Académique Documents

Professionnel Documents

Culture Documents

05 10 00 Metal Decking

Transféré par

Kiran D Anvekar0 évaluation0% ont trouvé ce document utile (0 vote)

24 vues5 pagesMetal Decking

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentMetal Decking

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

24 vues5 pages05 10 00 Metal Decking

Transféré par

Kiran D AnvekarMetal Decking

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

05 10 00

METAL DECKING

INDEX TO ARTICLES

PART 1 - GENERAL

1.1 Contract Documents

1.2 Work Included

1.3 Related Work Specified Elsewhere

1.4 Quality Assurance

1.5 Submittals

PART 2 - PRODUCTS

2.1 Materials

2.2 Delivery, Storage & Handling

PART 3 - EXECUTION

3.1 Installation

3.2 Acoustic Performance Testing

3.3 Cleaning and Protection

05 10 00 Metal Decking Page 1 of 5

05 10 00

METAL DECKING

1. GENERAL

1.1 Contract Documents

1.1.1 All Work of this Section shall comply with the requirements of the Contract

Documents for the Main Building Works with the Drawings, Schedules and with

all other Contract Documents.

1.2 Work Included

1.2.1 Supply and install metal roof decking comprising steel and aluminium profiled roof

sheets, wire mesh, related trims and accessories, insulation and sound deadening

fibre-cement boards as specified herein and all in accordance with the

requirements set out in this Specification and manufacturer's recommendations.

1.2.2 Supply and install gutters comprising hard-backed fibreglass insulation and steel

faced sound deadening fibre-cement boards as specified herein and all in

accordance with the requirements set out in this Specification and manufacturer's

recommendations.

1.2.3 Supply and install stainless steel rainwater downpipes with connections to gutters.

1.2.4 Supply and install fall arrest system to roofing.

1.3 Related Work Specified Elsewhere

a) Reference Standard - 01 02 10

b) Membrane and Roofing - 07 10 00

c) Structural Steelwork - Refer to Structural Steelwork

Specification

1.4 Quality Assurance

1.4.1 Refer to Section 01 02 10 Reference Standards to comply with the requirements

of the referenced Standards.

1.5 Submittals

1.5.1 Product data:

a) Submit manufacturer's products and installation instructions for each type

of material.

b) Manufacturer's certifications of fire tests relating to the products supplied

under this Section.

c) Submit manufacturer's technical descriptive data.

d) Intent of Contractor to use products specified does not relieve him from

responsibility of submitting product list.

1.5.2 Shop Drawings:

The Contractor shall submit Shop Drawings showing details of typical installations

and relation to adjoining construction and structural support.

1.5.3 Samples:

Submit three (3) samples of each of the following materials:

a) Metal roof decking, 300mm x 300mm.

b) Roof decking accessories, 150mm long of each type.

c) Fibre-cement board underlayment, 300mm x 300mm.

d) Hardbacked fibreglass insulation, 300mm x 300mm.

05 10 00 Metal Decking Page 2 of 5

e) Rockwool insulation, 300mm x 300mm.

f) Stainless steel rainwater downpipe, 300mm length.

1.5.4 Indemnities and Warrenties

a) The Contracto shall provide a ten (10) year Deed of Indemnity in the form

set out in the Tender Documents, against roof leaks and defects in design,

workmanship, quality of matereials, perforamance of the metal roof

decking and deterioration of the work.

b) If, in the opinion of the Contractor, the foregoing Specifications are in

sufficient for him to provide the indemnity, then he shall allow in his tender

for upgrading the Specifications as necessary to enable him to so

indemnity.

2. PRODUCTS

2.1 Materials

2.1.1 Steel Roofing.

a) Exposed Fixing Type

Profiled steel roofing, where indicated in the Drawings, shall be Lysaght

0.48mm (BMT) "Zincalume Colorbond Spandek Hi-Ten" or approved

equal in single continuous lengths for the total span. The colour shall be

for one side and shall be selected by the Architect.

b) Concealed Fixing Type

Standard Profile

Profiled concealed-fix steel roofing where indicated in the Drawings, shall

be Lysaght 0.60mm (BMT) “Zincalume Colorbond Kliplok 406“ or

approved equal in single continuous lengths for the total span. The colour

shall be for one side and shall be selected by the Architect.

c) Concealed Fixing Standing Seam

Standing seam architectural roofing profile where indicated in the

Drawings, shall be Lysaght Flex-Lok 400 , 0.80 mm(BMT) in Zincalume

Colorbond or approved equal in single continuous lengths for the total

span. Colour shall be for one side and shall be selected by the Architect.

d) Roofing accessories, where required shall be 0.60 mm thick “Colorbond”

steel sheet or approved equal formed to shalpes and profiles as required

or shown in Drawings.

2.1.2 Aluminium Standing Seam Roofing

a) Aluminium profiled sheet standing seam roofing composite roofing system

where indicated in Drawings or schedules shall be a proprietary system

inclusive of secondary support decking and infill insulation to specified

heat and acoustic requirement, sound deadening board, fixing

accessories and trim. Finish shall be in PVDF, colour as selected by the

Architect.

Approved manufacturer: Corus “Kalzip” system or approved equal.

2.1.3 Insulation.

a) Insulation as shown in the Drawings, shall be one layer of 50mm thick

"Thermafiber" foil backed non-asbestos mineral fibre insulation, minimum

60 kg/m3 density or approved equal. For proprietary systems the amount

of insulation in density and height shall be in accordance with the acoustic

performance compliance.

05 10 00 Metal Decking Page 3 of 5

Where fibre glass insulation is required this shall be with aluminium foil

top and bottom and a minimum density of 16 kg/m3

b) Insulation to be laid between sound deadening boards shall be sealed in

polyethylene bags and installed in accordance with manufacturer's

recommendations.

c) Hardbacked sound insulation as shown in the Drawings shall be one layer

of 50mm thick Owens-Corning type 705 fibreglass insulation, minimum

32kg/m3 density or approved equal.

2.1.4 Sound Deadening Board.

a) Sound deadening board shall be 10mm and 20mm thick fibre-cement

board as shown in the Drawings.

b) At gutters, provide 1.5mm thick stainless steel lining to both faces of

sound deadening board as indicated in the Drawings.

2.1.5 Galvanised Wire Mesh.

a) Galvanised wire mesh shall be BRC reference 5515 or approved equal.

2.1.6 Stainless Steel Downpipe

a) Rainwater downpipes shall be 0.7mm thick Type 304 stainless steel with

welded joints.

2.1.7 Fall Arrest System

a) Where indicated as a requirement, supply and install a reliable fall arrest

system to secure walkways on the finished roof. This shall consist of a

stainless steel rope fastened to permanently fixed anchors coupled to

safety harness by means of a guide link.

Approved Manufacturer: Tractile

2.2 Delivery, Storage & Handling

2.2.1 All materials shall be delivered in their original unopened packages and stored in

an enclosed shelter providing protection from damage and exposure to the

elements. Damaged or deteriorated materials shall be removed from the

premises.

2.2.2 Packs of metal roofing sheets shall be kept dry in transit and on site to prevent

water and/or condensation being trapped between adjacent surfaces. Packs of

sheets standing on site shall be stored clean of the ground. Sheets shall be

handled using clean, dry gloves. If the packs become wet, the sheets should be

separated, wiped with a clean cloth without delay and placed so that air circulation

completes the drying process

2.2.3 Fibre Cement boards shall be strapped on a wooden pallet and protected against

moisture during transportation. Boards shall be stored horizontally on pallets or

beams with sufficient support to avoid sagging. To prevent excessive flexing,

boards shall be lifted by sliding sideways from the stack and lifting on the edge.

3. EXECUTION

3.1 Installation

3.1.1 The metal roofing, fibre cement boards, insulation, gutters and others shall be

installed in accordance with the manufacturers' recommendations together with

the quality assurance and quality control standards imposed.

3.1.2 Fix roofing in continuous lengths to metal steel supports with approved fasteners.

3.1.3 Lay insulation materials between steel purlins or spacers.

3.1.4 Fibre Cement boards shall be fixed to steel supports with approved fasteners.

05 10 00 Metal Decking Page 4 of 5

3.2 Acoustic Performance Testing

3.2.1 The entire roof system inclusive of the external cladding panel shall be constructed

and tested to achieve a minimum STC (Sound Transmission Class) value of 45

when tested in an approved acoustic laboratory based either on ISO 140 or ASTM

E90 test standard, modified as required for simulation of rain impact.

3.2.2 The test sample shall be constructed flat across the acoustic test chamber

opening. The sample shall include for a run of gutter at the centre, either

horizontally or vertically across the sample, of approximately 10 m2 in area. The

complete sample assembly shall resemble actual installation, except flattened.

3.2.3 External cladding panel materials shall be furnished by the Cladding Sub-

Contractor for the test assembly.

3.2.4 All costs incurred for the tests shall be borne by the Contractor.

3.3 Cleaning and Protection

3.3.1 The roof and gutters shall be swept clean of all debris using a soft broom at least

at the end of each day's work and particularly on the completion of fixing. The

work shall be left clean and in a weathertight condition.

- END -

05 10 00 Metal Decking Page 5 of 5

Vous aimerez peut-être aussi

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- 09 50 00 Gypsum BoardDocument14 pages09 50 00 Gypsum BoardKiran D AnvekarPas encore d'évaluation

- Structural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesD'EverandStructural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesÉvaluation : 3.5 sur 5 étoiles3.5/5 (13)

- 09 40 00 Metal FurringDocument7 pages09 40 00 Metal FurringKiran D AnvekarPas encore d'évaluation

- 10 22 00 Wall-Door ProtectionDocument5 pages10 22 00 Wall-Door ProtectionKiran D AnvekarPas encore d'évaluation

- 09 22 00 Acoustical CeilingsDocument9 pages09 22 00 Acoustical CeilingsKiran D AnvekarPas encore d'évaluation

- 09 20 00 Gypsum Board Etc Ceiling PDFDocument8 pages09 20 00 Gypsum Board Etc Ceiling PDFKiran D AnvekarPas encore d'évaluation

- 06 20 00 Finish CarpentryDocument14 pages06 20 00 Finish CarpentryKiran D AnvekarPas encore d'évaluation

- 07 30 00 Joint SealantsDocument9 pages07 30 00 Joint SealantsKiran D AnvekarPas encore d'évaluation

- 08 40 00 Coiling Doors and GrillesDocument7 pages08 40 00 Coiling Doors and GrillesKiran D AnvekarPas encore d'évaluation

- 07 20 00 Fire and Smoke ProtectionDocument5 pages07 20 00 Fire and Smoke ProtectionKiran D AnvekarPas encore d'évaluation

- Section 077100 - Roof SpecialtiesDocument6 pagesSection 077100 - Roof SpecialtiesWENDING HUPas encore d'évaluation

- Composite Panel SpecificationDocument6 pagesComposite Panel SpecificationracvillePas encore d'évaluation

- 2500 SpecificationDocument5 pages2500 SpecificationMelissa ArandaPas encore d'évaluation

- Oblepas-Residence - Specification-01 16 23Document5 pagesOblepas-Residence - Specification-01 16 23jp.fajardo777Pas encore d'évaluation

- 04 30 00 Stone MasonryDocument6 pages04 30 00 Stone MasonryKiran D AnvekarPas encore d'évaluation

- Tensile Membrane Structures: Name of Project Page - of - July 9, 2013Document18 pagesTensile Membrane Structures: Name of Project Page - of - July 9, 2013jackPas encore d'évaluation

- Section 08630 Metal-Framed SkylightDocument4 pagesSection 08630 Metal-Framed SkylightMØhãmmed ØwięsPas encore d'évaluation

- 05 30 00 Decorative MetalsDocument16 pages05 30 00 Decorative MetalsKiran D AnvekarPas encore d'évaluation

- Division 05 - Metals: Structural SpecificationDocument19 pagesDivision 05 - Metals: Structural SpecificationFranklyn GenovePas encore d'évaluation

- SF - Glass-Fiber-Reinforced Concrete (GFRC)Document6 pagesSF - Glass-Fiber-Reinforced Concrete (GFRC)SunilPas encore d'évaluation

- BSTR PN 003E (Annex 1D) Sample Particular Specification For Noise Barriers With Transparent PanelsDocument21 pagesBSTR PN 003E (Annex 1D) Sample Particular Specification For Noise Barriers With Transparent PanelsPeter ChanPas encore d'évaluation

- 04 10 00 MasonryDocument17 pages04 10 00 MasonryKiran D Anvekar100% (1)

- Flexospan 07 42 13fleDocument23 pagesFlexospan 07 42 13fleAashish MuraliPas encore d'évaluation

- Plot A 007: Curtain Wall and Glazed AssembliesDocument6 pagesPlot A 007: Curtain Wall and Glazed AssembliesRACHED ABBOUDPas encore d'évaluation

- 09 20 00 Gypsum Board Etc CeilingDocument12 pages09 20 00 Gypsum Board Etc CeilingKiran D AnvekarPas encore d'évaluation

- De635 Suggested SpecificationDocument2 pagesDe635 Suggested Specificationqpuc198Pas encore d'évaluation

- 08 90 00 Glazing Index To Articles: Part 1 - GeneralDocument8 pages08 90 00 Glazing Index To Articles: Part 1 - GeneralKiran D AnvekarPas encore d'évaluation

- PVC SpecificationDocument17 pagesPVC SpecificationDavid Ruelas50% (2)

- PFEIFER Structures Section 133100 PVC SpecificationDocument17 pagesPFEIFER Structures Section 133100 PVC Specificationtidipa8386Pas encore d'évaluation

- M - Series Specification 02 - 2018Document5 pagesM - Series Specification 02 - 2018Ahsan KhanPas encore d'évaluation

- Section 09514Document7 pagesSection 09514motaz alzoubiPas encore d'évaluation

- Section 12090 UpholsteryDocument4 pagesSection 12090 UpholsteryMØhãmmed ØwięsPas encore d'évaluation

- Wooden DoorsDocument6 pagesWooden DoorsAnvekarPas encore d'évaluation

- ES-3 Thermal, Openings, Finishes-MIRANDA, KEINDocument6 pagesES-3 Thermal, Openings, Finishes-MIRANDA, KEINKein MirandaPas encore d'évaluation

- SECTION 03 51 13 Cementitious Wood Fiber DecksDocument6 pagesSECTION 03 51 13 Cementitious Wood Fiber DecksJuanPaoloYbañezPas encore d'évaluation

- PlasterDocument12 pagesPlasterAhmed GhariebPas encore d'évaluation

- Basteel Perimeter Systems: Citadel Security Fence SystemDocument5 pagesBasteel Perimeter Systems: Citadel Security Fence SystemMathias OnosemuodePas encore d'évaluation

- Asm XDocument6 pagesAsm XAlijihad2001aoPas encore d'évaluation

- Section 03490-Glass-Fiber-Reinforced Precast ConcreteDocument5 pagesSection 03490-Glass-Fiber-Reinforced Precast ConcreteMØhãmmed ØwięsPas encore d'évaluation

- Standard Specification No: Kpc-A-07 Standard Specification For Roof and Wall Cladding FOR PT Kaltim Prima Coal Project at East Kalimantan, IndonesiaDocument12 pagesStandard Specification No: Kpc-A-07 Standard Specification For Roof and Wall Cladding FOR PT Kaltim Prima Coal Project at East Kalimantan, Indonesiabarian karopebokaPas encore d'évaluation

- Keystone Compac PDocument8 pagesKeystone Compac PcinevaundevaPas encore d'évaluation

- Arch 2.4 Carbon Steel FinishesDocument2 pagesArch 2.4 Carbon Steel FinishesSherazPas encore d'évaluation

- 09 28 13 Cement Board CeilingsDocument6 pages09 28 13 Cement Board CeilingsWagih NabihPas encore d'évaluation

- Series 4000 - Noise Barrier: 4001 General RequirementsDocument13 pagesSeries 4000 - Noise Barrier: 4001 General RequirementsAbdullah AkbulutPas encore d'évaluation

- C 1063 - 03 QzewnjmDocument9 pagesC 1063 - 03 QzewnjmGarcia ManuelPas encore d'évaluation

- Sec 07620Document7 pagesSec 07620Sherif AshrafPas encore d'évaluation

- Section 03300 Cast-In-place Concrete Part 1Document16 pagesSection 03300 Cast-In-place Concrete Part 1jacksondcpl100% (1)

- Pyramid PDFDocument7 pagesPyramid PDFAndriPas encore d'évaluation

- AISI Section 092600 - Metal Framing For Gypsum Board AssembliesDocument6 pagesAISI Section 092600 - Metal Framing For Gypsum Board AssembliesĐường Nguyễn ThừaPas encore d'évaluation

- 03455-Glass Reinforced Concrete (GRC) - Rev.0 PDFDocument12 pages03455-Glass Reinforced Concrete (GRC) - Rev.0 PDFMithun UdayanarayanaPas encore d'évaluation

- 08 4400 - Curtain Wall and Glazed Assemblies - FinalDocument50 pages08 4400 - Curtain Wall and Glazed Assemblies - FinalAbdullah NajjarPas encore d'évaluation

- Material SpecificationsDocument2 pagesMaterial SpecificationsBonnie BalaguerPas encore d'évaluation

- SECTION 07 71 00 Roof SpecialtiesDocument12 pagesSECTION 07 71 00 Roof SpecialtiesJuanPaoloYbañezPas encore d'évaluation

- AAB 092813 Calcium Silicate Board CeilingDocument7 pagesAAB 092813 Calcium Silicate Board CeilingTewodros TeferaPas encore d'évaluation

- SECTION 09 29 00 Gypsum BoardDocument10 pagesSECTION 09 29 00 Gypsum BoardRima Baz FadousPas encore d'évaluation

- Specifications - Tensioned Fabric StructuresDocument12 pagesSpecifications - Tensioned Fabric StructuresAristeo V. CabantingPas encore d'évaluation

- Fabcon Guide Specification Plant Precast Structural Concrete Panels Long Version 1Document6 pagesFabcon Guide Specification Plant Precast Structural Concrete Panels Long Version 1Ahmad BalahPas encore d'évaluation

- SECTION 07 60 00 Flashing and Sheet MetalDocument31 pagesSECTION 07 60 00 Flashing and Sheet MetalJuanPaoloYbañezPas encore d'évaluation

- Nonstructural Steel Framing Members: Standard Specification ForDocument6 pagesNonstructural Steel Framing Members: Standard Specification ForJesús Luis Arce GuillermoPas encore d'évaluation

- 11 10 00 Security EquipmentDocument2 pages11 10 00 Security EquipmentKiran D AnvekarPas encore d'évaluation

- 16 10 00 Termite ControlDocument3 pages16 10 00 Termite ControlKiran D AnvekarPas encore d'évaluation

- 17 11 00 PavingDocument14 pages17 11 00 PavingKiran D AnvekarPas encore d'évaluation

- 17 11 00 PavingDocument14 pages17 11 00 PavingKiran D AnvekarPas encore d'évaluation

- 17 10 00 External WorksDocument6 pages17 10 00 External WorksKiran D AnvekarPas encore d'évaluation

- 15 20 00 Sanitary Fixtures and FittingsDocument8 pages15 20 00 Sanitary Fixtures and FittingsKiran D AnvekarPas encore d'évaluation

- 10 24 00 Toilet-Bath-Laundry AccDocument6 pages10 24 00 Toilet-Bath-Laundry AccKiran D AnvekarPas encore d'évaluation

- 21 Soil, Waste and Vent Piping SystemsDocument4 pages21 Soil, Waste and Vent Piping SystemsKiran D AnvekarPas encore d'évaluation

- 14 Wood Protection Paint SystemDocument3 pages14 Wood Protection Paint SystemKiran D AnvekarPas encore d'évaluation

- 12 Plasterboard Grid-Tile Ceiling SystemsDocument5 pages12 Plasterboard Grid-Tile Ceiling SystemsKiran D AnvekarPas encore d'évaluation

- EQ26Document7 pagesEQ26Kiran D AnvekarPas encore d'évaluation

- 13 Ceramic TilesDocument4 pages13 Ceramic TilesKiran D AnvekarPas encore d'évaluation

- Design of 6 Storey Building in EtabsDocument51 pagesDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- 11 Glass and GlazingDocument6 pages11 Glass and GlazingKiran D AnvekarPas encore d'évaluation

- 5 Post - Tensioned ConcreteDocument17 pages5 Post - Tensioned ConcreteKiran D AnvekarPas encore d'évaluation

- Fidic Claims ProcedureDocument60 pagesFidic Claims Procedurelaucamp82% (11)

- Pipes & Tube RailingsDocument4 pagesPipes & Tube RailingsKiran D AnvekarPas encore d'évaluation

- 7 IronmongeryDocument3 pages7 IronmongeryKiran D AnvekarPas encore d'évaluation

- 1 Demolition $ AlterationsDocument2 pages1 Demolition $ AlterationsKiran D AnvekarPas encore d'évaluation

- 10 Steel Protective CoatingsDocument5 pages10 Steel Protective CoatingsKiran D AnvekarPas encore d'évaluation

- 7 IronmongeryDocument3 pages7 IronmongeryKiran D AnvekarPas encore d'évaluation

- 3 Termite ControlDocument2 pages3 Termite ControlKiran D AnvekarPas encore d'évaluation

- Architectural Wood WorkDocument4 pagesArchitectural Wood WorkKiran D AnvekarPas encore d'évaluation

- 2 EarthworksDocument2 pages2 EarthworksKiran D AnvekarPas encore d'évaluation

- 10 21 00 Toilet CompartmentsDocument5 pages10 21 00 Toilet CompartmentsKiran D AnvekarPas encore d'évaluation

- 10 24 00 Toilet-Bath-Laundry AccDocument6 pages10 24 00 Toilet-Bath-Laundry AccKiran D AnvekarPas encore d'évaluation

- 11 10 00 Security EquipmentDocument2 pages11 10 00 Security EquipmentKiran D AnvekarPas encore d'évaluation

- 10 20 00 Shower ScreenDocument7 pages10 20 00 Shower ScreenKiran D AnvekarPas encore d'évaluation

- Method Statement For Laying of MCC Duct and Civil Works For MCC NetworkDocument26 pagesMethod Statement For Laying of MCC Duct and Civil Works For MCC NetworkVenkadesh PeriathambiPas encore d'évaluation

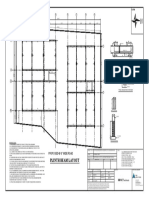

- Plinth Beam Layout: Proposed 40'-0" Wide RoadDocument1 pagePlinth Beam Layout: Proposed 40'-0" Wide RoadMurthy GunaPas encore d'évaluation

- Method Statement & Risk Assessment Installation of Sanitary WaresDocument18 pagesMethod Statement & Risk Assessment Installation of Sanitary WaresAbu Muhammed KhwajaPas encore d'évaluation

- CRC - MHA - CV - Mohamed Resume - TO-CC - V07 - 20210201Document5 pagesCRC - MHA - CV - Mohamed Resume - TO-CC - V07 - 20210201Mohamed Al-GizawyPas encore d'évaluation

- New Fulcrum Canopies - Structural Drawings - PermitDocument6 pagesNew Fulcrum Canopies - Structural Drawings - PermitJorge Alnerto Perez SanchezPas encore d'évaluation

- Electrical Engineer (CV)Document4 pagesElectrical Engineer (CV)Abdul JabbarPas encore d'évaluation

- Classified2016 10 2626534Document9 pagesClassified2016 10 2626534sasikalaPas encore d'évaluation

- Architectural Specification DBI SALA RoofSafe Rail SystemDocument6 pagesArchitectural Specification DBI SALA RoofSafe Rail SystemCoordinación de Proyectos Médico ArquitectónicosPas encore d'évaluation

- PL-MEP-002 Installation & Testing of Underground Drainage PipingDocument21 pagesPL-MEP-002 Installation & Testing of Underground Drainage PipingMina KhalilPas encore d'évaluation

- Building Planning and DrawingDocument35 pagesBuilding Planning and DrawingArun Bhuyan100% (2)

- Waleed Hamed PDFDocument4 pagesWaleed Hamed PDFShadi AbdelsalamPas encore d'évaluation

- Section VI - Pipe Fabrication Shop IssuesDocument11 pagesSection VI - Pipe Fabrication Shop Issuesarshad1000Pas encore d'évaluation

- Method Statement For Septic Tank ConstructionDocument10 pagesMethod Statement For Septic Tank ConstructionCobbinah Mark100% (5)

- Method Statement For Earthing PDFDocument12 pagesMethod Statement For Earthing PDFPraveen Kumar50% (2)

- Metal Stairs: 1.0 GeneralDocument7 pagesMetal Stairs: 1.0 GeneralDipu GeorgePas encore d'évaluation

- 2021-Mohamed Gamal Abd Elnaser El KashashDocument9 pages2021-Mohamed Gamal Abd Elnaser El KashashMohamed KashashPas encore d'évaluation

- Inspection and Test Plan: Project NameDocument2 pagesInspection and Test Plan: Project NameehteshamPas encore d'évaluation

- Spec VCL PDFDocument4 pagesSpec VCL PDFValiPas encore d'évaluation

- Project Execution Plan 27 PDFDocument27 pagesProject Execution Plan 27 PDFbakabaka100% (1)

- Quality Management PlanDocument67 pagesQuality Management PlanHamza El FadiliPas encore d'évaluation

- Tahir Hussain: ObjectiveDocument20 pagesTahir Hussain: Objectivetahir HussainPas encore d'évaluation

- Construction Pre PlanningDocument52 pagesConstruction Pre PlanningAPIC100% (3)

- Structural SpecificationsDocument102 pagesStructural SpecificationsAlden CayagaPas encore d'évaluation

- 3-Method of Statment - CableTraysDocument16 pages3-Method of Statment - CableTraysSyed AtherPas encore d'évaluation

- Blank BOQDocument58 pagesBlank BOQThushan Madu0% (1)

- CE Laws, Ethics and Contracts Module 7 - CIAP Document 102 Uniform General Conditions of Contract For Private ConstructionDocument34 pagesCE Laws, Ethics and Contracts Module 7 - CIAP Document 102 Uniform General Conditions of Contract For Private ConstructionJayson CastilloPas encore d'évaluation

- Curriculum Vitae (CV) : Wadah SalihDocument2 pagesCurriculum Vitae (CV) : Wadah SalihHR UAEPas encore d'évaluation

- Electrical Spec PDFDocument138 pagesElectrical Spec PDFonspsnonsPas encore d'évaluation

- Method Statement of Installation of Ductile Iron FlangeDocument10 pagesMethod Statement of Installation of Ductile Iron FlangeshahidPas encore d'évaluation

- Usacoe Pump Sta Design em - 1110-2-3105 PDFDocument171 pagesUsacoe Pump Sta Design em - 1110-2-3105 PDFT. E. MCLAUGHLIN, P.E.Pas encore d'évaluation

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseD'EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseÉvaluation : 5 sur 5 étoiles5/5 (3)

- Building Construction Technology: A Useful Guide - Part 1D'EverandBuilding Construction Technology: A Useful Guide - Part 1Évaluation : 4 sur 5 étoiles4/5 (3)

- A Place of My Own: The Architecture of DaydreamsD'EverandA Place of My Own: The Architecture of DaydreamsÉvaluation : 4 sur 5 étoiles4/5 (242)

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionD'EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AD'EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&APas encore d'évaluation

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceD'EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceÉvaluation : 4 sur 5 étoiles4/5 (19)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideD'Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideÉvaluation : 3.5 sur 5 étoiles3.5/5 (7)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedD'EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedÉvaluation : 5 sur 5 étoiles5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tD'EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tÉvaluation : 4.5 sur 5 étoiles4.5/5 (27)

- Field Guide for Construction Management: Management by Walking AroundD'EverandField Guide for Construction Management: Management by Walking AroundÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesD'EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesPas encore d'évaluation

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATED'EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEÉvaluation : 4 sur 5 étoiles4/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceD'EverandAnalog Design and Simulation Using OrCAD Capture and PSpicePas encore d'évaluation

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchD'EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchÉvaluation : 4 sur 5 étoiles4/5 (10)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsD'EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsPas encore d'évaluation

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftD'EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftÉvaluation : 5 sur 5 étoiles5/5 (5)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneD'EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Practical Power Distribution for IndustryD'EverandPractical Power Distribution for IndustryÉvaluation : 2.5 sur 5 étoiles2.5/5 (2)