Académique Documents

Professionnel Documents

Culture Documents

Ma 1C7-CX5 U

Transféré par

richintukTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ma 1C7-CX5 U

Transféré par

richintukDroits d'auteur :

Formats disponibles

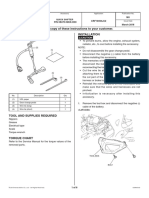

Installation Instruction

for 7/8” annular corrugation cable MA_1C7-CX5_U

60S1C7-CX5N1 60K1C7-CX5N1 53S1C7-CX5N1 53K1C7-CX5N1 64S1C7-CX5N1 64K1C7-CX5B1

Dieses Dokument ist urheberrechtlich geschützt ● This document is protected by copyright ● Rosenberger Hochfrequenztechnik GmbH & Co. KG

A) B)

SLT0002-000 SLT001-C05

Cut your cable with tool of picture A)

Attention: Do NOT use a saw for cutting

Straighten the first 200mm of the cable.

Connector components

Get a clean smooth cut.

99W057-000 SLZ0009-000

1) Insert the cable into the peeling tool on 2) Peel off the sheath until you can see the 3) Clear the cable off any removed sheath

the UniPrep tool. end of the outer conductor protruding residues.

slightly

4) Do not apply any pressure; use the 5) Hold the tool in the front and apply light 6) Using the peel insert on the UniPrep

tool's spring force to apply the tool pressure until the inner conductor is tool, peel the cable sheath back to

and rotate it all the way around the completely cut through. If this is the case, cut the previously formed sheath cut by

it around two to three times with pressure all

cable. turning it around the cable, and then

around, in order to carry out the mantle cut,

Only turn the tool until you have cut which is necessary for the correct plug remove any residues

through the outer conductor. installation.

7) Sheath cut 8) Optional: Daub grease onto the O-Ring. 9) Slide back nut onto the cable until it is

Sealing surface no nicks no deformed Be careful with daub it´s insanitary. completely seated. Please loose sealing

Control the cut surface and check the nut slightly (not complete) in order to

dimension easily install the back nut.

RF_35/06.10/1.0

Rosenberger Hochfrequenztechnik GmbH & Co. KG Page

Tel. : +49 8684 18-0

P.O.Box 1260 D-84526 Tittmoning Germany

Email : info@rosenberger.de

www.rosenberger.de 1/2

Installation Instruction

for 7/8” annular corrugation cable MA_1C7-CX5_U

Dieses Dokument ist urheberrechtlich geschützt ● This document is protected by copyright ● Rosenberger Hochfrequenztechnik GmbH & Co. KG

10) Put clamp ring onto outer conductor 11) Expanding outer conductor on one point 12) Start in expanded point and flare outer

with a screwdriver conductor with flaring tool by turning.

13) Proper shape after flaring operation.

14) Clean interface from flakes with brush 15) Clean the inner conductor with alcohol,

and alcohol. cleaning sticks and compressed air.

16) Put connector head by hand onto the 17) Tighten connector head and back nut 18) Tighten sealing nut with wrenches

cable and fix it with the back nut by with wrenches until stop. (Recommended torque: 18Nm)

hand. (Recommended torque: 40Nm)

Attention: Only turn the back nut, not the

connector head.

3D-Barcode for Video

19)

Link for Video: https://www.youtube.com/watch?v=yMMhysZPvB0

Draft Date Approved Date Rev. Engineering change number Name Date

RF_35/06.10/1.0

Fl. Öllerer 20.06.2018 R. Fang 20.06.2018 a00 18-0005 Fl. Öllerer 20.06.2018

Rosenberger Hochfrequenztechnik GmbH & Co. KG Page

Tel. : +49 8684 18-0

P.O.Box 1260 D-84526 Tittmoning Germany

Email : info@rosenberger.de

www.rosenberger.de 2/2

Vous aimerez peut-être aussi

- Ma 1C7-C03 UDocument2 pagesMa 1C7-C03 UrichintukPas encore d'évaluation

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsD'EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsÉvaluation : 5 sur 5 étoiles5/5 (1)

- TNC ConectorDocument2 pagesTNC ConectorLong ComtechPas encore d'évaluation

- Operating Instructions: Coring Stripping ToolDocument2 pagesOperating Instructions: Coring Stripping ToolCarlos CastilloPas encore d'évaluation

- Instruction: 1-1/4"波纹管电缆剥线工具使用说明 Manual of 1-1/4"R Ring Corrugated Cable Stripping ToolsDocument2 pagesInstruction: 1-1/4"波纹管电缆剥线工具使用说明 Manual of 1-1/4"R Ring Corrugated Cable Stripping ToolsrichintukPas encore d'évaluation

- Instruction: 1-1/4"波纹管电缆剥线工具使用说明 Manual of 1-1/4"R Ring Corrugated Cable Stripping ToolsDocument2 pagesInstruction: 1-1/4"波纹管电缆剥线工具使用说明 Manual of 1-1/4"R Ring Corrugated Cable Stripping ToolsrichintukPas encore d'évaluation

- AP-C40 (P) Series Instruction Manual: Digital Pressure Sensor With 2-Color DisplayDocument6 pagesAP-C40 (P) Series Instruction Manual: Digital Pressure Sensor With 2-Color DisplayHaris AhmadPas encore d'évaluation

- RVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsDocument12 pagesRVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsKip ClayPas encore d'évaluation

- MZ590803EX - Luz Interior PortonDocument11 pagesMZ590803EX - Luz Interior PortonPepe PerezPas encore d'évaluation

- Instruction C02 78.3Document4 pagesInstruction C02 78.3ВиталийКрутиковPas encore d'évaluation

- Apex'i AFC2 WiringDocument64 pagesApex'i AFC2 WiringDave_B0% (1)

- Ma 60W107-CX5Document2 pagesMa 60W107-CX5Hugo Arriagada AlbarranPas encore d'évaluation

- Connectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)Document2 pagesConnectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)ruizinho 1Pas encore d'évaluation

- Denon DN-S3500Document60 pagesDenon DN-S3500Tevel ComPas encore d'évaluation

- HTG GCU GS7d36sg Installation v12Document9 pagesHTG GCU GS7d36sg Installation v12Ioan Alexandru DragomirPas encore d'évaluation

- 200A 15 and 25Kv Class Deadbreak Elbow Installation & Operating InstructionsDocument4 pages200A 15 and 25Kv Class Deadbreak Elbow Installation & Operating InstructionsCesar PreciadoPas encore d'évaluation

- Ununtenna Assy 082217Document5 pagesUnuntenna Assy 082217kushanv1984Pas encore d'évaluation

- IM&OM - PC-AR - enDocument12 pagesIM&OM - PC-AR - enzodenapePas encore d'évaluation

- Installation Instruction No. 132101F/02.2008 Seik 14, 24, 34Document5 pagesInstallation Instruction No. 132101F/02.2008 Seik 14, 24, 34Sonia Noval LlorianPas encore d'évaluation

- YORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFDocument12 pagesYORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFFadul Chamie TietjenPas encore d'évaluation

- Service Manual: TV-FT2588Document21 pagesService Manual: TV-FT2588André LeftPas encore d'évaluation

- Manual Brother P-ToUCH PT-65Document4 pagesManual Brother P-ToUCH PT-65wiltrud.heinzelPas encore d'évaluation

- 9K688NDocument7 pages9K688NHelar Armejo VasquezPas encore d'évaluation

- Amp Netconnect Amp-Twist 6S SL Jacks 1711160-2 and 1711342-2Document2 pagesAmp Netconnect Amp-Twist 6S SL Jacks 1711160-2 and 1711342-28cesar5Pas encore d'évaluation

- Codan 463 Broadband Dipole Antenna Manual 15-00463-901L1Document11 pagesCodan 463 Broadband Dipole Antenna Manual 15-00463-901L1wipi12Pas encore d'évaluation

- Installation InstructionsDocument3 pagesInstallation InstructionsRosaLovaPas encore d'évaluation

- Instruction Sheet Lightcrimp Plus SC Simplex Connector Kits 5492643-, 6278079-, 6588291-, and 6693276-1Document17 pagesInstruction Sheet Lightcrimp Plus SC Simplex Connector Kits 5492643-, 6278079-, 6588291-, and 6693276-1Jose SenderoPas encore d'évaluation

- Aerial Closure Specification and Installation Manual: Ningbo Lonnet Telecommunications Equipment Co.,LtdDocument7 pagesAerial Closure Specification and Installation Manual: Ningbo Lonnet Telecommunications Equipment Co.,LtdKen NethPas encore d'évaluation

- SSC2802-TM Quick Installation Guide 01Document16 pagesSSC2802-TM Quick Installation Guide 01Samuel NesibuPas encore d'évaluation

- Ib63928c eDocument1 pageIb63928c eLucas PaulaPas encore d'évaluation

- Service Manual UN462A VA 492S VS 552 A S VS V UX552 S 5th EditionDocument1 120 pagesService Manual UN462A VA 492S VS 552 A S VS V UX552 S 5th EditionasreedharanPas encore d'évaluation

- Electronic Traffic Avoidance System D1RW3-W-0-FDocument21 pagesElectronic Traffic Avoidance System D1RW3-W-0-FGui233Pas encore d'évaluation

- Control Panel: Installation and User's Manual Installasjon Og Brukermanual InstallationsanleitungDocument16 pagesControl Panel: Installation and User's Manual Installasjon Og Brukermanual InstallationsanleitungAsep TatangPas encore d'évaluation

- Vibration Damper and Pulley - Remove - Pulley With Split Lock Rings (KENR6081-15)Document3 pagesVibration Damper and Pulley - Remove - Pulley With Split Lock Rings (KENR6081-15)Anderson Oliveira SilvaPas encore d'évaluation

- KM430TB - G - LCA 09 Revision 7 PDFDocument9 pagesKM430TB - G - LCA 09 Revision 7 PDFPaulo CardosoPas encore d'évaluation

- Kit de Terminacion TFT-150R-G TYCO ELECTRONICSDocument22 pagesKit de Terminacion TFT-150R-G TYCO ELECTRONICSWilbert ACPas encore d'évaluation

- Crimping Die Assemblies 58166 - For Shielded Data Link (SDL) ConnectorsDocument5 pagesCrimping Die Assemblies 58166 - For Shielded Data Link (SDL) ConnectorszavabossPas encore d'évaluation

- Fibra Optica - RS DataSheetDocument8 pagesFibra Optica - RS DataSheetAlex MoralesPas encore d'évaluation

- Icom MN-100 - L InstructionsDocument2 pagesIcom MN-100 - L Instructions_0379victor_100% (1)

- Conector LC Light Crimp - ManualDocument8 pagesConector LC Light Crimp - ManualTirso W. RodríguezPas encore d'évaluation

- Crimp Instructions For Amphenol BNC Plugs: Step 1 Step 2 Step 3Document1 pageCrimp Instructions For Amphenol BNC Plugs: Step 1 Step 2 Step 3KAZIMALI25Pas encore d'évaluation

- TV CN202Document33 pagesTV CN202jama35Pas encore d'évaluation

- 00E General ElectricalDocument12 pages00E General ElectricalMichael YazonPas encore d'évaluation

- Quick Shifter 08U70-MKK-D00Document6 pagesQuick Shifter 08U70-MKK-D00Anonymous 8w6kFviL100% (1)

- A82V 9580 00E - MK P06 - NC P03 - InstallDocument5 pagesA82V 9580 00E - MK P06 - NC P03 - InstallmfialloPas encore d'évaluation

- Electrical Services NotesDocument1 pageElectrical Services NotesDina ShresthaPas encore d'évaluation

- (K), (M), (P) 400TB/G: Separable Tee Connector - Type C InterfaceDocument9 pages(K), (M), (P) 400TB/G: Separable Tee Connector - Type C InterfaceJoão EwertonPas encore d'évaluation

- INSTRUCTION Heat Shrink Termination Single Core Cables MV HV 6.6kV 11kV 33kVDocument6 pagesINSTRUCTION Heat Shrink Termination Single Core Cables MV HV 6.6kV 11kV 33kVNemitha LakshanPas encore d'évaluation

- A6XX 9580 02E - MK 738 - FK 512 - InstallDocument6 pagesA6XX 9580 02E - MK 738 - FK 512 - InstallmfialloPas encore d'évaluation

- Light CrimpDocument19 pagesLight CrimpAlejandro PerezPas encore d'évaluation

- Service Manual: GR-D93US, GR-D94USDocument22 pagesService Manual: GR-D93US, GR-D94USsilictronicPas encore d'évaluation

- NKF-770 TD Exchange Procedure (JLN-550Ver1 0)Document11 pagesNKF-770 TD Exchange Procedure (JLN-550Ver1 0)Abel Francisco Villadiego CaballeroPas encore d'évaluation

- BQ5477Document10 pagesBQ5477Helar Armejo VasquezPas encore d'évaluation

- Instrucción de Armado Conector DIN y N Rosenberger MA - 1C7-C03Document2 pagesInstrucción de Armado Conector DIN y N Rosenberger MA - 1C7-C03Antonio Antilef100% (1)

- PPC Fsj4 & Scf12 Install InstDocument2 pagesPPC Fsj4 & Scf12 Install InstTower_DocPas encore d'évaluation

- Syringe Pump PG-901A Service Manual V1.0Document13 pagesSyringe Pump PG-901A Service Manual V1.0motaznasser117100% (1)

- RG6 Cable Mounting InstructionsDocument2 pagesRG6 Cable Mounting InstructionsStaffan FogelbergPas encore d'évaluation

- Brother P-Touch 1000 PDFDocument1 pageBrother P-Touch 1000 PDFJohnPas encore d'évaluation

- SauDocument2 pagesSaurichintukPas encore d'évaluation

- Remote Electrical Downtilt System Handbook: Installation Overview and Troubleshooting GuideDocument82 pagesRemote Electrical Downtilt System Handbook: Installation Overview and Troubleshooting GuiderichintukPas encore d'évaluation

- Satmotion Pocket PC User GuideDocument27 pagesSatmotion Pocket PC User GuiderichintukPas encore d'évaluation

- Ma 1C7-C08Document2 pagesMa 1C7-C08richintukPas encore d'évaluation

- Ma 60W110-C08 PDFDocument2 pagesMa 60W110-C08 PDFrichintukPas encore d'évaluation

- 85001-0293 - 8-Inch Speaker and Speaker-StrobeDocument6 pages85001-0293 - 8-Inch Speaker and Speaker-StrobemohammadPas encore d'évaluation

- Dodge Nitro KA - 2007 - Exterior Lights ElectricalDocument77 pagesDodge Nitro KA - 2007 - Exterior Lights ElectricaleephantomPas encore d'évaluation

- Repair Manual v4.3Document34 pagesRepair Manual v4.3ramon_portillo_nd_64100% (4)

- Wiring of Fluorescent Lamp With Light Socket: Experiment No. 4Document4 pagesWiring of Fluorescent Lamp With Light Socket: Experiment No. 4ASHIK NPas encore d'évaluation

- Reichert Phoroptor: User's GuideDocument40 pagesReichert Phoroptor: User's Guidepqwoeifjpakou134Pas encore d'évaluation

- Daewoo Service Manual Tail Lamp MatizDocument12 pagesDaewoo Service Manual Tail Lamp Matizjulio797Pas encore d'évaluation

- Bk-Tyre Pressure GaugeDocument2 pagesBk-Tyre Pressure Gaugepankaj doshiPas encore d'évaluation

- AMIAD Automatic Filters: "Ebs" FilterDocument21 pagesAMIAD Automatic Filters: "Ebs" FilterDENOUPas encore d'évaluation

- Manual DSR Pd170Document413 pagesManual DSR Pd170Javier Fernando Ayasta VenturaPas encore d'évaluation

- Pennbarry Fumex IOM v6Document22 pagesPennbarry Fumex IOM v6RanielPas encore d'évaluation

- Parts Lincoln Ranger 305D PDFDocument22 pagesParts Lincoln Ranger 305D PDFmekanicobucaro50% (2)

- Edwards Signaling ANS25MDR Data SheetDocument6 pagesEdwards Signaling ANS25MDR Data SheetJMAC SupplyPas encore d'évaluation

- How To Design A Flexible PCBDocument10 pagesHow To Design A Flexible PCBjackPas encore d'évaluation

- ABB1000 AntennaDocument16 pagesABB1000 Antennasv6jhaPas encore d'évaluation

- LT Tool Changer Brochure 2021Document20 pagesLT Tool Changer Brochure 2021Kien Nguyen TrungPas encore d'évaluation

- Vantage 300: Parts List ForDocument28 pagesVantage 300: Parts List ForGabriel AmorimPas encore d'évaluation

- DINSE Plugs Sockets USDocument4 pagesDINSE Plugs Sockets USFrancisco Mosquera LopezPas encore d'évaluation

- Cetop8 PDFDocument8 pagesCetop8 PDFZMCONTROLPas encore d'évaluation

- ECU Tuning Price List Eng 2017 (Rel F)Document6 pagesECU Tuning Price List Eng 2017 (Rel F)Alejandro BonillaPas encore d'évaluation

- 3600Document41 pages3600Ruben Eduardo Arismendi Argandoña100% (1)

- Is Hc1909flDocument1 pageIs Hc1909fldayshift5Pas encore d'évaluation

- Ac To DC Stator Conversion KTMDocument5 pagesAc To DC Stator Conversion KTMJim Stewart100% (1)

- E Hardware Manual V3iDocument50 pagesE Hardware Manual V3iSyamsiar AhmadPas encore d'évaluation

- 1z Ahu Diesel Tdi Servicing PDFDocument149 pages1z Ahu Diesel Tdi Servicing PDFuriiiPas encore d'évaluation

- DC30-035 - QT-711-EV Elevating Mobil Float-Top Table Operator Manual - Rev HDocument54 pagesDC30-035 - QT-711-EV Elevating Mobil Float-Top Table Operator Manual - Rev HJose QuiscaPas encore d'évaluation

- Biodex ManualDocument123 pagesBiodex ManualLusy Jimenez OrtizPas encore d'évaluation

- Human Factors Ergonomics Handbook For The Design For Ease of Maintenance PDFDocument231 pagesHuman Factors Ergonomics Handbook For The Design For Ease of Maintenance PDFRafael Rodriguez SPas encore d'évaluation

- TVL EIM11 Q1 Mod1 Prepare Electronic and Hydraulic Tools v3Document72 pagesTVL EIM11 Q1 Mod1 Prepare Electronic and Hydraulic Tools v3Ampolitoz100% (2)

- Perkins 2800 InstallationDocument46 pagesPerkins 2800 InstallationRobiPas encore d'évaluation

- Manual Axis AlnDocument61 pagesManual Axis AlnGustavo ZapataPas encore d'évaluation