYA GEBRESLASSIE BERHEMengstu Gebreslassie50% (2)

- Non-Destructive Testing TechniquesDocument145 pagesNon-Destructive Testing TechniquesAli R.M89% (9)

- Norsok C 001 2015Document60 pagesNorsok C 001 2015Bauyrzhan100% (1)

- Norsok C 001 2015Document60 pagesNorsok C 001 2015Bauyrzhan100% (1)

- Shades of GreyDocument1 pageShades of GreyNatraji0% (1)

- Ams4945h 2020Document10 pagesAms4945h 2020BauyrzhanPas encore d'évaluation

- Ultrasonic Test Report: Testing TechniqueDocument2 pagesUltrasonic Test Report: Testing TechniqueMd RizwanPas encore d'évaluation

- Pmi Solution Report FormDocument1 pagePmi Solution Report FormqaqcpipemanPas encore d'évaluation

- Fir-001 - 10 03 18Document1 pageFir-001 - 10 03 18Kartik SolankiPas encore d'évaluation

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirPas encore d'évaluation

- Ams4943l 2020Document8 pagesAms4943l 2020BauyrzhanPas encore d'évaluation

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuPas encore d'évaluation

- Magnetic Particle Examination: DateDocument2 pagesMagnetic Particle Examination: DateAbhishek SharmaPas encore d'évaluation

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Document22 pagesP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonPas encore d'évaluation

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASIPas encore d'évaluation

- Ultrasonic Test Report SummaryDocument6 pagesUltrasonic Test Report SummaryGibson FisherPas encore d'évaluation

- NDT Level 2Document4 pagesNDT Level 2sateeshPas encore d'évaluation

- Hardness TestDocument117 pagesHardness TestMohdHuzairiRusliPas encore d'évaluation

- Radiography Acceptance Criteria As Per B 31.3Document2 pagesRadiography Acceptance Criteria As Per B 31.3mohamedPas encore d'évaluation

- Visual inspection report templateDocument1 pageVisual inspection report templateAbhishek SharmaPas encore d'évaluation

- Magnetic Particle Testing ReporDocument2 pagesMagnetic Particle Testing ReporGabriela MotaPas encore d'évaluation

- Report - Form - MT - PT - RT - Ut - Cal - 2015Document9 pagesReport - Form - MT - PT - RT - Ut - Cal - 2015YuwantoniAlPas encore d'évaluation

- Epz NCS RT 02Document1 pageEpz NCS RT 02Mijanur RahmanPas encore d'évaluation

- Patels Radiography Services RT ReportDocument1 pagePatels Radiography Services RT ReportRavi patelPas encore d'évaluation

- Ultrasonic Test SystemDocument4 pagesUltrasonic Test SystemsaravananjaiPas encore d'évaluation

- MPI Cal Cert-002 SampleDocument1 pageMPI Cal Cert-002 SampleJohn OLiverPas encore d'évaluation

- Manoj Kumar QC (C.V)Document4 pagesManoj Kumar QC (C.V)HeartyscorpionPas encore d'évaluation

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putraPas encore d'évaluation

- Tankguard Storage: Technical Data SheetDocument5 pagesTankguard Storage: Technical Data SheetEngTamerPas encore d'évaluation

- ET NDT Sample Test Report FormatDocument1 pageET NDT Sample Test Report Formatanas dwiPas encore d'évaluation

- NDT Application FormDocument4 pagesNDT Application FormAhmed Shaban KotbPas encore d'évaluation

- Dimensional Check-Form 3TDocument3 pagesDimensional Check-Form 3Tlempeng durianPas encore d'évaluation

- 2013-11-030M PT AHUDocument11 pages2013-11-030M PT AHUEdison WalitPas encore d'évaluation

- D-p5-Bv-pd-006 - Tofd, Issue 01, Rev 00 - Time of Flight Diffraction InspectionDocument33 pagesD-p5-Bv-pd-006 - Tofd, Issue 01, Rev 00 - Time of Flight Diffraction InspectionThinh NguyenPas encore d'évaluation

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahPas encore d'évaluation

- DMTA 20006 01EN - Rev - B COBRA - Scanner Users - Manual PDFDocument80 pagesDMTA 20006 01EN - Rev - B COBRA - Scanner Users - Manual PDFDanny Milton Silva VasquezPas encore d'évaluation

- SSIS Visual Examination Report FormatDocument1 pageSSIS Visual Examination Report FormatSalman KhanPas encore d'évaluation

- 05 Ultrasonic Test Procedure 500405Document11 pages05 Ultrasonic Test Procedure 500405Sefa KasapogluPas encore d'évaluation

- LPT As Per Asme & IsoDocument2 pagesLPT As Per Asme & IsosbmmlaPas encore d'évaluation

- Painting Report - C1742 & 43 PDFDocument1 pagePainting Report - C1742 & 43 PDFRyan Flores100% (1)

- Form PAUTDocument2 pagesForm PAUTLuong Ho Vu100% (1)

- Updated Asnt-Ndt Level - II in RT Ut MT PTDocument4 pagesUpdated Asnt-Ndt Level - II in RT Ut MT PTJason RogersPas encore d'évaluation

- Magnetic Particle Examination of WeldsDocument4 pagesMagnetic Particle Examination of WeldsshruthiPas encore d'évaluation

- Liquid Penetrant (Lev1el-I-level - II''Document100 pagesLiquid Penetrant (Lev1el-I-level - II''Chandresh100% (1)

- Cswip 3.0 ReportingDocument32 pagesCswip 3.0 ReportingAvijit DebnathPas encore d'évaluation

- Radiographic Report SummaryDocument4 pagesRadiographic Report SummaryTuấn ĐậuPas encore d'évaluation

- Epoxy Coating Batch Test CertificateDocument1 pageEpoxy Coating Batch Test CertificateTarun KaushalPas encore d'évaluation

- Leak Test Procedure for Atmospheric VesselDocument9 pagesLeak Test Procedure for Atmospheric VesselRicardo NapitupuluPas encore d'évaluation

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MP100% (1)

- International Limited: Certificate of Visual Examination and MpiDocument2 pagesInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaPas encore d'évaluation

- Welding Inspection Consumables PDFDocument28 pagesWelding Inspection Consumables PDFJoseph PeterPas encore d'évaluation

- Adore Electrode BookletDocument207 pagesAdore Electrode BookletKrisna SinghPas encore d'évaluation

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibPas encore d'évaluation

- 096 SelDocument3 pages096 SelPiyush SrivastavaPas encore d'évaluation

- Senior Welding Inspector NDT Report ChecklistDocument4 pagesSenior Welding Inspector NDT Report ChecklistAdil HasanovPas encore d'évaluation

- Report-1683-1 B1 25mm 14 10 2020Document7 pagesReport-1683-1 B1 25mm 14 10 2020sakthi velPas encore d'évaluation

- Ultrasonic Report: Probe Details and Position (Fig 1)Document2 pagesUltrasonic Report: Probe Details and Position (Fig 1)BALA GANESH100% (1)

- Paut Inspection Report: Client Rfi NoDocument6 pagesPaut Inspection Report: Client Rfi NoThiru Maran MasterscanPas encore d'évaluation

- Calibration Certificate for PT100 Temperature SensorDocument2 pagesCalibration Certificate for PT100 Temperature SensorSazzath HossainPas encore d'évaluation

- DPI (Dye Penetrant Inspection) : Main PurposedDocument9 pagesDPI (Dye Penetrant Inspection) : Main PurposedAgung Prastyo WibowoPas encore d'évaluation

- PA Probe Catalog en 201308Document24 pagesPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaPas encore d'évaluation

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 pagesVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTAPas encore d'évaluation

- Form UT, MT, PT, RTDocument5 pagesForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Nde ProceduresDocument66 pagesNde Proceduressoumaya yahyaouiPas encore d'évaluation

- Austenitic Weld Inspection Solution OverviewDocument17 pagesAustenitic Weld Inspection Solution OverviewRupam BaruahPas encore d'évaluation

- Welder Qualification ReportDocument2 pagesWelder Qualification ReportSyed Mahmud Habibur RahmanPas encore d'évaluation

- Industrial radiography A Complete Guide - 2019 EditionD'EverandIndustrial radiography A Complete Guide - 2019 EditionPas encore d'évaluation

- Phased Array Ultrasonic Testing ProcedureDocument43 pagesPhased Array Ultrasonic Testing ProcedureBauyrzhanPas encore d'évaluation

- Ultrasonic Testing of Metal Pipe and Tubing: Standard Practice ForDocument11 pagesUltrasonic Testing of Metal Pipe and Tubing: Standard Practice ForBauyrzhanPas encore d'évaluation

- Development of gamma exposure chart for Selenium-75 industrial radiographyDocument8 pagesDevelopment of gamma exposure chart for Selenium-75 industrial radiographyNidharshan Selvaraj RPas encore d'évaluation

- 1-Емкость AL SHIARWI - распознанDocument2 pages1-Емкость AL SHIARWI - распознанBauyrzhanPas encore d'évaluation

- VS70Document1 pageVS70BauyrzhanPas encore d'évaluation

- Sentinel Collim Rev1.2 CompressedDocument2 pagesSentinel Collim Rev1.2 CompressedBauyrzhanPas encore d'évaluation

- Ultrasonic Testing of Metal Pipe and Tubing: Standard Practice ForDocument11 pagesUltrasonic Testing of Metal Pipe and Tubing: Standard Practice ForBauyrzhanPas encore d'évaluation

- скачатьDocument1 pageскачатьBauyrzhanPas encore d'évaluation

- ChewlogDocument1 pageChewlogBauyrzhanPas encore d'évaluation

- 2Document2 pages2BauyrzhanPas encore d'évaluation

- Icr-Pr-18 NDT ProcedureDocument4 pagesIcr-Pr-18 NDT ProcedureBauyrzhanPas encore d'évaluation

- (Draft) KPC-Shutdown (01.04.16)Document2 pages(Draft) KPC-Shutdown (01.04.16)BauyrzhanPas encore d'évaluation

- What Are Ultrasonic Phased ArraysDocument4 pagesWhat Are Ultrasonic Phased ArraysAshadi Angka NolPas encore d'évaluation

- Compressionwaves PDFDocument5 pagesCompressionwaves PDFRakesh Kumar MundaPas encore d'évaluation

- UNIT 2 ShutdownDocument2 pagesUNIT 2 ShutdownBauyrzhanPas encore d'évaluation

- ASTM Norms Commonly UsedDocument1 pageASTM Norms Commonly UsedBauyrzhanPas encore d'évaluation

- DefectsDocument11 pagesDefectsBauyrzhanPas encore d'évaluation

- ASTM Norms Commonly UsedDocument1 pageASTM Norms Commonly UsedBauyrzhanPas encore d'évaluation

- AnnexD - NDE Techs ComparedDocument56 pagesAnnexD - NDE Techs ComparedKir VinPas encore d'évaluation

- 7.2 Radiaographic Testing ProcedureDocument14 pages7.2 Radiaographic Testing ProcedureAhmed Shaban KotbPas encore d'évaluation

- DownloadDocument3 pagesDownloadBauyrzhanPas encore d'évaluation

- Battery CR 2032Document1 pageBattery CR 2032BauyrzhanPas encore d'évaluation

- MC 8051Document85 pagesMC 8051Sonu SatishPas encore d'évaluation

- Fundamentals 2014Document959 pagesFundamentals 2014Angelo Vittorio VettorazziPas encore d'évaluation

- CV Summary for IT Position Seeking Recent GraduateDocument5 pagesCV Summary for IT Position Seeking Recent Graduateeang barangPas encore d'évaluation

- PDF Saa6d140e 2 Seriespdf CompressDocument8 pagesPDF Saa6d140e 2 Seriespdf CompressNathawatPas encore d'évaluation

- Air Pak SCBA Ordering Specifications (HS 6701)Document8 pagesAir Pak SCBA Ordering Specifications (HS 6701)QHSE ManagerPas encore d'évaluation

- Artikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsDocument9 pagesArtikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsJohny DoelPas encore d'évaluation

- DC Motor Direction Control ReportDocument6 pagesDC Motor Direction Control ReportEngr Farhanullah SarkiPas encore d'évaluation

- Assessment of Groundwater Quality Using GIS - A Case Study of The Churu District of RajasthanDocument9 pagesAssessment of Groundwater Quality Using GIS - A Case Study of The Churu District of RajasthanSivaShankarPas encore d'évaluation

- Form 1 Lesson 88 SpeakingDocument2 pagesForm 1 Lesson 88 Speakinga multifandom fangirlPas encore d'évaluation

- Conceptual Design Deliverables Latest Rev2Document14 pagesConceptual Design Deliverables Latest Rev2dhanu_lagwankarPas encore d'évaluation

- Hughes Brothers PDFDocument52 pagesHughes Brothers PDFJavier MaldonadoPas encore d'évaluation

- JonWeisseBUS450 04 HPDocument3 pagesJonWeisseBUS450 04 HPJonathan WeissePas encore d'évaluation

- Sample Cover Letter: No Work ExperienceDocument4 pagesSample Cover Letter: No Work ExperienceMaya ElvisaPas encore d'évaluation

- Grade 6 Science PuzzleDocument4 pagesGrade 6 Science Puzzlemargie riveraPas encore d'évaluation

- Hublit Limphaire Leaflet India PDFDocument2 pagesHublit Limphaire Leaflet India PDFAkshay RaiPas encore d'évaluation

- Gpa 2145Document15 pagesGpa 2145Sergio David Ruiz100% (1)

- Learning One-to-One - Book ReviewDocument3 pagesLearning One-to-One - Book Reviewwhistleblower100% (1)

- Mid Exam Odd Semester Academic Year 2021/2022 Study Program Management Faculty of Business Universitas Multimedia NusantaraDocument9 pagesMid Exam Odd Semester Academic Year 2021/2022 Study Program Management Faculty of Business Universitas Multimedia NusantaraaekimPas encore d'évaluation

- OFFICE 365 PROXY GUIDEDocument4 pagesOFFICE 365 PROXY GUIDErossloveladyPas encore d'évaluation

- Amptec Issue 7Document8 pagesAmptec Issue 7Linda Turner-BoothPas encore d'évaluation

- Factors Effecting PerformanceDocument47 pagesFactors Effecting Performancebembie83Pas encore d'évaluation

- Breaking Water Protection Paradigms: RTM Composite DomesDocument52 pagesBreaking Water Protection Paradigms: RTM Composite DomesaerostressPas encore d'évaluation

- Updated After 11th BoS Course Curriculum - B.tech CSEDocument120 pagesUpdated After 11th BoS Course Curriculum - B.tech CSEAnonymous 9etQKwWPas encore d'évaluation

- Allcargo Corporate BrochureDocument12 pagesAllcargo Corporate BrochureallinonecargologisticsPas encore d'évaluation

- Budget EstimatesDocument251 pagesBudget EstimatesMUHAMMAD QASIM RAJPARPas encore d'évaluation

- August 2017Document72 pagesAugust 2017Treatment Plant Operator MagazinePas encore d'évaluation

- PV Design WorksheetDocument4 pagesPV Design WorksheetLarry Walker II100% (1)