Académique Documents

Professionnel Documents

Culture Documents

Manual Intelligent Barriers Instruction: Pdf 文件使用 "Pdffactory Pro" 试用版本创建

Transféré par

Oliver HermosaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Manual Intelligent Barriers Instruction: Pdf 文件使用 "Pdffactory Pro" 试用版本创建

Transféré par

Oliver HermosaDroits d'auteur :

Formats disponibles

MAnual

Intelligent barriers

Instruction

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

Table of contents:

1) Outline Features 2

2) Production Type 2

3) Functions and speciation 2

4) Working environment 3

5) The machine core of the barriers 3

6) Barriers installation and debug 5

6.1) Installation for the mechanism. 5

6.2) Debug for the mechanism. 6

6.3)The selection, installation and adjustment of the spring 9

6.4)Electrical connections 11

6.5)Debug 13

7) What to do if... 13

Rider. 14

Packing list 18

PDF 文件使用 "pdfFactory Pro" 试用版本创建 炣

www.fineprint.cn

1) Outline Features

Our series intelligent barriers use the international newest tech-nical design and

manufactured with precision machine tool. The automatic and intelligent barriers can be used

convenient and safely added our the humanization clutch device and balance device.

2) Production Type

3) Functions and speciation

3.1) The humanization clutch make you loosen the barriers bar conveniently .After open the

humanization clutch. You can up or down the bars by hand easy. The control system can

be reset automatically when power on.

3.2)Special craft machine core with the mechanism and the ele-ctronic technology and use the

compress spring. Compress spring prevent the system accident from the drawing spring

breaking ,which is often happen.

3.3) Three keys control the barriers bar up , down and stop..

3.4) Pototest, the best possible solution for safety.

3.5)Vehicles detector connection.

3.6) IC card connection.

3.7)Red and green traffic lights connection.

3.8)Radio control or line key control selection.

3.9)RS-485 communication.

4) Working environment

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

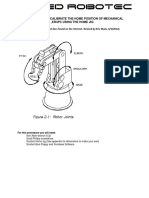

5) The machine core of the barriers

The barriers installation and debug

The left side barriers installation

Fig.1

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

The right side barriers installation

The bar inside the gate

Fig.2

6) Barriers installation and debug

Fig.3

6.1) Installation for the mechanism.

6.1.1)Select the right barriers production code and fix the barr-iers base with screws refer the

diagram.

6.1.2)Demount the cover of the bars tray. And mount the bar onand fixed it by the screws on

compress board. And then cover the barrier's cover.

6.1.3)Unlock the clutch by clutch handle clockwise .move bar-rier's bar by hand to the horizontal

position and vertical position by hand. Make sure that and lock the clutch dev-ice. And

power on the system.

Fig.4

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

6.2) Debug for the mechanism.

6.2.1)Almost all barriers have been set well in our factory.If you find something not satisfy you

need ,you can adjust it you-rself but you should make sure the barriers and the control

circuit have been power off.

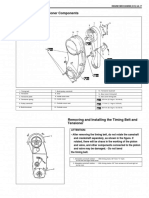

6.2.2)Open the barriers cover:firstly, screw the cover fixedscrews (refer the Fig.5) .Secondly, open

the barriers door and screw the lock nut. Thirdly , open the barriers cover.

6.2.3) The bars move to vertical position by motor if the bars isnot at vertical position you can

loosen the screw 1 that use to adjust the vibrancy of the bars. And reduce the distance

between the screw 1 and cushion. and check if the bar is at vertical position . if not, continue

to adjust the di-stance between the screw 1 and cushion. (refer Fig. 6)If the bar is unsteady

(refer diagram7) you can screw adjust screws of the balance spring clockwise to make the

pull spring tighten. (note :the pull spring can not been too tight refer Fig. 4 when adjusting

the bars)

Fig.5

6.2.4)Adjust the bars when the bar move to vertical position by hand or the bar come back for

hitting something.

6.2.4.1)If the bars is unsteady at the vertical position you can make the bar stop at the position

refer the Fig. 7 and adjust the pull spring tighten or loosen. Make the bars stop at that

position steady.

6.2.4.2)If the bar librate too much when come back for hitting something .you can power off first

and unlock the clutch by clutch key . then move the bar to the vertical position and

continue the step 6.2.4.1). If the bars is unsteady still after step 6.2.4.1), you can select

the follow way :

a change the pull spring link position from hole 1 to hole 2 .

b change the pull spring type then readjust the bar againby step 6.2.4.1).

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

6.2.5.1)If the bars is not right at the horizontal position, you can try the follow ways:

a. You can loosen the screw 2 that use to adjust the vibrancy of the bars when it at the horizontal

position.

b. Screw the screw between the link pole anticlockwise or clo-ckwise until the bar to the

horizontal position.

6.2.5.2) If the bar librate too much when the bar go to the horiz-ontal position (refer Fig.9.1)

You can loosen the screw 2 that use to adjust the vibra-ncy of the bars when it at the

horizontal position. If thisway can not satisfy you can unlock the unlock the clut-ch and

move the bars to the vertical position to adjustthe pull spring tighten or loosen, and

lock the clutchturn on the control system check it .If the bar librate toomuch still , you

can repeat the last step.

6.2.6) If the clutch can not been unlock you should check that the contact between the screw 2 that

use to adjust the vi-brancy of the bars and the cushion is too tight or checkif the adjust

balance spring is suitable length , you can p-ull up or pull down the bars lightly when

unlock the clut-ch(refer Fig.4).

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

6.3).The selection, installation and adjustment of the spring

A.Selection:

Balance spring:

Diagram for balance spring selection

(The date above just match with the bar produced by out company)

B.Installation:

a.Select a right spring and insert it into the spring canister.

b .Put the spring and the canister into the Spring base.

c. Insert the screw thread pole from the top hole of the flat to the center of the spring, and use the

right screw to fix it on to the right hang hole.

d.Install the gasket and the Adjust screw at the bottom of the sc-rew thread pole,deasil spin the

Adjust screw to adjust the str-ess of the spring and make the bar balance.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

C. Exchang:

a. Unlock the clutch and put the bar at the vertical position,and do not let the bar fall.

b. Anticlockwise spin the Adjust screw and unlade the it and ca-nister.

c. Put the bar at the horizontal position, unlade the link hole sc-rew and take out the screw thread

pole.

d. Loosen the fix screws for spring base and take out sleeve, ex-change the right spring and put

it into the spring base.(Fig.10)

e. Insert the screw thread pole and hitch it in the link hole.

f. Put the bar at the vertical position and do not let it fall.

g.Install the gasket and the Adjust screw at the bottom of the sc-rew thread pole, deasil spin

the Adjust screw to adjust the str-ess of the spring and make the bar balance.

D.Adjustment:

You can adjust the spring by deasil or anticlockwise spin the

Adjust screw, please refer to Fig.11 for the best state.

a. The bar can be pull to vertical position by spring at the uptrendarea.

b. The bar can keep motionless at the balance area.

c. The bar can fall to horizontal position by its weight at the do-wntrend area.

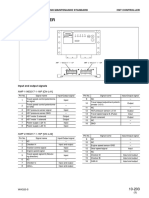

6.5)Debug

6.5.1) Control the machine:Put the main power on, use the radio controller to control

the machine.If you find the bar does not work normally, check if the Vehicles detector is

working. Otherwire, ch-eck if the BAR TYPE SELECT switch is on the right po-sition.

(Refer Fig.11)

6.5.2) Automatic rise for resistance if the bar meet roadblock when falling, it will rise

autom-atically for safety.

6.5.3)Phototest if the infrared ray sending by the phototest is obstruct by something, the bar will

rise automatically.

6.5.4)R&G light The green light will turn on when the bar at the vertical po-sition,otherwise

the red light turn on.

6.5.5)Vehicles detector If the vehicles detector is installed correctly, the bar will

automatic rise when vehicles move on the detector loop,and it automatic fall when the

vehicles leave.

7) What to do if...

7.1)The motor run but the bar doesn't move:Check and make sure the clutch has lock.

7.2)The bar shake terrible when moving at the end.Adjust the balance spring.

7.3)The bar can't move to horizontal and vertical position.

a.Have not adjust the balance spring when exchang long bar to shot bar.

b.The sensor connector has not inserted in the circuit board.

c.The sensor is broken, exchange it with the same type.

7.4)The distance of radio turn short

a.Check the battery voltage of the mini radio controller is OK.

7.5)The machine do not move when press the radio controller

a. Check the fuse is all right

b.Check the radio codes are match.

7.6)The bar can not move normally when exchange the circuit board.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

A.Check if the BAR TYPE SELECT switch is right

Rider

If the radio controller or phototest are not match with the machi-ne, you must make their

radio code identical with the machine. Step:

Read the code:

The radio code is signed behind the matched radio controller and on the transformer of

the barrier controller.

How to code :

Open the radio controller cover, take out the battery. You can see the code pad on the PCB,

the code is from right to left, the first code on the right.Short the middle pad and the above

pad stands for 1, short the middle pad and the bottom pad stands for 0, N/C stands for X.

The follow code is:10XX0X1X

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

Phototest(Fig.13)

Packing list

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

Vous aimerez peut-être aussi

- Prompting Science and Engineering Students in Practical TrigonometryD'EverandPrompting Science and Engineering Students in Practical TrigonometryPas encore d'évaluation

- UntitledDocument76 pagesUntitledMohmed HafejeePas encore d'évaluation

- D-1967 (Clean) Quilting Machine ManualDocument33 pagesD-1967 (Clean) Quilting Machine Manualvalter craccoPas encore d'évaluation

- Vemco 612 User's ManualDocument25 pagesVemco 612 User's ManualRobert Cannavino100% (1)

- Installation Instructions For Vertical SystemsDocument12 pagesInstallation Instructions For Vertical SystemsMonty Va Al MarPas encore d'évaluation

- Memory Craf Service Manual T - 9000Document31 pagesMemory Craf Service Manual T - 9000Petronyo PitPas encore d'évaluation

- Cam and ValveDocument13 pagesCam and ValveTi PiccoliPas encore d'évaluation

- Alignment Light AdjustmentDocument11 pagesAlignment Light AdjustmentNooruddin DeroPas encore d'évaluation

- Windshield Wiper and Washer SystemsDocument22 pagesWindshield Wiper and Washer SystemsChristian MartinezPas encore d'évaluation

- TY Manual GC20606 en 01Document59 pagesTY Manual GC20606 en 01JOSE GARCIAPas encore d'évaluation

- Voith Friction Driven Conveyor Belt Motion Monitor - Voith TurboDocument4 pagesVoith Friction Driven Conveyor Belt Motion Monitor - Voith Turboatorresh090675Pas encore d'évaluation

- Y9453 User ManualDocument10 pagesY9453 User ManualcormiersaPas encore d'évaluation

- M-19216 8 - 14DX FAST Installation Avio 200 - 500 - PEDocument20 pagesM-19216 8 - 14DX FAST Installation Avio 200 - 500 - PEta quang khanhPas encore d'évaluation

- Six Shuttle Circular Loom User ManualDocument23 pagesSix Shuttle Circular Loom User Manualabdi75% (4)

- 512 User's ManualDocument17 pages512 User's ManualSam CozaPas encore d'évaluation

- Syringe Pump PG-901A Service Manual V1.0Document13 pagesSyringe Pump PG-901A Service Manual V1.0motaznasser117100% (1)

- Syncro Trak Service ManualDocument26 pagesSyncro Trak Service ManualMelina SbhPas encore d'évaluation

- 4bar Veloc Wiper CMDocument22 pages4bar Veloc Wiper CMManik SinghPas encore d'évaluation

- Seccion 3BDocument68 pagesSeccion 3BJuan Gabriel Hernandez LunaPas encore d'évaluation

- Heavy Duty Sewing Machine Servo MotorDocument15 pagesHeavy Duty Sewing Machine Servo MotorBill Jiang100% (3)

- Scorbot ER-III Arm Calibration & Testing (EDM)Document15 pagesScorbot ER-III Arm Calibration & Testing (EDM)pauloPas encore d'évaluation

- Mechanism Design TutorialDocument13 pagesMechanism Design Tutorialnikomi99Pas encore d'évaluation

- Bifurcated Fan OM ManualDocument10 pagesBifurcated Fan OM ManualYana AzaharPas encore d'évaluation

- Cutter Option: Installation InstructionsDocument14 pagesCutter Option: Installation InstructionsDan ChiPas encore d'évaluation

- 3 D Printer ManualDocument14 pages3 D Printer ManualyuliantoPas encore d'évaluation

- Caterpillar Cat M322D Wheeled Excavator (Prefix W2S) Service Repair Manual (W2S00001 and Up) PDFDocument22 pagesCaterpillar Cat M322D Wheeled Excavator (Prefix W2S) Service Repair Manual (W2S00001 and Up) PDFfkdmma100% (1)

- For Safety: 1. Before Us e Ing MachineDocument24 pagesFor Safety: 1. Before Us e Ing MachineandresPas encore d'évaluation

- User Manual CNCHK 9.2Document38 pagesUser Manual CNCHK 9.2KursergPas encore d'évaluation

- Dxdf-40vi ManualDocument25 pagesDxdf-40vi ManualCarlos RamirezPas encore d'évaluation

- Courseware Sample: Mechanical Training SystemDocument28 pagesCourseware Sample: Mechanical Training SystemSreenivasPas encore d'évaluation

- Ysc 8320Document32 pagesYsc 8320flaudemir aparecidoPas encore d'évaluation

- EC 120 Adjustment Using The STEADYControl Adjustment Equipment - Cabin Antivibrators (AMM 53-37-00, 5-2)Document16 pagesEC 120 Adjustment Using The STEADYControl Adjustment Equipment - Cabin Antivibrators (AMM 53-37-00, 5-2)Latest RumorPas encore d'évaluation

- Spe11t050a 2 PDF 1Document20 pagesSpe11t050a 2 PDF 1Antoni WójcikPas encore d'évaluation

- Memory Craft 3000Document31 pagesMemory Craft 3000Craig JenkinsPas encore d'évaluation

- Manual Book ZS 265Document8 pagesManual Book ZS 265Yulissa Paola Galeana RamosPas encore d'évaluation

- Suzuki APV Service ManualDocument7 pagesSuzuki APV Service ManualdhgdfgPas encore d'évaluation

- Ferris 400S Series Dealer Setup & Adjustment Instructions ManualDocument16 pagesFerris 400S Series Dealer Setup & Adjustment Instructions ManualGustavs KrievkalnsPas encore d'évaluation

- 6 SteeringDocument63 pages6 SteeringAdrian MotocPas encore d'évaluation

- Kickert Bowed SpreaderDocument5 pagesKickert Bowed SpreaderOSAMAPas encore d'évaluation

- Dokumen - Tips - Planmed Sophie Part2 ServicemanualDocument37 pagesDokumen - Tips - Planmed Sophie Part2 ServicemanualMohammed BenzaidiPas encore d'évaluation

- Singer 7466 Service ManualDocument40 pagesSinger 7466 Service ManualRamon Johnson100% (2)

- Eaton CM-52 Remote Racking IL02400003EDocument16 pagesEaton CM-52 Remote Racking IL02400003EadvancedmotorPas encore d'évaluation

- Alineacion CatDocument4 pagesAlineacion CatAndrea Zalamea100% (1)

- E-Brake-Adjust-Instructions 1Document1 pageE-Brake-Adjust-Instructions 1greg titanPas encore d'évaluation

- Autodesk Inventor - Cam and ValveDocument12 pagesAutodesk Inventor - Cam and ValveNdianabasi UdonkangPas encore d'évaluation

- Manual Tong WTMDocument45 pagesManual Tong WTMYuliana Andrea Zapata Rubio100% (1)

- KYB and Showa Shock ServiceDocument4 pagesKYB and Showa Shock ServiceJose Luis SabinoPas encore d'évaluation

- DDL 8100e ManualDocument14 pagesDDL 8100e ManualiwanPas encore d'évaluation

- HTTPSWWW - Juki.co - Jpindustrial Jdownload Jmanual Jdlu5494n7it100amenusc922pdfinstruction Eg PDFDocument61 pagesHTTPSWWW - Juki.co - Jpindustrial Jdownload Jmanual Jdlu5494n7it100amenusc922pdfinstruction Eg PDFHoàng TônPas encore d'évaluation

- Manual Stiga VILLA 92 MDocument6 pagesManual Stiga VILLA 92 MCzesław WierzchowskiPas encore d'évaluation

- Nagel Foldnak 4Document24 pagesNagel Foldnak 4Victor Kawaii100% (1)

- The 2nd Assessment ProblemDocument4 pagesThe 2nd Assessment ProblemrisirarocksPas encore d'évaluation

- Instruction For Tubular Motor: NO35, NO45 NO60/NOM60 SeriesDocument2 pagesInstruction For Tubular Motor: NO35, NO45 NO60/NOM60 SeriesMarcio LopesPas encore d'évaluation

- Horizontal Band SawDocument17 pagesHorizontal Band SawOscar AdrianPas encore d'évaluation

- S400-User Manual EN - Set-1340243890Document15 pagesS400-User Manual EN - Set-1340243890noriel llanetaPas encore d'évaluation

- A21 Engine - 1.6Document53 pagesA21 Engine - 1.6ahmedPas encore d'évaluation

- Module 17 Physics 605Document24 pagesModule 17 Physics 605Automan IntertradePas encore d'évaluation

- Sprint 3000 Bookletmaker Service ManualDocument32 pagesSprint 3000 Bookletmaker Service ManualCaroline DanielPas encore d'évaluation

- Catalogo TypicalDocument40 pagesCatalogo TypicalLiliana SantanaPas encore d'évaluation

- Paul Gill - Eqpt Maint & TestingDocument1 pagePaul Gill - Eqpt Maint & TestingOliver HermosaPas encore d'évaluation

- HV Sheath Voltage Calculation - SampleDocument8 pagesHV Sheath Voltage Calculation - SampleOliver HermosaPas encore d'évaluation

- Non-Segregated Phase Bus Duct BR en 6 2012Document8 pagesNon-Segregated Phase Bus Duct BR en 6 2012Aziddin GadingPas encore d'évaluation

- Copper Bus Bar Ampacity - TablesDocument4 pagesCopper Bus Bar Ampacity - TablesOliver HermosaPas encore d'évaluation

- Schneider (1000A) Bus DuctDocument342 pagesSchneider (1000A) Bus DuctOliver HermosaPas encore d'évaluation

- Panel Wiring Cable SpecsDocument8 pagesPanel Wiring Cable SpecsOliver HermosaPas encore d'évaluation

- Turn StilDocument3 pagesTurn StilOliver HermosaPas encore d'évaluation

- Canalis KSDocument36 pagesCanalis KSrubysultanaPas encore d'évaluation

- Eaton Nonsegregated BusductDocument28 pagesEaton Nonsegregated BusducthanythekingPas encore d'évaluation

- 3PH Electric Chain Hoist ManualDocument48 pages3PH Electric Chain Hoist ManualOliver HermosaPas encore d'évaluation

- Cutler Hammer Bus DuctsDocument28 pagesCutler Hammer Bus DuctsOliver HermosaPas encore d'évaluation

- Pipeline Protection TechnicalDocument4 pagesPipeline Protection TechnicalOliver HermosaPas encore d'évaluation

- Canalis KSDocument36 pagesCanalis KSrubysultanaPas encore d'évaluation

- Apollo Swing GateDocument25 pagesApollo Swing GateOliver HermosaPas encore d'évaluation

- Apollo Swing GateDocument25 pagesApollo Swing GateOliver HermosaPas encore d'évaluation

- Manual Intelligent Barriers Instruction: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Document14 pagesManual Intelligent Barriers Instruction: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Oliver HermosaPas encore d'évaluation

- Steel Conduit Install GuideDocument7 pagesSteel Conduit Install GuideOliver HermosaPas encore d'évaluation

- Steel Conduit Install Guide PDFDocument32 pagesSteel Conduit Install Guide PDFOliver Hermosa100% (1)

- Stauff Surface Cable ClampsDocument54 pagesStauff Surface Cable ClampsOliver HermosaPas encore d'évaluation

- Tyco Plastic ConduitsDocument6 pagesTyco Plastic ConduitsOliver HermosaPas encore d'évaluation

- Cannon Cable PrinterDocument6 pagesCannon Cable PrinterOliver HermosaPas encore d'évaluation

- Thermal ImagerDocument46 pagesThermal ImagerOliver HermosaPas encore d'évaluation

- Cannon Cable Printer PDFDocument2 pagesCannon Cable Printer PDFOliver HermosaPas encore d'évaluation

- Thermal Imager PDFDocument24 pagesThermal Imager PDFOliver HermosaPas encore d'évaluation

- Caddy Electrical Fixings PDFDocument2 pagesCaddy Electrical Fixings PDFOliver HermosaPas encore d'évaluation

- Bentel by Tyco Fire Catalgoye PDFDocument36 pagesBentel by Tyco Fire Catalgoye PDFOliver HermosaPas encore d'évaluation

- Caddy Electrical FixingsDocument36 pagesCaddy Electrical FixingsOliver HermosaPas encore d'évaluation

- Farnell SS Cable TiesDocument5 pagesFarnell SS Cable TiesOliver HermosaPas encore d'évaluation

- Caddy Pyramid Pipe SupportsDocument12 pagesCaddy Pyramid Pipe SupportsOliver HermosaPas encore d'évaluation

- Cable Gland Size TableDocument1 pageCable Gland Size TableOliver HermosaPas encore d'évaluation

- Budgetary Cost - TNB Sub Station Electrical WorkDocument2 pagesBudgetary Cost - TNB Sub Station Electrical WorkAhmad Hisham Shuhim33% (3)

- Manual Del CronómetroDocument2 pagesManual Del CronómetroLupita VelpePas encore d'évaluation

- Ashok Leyland LimitedDocument19 pagesAshok Leyland LimitedgsPas encore d'évaluation

- Liquid Crystals Seminar SMDocument7 pagesLiquid Crystals Seminar SMSmriti100% (1)

- PSoC3 Architecture TRM 001-50235Document456 pagesPSoC3 Architecture TRM 001-50235nickynick2007Pas encore d'évaluation

- Mobile Business Intelligence App Design & DevelopmentDocument2 pagesMobile Business Intelligence App Design & DevelopmentInfoCepts IncPas encore d'évaluation

- NTDCL 2023 InterviwesDocument12 pagesNTDCL 2023 InterviwesAehtsham Ul HaqPas encore d'évaluation

- Electronic Circuits and Analysis-I Lab ECE 217 Credits:2Document49 pagesElectronic Circuits and Analysis-I Lab ECE 217 Credits:2vj86Pas encore d'évaluation

- SummitFamilySwitchesHardwareInstallationGuide Rev05Document210 pagesSummitFamilySwitchesHardwareInstallationGuide Rev05Valdir SouzaPas encore d'évaluation

- KC 62133-2-제정고시 제2020-0138호 (2020.07.21.)Document52 pagesKC 62133-2-제정고시 제2020-0138호 (2020.07.21.)on.insight1829Pas encore d'évaluation

- HD Led Projector: User's ManualDocument14 pagesHD Led Projector: User's Manualmr_silencioPas encore d'évaluation

- WinPower Quick Installation and SetupDocument12 pagesWinPower Quick Installation and SetupcadutaPas encore d'évaluation

- True RMS Voltmeter: Instruction ManualDocument124 pagesTrue RMS Voltmeter: Instruction ManualRafa DuverheisenPas encore d'évaluation

- 3 2 4 Teacher Notes Wave BehaviorDocument6 pages3 2 4 Teacher Notes Wave Behaviorapi-369706779Pas encore d'évaluation

- HST Pines Komatsu Wa320Document1 pageHST Pines Komatsu Wa320Victor Rodrigo Cortes YañezPas encore d'évaluation

- Analog & Discrete IC Design: Dr. Ali Imran Najam 21 01 12Document38 pagesAnalog & Discrete IC Design: Dr. Ali Imran Najam 21 01 12Muhammad AdnanPas encore d'évaluation

- A I RS: David G. Dorrell, William ThomsonDocument11 pagesA I RS: David G. Dorrell, William ThomsonEng Bagaragaza RomualdPas encore d'évaluation

- EasyCan Brochure 2013Document14 pagesEasyCan Brochure 2013nooruddinkhan1Pas encore d'évaluation

- Selak - Power System Protection - Where Are We Today PDFDocument42 pagesSelak - Power System Protection - Where Are We Today PDFIvan CabanalanPas encore d'évaluation

- Chapter 1Document21 pagesChapter 1iris33% (3)

- Plastic-Insulated Winding Wires: Norddeutsche Seekabelwerke GMBH & Co. KGDocument6 pagesPlastic-Insulated Winding Wires: Norddeutsche Seekabelwerke GMBH & Co. KGcesar007chPas encore d'évaluation

- Error Code Manual For ECORAY Generator XR7Document16 pagesError Code Manual For ECORAY Generator XR7Tekniah GlobalPas encore d'évaluation

- Datasheet: ToshibaDocument11 pagesDatasheet: ToshibaSergio Trujillo CerroPas encore d'évaluation

- The Quest For Robust Wireless High-Def Video Connections: Voice of The EngineerDocument56 pagesThe Quest For Robust Wireless High-Def Video Connections: Voice of The EngineerJim Redpath100% (2)

- Bose: Competing by Being Truly DifferentDocument4 pagesBose: Competing by Being Truly DifferentAngela AngelesPas encore d'évaluation

- Troubleshooting - Physical Connection and Interfaces (V600R003C00 - 02)Document44 pagesTroubleshooting - Physical Connection and Interfaces (V600R003C00 - 02)Euripedes Pimenta Da Silva JuniorPas encore d'évaluation

- IEEE STD 404-2012 RedlineDocument89 pagesIEEE STD 404-2012 Redlineanonimoefra100% (1)

- Concept of Electrical InterlocksDocument15 pagesConcept of Electrical Interlocksprateek43513100% (1)

- Plano Antena Yagi Frecuencia 850 MHZDocument2 pagesPlano Antena Yagi Frecuencia 850 MHZageroPas encore d'évaluation

- JOB SHEET Drafting PCBDocument3 pagesJOB SHEET Drafting PCBZeen DeePas encore d'évaluation