Académique Documents

Professionnel Documents

Culture Documents

Victor Tip Charts: Acetylene Cutting Tip Chart

Transféré par

ahmedTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Victor Tip Charts: Acetylene Cutting Tip Chart

Transféré par

ahmedDroits d'auteur :

Formats disponibles

Victor Tip Charts

ACETYLENE

Cutting Tip Chart

Cutting Tip Series 1-101 and 3-101

Metal Tip Cutting Preheat Acetylene Speed Kerf

Thickness Size Oxygen (PSIG)*** Oxygen (PSIG)* Pressure (PSIG) I.P.M. Width

1/8" 000 20/25 3/5 3/5 20/30 .04

1/4" 00 20/25 3/5 3/5 27/30 .05

3/8" 0 25/30 3/5 3/5 24/28 .06

1/2" 0 30/35 3/6 3/5 20/24 .06

3/4" 1 30/35 4/7 3/5 17/21 .07

1" 2 35/40 4/8 3/6 15/19 .09

2" 3 40/45 5/10 4/8 12/15 .11

3" 4 40/50 5/10 5/11 9/12 .12

4" 5 45/55 6/12 6/13 8/11 .15

6" 6** 45/55 6/15 8/14 6/8 .15

10" 7** 45/55 6/20 10/15 4/5 .34

12" 8** 45/55 7/25 10/15 3/5 .41

* Applicable for 3-hose machine cutting torches only. With a 2-hose cutting torch, preheat pressure is set by the cutting oxygen.

** For best results use appropriate capacity torches and 3/8" hose when using tip size 6 or larger. Torches with flashback

arrestors require up to 25% more pressure as tip size increases (15 PSI maximum acetylene pressure).

*** All pressures are measured at the regulator using a 25' X 3/8" hose for tip size 6 and larger.

CAUTION

At no time should the withdrawal rate of an individual acetylene cylinder exceed 1/7 of the cylinder contents per hour.

If additional flow capacity is required, use an acetylene manifold system of sufficient size to supply the necessary volume.

Welding Nozzle Flow Data

Oxygen Acetylene Acetylene

Metal Tip Drill Pressure (PSIG) Pressure (PSIG) Consumption (SCFH)

Thickness Size Size

Min Max Min Max Min Max

Up to 1/32" 000 75 (.022) 3 5 3 5 1 2

1/16" - 3/64" 00 70 (.028) 3 5 3 5 1 1/2 3

1/32" - 5/64" 0 65 (.035) 3 5 3 5 2 4

3/64" - 3/32" 1 60 (.040) 3 5 3 5 3 6

1/16" - 1/8" 2 56 (.046) 3 5 3 5 5 10

1/8" - 3/16" 3 53 (.060) 4 7 3 6 8 18

3/16" - 1/4" 4 49 (.073) 5 10 4 7 10 25

1/4" - 1/2" 5 43 (.089) 6 12 5 8 15 35

1/2" - 3/4" 6 36 (.106) 7 14 6 9 25 45

3/4" - 1 1/4" 7 30 (.128) 8 16 8 10 30 60

1 1/4" - 2" 8 29 (.136) 10 19 9 12 35 75

2 1/2" - 3" 10 27 (.144) 12 24 12 15 50 100

3 1/2" - 4" 12* 25 (.149) 18 28 12 15 80 160

MFA Heating Nozzles

Tip Acetylene Pressure Oxygen Pressure Acetylene ft³/hr Oxygen ft³/hr BTU

Size Range (PSIG) Range (PSIG) Min Max Min Max per Hour

4 6 - 10 8 - 12 6 20 7 22

6 8 - 12 10 - 15 14 40 15 44

8 10 - 15 20 - 30 30 80 33 88

SEE BELOW **

10 12 - 15 30 - 40 40 100 44 110

12* 12 - 15 50 - 60 60 150 66 165

15* 12 - 15 50 - 60 90 220 99 244

* Use model HD310C torch and 3/8" hose.

** Approximately 1470 gross BTU per cubic foot.

65-2505 Support Documents © 2011 Thermadyne Industries, Inc. www.thermadyne.com

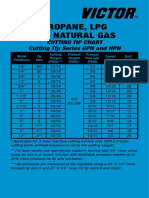

Victor Tip Charts

PROPANE, LPG and NATURAL GAS

Cutting Tip Chart

Cutting Tip Series GPN and HPN

Metal Tip Cutting Preheat Preheat Speed Kerf

Thickness Size Oxygen (PSIG)*** Oxygen (PSIG)* Fuel Gas (PSIG) I.P.M. Width

1/8" 000 20/25 3/5 24/28 .04

1/4" 00 20/25 3/5 21/25 .05

3/8" 0 25/30 3/5 20/24 .06

1/2" 0 30/35 3/5 18/22 .06

3/4" 1 30/35 FOR 3-HOSE 3/6 15/20 .08

1" 2 35/40 MACHINE 3/6 14/18 .09

1 1/2" 2 40/45 TORCHES ONLY 5/9 12/16 .09

2" 3 40/45 5/9 10/14 .10

2 1/2" 3 45/50 SEE TABLE 6/10 9/12 .10

3" 4 40/50 BELOW 8/12 8/11 .12

4" 5 45/55 8/12 7/10 .14

5" 5 50/55 8/12 6/9 .14

6" 6** 45/55 10/15 5/7 .17

8" 6** 55/65 10/15 4/6 .18

12" 8** 60/70 10/15 3/5 .24

* Applicable for 3-hose machine cutting torches only. With a 2-hose cutting torch, preheat pressure is set by the cutting oxygen.

** For best results use appropriate capacity torches and 3/8" hose when using tip size 6 or larger. Torches with flashback

arrestors require up to 25% more pressure as tip size increases.

*** All pressures are measured at the regulator using a 25' X 1/4" hose through tip size 5 and 25' X 3/8" hose for tip sizes

6 and larger.

Cutting Tip Series MTHN

(High Speed Machine Cutting)

Metal Tip Cutting Preheat Preheat Speed Kerf

Thickness Size Oxygen (PSIG) Oxygen (PSIG)* Fuel Gas (PSIG) I.P.M. Width

1/4" 00 85/95 23/30 .05

3/8" 00 85/95 22/29 .06

1/2" 0 85/95 18/26 .06

3/4" 0 85/95 17/24 .06

1" 1 85/95 15/22 .07

1 1/2" 1 85/95 12/16 .07

2" 2 85/95 SEE BELOW 11/15 .09

2 1/2" 2 85/95 10/13 .09

3" 2 85/95 9/11 .09

4" 3 85/95 7/10 .11

6" 3 85/95 5/7 .11

8" 4 85/95 4/6 .14

10" 5 85/95 3/5 .18

3 1/2" - 4" 12* 25 (.149) 18 28 12 15

NOTE: The above data applies to all torches with the following exceptions:

Torch Series Preheat Oxygen Preheat Fuel

MT200N Series N/A 8 oz. – up

MT300N Series 10-25 PSIG 8 oz. – up

NOTE: Data compiled used clean mild steel as test material.

*Pressure is measured at the torch inlet on MTH Series Tips. Torches with flashback arrestors require up to 25% more

pressure as tip size increases.

65-2505 Support Documents © 2011 Thermadyne Industries, Inc. www.thermadyne.com

Victor Tip Charts

PROPYLENE

Cutting Tip Chart

Cutting Tip Series GPP and HPP

Metal Tip Cutting Preheat Preheat Speed Kerf

Thickness Size Oxygen (PSIG)*** Oxygen (PSIG)* Fuel Gas (PSIG) I.P.M. Width

1/8" 000 20/25 2/5 24/28 .04

1/4" 00 20/25 2/5 21/25 .05

3/8" 0 25/30 3/5 20/24 .06

1/2" 0 25/35 3/5 18/22 .06

3/4" 1 30/35 3/6 15/20 .08

1" 2 35/40 3/6 14/18 .09

1 1/2" 2 40/45 FOR 3-HOSE 4/8 12/16 .09

MACHINE

2" 3 40/45 4/8 10/14 .10

TORCHES ONLY

2 1/2" 3 45/50 5/9 9/12 .10

3" 4 40/50 6/9 8/11 .12

SEE TABLE

4" 5 45/55 6/9 7/10 .14

BELOW

5" 5 50/55 6/10 6/9 .14

6" 6** 45/55 6/10 5/7 .17

8" 6** 55/65 8/12 4/6 .18

10" 7** 55/65 8/12 3/5 .34

12" 8** 60/70 10/14 3/4 .41

15" 10** 50/70 10/16 2/4 --

18" 12** 45/65 -- 2/3 --

* Applicable for 3-hose machine cutting torches only. With a 2-hose cutting torch, preheat pressure is set by the cutting oxygen.

** For best results use appropriate capacity torches and 3/8" hose when using tip size 6 or larger. Torches with flashback

arrestors require up to 25% more pressure as tip size increases (15 PSI maximum acetylene pressure).

*** All pressures are measured at the regulator using a 25' X 3/8" hose for tip size 6 and larger.

Cutting Tip Series MTHP

(High Speed Machine Cutting)

Metal Tip Cutting Preheat Preheat Speed Kerf

Thickness Size Oxygen (PSIG) Oxygen (PSIG) Fuel Gas (PSIG) I.P.M. Width

1/4" 00 85/95 23/30 .05

3/8" 00 85/95 22/29 .05

1/2" 0 85/95 20/28 .06

3/4" 0 85/95 18/26 .06

1" 1 85/95 17/24 .07

1 1/4" 1 85/95 16/20 .07

1 1/2" 1 85/95 12/16 .07

2" 2 85/95 11/15 .09

2 1/2" 2 85/95 SEE BELOW 10/13 .09

3" 2 85/95 9/11 .09

4" 3 85/95 7/10 .11

5" 3 85/95 6/8 .11

6" 3 85/95 5/7 .11

7" 4 85/95 5/6 .14

8" 4 85/95 4/6 .14

9" 5 85/95 4/5 .18

10" 5 85/95 3/5 .18

NOTE: The above data applies to all torches with the following exceptions:

Torch Series Preheat Oxygen Preheat Fuel

MT200N Series N/A 8 oz. – up

MT300N Series 10-25 PSIG 8 oz. – up

NOTE: These speeds and pressure settings apply only to mild steel in good condition. Torches with flashback arrestors

require up to 25% more pressure as tip size increases.

CAUTION

High gas withdrawal rates may require cylinder manifolding. Consult your gas supplier.

65-2505 Support Documents © 2011 Thermadyne Industries, Inc. www.thermadyne.com

Vous aimerez peut-être aussi

- SK 26139Document1 pageSK 26139eefutestPas encore d'évaluation

- Single-Reduction Forward Differential Carriers On Tandem and Tridem AxlesDocument132 pagesSingle-Reduction Forward Differential Carriers On Tandem and Tridem AxlesGlez BaPas encore d'évaluation

- Detroit Diesel Diagnostic CodesDocument21 pagesDetroit Diesel Diagnostic CodesVolvo TrucksPas encore d'évaluation

- Single-Reduction Differential Carriers: Single Rear Drive Axles, Rear-Rear Tandem Drive Axles and Front Drive Steer AxlesDocument94 pagesSingle-Reduction Differential Carriers: Single Rear Drive Axles, Rear-Rear Tandem Drive Axles and Front Drive Steer AxlesTavyLocPas encore d'évaluation

- DuraMax Manual REV5Document20 pagesDuraMax Manual REV5CanadaPoolPas encore d'évaluation

- 6.3.1 Gear Terms Lesson Rev3Document19 pages6.3.1 Gear Terms Lesson Rev3Deepak GirotraPas encore d'évaluation

- MC 10127081 9999Document4 pagesMC 10127081 9999Jose yanezPas encore d'évaluation

- Victor Propane LPG Natural Gas Cutting Tip ChartDocument2 pagesVictor Propane LPG Natural Gas Cutting Tip ChartYhamil La MadridPas encore d'évaluation

- Help Welding Calculation - WeldingDocument14 pagesHelp Welding Calculation - Weldingahmed100% (1)

- Pullers & Puller Sets Proto PDFDocument24 pagesPullers & Puller Sets Proto PDFMauricio GarciaPas encore d'évaluation

- Installation Instructions For DC and AC Electric Rewind ReelsDocument4 pagesInstallation Instructions For DC and AC Electric Rewind ReelsGinoGuanPas encore d'évaluation

- Genie 5394Document238 pagesGenie 5394Zian HennPas encore d'évaluation

- REG841 - Disassembly and Assembly (D6C TRACTOR ENGINE)Document178 pagesREG841 - Disassembly and Assembly (D6C TRACTOR ENGINE)jeffreyguy1Pas encore d'évaluation

- Sterling L Line A LineDocument2 894 pagesSterling L Line A LineJeremy JonesPas encore d'évaluation

- A Guide To Safe Farm Tractor OperationDocument29 pagesA Guide To Safe Farm Tractor OperationncysysPas encore d'évaluation

- Service Manual Trucks: Frame Rails and Crossmembers VN/VHDDocument66 pagesService Manual Trucks: Frame Rails and Crossmembers VN/VHDsetiup holjiPas encore d'évaluation

- 2016-Catalog Keene Engineering PDFDocument44 pages2016-Catalog Keene Engineering PDFZuwairi NawawiPas encore d'évaluation

- Ge W1001016 (TJK)Document118 pagesGe W1001016 (TJK)Ana Hernández MonterrubioPas encore d'évaluation

- Consumables For The Welding of Hardox, Strenx™, Toolox and Armox Techsupport #60Document8 pagesConsumables For The Welding of Hardox, Strenx™, Toolox and Armox Techsupport #60MOPas encore d'évaluation

- Compresor: Servi CE Parts LI ST F or 05G BUS 41 CF M HGB MF R # 6GCH00GTA03404Document12 pagesCompresor: Servi CE Parts LI ST F or 05G BUS 41 CF M HGB MF R # 6GCH00GTA03404Pablo Porras100% (1)

- Deposition RateDocument4 pagesDeposition Rateahmed100% (1)

- Propelyne ChartDocument2 pagesPropelyne ChartKurt BuehringPas encore d'évaluation

- Section 1.33 Bull Gear and Camshaft Idler Gear Assembly: Figure 1. Engine Gear TrainDocument9 pagesSection 1.33 Bull Gear and Camshaft Idler Gear Assembly: Figure 1. Engine Gear TrainJuanAméricaBerzunzaPas encore d'évaluation

- Axsm 0041Document98 pagesAxsm 0041Walter ╰⏝╯ MaonesPas encore d'évaluation

- John Deere 300 Lawn Garden Tractor Operators ManualDocument10 pagesJohn Deere 300 Lawn Garden Tractor Operators Manualsrude8008Pas encore d'évaluation

- Kubota D600B Service ManualDocument129 pagesKubota D600B Service Manualsebastião gonçalves mendonçaPas encore d'évaluation

- Starrett Inch Metric Tap DrillDocument1 pageStarrett Inch Metric Tap DrillJan baPas encore d'évaluation

- Salt Presentation2Document41 pagesSalt Presentation2asivachemPas encore d'évaluation

- Gas Cutting Pressure Tip Chart PDFDocument2 pagesGas Cutting Pressure Tip Chart PDFChozha RajanPas encore d'évaluation

- Module 6 PDFDocument180 pagesModule 6 PDFyoustruelyPas encore d'évaluation

- 10 Defects of TabletsDocument3 pages10 Defects of TabletsHolihuaChua100% (2)

- Iris PDFDocument4 pagesIris PDFdinhvuPas encore d'évaluation

- Chapter 3-Section 3.2-Cylinder BlockDocument46 pagesChapter 3-Section 3.2-Cylinder BlockNikkikumar MaisuriyaPas encore d'évaluation

- Series 60 - Section 1.9 Crankshaft Main BearingsDocument11 pagesSeries 60 - Section 1.9 Crankshaft Main BearingsJuan RiveraPas encore d'évaluation

- Arc Welding ElectrodesDocument6 pagesArc Welding ElectrodeswaleedyossefPas encore d'évaluation

- 76 Sears Tractors 3Document16 pages76 Sears Tractors 3andre leducPas encore d'évaluation

- Amta5 6 Applying Shielded Metal Arc Welding Smaw TechniquesDocument132 pagesAmta5 6 Applying Shielded Metal Arc Welding Smaw TechniquesSaurav Kumaar GuptaPas encore d'évaluation

- Rca Chassis Ctc185 Training Manual (ET)Document58 pagesRca Chassis Ctc185 Training Manual (ET)Keith GeusicPas encore d'évaluation

- Why Is "Cold Cutting" Superior To Plasma Cutting?Document9 pagesWhy Is "Cold Cutting" Superior To Plasma Cutting?ahmedPas encore d'évaluation

- Competency Based Learning Material: S: A F Q: O A P Ncii U C: P O V M T: P O VDocument36 pagesCompetency Based Learning Material: S: A F Q: O A P Ncii U C: P O V M T: P O VErethro Cytes80% (5)

- First Quarter Exam Tle 7 CookeryDocument8 pagesFirst Quarter Exam Tle 7 CookeryDominic Camacho Rota100% (2)

- Crowd Cylinder Assembly, Double Acting, 750-Series, 753-Series, 755-Series - 19-388,19-389,19-390Document5 pagesCrowd Cylinder Assembly, Double Acting, 750-Series, 753-Series, 755-Series - 19-388,19-389,19-390ws253294388Pas encore d'évaluation

- Method of Calculating The Cooling Rate in HAZ During WeldingDocument6 pagesMethod of Calculating The Cooling Rate in HAZ During WeldingahmedPas encore d'évaluation

- MRS 07updateDocument3 pagesMRS 07updateИгорь БасмановPas encore d'évaluation

- Unit - Iii: Ferrous and Non Ferrous MetalsDocument101 pagesUnit - Iii: Ferrous and Non Ferrous Metalssenthilkumar tsPas encore d'évaluation

- DESIGN OF PRESSURE VESSEL Full Report DEDocument48 pagesDESIGN OF PRESSURE VESSEL Full Report DELuis Muñoz100% (1)

- Gas SolubilityDocument59 pagesGas SolubilityAustine Ameh0% (1)

- Segadora de Discos R240 PDFDocument24 pagesSegadora de Discos R240 PDFcarlose_cordoba5065Pas encore d'évaluation

- Drill Bit Size ChartDocument22 pagesDrill Bit Size ChartahmedPas encore d'évaluation

- 40 Series Row Crop TractorDocument2 pages40 Series Row Crop TractorRafael SalazarPas encore d'évaluation

- What Is Mild SteelDocument2 pagesWhat Is Mild SteelahmedPas encore d'évaluation

- Corrosion and RustDocument9 pagesCorrosion and RustahmedPas encore d'évaluation

- 96 Rotary Hay MowerDocument65 pages96 Rotary Hay MowerАнатолій Гуменюк0% (1)

- Gear Ratio WorksheetDocument2 pagesGear Ratio WorksheetJosseline ObregónPas encore d'évaluation

- Landpreparation Tractor Operation and MaintenanceDocument8 pagesLandpreparation Tractor Operation and MaintenanceAmborsius SitorusPas encore d'évaluation

- National Ffa Offician Manual - 2020Document100 pagesNational Ffa Offician Manual - 2020api-526186145Pas encore d'évaluation

- AXSM0034-In Axle Speed SensorDocument34 pagesAXSM0034-In Axle Speed Sensorwadalla100100% (1)

- Shift - Pattern t1-t4 New - 1 PDFDocument1 pageShift - Pattern t1-t4 New - 1 PDFJPas encore d'évaluation

- 2 Interference in Spur GearsDocument2 pages2 Interference in Spur Gearschris100% (1)

- JD 2030 Kvačilo PDFDocument7 pagesJD 2030 Kvačilo PDFBranko Mikulinjak100% (1)

- 903 - Cylinder LinerDocument13 pages903 - Cylinder LinerVuHongNhatPas encore d'évaluation

- Dewalt Power Washer 4000 PsiDocument52 pagesDewalt Power Washer 4000 PsiTiftenPas encore d'évaluation

- Kubota 10 Commandments Tractor SafetyDocument10 pagesKubota 10 Commandments Tractor SafetyvaneaPas encore d'évaluation

- BHHayMowerdm PDFDocument20 pagesBHHayMowerdm PDFcoyote556100% (1)

- Blower 6/71Document6 pagesBlower 6/71RV PenrroiPas encore d'évaluation

- Service Bulletin Trucks: Instrumentation TroubleshootingDocument4 pagesService Bulletin Trucks: Instrumentation Troubleshootingsetiup holjiPas encore d'évaluation

- Gearsand GearingDocument57 pagesGearsand Gearingcamohunter71Pas encore d'évaluation

- Caterpillar D50 4 CAT C4.4 Spec SheeetDocument7 pagesCaterpillar D50 4 CAT C4.4 Spec SheeetKCV CoretechPas encore d'évaluation

- Miller - Ten Common TIG Problems - A Visual GuideDocument7 pagesMiller - Ten Common TIG Problems - A Visual GuideGabor VatoPas encore d'évaluation

- (1900-1915) IHC Mogul Oil EnginesDocument42 pages(1900-1915) IHC Mogul Oil EnginesHerbert Hillary Booker 2nd100% (2)

- Bombas Gorman RuppDocument12 pagesBombas Gorman RuppRafael Hernández RcrewPas encore d'évaluation

- RTXF-14708LL Eaton FullerDocument42 pagesRTXF-14708LL Eaton FullerAlexis Valle0% (1)

- Gator TX y TX TurfDocument340 pagesGator TX y TX TurfAlberto Garcia OliverPas encore d'évaluation

- 65-1501 Victor Boquillas Corte Serie 3Document3 pages65-1501 Victor Boquillas Corte Serie 3carlosPas encore d'évaluation

- Solder-Joint: Pressure Fittings Wrot Copper 45 Deg. ElbowDocument16 pagesSolder-Joint: Pressure Fittings Wrot Copper 45 Deg. ElbowayrtmoranPas encore d'évaluation

- Department OF Mechanical Engineering Technology: Materials Testing LaboratoryDocument2 pagesDepartment OF Mechanical Engineering Technology: Materials Testing LaboratoryahmedPas encore d'évaluation

- Department OF Mechanical Engineering Technology: Heat Engines LaboratoryDocument2 pagesDepartment OF Mechanical Engineering Technology: Heat Engines LaboratoryahmedPas encore d'évaluation

- Grade Structure Revamping TemplateDocument1 pageGrade Structure Revamping TemplateahmedPas encore d'évaluation

- Assignment No. 4 BlankDocument15 pagesAssignment No. 4 BlankahmedPas encore d'évaluation

- Measuring Metal Strength (Tensile & Impact Strength)Document5 pagesMeasuring Metal Strength (Tensile & Impact Strength)ahmedPas encore d'évaluation

- Btus, CFMS, and Gges DemystifiedDocument2 pagesBtus, CFMS, and Gges DemystifiedahmedPas encore d'évaluation

- ASGEpg187 PDFDocument3 pagesASGEpg187 PDFbkprodhPas encore d'évaluation

- Grinding Wheel SpecificationsDocument2 pagesGrinding Wheel SpecificationsahmedPas encore d'évaluation

- UNCUNF Threads - SizeDocument1 pageUNCUNF Threads - SizeahmedPas encore d'évaluation

- To Be Free From Oil and Dirt ADAPTOR, CGA-022 To 1/4 NPT GDG PSMDocument1 pageTo Be Free From Oil and Dirt ADAPTOR, CGA-022 To 1/4 NPT GDG PSMahmedPas encore d'évaluation

- What Is Hsla SteelDocument4 pagesWhat Is Hsla SteelahmedPas encore d'évaluation

- Difference Between Pipe and Tube: ShapeDocument3 pagesDifference Between Pipe and Tube: ShapeahmedPas encore d'évaluation

- The National Institute For Occupational Safety and Health (Niosh)Document1 pageThe National Institute For Occupational Safety and Health (Niosh)ahmedPas encore d'évaluation

- Understanding Copper AlloysDocument1 pageUnderstanding Copper AlloysahmedPas encore d'évaluation

- Equipment Operation: Safety GuidelinesDocument4 pagesEquipment Operation: Safety GuidelinesahmedPas encore d'évaluation

- Food Kitchen SafetyDocument45 pagesFood Kitchen SafetyLaila Idaloy ArcillasPas encore d'évaluation

- MSDS RUSTOFF 250 UnlockedDocument2 pagesMSDS RUSTOFF 250 UnlockedANCHAL RAJPUTPas encore d'évaluation

- Shuttle Valve PDFDocument17 pagesShuttle Valve PDFBenjamin Musa ダPas encore d'évaluation

- Enthalpy - Chemistry LibreTextsDocument5 pagesEnthalpy - Chemistry LibreTextsshiel175Pas encore d'évaluation

- Polymer Carrer 12Document33 pagesPolymer Carrer 12Ếch OrsonPas encore d'évaluation

- Hojas de Seguridad de ProductosDocument76 pagesHojas de Seguridad de ProductosLuis Aleman CuestasPas encore d'évaluation

- Flow Simulation and Static Structural Analysis On Pelton TurbineDocument7 pagesFlow Simulation and Static Structural Analysis On Pelton TurbineRahul ReddyPas encore d'évaluation

- IG System Solas ch2 Regulation 62Document3 pagesIG System Solas ch2 Regulation 62Ravi chinnaduraiPas encore d'évaluation

- General Biology II Q5 Regulation of Body FluidsDocument29 pagesGeneral Biology II Q5 Regulation of Body FluidsrickadoodledooPas encore d'évaluation

- AIS Sports Supplement Framework 2019 PDFDocument8 pagesAIS Sports Supplement Framework 2019 PDFconicharlesPas encore d'évaluation

- Equilibrium Ahl (HL Only) QuestionsDocument2 pagesEquilibrium Ahl (HL Only) Questionsdropmix2019Pas encore d'évaluation

- NTPC DADRI TrainingDocument21 pagesNTPC DADRI Trainingujjawal100% (2)

- Eco Friendly SalonDocument9 pagesEco Friendly SalonRakib HasanPas encore d'évaluation

- 15.0 Colgrout Masonry Works HandbookDocument48 pages15.0 Colgrout Masonry Works HandbookShabbir LokhandwalaPas encore d'évaluation

- Class11 Biology Unit19 NCERT TextBook EnglishEditionDocument12 pagesClass11 Biology Unit19 NCERT TextBook EnglishEditionUdit ChaudharyPas encore d'évaluation

- KLORDocument12 pagesKLORLucijaa VebleePas encore d'évaluation

- MS 01 181 PDFDocument12 pagesMS 01 181 PDFimmortalwortelPas encore d'évaluation

- Im 10212Document52 pagesIm 10212JIRMAN ALEXANDER RODRIGUEZPas encore d'évaluation

- Nylon ProcedureDocument2 pagesNylon ProcedureJohn Sepulveda0% (1)

- ISO 3821-2008 Mangueiras de Borracha para Soldadura, Corte e AfinsDocument22 pagesISO 3821-2008 Mangueiras de Borracha para Soldadura, Corte e AfinsvictorPas encore d'évaluation

- 7th Sem Minor ProjectDocument13 pages7th Sem Minor ProjectRajesh Nayak100% (1)

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrlePas encore d'évaluation