Académique Documents

Professionnel Documents

Culture Documents

ITP

Transféré par

Karthikeyan ShanmugavelDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ITP

Transféré par

Karthikeyan ShanmugavelDroits d'auteur :

Formats disponibles

1 of 2

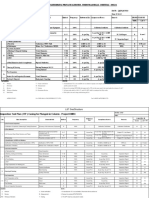

Inspection and Test Plan (ITP)

Document no. :

Project No./Name : Job No./name : H=Hold Point Rev No. :

Customer/Client : Item-Description Name : Convection Part R=Review Point Date :

Customer Project n: Serial No. : W=Witness Point

Manufacturer : Getabec Energy Co.,Ltd. Drawing No./Rev. : SW=Spot witness

CODE : EN12953:2002 CODE Stamp. : N/A D=Documented

Quality Surveillance

Document

GETABEC

Third Party Contractor

Reference Document/Drawings/ Standard Production QA/QC

Item Area of activity Quality control activity Acceptance Criteria

Code

Point

Point

Point

Point

Signature Date Signature Date Signature Date Signature Date

1 Specification Verity that all relevant document have been received Client order and requisition

2 Design Document Submittal Technical requirement

Client order and requisition

a) Drawing Review to meet code and Specification Design code and standard

b) calculation Design Calculation,code and standard

3 Material Procurement Review material requisition against spec. Material certificates

EN 12953:2002 and

Request

4 Material Incoming a) Damage inspection Material receiving reports

b) Mat & Mill certificate verification Purchase Specification Purchase Specification

5 Welding Procedure & Qualification Verify to meet Code & specification Drawing for construction EN 15614-1

6 Welder & Qualification Verify to meet Code & specification WPS EN 287-1

7 Pre-fabrication

7.1 Shell

7.1.1 1) Material Material identification check Material identification record EN 12953-4:2002 - 5.2

7.1.2 2) Cut lay-out Dimension check As Drawing As Drawing

7.1.3 3) Cutting & beveling Visual & Edge preparation check Drawing for con., WPS EN 12953-4:2002 - 5.15

7.1.4 4) Fit-up plate to plate a) Dimension check Drawing for con., WPS As Drawing

b) Preparation check Drawing for con., WPS Weld Map

(alignment,gap,cleanliness inspection)

7.1.5 5) Welding a) WPS,welder,visual Weld map,welding&NDESchedule EN 15614,287

7.1.6 6) NDE RT film review Weld map,welding&NDESchedule EN 12953-5:2002

7.1.7 7) Cold Rolling & fit-up a) roundness & dimension check Drawing for con. EN 12953-4:2002 - 5.15

b) Preparation check Drawing for con., WPS Weld Map

(alignment,gap,cleanliness inspection)

7.1.8 8) Welding a) WPS,welder,visual Weld map,welding&NDESchedule EN 15614,287

7.1.9 9) NDE RT film review Weld map,welding&NDESchedule EN 12953-5:2002

7.1.10 10) Fit-up shell to shell a) Dimension check As Drawing As Drawing

b) Preparation check Weld Map Weld Map

(alignment,gap,cleanliness inspection)

7.1.11 11) Welding a) WPS,welder,visual Weld map,welding&NDESchedule EN 15614,287

7.2 End Plate & Tube Plate

7.2.1 1) Material Material identification check Material identification record EN 12953-4:2002 - 5.2

7.2.2 2) Cut lay-out Dimension check As Drawing As Drawing

7.2.3 3) Cutting & beveling Visual & Edge preparation check Drawing for con., WPS EN 12953-4:2002 - 5.15

7.2.4 4) Fit-up a) Dimension check Drawing for con., WPS As Drawing

b) Preparation check Weld Map Weld Map

(alignment,gap,cleanliness inspection)

7.2.5 5) Welding a) WPS,welder,visual Weld map,welding&NDESchedule EN 15614,287

7.2.6 6) NDE PT/US Reports acceptable Weld map,welding&NDESchedule EN 12953-5:2002

7.3 Tube Plate to Shell

7.3.1 1) Material Material identification check Material identification record EN 12953-4:2002 - 5.2

7.3.2 2) Cut lay-out Dimension check As Drawing As Drawing

7.3.3 3) Cutting & beveling Edge preparation check Drawing for con., WPS EN 12953-4:2002 - 5.15

7.3.4 4) Fit-up a) Dimension check Drawing for con., WPS As Drawing

b) Preparation check Weld Map Weld Map

(alignment,gap,cleanliness inspection)

7.3.5 5) Welding a) WPS,welder,visual Weld map,welding&NDESchedule EN 15614,287

7.3.6 6) NDE MPT/US Reports acceptable PT Reports EN 12953-5:2002

7.3 Tube to Tube sheet

7.3.1 1) Fit-up a) Dimension check As Drawing for construction As Drawing

b) Preparation check As Drawing for construction As Drawing

(alignment,gap,cleanliness inspection)

7.3.2 2) Tube Expansion a) Visual and Dimension Check As Drawing for construction As Drawing

7.3.2 3)Seal Welding a) Review WPS, welder certificates and visual Weld map,welding&NDESchedule EN 15614,287

7.3.3. 4)NDE b) PT Examination Weld map,welding&NDESchedule EN 12952-6:2001 - 9.3.3

7.4 Gusset Stay

7.4.1 1) Material Material identification check Material identification record EN 12953-4:2002 - 5.2

7.4.2 2) Cut lay-out Dimension check As Drawing As Drawing

7.4.3 3) Cutting & beveling Edge preparation check Drawing for con., WPS EN 12953-4:2002 - 5.15

7.4.4 4) Fit-up a) Dimension check Drawing for con., WPS As Drawing

b) Preparation check Weld Map Weld Map

(alignment,gap,cleanliness inspection)

7.4.5 5) Welding a) WPS,welder,visual Weld map,welding&NDESchedule EN 15614,287

7.4.6 6) NDE MPT/US Reports acceptable Weld map,welding&NDESchedule EN 12953-5:2002

7.5 Nozzle

7.5.1 1) Material Material identification Material identification record EN 12953-4:2002 - 5.2

7.5.2 2) Cut lay-out Dimension check As Drawing As drawing

7.5.3 3) Cutting & grinding Edge preparation check Drawing for con., WPS EN 12953-4:2002 - 5.15

7.5.4 4) Fit-up flange to neck & weld a) Dimension check Drawing for con., WPS As drawing

b) Alignment,gap,cleanliness inspection Weld Map Weld Map

7.5.5 5) Welding a) WPS,welder,visual EN 15614,287

7.5.6 6) NDE RT film review.MPT/US Reports review Weld map,welding&NDESchedule EN 12953-5:2002

8 Support & Accessories

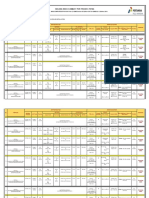

2 of 2

Inspection and Test Plan (ITP)

Document no. :

Project No./Name : Job No./name : H=Hold Point Rev No. :

Customer/Client : Item-Description Name : Convection Part R=Review Point Date :

Customer Project n: Serial No. : W=Witness Point

Manufacturer : Getabec Energy Co.,Ltd. Drawing No./Rev. : SW=Spot witness

CODE : EN12953:2002 CODE Stamp. : N/A D=Documented

Quality Surveillance

Document

GETABEC

Third Party Contractor

Reference Document/Drawings/ Standard Production QA/QC

Item Area of activity Quality control activity Acceptance Criteria

Code

Point

Point

Point

Point

Signature Date Signature Date Signature Date Signature Date

8.1 Fit-up a) Dimension check Drawing for con., WPS As drawing

b)Preparation check Drawing for con., WPS Weld Map

8.2 Welding a) Visual Drawing for con., WPS EN 15614,287

US/MPT & Reports acceptable Weld map,welding&NDESchedule EN 12953-5:2002

a) Final dimension check Drawing for con., WPS,Weldmap EN 15614,287,EN 12952-6:2001 -10.1

8 Finishing (for internals & externals) b) Final weld inspection Final dimension check reports EN 15614,287,EN 12952-6:2001 - 10.1

c) Cleanliness inspection of all tubes Project Spec. Project Spec.

9 Pressure Test

9.1 Hydrostatic test a) Gage calibration Calibration Records Calibration Standard

b) Proper support Fabrication Standard Fabrication Standard

c) Test medium Clean Neutral Water Project Spec.

d) Holding time ( 1 Hr.) Drawing for con., EN 12952-6:2001 - 10.2

e) Leakage test Drawing for con., EN 12952-6:2001 - 10.2

f) Reviewed and approve pressure test report Pressure Test Reports EN 12952-6:2001 - 10.2

g) Drain out of all water from inside Project Spec. Project Spec.

10 Surface Finishing Visual Check Pressure Test Reports Project Spec.

11 Painting Verify to meet specification(If applied) Project Spec. Project Spec.

12 Manufacturer's Data Report (MDR) Prepare and review As Request As Request

----------- End of Convection Part Fabrication Process and Ready for Transport to site------------------

Prepared by Approved by Accepted by Reviewed by

QA/AC Engineer QA/QC Manager Third Party Customer

Vous aimerez peut-être aussi

- Daily Welding Progress ReportDocument1 pageDaily Welding Progress ReportManoj KumarPas encore d'évaluation

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyPas encore d'évaluation

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadPas encore d'évaluation

- Visual Inspection FormatDocument2 pagesVisual Inspection Formattuan mai vanPas encore d'évaluation

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198Pas encore d'évaluation

- Post Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2Document15 pagesPost Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2williamsenPas encore d'évaluation

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Document19 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefPas encore d'évaluation

- Welding Procedure Specification and Procedure Qualification RecordDocument2 pagesWelding Procedure Specification and Procedure Qualification RecordNatdanai NorawanPas encore d'évaluation

- Weld Visual Report Rev.0Document1 pageWeld Visual Report Rev.0John TerryPas encore d'évaluation

- Welding Procedure PIPE HDPE - Rev.03Document29 pagesWelding Procedure PIPE HDPE - Rev.03DORBANI NedjmeddinePas encore d'évaluation

- ITP Format For New PVDocument8 pagesITP Format For New PVDavid LambertPas encore d'évaluation

- Welding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotDocument3 pagesWelding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotRicardo LourençoPas encore d'évaluation

- Release For GroutingDocument1 pageRelease For GroutingUmair AwanPas encore d'évaluation

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliPas encore d'évaluation

- Approved Welding Procedures List RegioDocument2 pagesApproved Welding Procedures List Regiogabriel__regio100% (1)

- Form Attchment - RFI PICTURE-2Document2 pagesForm Attchment - RFI PICTURE-2Echik Kici100% (1)

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganPas encore d'évaluation

- Pre Tanking Inspection Repor1Document2 pagesPre Tanking Inspection Repor1Sumit GuptaPas encore d'évaluation

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- Inspection & Test Plan: Sub-Contractor Con - Tractor Saudi AramcoDocument1 pageInspection & Test Plan: Sub-Contractor Con - Tractor Saudi AramcoDelta akathehusky100% (1)

- Inspection and Test Plan For Pressure VesselDocument4 pagesInspection and Test Plan For Pressure VesselNurul Amirah Princesza100% (3)

- Final Inspection Release NoteDocument2 pagesFinal Inspection Release NoteMark ThrelfallPas encore d'évaluation

- Weld ShrinkageDocument16 pagesWeld ShrinkageWeff JingPas encore d'évaluation

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelPas encore d'évaluation

- Material Inspection Report: Project Name Date InspDocument22 pagesMaterial Inspection Report: Project Name Date InspRafiqKuPas encore d'évaluation

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- Condensate Tank WELDING LOGDocument6 pagesCondensate Tank WELDING LOGhasan shahriarPas encore d'évaluation

- Sample Heat Treatment ProcedureDocument13 pagesSample Heat Treatment ProcedureAnonymous uXdS9Y7100% (1)

- 10 Procedure For PWHTDocument5 pages10 Procedure For PWHTSachin S. SalunkhePas encore d'évaluation

- 2037-PL-PL-0058-IR-T-014 Dated 10.12.19Document16 pages2037-PL-PL-0058-IR-T-014 Dated 10.12.19Dadaso Baburao Jamdar100% (1)

- Qa&qc-Log-04 PQR Log Sheet With CSD CommentsDocument2 pagesQa&qc-Log-04 PQR Log Sheet With CSD CommentsasiqPas encore d'évaluation

- VT ReportDocument1 pageVT ReportBauyrzhanPas encore d'évaluation

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimPas encore d'évaluation

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 pagesElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifPas encore d'évaluation

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- List Applicable WPS Piping & PipelineDocument6 pagesList Applicable WPS Piping & PipelineFerdie OSPas encore d'évaluation

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocument31 pagesALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahPas encore d'évaluation

- QAP For PQR'S - For Impact TestingDocument3 pagesQAP For PQR'S - For Impact TestingDries VandezandePas encore d'évaluation

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouPas encore d'évaluation

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitPas encore d'évaluation

- 005-WPS For Carbon Steel (1.6-4.6MM) PDFDocument7 pages005-WPS For Carbon Steel (1.6-4.6MM) PDFKöksal Patan0% (1)

- Back Gouging ProcedureDocument2 pagesBack Gouging ProcedureVishal SharmaPas encore d'évaluation

- General Welding Procedure - Rev0Document27 pagesGeneral Welding Procedure - Rev0Jayan VKPas encore d'évaluation

- Tack Welding Method Welding Sequence For Carbon SteelDocument6 pagesTack Welding Method Welding Sequence For Carbon SteelansarALLAAHPas encore d'évaluation

- PP WP28Document15 pagesPP WP28mohd as shahiddin jafriPas encore d'évaluation

- Inspection Test Plan For Pipeline JobsDocument6 pagesInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينPas encore d'évaluation

- Fit Up ReportDocument41 pagesFit Up ReportFendik NewbiePas encore d'évaluation

- Welding Parameter Record SheetDocument2 pagesWelding Parameter Record SheetPravin Patil100% (1)

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocument5 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariPas encore d'évaluation

- Ammonia Vaporizer ITPDocument2 pagesAmmonia Vaporizer ITPKarthikeyan ShanmugavelPas encore d'évaluation

- ITP SampleDocument4 pagesITP SampleKarthik S100% (1)

- Vendor Fabrica Tion Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument3 pagesVendor Fabrica Tion Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyPas encore d'évaluation

- Quality Control Plan For Ducting: Project Name: TokushimaDocument4 pagesQuality Control Plan For Ducting: Project Name: TokushimaNguyen Anh TuanPas encore d'évaluation

- ITP Format - Excel GEP 1120Document22 pagesITP Format - Excel GEP 1120raghuvarma100% (1)

- Metallic Tanks - Sample ITPDocument2 pagesMetallic Tanks - Sample ITPSuraj ShettyPas encore d'évaluation

- Anpqp - Component Supply Chain Chart (CSCC) : Nissan Important Part Renault - CSRDocument1 pageAnpqp - Component Supply Chain Chart (CSCC) : Nissan Important Part Renault - CSRjefry sitorusPas encore d'évaluation

- Organizational APQP Responsibilities and Interfaces: ElementDocument2 pagesOrganizational APQP Responsibilities and Interfaces: ElementTutis05Pas encore d'évaluation

- QO390-SS200025 Technical Sheet (Actuated On Off Valve & RESDVForel Bronang)Document2 pagesQO390-SS200025 Technical Sheet (Actuated On Off Valve & RESDVForel Bronang)Iqbal MatondangPas encore d'évaluation

- Safe Distance Stored Energy Calculator - Pneumatic TestingDocument3 pagesSafe Distance Stored Energy Calculator - Pneumatic TestingKarthikeyan ShanmugavelPas encore d'évaluation

- ASTM ComparisonDocument1 pageASTM ComparisonKarthikeyan ShanmugavelPas encore d'évaluation

- Ship Loose Spools Packing DetailsDocument2 pagesShip Loose Spools Packing DetailsKarthikeyan ShanmugavelPas encore d'évaluation

- Iob Service Charges 01012019Document4 pagesIob Service Charges 01012019Karthikeyan ShanmugavelPas encore d'évaluation

- Rietu To: TR TR Saving CurrentDocument2 pagesRietu To: TR TR Saving CurrentKarthikeyan ShanmugavelPas encore d'évaluation

- AISI 1015 Carbon Steel (UNS G10150) : Topics CoveredDocument3 pagesAISI 1015 Carbon Steel (UNS G10150) : Topics CoveredKarthikeyan ShanmugavelPas encore d'évaluation

- Cooker ManualDocument2 pagesCooker ManualKarthikeyan ShanmugavelPas encore d'évaluation

- KT-100/ KT-200 Series Ultrasonic Thickness GaugesDocument1 pageKT-100/ KT-200 Series Ultrasonic Thickness GaugesKarthikeyan ShanmugavelPas encore d'évaluation

- ASME Section I and VIII-Div-1 Training Course OutlineDocument2 pagesASME Section I and VIII-Div-1 Training Course OutlineKarthikeyan ShanmugavelPas encore d'évaluation

- CH4 2 Welding Joint PreparationDocument46 pagesCH4 2 Welding Joint PreparationMatija BušićPas encore d'évaluation

- Chart Hydrostatic Test ASME RenewalDocument4 pagesChart Hydrostatic Test ASME RenewalKarthikeyan ShanmugavelPas encore d'évaluation

- Flow Chart - QCDocument2 pagesFlow Chart - QCKarthikeyan Shanmugavel100% (1)

- Ammonia Vaporizer ITPDocument2 pagesAmmonia Vaporizer ITPKarthikeyan ShanmugavelPas encore d'évaluation

- Ammonia Vaporizer ITPDocument2 pagesAmmonia Vaporizer ITPKarthikeyan ShanmugavelPas encore d'évaluation

- All in One Standards Introduction PDFDocument136 pagesAll in One Standards Introduction PDFKarthikeyan ShanmugavelPas encore d'évaluation

- Pipe and Tube Comparison and Application AreasDocument8 pagesPipe and Tube Comparison and Application AreasKarthikeyan ShanmugavelPas encore d'évaluation

- Release Note For DeliveryDocument6 pagesRelease Note For DeliveryKarthikeyan ShanmugavelPas encore d'évaluation

- Coimbatore: PSG College of Technology Campus Peelamedu, Coimbatore 641 004 PH: (0422) 2580733, EmailDocument1 pageCoimbatore: PSG College of Technology Campus Peelamedu, Coimbatore 641 004 PH: (0422) 2580733, EmailKarthikeyan ShanmugavelPas encore d'évaluation

- Surface Preparation StandardDocument5 pagesSurface Preparation StandardKarthikeyan ShanmugavelPas encore d'évaluation

- 1MRK504051-UEN - AM RET670 IEC 1pBDocument430 pages1MRK504051-UEN - AM RET670 IEC 1pBJOSEPas encore d'évaluation

- 1.5 3.8t XE Series Electric Forklift With Li Ion TechnologyDocument6 pages1.5 3.8t XE Series Electric Forklift With Li Ion TechnologyScottJacksonPas encore d'évaluation

- I-1a FarmMech 1-11Document12 pagesI-1a FarmMech 1-11SannyBombeoJomocPas encore d'évaluation

- Technical Data Sheet-Apfc Panel SL - No Description Specification Make of EquipmentDocument2 pagesTechnical Data Sheet-Apfc Panel SL - No Description Specification Make of EquipmentPraveen KumarPas encore d'évaluation

- Blue Paper 1 1Document6 pagesBlue Paper 1 1Washington Examiner100% (4)

- Database Management System - Ch07Document25 pagesDatabase Management System - Ch07Osei BanningPas encore d'évaluation

- The ECDIS Solution: Chartpilot 1100Document8 pagesThe ECDIS Solution: Chartpilot 1100Thutasoe thomasPas encore d'évaluation

- Grameenphone ReportDocument122 pagesGrameenphone ReportNayamotPas encore d'évaluation

- Yale mr14 16Document26 pagesYale mr14 16Aren MendozaPas encore d'évaluation

- DE0 CV User Manual 112Document60 pagesDE0 CV User Manual 112RicardoPas encore d'évaluation

- Service Bulletin: Firmware Upgrade (Upgrade Pack Ver. V1.02) FS-6030MFP, FS-6025MFP, FS-6025MFP/BDocument1 pageService Bulletin: Firmware Upgrade (Upgrade Pack Ver. V1.02) FS-6030MFP, FS-6025MFP, FS-6025MFP/Bdorcelli1234Pas encore d'évaluation

- Unicorn 150Document2 pagesUnicorn 150Nirmal GorePas encore d'évaluation

- DO-363 Modelo RelatorioDocument15 pagesDO-363 Modelo RelatorioJosue Jet avionicsPas encore d'évaluation

- Base Line: Air. Anytime. AnywhereDocument4 pagesBase Line: Air. Anytime. Anywheremogwai71Pas encore d'évaluation

- SessionDocument13 pagesSessionVarun BhandariPas encore d'évaluation

- Animation Bridge Rectifier NonidealDocument24 pagesAnimation Bridge Rectifier NonidealAla'a HusseinPas encore d'évaluation

- 01 Mototrbo OverviewDocument21 pages01 Mototrbo OverviewirwanPas encore d'évaluation

- SmartHDM Brochure English A4Document6 pagesSmartHDM Brochure English A4dawitPas encore d'évaluation

- Robbi PDocument4 pagesRobbi PRizki AprilrianaPas encore d'évaluation

- As ISO 8930-2005 General Principles On Reliability of Structures - List of Equivalent TermsDocument6 pagesAs ISO 8930-2005 General Principles On Reliability of Structures - List of Equivalent TermsSAI Global - APACPas encore d'évaluation

- Simplification of WCS and ED Syllabus of Max 40 Hours Each and Merging With Trade TheoryDocument415 pagesSimplification of WCS and ED Syllabus of Max 40 Hours Each and Merging With Trade TheorySourav ChowdhuryPas encore d'évaluation

- RAN Feature Documentation RAN17.1 - 10 - ANRDocument117 pagesRAN Feature Documentation RAN17.1 - 10 - ANRbrunoPas encore d'évaluation

- Us 16 Malone Using An Expanded Cyber Kill Chain Model To Increase Attack ResiliencyDocument27 pagesUs 16 Malone Using An Expanded Cyber Kill Chain Model To Increase Attack ResiliencytesterPas encore d'évaluation

- Big Data in FintechDocument21 pagesBig Data in Fintechakanksha_ambitionPas encore d'évaluation

- WebDocument72 pagesWebRakesh GunduPas encore d'évaluation

- Analysis of @darealbubu - Whotwi Graphical Twitter AnalysisDocument1 pageAnalysis of @darealbubu - Whotwi Graphical Twitter Analysisdeer muPas encore d'évaluation

- N.D N.D N.D: Free Proxy List - Free Proxy Servers - ProxydDocument1 pageN.D N.D N.D: Free Proxy List - Free Proxy Servers - ProxydJesús David PerezPas encore d'évaluation

- Mechnotes: Electrical and Electronics EngineeringDocument17 pagesMechnotes: Electrical and Electronics EngineeringRanchuPas encore d'évaluation

- Service Manual 'B' SC Vac 16 L. AL2Document71 pagesService Manual 'B' SC Vac 16 L. AL2Anwar Dheen67% (3)

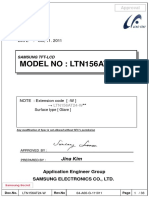

- Ltn156at24 W01 PDFDocument33 pagesLtn156at24 W01 PDFspider. methanolPas encore d'évaluation