Académique Documents

Professionnel Documents

Culture Documents

MQ-7 Ver1.3 - Manual PDF

Transféré par

bioineTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MQ-7 Ver1.3 - Manual PDF

Transféré par

bioineDroits d'auteur :

Formats disponibles

Toxic Gas Sensor

(Model:MQ-7)

Manual

Version: 1.3

Valid from: 2014-05-01

Zhengzhou Winsen Electronics Technology Co., Ltd

Statement

This manual copyright belongs to Zhengzhou Winsen Electronics Technology Co., LTD. Without the

written permission, any part of this manual shall not be copied, translated, stored in database or

retrieval system, also can’t spread through electronic, copying, record ways.

Thanks for purchasing our product. In order to let customers use it better and reduce the faults

caused by misuse, please read the manual carefully and operate it correctly in accordance with the

instructions. If users disobey the terms or remove, disassemble, change the components inside of

the sensor, we shall not be responsible for the loss.

The specific such as color, appearance, sizes &etc, please in kind prevail.

We are devoting ourselves to products development and technical innovation, so we reserve the

right to improve the products without notice. Please confirm it is the valid version before using this

manual. At the same time, users’ comments on optimized using way are welcome.

Please keep the manual properly, in order to get help if you have questions during the usage in the

future.

Zhengzhou Winsen Electronics Technology CO., LTD

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsensor.com

MQ-7 Semiconductor Sensor for Carbon Monoxide

Profile

Sensitive material of MQ-7 gas sensor is SnO2, which

with lower conductivity in clean air. It make detection

by method of cycle high and low temperature, and

detect CO at low temperature(heated by 1.5V).The

sensor’s conductivity gets higher along with the CO

gas concentration rising. At high temperature(heated

by 5.0V),it cleans the other gases adsorbed at low

temperature. Users can convert the change of

conductivity to correspond output signal of gas

concentration through a simple circuit.

Features

It has good sensitivity to carbon monoxide in wide range, and has advantages such as long lifespan, low

cost and simple drive circuit &etc.

Main Applications

It is widely used in domestic CO gas leakage alarm, industrial CO gas alarm and portable CO gas detector.

Technical Parameters Stable.1

Model MQ-7

Sensor Type Semiconductor

Standard Encapsulation Plastic cap

Target Gas carbon monoxide

Detection range 10~500ppm CO

Loop Voltage Vc ≤10V DC

5.0V±0.1V AC or DC(High tem.)

Heater Voltage VH

Standard Circuit 1.5V±0.1V AC or DC(Low tem.)

Conditions ,

60 S±1S(High tem.)

Heater Time TL

90 S±1S(Low tem.)

Load Resistance RL Adjustable

Heater Resistance RH 29Ω±3Ω(room tem.)

Sensor character Heater consumption PH ≤900mW

under standard Sensitivity S Rs(in air)/Rs(in 150ppm CO)≥5

test conditions Output Voltage Vs 2.5V~4.3V (in 150ppm CO)

Concentration Slope α ≤0.6(R300ppm/R50ppm CO)

Tem. Humidity 20℃±2℃;55%±5%RH

Vc:5.0V±0.1V;

Standard test

Standard test circuit VH(High tem.)

: 5.0V±0.1V;

conditions

VH (Low tem.)

: 1.5V±0.1V Fig1.Sensor Structure

Preheat time Over 48 hours Unit: mm

NOTE: Output voltage (Vs) is VRL in test environment.

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsensor.com

Basic Circuit

VH AC or DC

High voltage and

low voltage

can switch

Fig2. MQ-7 Test Circuit

Instructions: The above fig is the basic test circuit of MQ-7.The sensor requires two voltage inputs: heater

voltage (VH) and circuit voltage(VC). VH is used to supply standard working temperature to the sensor and it

can adopt DC or AC power. For this model sensor, VH should be at 1.5V±0.1V low voltage when detect CO

while should be at 5V±0.1V at non detection status(resuming period). VRL is the voltage of load

resistance RL which is in series with sensor. Vc supplies the detect voltage to load resistance RL and it

should adopts DC power.

Description of Sensor Characters

CO

Air

CH4

H2

Fig3.Typical Sensitivity Curve

Fig4.Typical temperature/humidity characteristics

The ordinate is resistance ratio of the sensor (Rs/R0), the

The ordinate is resistance ratio of the sensor (Rs/Rso).Rs

abscissa is concentration of gases. Rs means resistance in

means resistance of sensor in 150ppm CO gas under different

target gas with different concentration, R0 means

tem. and humidity. Rso means resistance of the sensor in

resistance of sensor in clean air. All tests are finished

150ppm CO gas under 20℃/55%RH.

under standard test conditions.

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsensor.com

150ppm CO gas (RL=4.7k)

Time(s)

Fig5.Sensitity Curve Fig6.Responce and Resume

Fig5 shows the VRL in CO gas with different concentration.

Fig5 shows the changing of VRL in the process of putting

The resistance load RL is 4.7 KΩ and the test is finished in

the sensor into target gas and removing it out.

standard test conditions.

150ppm CO gas (RL=4.7k)

Time(day)

Fig7.long-term Stability

Test is finished in standard test conditions, the abscissa is observing time and the ordinate is VRL.

Cautions

1 .Following conditions must be prohibited

1.1 Exposed to organic silicon steam

Sensing material will lose sensitivity and never recover if the sensor absorbs organic silicon steam.

Sensors must avoid exposing to silicon bond, fixature, silicon latex, putty or plastic contain silicon

environment.

1.2 High Corrosive gas

If the sensors are exposed to high concentration corrosive gas (such as H2S, SOX, Cl2, HCl etc.), it will

not only result in corrosion of sensors structure, also it cause sincere sensitivity attenuation.

1.3 Alkali, Alkali metals salt, halogen pollution

The sensors performance will be changed badly if sensors be sprayed polluted by alkali metals salt

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsensor.com

especially brine, or be exposed to halogen such as fluorine.

1.4 Touch water

Sensitivity of the sensors will be reduced when spattered or dipped in water.

1.5 Freezing

Do avoid icing on sensor’s surface, otherwise sensing material will be broken and lost sensitivity.

1.6 Applied higher voltage

Applied voltage on sensor should not be higher than stipulated value, even if the sensor is not

physically damaged or broken, it causes down-line or heater damaged, and bring on sensors’

sensitivity characteristic changed badly.

1.7 Voltage on wrong pins

For 6 pins sensor, Pin 2&5 is heating electrodes, Pin (1,3)/(4,6) are testing

electrodes (Pin 1 connects with Pin 3, while Pin 4 connects with Pin 6).If

apply voltage on Pin 1&3 or 4&6, it will make lead broken; and no signal

putout if apply on pins 2&4.

Fig8. Lead sketch

2 .Following conditions must be avoided

2.1 Water Condensation

Indoor conditions, slight water condensation will influence sensors’ performance lightly. However, if

water condensation on sensors surface and keep a certain period, sensors’ sensitive will be decreased.

2.2 Used in high gas concentration

No matter the sensor is electrified or not, if it is placed in high gas concentration for long time, sensors

characteristic will be affected. If lighter gas sprays the sensor, it will cause extremely damage.

2.3 Long time storage

The sensors resistance will drift reversibly if it’s stored for long time without electrify, this drift is

related with storage conditions. Sensors should be stored in airproof bag without volatile silicon

compound. For the sensors with long time storage but no electrify, they need long galvanical aging

time for stability before using. The suggested aging time as follow:

Stable2.

Storage Time Suggested aging time

Less than one month No less than 48 hours

1 ~ 6 months No less than 72 hours

More than six months No less than 168 hours

2.4 Long time exposed to adverse environment

No matter the sensors electrified or not, if exposed to adverse environment for long time, such as high

humidity, high temperature, or high pollution etc., it will influence the sensors’ performance badly.

2.5 Vibration

Continual vibration will result in sensors down-lead response then break. In transportation or

assembling line, pneumatic screwdriver/ultrasonic welding machine can lead this vibration.

2.6 Concussion

If sensors meet strong concussion, it may lead its lead wire disconnected.

2.7 Usage Conditions

2.7.1For sensor, handmade welding is optimal way. The welding conditions as follow:

Soldering flux: Rosin soldering flux contains least chlorine

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsensor.com

homothermal soldering iron

Temperature: 250℃

Time:less than 3 seconds

2.7.1If users choose wave-soldering, the following conditions should be obey:

Soldering flux: Rosin soldering flux contains least chlorine

Speed: 1-2 Meter/ Minute

Warm-up temperature:100±20℃

Welding temperature:250±10℃

One time pass wave crest welding machine

If disobey the above using terms, sensors sensitivity will reduce.

Zhengzhou Winsen Electronics Technology Co., Ltd

Add: No.299, Jinsuo Road, National Hi-Tech Zone,

Zhengzhou 450001 China

Tel: +86-371-67169097/67169670

Fax: +86-371-60932988

E-mail: sales@winsensor.com

Website: www.winsensor.com

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 9600 DocumentDocument174 pages9600 Documentthom38% (13)

- Ricoh 4055 PDFDocument1 280 pagesRicoh 4055 PDFPham Nguyen Hoang Minh100% (1)

- How Computers WorkDocument158 pagesHow Computers Workvijai daniel100% (1)

- Naples and Campania Region: Tutto Questo in Un Pass! All This in Just One Pass!Document17 pagesNaples and Campania Region: Tutto Questo in Un Pass! All This in Just One Pass!bioinePas encore d'évaluation

- The Effect of Power Sensor Variation and Measurement ErrorDocument10 pagesThe Effect of Power Sensor Variation and Measurement ErrorbioinePas encore d'évaluation

- Predator Mission Aircrew Training SystemDocument2 pagesPredator Mission Aircrew Training SystembioinePas encore d'évaluation

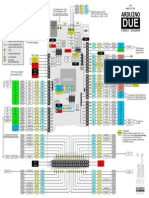

- Due PinoutDocument1 pageDue Pinoutmanuel99a2kPas encore d'évaluation

- F-16 Wide Band RadomeDocument2 pagesF-16 Wide Band RadomebioinePas encore d'évaluation

- 1Document100 pages1Niomi GolraiPas encore d'évaluation

- IAI ELTA Radar SAR SystemsDocument1 pageIAI ELTA Radar SAR SystemsbioinePas encore d'évaluation

- KZO Brochure PDFDocument2 pagesKZO Brochure PDFbioinePas encore d'évaluation

- SBL Fretboard Diagrams PDFDocument4 pagesSBL Fretboard Diagrams PDFbioinePas encore d'évaluation

- Party ListDocument1 pageParty ListbioinePas encore d'évaluation

- Bibliographie: Parcours de vie et vulnérabilitéDocument2 pagesBibliographie: Parcours de vie et vulnérabilitébioinePas encore d'évaluation

- Technical Data Mq-7 Gas Sensor: FeaturesDocument3 pagesTechnical Data Mq-7 Gas Sensor: FeaturesFarshad yazdiPas encore d'évaluation

- Mi DeviceDocument20 pagesMi DeviceTrbvmPas encore d'évaluation

- Blindfolded SQL InjectionDocument17 pagesBlindfolded SQL InjectionLuis CarlosPas encore d'évaluation

- Microdem3 Man v1 enDocument6 pagesMicrodem3 Man v1 enbioinePas encore d'évaluation

- Upgrading From Oracle 9i To Oracle Database 11g:: A Real World Customer ExperienceDocument41 pagesUpgrading From Oracle 9i To Oracle Database 11g:: A Real World Customer ExperienceEmerson Rodrigo OrciPas encore d'évaluation

- Telco XPOL MIMO Industrial Class Solid Dish AntennaDocument4 pagesTelco XPOL MIMO Industrial Class Solid Dish AntennaOmar PerezPas encore d'évaluation

- Lec9-Rock Cutting ToolsDocument35 pagesLec9-Rock Cutting ToolsAmraha NoorPas encore d'évaluation

- JY Series Single-Phase Capacitor Induction MotorsDocument1 pageJY Series Single-Phase Capacitor Induction MotorsAditya PrasetyoPas encore d'évaluation

- GLOBAL Hydro Turbine Folder enDocument4 pagesGLOBAL Hydro Turbine Folder enGogyPas encore d'évaluation

- Antonovsky (1979)Document280 pagesAntonovsky (1979)M.Fakhrul Kurnia100% (1)

- Antennas Since Hertz and MarconiDocument7 pagesAntennas Since Hertz and MarconiTaiwo Ayodeji100% (1)

- IEEE T&D Insulators 101 Design CriteriaDocument84 pagesIEEE T&D Insulators 101 Design Criteriasachin HUPas encore d'évaluation

- Clausius TheoremDocument3 pagesClausius TheoremNitish KumarPas encore d'évaluation

- Ancient MesopotamiaDocument69 pagesAncient MesopotamiaAlma CayapPas encore d'évaluation

- Artifact and Thingamy by David MitchellDocument8 pagesArtifact and Thingamy by David MitchellPedro PriorPas encore d'évaluation

- Discuss The Challenges For Firms To Operate in The Hard-Boiled Confectionery Market in India?Document4 pagesDiscuss The Challenges For Firms To Operate in The Hard-Boiled Confectionery Market in India?harryPas encore d'évaluation

- OpenROV Digital I/O and Analog Channels GuideDocument8 pagesOpenROV Digital I/O and Analog Channels GuidehbaocrPas encore d'évaluation

- NDE Procedure - Radiographic TestingDocument43 pagesNDE Procedure - Radiographic TestingJeganeswaranPas encore d'évaluation

- PDFViewer - JSP 3Document46 pagesPDFViewer - JSP 3Kartik ChaudharyPas encore d'évaluation

- Quaternary Protoberberine Alkaloids (Must Read)Document26 pagesQuaternary Protoberberine Alkaloids (Must Read)Akshay AgnihotriPas encore d'évaluation

- Update On The Management of Acute Pancreatitis.52Document7 pagesUpdate On The Management of Acute Pancreatitis.52Sebastian DeMarinoPas encore d'évaluation

- GIS AccidentsDocument5 pagesGIS Accidentsali110011Pas encore d'évaluation

- Maureen L. Walsh - Re-Imagining Redemption. Universal Salvation in The Theology of Julian of NorwichDocument20 pagesMaureen L. Walsh - Re-Imagining Redemption. Universal Salvation in The Theology of Julian of NorwichAni LupascuPas encore d'évaluation

- Lyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticDocument13 pagesLyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticJayr Mercado0% (1)

- Chap 2 Debussy - LifejacketsDocument7 pagesChap 2 Debussy - LifejacketsMc LiviuPas encore d'évaluation

- TIA Selection Tool: Release Notes V2022.05Document10 pagesTIA Selection Tool: Release Notes V2022.05Patil Amol PandurangPas encore d'évaluation

- WL 318 PDFDocument199 pagesWL 318 PDFBeckty Ahmad100% (1)

- Analysis and Calculations of The Ground Plane Inductance Associated With A Printed Circuit BoardDocument46 pagesAnalysis and Calculations of The Ground Plane Inductance Associated With A Printed Circuit BoardAbdel-Rahman SaifedinPas encore d'évaluation

- Datasheet PDFDocument6 pagesDatasheet PDFAhmed ElShoraPas encore d'évaluation

- Application of Fertility Capability Classification System in Rice Growing Soils of Damodar Command Area, West Bengal, IndiaDocument9 pagesApplication of Fertility Capability Classification System in Rice Growing Soils of Damodar Command Area, West Bengal, IndiaDr. Ranjan BeraPas encore d'évaluation

- Proceedings of The 16 TH WLCDocument640 pagesProceedings of The 16 TH WLCSabrinaPas encore d'évaluation

- Casio AP-80R Service ManualDocument41 pagesCasio AP-80R Service ManualEngkiong Go100% (1)

- Parts of ShipDocument6 pagesParts of ShipJaime RodriguesPas encore d'évaluation