Académique Documents

Professionnel Documents

Culture Documents

VT Report

Transféré par

Bauyrzhan0 évaluation0% ont trouvé ce document utile (0 vote)

181 vues1 pageTitre original

VT report.doc

Copyright

© © All Rights Reserved

Formats disponibles

DOC, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

181 vues1 pageVT Report

Transféré par

BauyrzhanDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

VT Report

CI569832-31871.doc

Conveyed confidentially as trade secret

VT Report Page 1/2

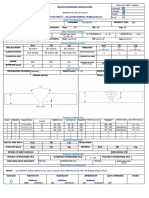

Period of examination / Date Technician (Init.) Certificate no. Assistant 1 (Init.) Cert. no. Assisitant. 1 Assistant 2 (Init.) Cert. no. Assistant. 2

28.10.2010 Gaivoronskiy 4355.VT.2/10

Assistant 3 (Init.) Cert. no. Assistant. 3 Assistant 4 (Init.) Cert. no. Assistant. 4 Examination organization / Inspection authority

PE "DDP"

Client Contractor Location

Wadan Yards Okean 1.Zavodskay Sgyare.Mykolaiv.Ukraine 54050

Object Section ID-no. Drawing no. ECN. no.

door frame 177R 1004720 30991

Examination procedure Acceptance criteria Material.

CI 568932-31871 CI 568932-31871 Steel

Supplementary information

Weld preparation Time of examination Heat-treated Other

X Y U V K I Fillet Hours after weld 24 Yes No

Welding Process 121 131 135 136 141 Other

Man.elec. 111 Sup. arc. Mic Mag Fluxcored wire TIG

Surface condition

Ground Smooth Coarse

Technique Other

EN 970

Aids

Ruler Tape measure Caliper Feeler gauge Weld gauge Contour gauge Material for replica

Quality requirements (Standard) for finished welds Other standards

ISO EN 5817 level B

Time of examination Extent of examination

Before welding During welding After welding 100 % Random

Extent of examination

100% of weld no. 1 100% of weld no.2

100% of weld no. 3 100% of weld no.4

100% of weld no. 5 100% of weld no.6

100% of weld no. 7 100% of weld no.8

100%of all non-specified welding

Results of examination

acceptable

Repairs Enclosures Technician (Date/Signature)

Marked on object Marked on sketch Checked after grinding 1 sheets Gaivoronskiy

09.09.2010

Siemens Wind Power A/S 1/1

© All Rights Reserved 2006

Vous aimerez peut-être aussi

- MT ReportDocument1 pageMT ReportBauyrzhanPas encore d'évaluation

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 pageJNK Heaters Co - LTD: Ferrite Test ReportUzorPas encore d'évaluation

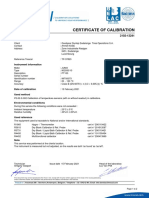

- Calibration Certificate for PT100 Temperature SensorDocument2 pagesCalibration Certificate for PT100 Temperature SensorSazzath HossainPas encore d'évaluation

- Elcometer 345 Coating Thickness Gauge - Datasheet PDFDocument1 pageElcometer 345 Coating Thickness Gauge - Datasheet PDFVallik TadPas encore d'évaluation

- VT Procedure: 1 - PurposeDocument4 pagesVT Procedure: 1 - PurposeElvin Menlibai100% (1)

- Vacuum Box Test PDFDocument3 pagesVacuum Box Test PDFWilson RodriguezPas encore d'évaluation

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6Pas encore d'évaluation

- PT ProcedureDocument18 pagesPT Procedureاباذر الدراجيPas encore d'évaluation

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 pagesVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTAPas encore d'évaluation

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriPas encore d'évaluation

- Trinity Transformer PVT LTD: Liquidpenetrant Examination ReportDocument2 pagesTrinity Transformer PVT LTD: Liquidpenetrant Examination ReportipraoPas encore d'évaluation

- Visual Inspection Checklist PipingDocument2 pagesVisual Inspection Checklist PipingshifaPas encore d'évaluation

- Visual Inspection Procedure for Piping WeldsDocument6 pagesVisual Inspection Procedure for Piping WeldsPand AemonaEonPas encore d'évaluation

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH APas encore d'évaluation

- VACCUM BOX Test ReportDocument1 pageVACCUM BOX Test ReportYu Haiyue100% (1)

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruPas encore d'évaluation

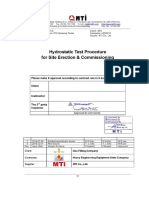

- Hydrostatic Test Procedure For Site & Commissioning HT-031-R1Document7 pagesHydrostatic Test Procedure For Site & Commissioning HT-031-R1Hatem Ragab100% (1)

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonPas encore d'évaluation

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiPas encore d'évaluation

- Liquid Penetrant Examination Report: PO No.&Document2 pagesLiquid Penetrant Examination Report: PO No.&Samir Chaudhary100% (2)

- Customer Report Dimensions Visual InspectionDocument9 pagesCustomer Report Dimensions Visual Inspectioniftekhar ahmedPas encore d'évaluation

- UT Personnel Mockup ProcedureDocument19 pagesUT Personnel Mockup ProcedureIksan Adityo Mulyo100% (1)

- Magnetic Particle Testing Report SummaryDocument4 pagesMagnetic Particle Testing Report Summarypankaj ranaPas encore d'évaluation

- Fm-Ti-050 - Rev.0 Inspection Report Ultrasonic Examination - Eff.170107Document1 pageFm-Ti-050 - Rev.0 Inspection Report Ultrasonic Examination - Eff.170107Jindarat KasemsooksakulPas encore d'évaluation

- Process Validation 1Document1 pageProcess Validation 1tayyabPas encore d'évaluation

- Weld Visual Report Rev.0Document1 pageWeld Visual Report Rev.0John TerryPas encore d'évaluation

- F07-Visual Inspection Report NEWDocument1 pageF07-Visual Inspection Report NEWmohd as shahiddin jafriPas encore d'évaluation

- Long Seam Inspection ProcedureDocument4 pagesLong Seam Inspection ProcedureDeepak100% (1)

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Document22 pagesP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonPas encore d'évaluation

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizPas encore d'évaluation

- Circularity Inspection Report: Shell Course (LW) CW CWDocument14 pagesCircularity Inspection Report: Shell Course (LW) CW CWaszlizaPas encore d'évaluation

- Magnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiDocument1 pageMagnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiMurugan RajaPas encore d'évaluation

- Mesuring Tape HE - mt.001Document2 pagesMesuring Tape HE - mt.001Chethan Nagaraju KumbarPas encore d'évaluation

- WELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Document65 pagesWELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Ethem Güngör100% (1)

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDocument2 pagesNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyPas encore d'évaluation

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliPas encore d'évaluation

- 1.request For Inspection (HEMT FO QC 01)Document1 page1.request For Inspection (HEMT FO QC 01)Balasai SabarinathPas encore d'évaluation

- Senior Welding Inspector NDT Report ChecklistDocument4 pagesSenior Welding Inspector NDT Report ChecklistAdil HasanovPas encore d'évaluation

- QA-R-05 - Weld Traceability RecordDocument1 pageQA-R-05 - Weld Traceability RecordvinothPas encore d'évaluation

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesPas encore d'évaluation

- Magnetic Particle Test Quality Control and Inspection Report FormDocument1 pageMagnetic Particle Test Quality Control and Inspection Report FormRicardo MachadoPas encore d'évaluation

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASIPas encore d'évaluation

- MPT Report FormatDocument1 pageMPT Report FormatRoshan ThomasPas encore d'évaluation

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putraPas encore d'évaluation

- Ea 4 15 G Rev01 May 2015 Rev PDFDocument24 pagesEa 4 15 G Rev01 May 2015 Rev PDFandrej_voloscuk13100% (1)

- 12 MT ProcedureDocument17 pages12 MT ProcedureThân KhaPas encore d'évaluation

- Welder Qualification Test RequestDocument1 pageWelder Qualification Test RequestgoguluPas encore d'évaluation

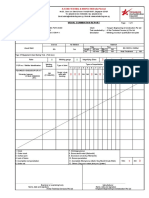

- Wash Tank Repair & Improvement Minas and Petapahan ProjectDocument9 pagesWash Tank Repair & Improvement Minas and Petapahan ProjectEndika Alfan100% (2)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387Pas encore d'évaluation

- International Limited: Certificate of Visual Examination and MpiDocument2 pagesInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaPas encore d'évaluation

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiPas encore d'évaluation

- Industrial radiography A Complete Guide - 2019 EditionD'EverandIndustrial radiography A Complete Guide - 2019 EditionPas encore d'évaluation

- Non Destructive Testing of Primary Steel Components, Tower Sections and Embedment's For Vestas Wind TurbinesDocument5 pagesNon Destructive Testing of Primary Steel Components, Tower Sections and Embedment's For Vestas Wind TurbinesDavisTranPas encore d'évaluation

- Bis-Dk-Ut 1152 - 1200-24-VC01Document6 pagesBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicPas encore d'évaluation

- ITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFDocument3 pagesITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFMuhammad YahdimanPas encore d'évaluation

- ITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFDocument3 pagesITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFMuhammad YahdimanPas encore d'évaluation

- Visual Examination ReportDocument47 pagesVisual Examination ReportalouisPas encore d'évaluation

- TSH Ip 53.0070 - 01Document4 pagesTSH Ip 53.0070 - 01Cong BuiPas encore d'évaluation

- Part 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksDocument5 pagesPart 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksErickson Malicsi100% (2)

- Ultrasonic Testing of Metal Pipe and Tubing: Standard Practice ForDocument11 pagesUltrasonic Testing of Metal Pipe and Tubing: Standard Practice ForBauyrzhanPas encore d'évaluation

- Phased Array Ultrasonic Testing ProcedureDocument43 pagesPhased Array Ultrasonic Testing ProcedureBauyrzhanPas encore d'évaluation

- VS70Document1 pageVS70BauyrzhanPas encore d'évaluation

- Non-Destructive Testing TechniquesDocument145 pagesNon-Destructive Testing TechniquesAli R.M89% (9)

- Sentinel Collim Rev1.2 CompressedDocument2 pagesSentinel Collim Rev1.2 CompressedBauyrzhanPas encore d'évaluation

- Norsok C 001 2015Document60 pagesNorsok C 001 2015Bauyrzhan100% (1)

- Ultrasonic Testing of Metal Pipe and Tubing: Standard Practice ForDocument11 pagesUltrasonic Testing of Metal Pipe and Tubing: Standard Practice ForBauyrzhanPas encore d'évaluation

- Development of gamma exposure chart for Selenium-75 industrial radiographyDocument8 pagesDevelopment of gamma exposure chart for Selenium-75 industrial radiographyNidharshan Selvaraj RPas encore d'évaluation

- Norsok C 001 2015Document60 pagesNorsok C 001 2015Bauyrzhan100% (1)

- Icr-Pr-18 NDT ProcedureDocument4 pagesIcr-Pr-18 NDT ProcedureBauyrzhanPas encore d'évaluation

- скачатьDocument1 pageскачатьBauyrzhanPas encore d'évaluation

- Shades of GreyDocument1 pageShades of GreyNatraji0% (1)

- 2Document2 pages2BauyrzhanPas encore d'évaluation

- 1-Емкость AL SHIARWI - распознанDocument2 pages1-Емкость AL SHIARWI - распознанBauyrzhanPas encore d'évaluation

- What Are Ultrasonic Phased ArraysDocument4 pagesWhat Are Ultrasonic Phased ArraysAshadi Angka NolPas encore d'évaluation

- ChewlogDocument1 pageChewlogBauyrzhanPas encore d'évaluation

- (Draft) KPC-Shutdown (01.04.16)Document2 pages(Draft) KPC-Shutdown (01.04.16)BauyrzhanPas encore d'évaluation

- Battery CR 2032Document1 pageBattery CR 2032BauyrzhanPas encore d'évaluation

- Ams4943l 2020Document8 pagesAms4943l 2020BauyrzhanPas encore d'évaluation

- ASTM Norms Commonly UsedDocument1 pageASTM Norms Commonly UsedBauyrzhanPas encore d'évaluation

- Compressionwaves PDFDocument5 pagesCompressionwaves PDFRakesh Kumar MundaPas encore d'évaluation

- Ams4945h 2020Document10 pagesAms4945h 2020BauyrzhanPas encore d'évaluation

- UNIT 2 ShutdownDocument2 pagesUNIT 2 ShutdownBauyrzhanPas encore d'évaluation

- ASTM Norms Commonly UsedDocument1 pageASTM Norms Commonly UsedBauyrzhanPas encore d'évaluation

- AnnexD - NDE Techs ComparedDocument56 pagesAnnexD - NDE Techs ComparedKir VinPas encore d'évaluation

- DefectsDocument11 pagesDefectsBauyrzhanPas encore d'évaluation

- DownloadDocument3 pagesDownloadBauyrzhanPas encore d'évaluation

- ASNT Magnetic Particle Testing Level - II Questions and AnswersDocument6 pagesASNT Magnetic Particle Testing Level - II Questions and AnswersBauyrzhan100% (5)

- 7.2 Radiaographic Testing ProcedureDocument14 pages7.2 Radiaographic Testing ProcedureAhmed Shaban KotbPas encore d'évaluation

- 8.1 ASNT Ultrasonic Testing Level - II Questions and AnswersDocument6 pages8.1 ASNT Ultrasonic Testing Level - II Questions and AnswersGururaja G86% (21)

- Grammar Worksheet: If You Turn Off The Lights, You Will Save EnergyDocument2 pagesGrammar Worksheet: If You Turn Off The Lights, You Will Save EnergybkksmkturenPas encore d'évaluation

- SY35U PART FILTER PERIODICAL SERVICEDocument2 pagesSY35U PART FILTER PERIODICAL SERVICEIman SantosaPas encore d'évaluation

- Dts-Lesson PlanDocument3 pagesDts-Lesson Plansujithaa13Pas encore d'évaluation

- Dies and Inserts Catalog 2018Document36 pagesDies and Inserts Catalog 2018Ahmed MohamedPas encore d'évaluation

- Lofa El240g1hsDocument2 pagesLofa El240g1hsDouglas MPas encore d'évaluation

- Painting Specification for Aegean Refinery ProjectDocument18 pagesPainting Specification for Aegean Refinery Projectraluca_19735597Pas encore d'évaluation

- Ingersoll Rand Dryer O&M Manual 80442833-EnDocument48 pagesIngersoll Rand Dryer O&M Manual 80442833-EnBill BrighamPas encore d'évaluation

- General Issues and The Recommended StandardsDocument60 pagesGeneral Issues and The Recommended StandardsTomislav RogićPas encore d'évaluation

- Definition of Tunnel BoringDocument13 pagesDefinition of Tunnel BoringUji FauziahPas encore d'évaluation

- Stress Corrosion Cracking of ASTM A517 Steel in Liquid Ammonia - Environmental FactorsDocument11 pagesStress Corrosion Cracking of ASTM A517 Steel in Liquid Ammonia - Environmental FactorsEzzah HanifPas encore d'évaluation

- Tantalum Niobium EtchantsDocument2 pagesTantalum Niobium EtchantsmitgraPas encore d'évaluation

- Consolidated 1811 SeriesDocument16 pagesConsolidated 1811 Seriesivan_fuenzalida_1Pas encore d'évaluation

- Technical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHDocument77 pagesTechnical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHpht12345Pas encore d'évaluation

- Madpenguin - Ca-Tutorial Use An Old Inkjet Printer To Learn Servo Motor Control With EMC2 Part 2Document7 pagesMadpenguin - Ca-Tutorial Use An Old Inkjet Printer To Learn Servo Motor Control With EMC2 Part 2Rudi AribowoPas encore d'évaluation

- PN Infosheet Compressors K-Series en May18 LQDocument1 pagePN Infosheet Compressors K-Series en May18 LQJan HendriksPas encore d'évaluation

- Chemistry ProjectDocument16 pagesChemistry Projectgaganshishodia2Pas encore d'évaluation

- A815 PDFDocument8 pagesA815 PDFExport priminoxPas encore d'évaluation

- Ten Points For Safe LiftDocument8 pagesTen Points For Safe LifthazopmanPas encore d'évaluation

- EPC Contractor ListDocument20 pagesEPC Contractor ListAamir Shahzad71% (7)

- A Review On Rubber Compound Mixing in Banbury Mixer at Tire Industries-864 PDFDocument4 pagesA Review On Rubber Compound Mixing in Banbury Mixer at Tire Industries-864 PDFJin HernPas encore d'évaluation

- Chlorine Dioxide Generator Systems: Capacity OverviewDocument2 pagesChlorine Dioxide Generator Systems: Capacity OverviewOchoa Para La BandaPas encore d'évaluation

- AP Chem Test - Chapter 10,11,13 - Gases, Solutions, Solids, Liquids, Inter Forces (2010-2011)Document12 pagesAP Chem Test - Chapter 10,11,13 - Gases, Solutions, Solids, Liquids, Inter Forces (2010-2011)dlloyd63050% (2)

- 8000series Tech Datasheet 2018Document3 pages8000series Tech Datasheet 2018lucky414Pas encore d'évaluation

- IS-216 Queens Boiler Pit Leak RepairDocument8 pagesIS-216 Queens Boiler Pit Leak RepairShamsherHussainPas encore d'évaluation

- Pile Soil InteractionDocument250 pagesPile Soil Interactionnallay1705100% (3)

- Vitrified CBN Crankshaft Grinding WheelDocument18 pagesVitrified CBN Crankshaft Grinding WheelJulkar Nain ShakibPas encore d'évaluation

- MSDS Canada - ZRC Galvilite Galvanizing Repair CompoundDocument6 pagesMSDS Canada - ZRC Galvilite Galvanizing Repair CompoundRaymond LalumierePas encore d'évaluation

- ZF Astronic Bus Repair Manual Level 1-2-1337 751 101 2003Document8 pagesZF Astronic Bus Repair Manual Level 1-2-1337 751 101 2003Bette98% (48)

- Plasma arc cutting cost analysis and optimizationDocument5 pagesPlasma arc cutting cost analysis and optimizationLisandro GianottoPas encore d'évaluation

- Guide To ExtrusionDocument26 pagesGuide To ExtrusionThong Kin MunPas encore d'évaluation