Académique Documents

Professionnel Documents

Culture Documents

Contruction & Wiring Guildline

Transféré par

Thành DanhCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Contruction & Wiring Guildline

Transféré par

Thành DanhDroits d'auteur :

Formats disponibles

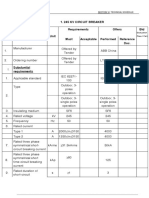

Construction and Wiring

Guidelines for Ergon Energy

Substation Panels

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

Table of Contents

Purpose and Scope ..................................................................................................... 1

Responsibilities ........................................................................................................... 1

Definitions, Abbreviations and Acronyms .................................................................... 1

References .................................................................................................................. 1

Panel Wiring ................................................................................................................ 2

Crimp Terminations ............................................................................................................. 2

Crimping Practices .............................................................................................................. 3

Terminating Wires ............................................................................................................... 4

Control Cables .................................................................................................................... 4

Wiring within a Panel........................................................................................................... 5

Bridging ....................................................................................................................... 8

Bridging within Terminal Blocks .......................................................................................... 8

Labelling ...................................................................................................................... 9

Wire Numbers ..................................................................................................................... 9

Terminal Blocks................................................................................................................. 10

Cable Numbers ................................................................................................................. 10

Relays and Devices .......................................................................................................... 11

Cubicle and Rack .............................................................................................................. 12

Placement ................................................................................................................. 12

Covers .......................................................................................................................12

Unused Ports .................................................................................................................... 12

Shrouding Contacts........................................................................................................... 13

Earthing .....................................................................................................................13

Cable Conduits .......................................................................................................... 14

Cable Trays and Ladders .......................................................................................... 14

Cable Penetration Firestops and Fire Breaks ............................................................ 14

i Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

PURPOSE AND SCOPE

To outline Ergon Energy requirements for acceptance of construction and wiring of Control,

Protection, Communications, Metering and Auxiliary Equipment Panels within Ergon Energy

Substations.

Specific wiring and construction standards in Ergon Energy drawings or Standards and Australian

Standards take precedence over the requirements outlined in this Reference.

The requirements of AS/NZS 3000 Wiring Rules shall be followed at all times.

RESPONSIBILITIES

The Executive General Manager Network Optimisation is the Process Owner responsible for

approving this Reference.

The General Manager Substations is the Subject Matter Expert (SME) for the content of this

Reference.

The Commissioning and Maintenance Manager is responsible for implementing and maintaining

this Reference.

The Manager Management Systems is responsible for the endorsement of this Reference prior to

submission for approval.

DEFINITIONS, ABBREVIATIONS AND ACRONYMS

RTU Remote Terminal Unit

REFERENCES

AS/NZS 3000 Wiring Rules

Page 1 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

PANEL WIRING

Crimp Terminations

Multi-stranded conductors with strands greater than or equal to

0.5 mm diameter (i.e. 7/0.50 1.5 mm2 and above) do not require

Multi-stranded crimp terminations, except as described below. These wires can

Conductors be stripped and terminated directly under a tunnel type terminal.

Conductor strands shall not be wound together after stripping.

Hard drawn conductors are not permitted.

Multi-stranded conductors of 1 mm2 cross sectional area and

below, and flexible conductors of stranding less than 0.5 mm

Ring diameter, must be terminated with a crimp fitting except when

indicated by the terminal manufacturer. Any crimp termination

used must suit the connecting terminal. The termination must be

made in accordance with the manufacturers’ specifications.

Bootlace Round bootlace crimps may be used where terminal screws make

direct contact onto the crimp.

Flat blade pre-insulated crimps must be used where the contact

Flat Blade surface is a flat plate. In this situation, bootlace crimps are not to

be used as the terminal surface exerts insufficient pressure on

the bootlace except when indicated by the terminal manufacturer,

e.g. ABB distribution terminal. Care must be taken when using flat

terminals to confirm that the blade is aligned correctly in the

terminal and the plates are parallel when secured.

Forked Forked spade terminals are suitable for use on relays where the

Spade connection is made on a centre screw arrangement (e.g. Izumi).

The fork surrounds the screw, and its concave washer together

with the terminal housing form a solid clamp which stops the fork

fingers from spreading.

Receptacle Receptacle terminals are only permitted when specified by the

Spade equipment manufacturer.

All crimps shall be fitted using the correct crimping tool.

Round bootlace crimp fittings or pre-insulated flat pin crimp

connectors shall be used on RTU terminal blocks using

communication wiring.

Some relay and other instrument terminal blocks require specific

crimps. Where this is the case only these specific crimps shall be

used.

Page 2 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

Crimping Practices

The distance between the insulation and crimp terminal shall be

between 0.25 mm and 1 mm.

Strip insulation with a wire stripping tool to make a clean cut.

The end of the wire must be visible in crimp terminals which

have an inspection hole. This is to confirm the conductor has

been properly inserted.

The conductor must not extend beyond the conductor crimp

edge.

Strands of the conductor are not to be bent when inserted into a

crimp.

Strands are not to protrude out from the crimp. If they protrude,

they are not to be cut but shall be redone.

Strands are not to be trimmed if the crimp barrel is too small for

the conductor.

Joining wires using crimps, solder, or other connection

techniques is not acceptable.

The crimps are not to be cut, trimmed or modified (bending,

Crimp Deformation

twisting, etc.) in any way.

Page 3 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

Terminating Wires

Wire insulation shall be stripped long enough to enable the

securing screw to attach to the bare conductor.

The wire must be inserted to the end of the terminal block. If

exposed copper can be seen, the wire must be trimmed and

reinserted.

Conductor strands must not be trimmed if the terminal is not large

enough to fit the conductor.

Wires shall be fastened tightly into terminal blocks so that they

cannot be pulled out when given a firm tug with long nose pliers.

No terminal will have more than two connections. Wires shall be

crimped individually to simplify the fault finding process. However,

wires can be crimped together if:

i) specified on the drawing, or

ii) a crimp designed for two conductors is used.

Each wire shall have 150 mm slack for the implementation of

additional crimps (following fault-finding) if two wires are crimped

together.

Control Cables

Multicore cables shall be fitted with cable glands, cable clamps or

cable ties as appropriate prior to the cable termination point.

Where multicore cables enter marshalling boxes via glands and

the cable is adequately supported, the use of cable clamps in

Cable Support addition to the glands is not required. Plastic cable glands must not

be used outdoors.

The weight of multicore cables shall be taken by the cable gland,

clamp or cable ties and no pressure or tension shall be exerted on

the terminal.

The outer sheath of the multicore cable shall be removed

immediately beyond the terminating gland, cable clamp or cable

tie-off point.

Heat shrink shall be installed on the control cable at the transition

point between the sheath and the exposed cores.

All jute and fillers shall be removed from the sheathing of the cable

Clean Wires / Cables

and wires before crimping is undertaken.

Page 4 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

Wiring within a Panel

Cores which are not required in new multicore cables shall be

labelled as spares at either end. Cores which are made

redundant due to the removal of functions shall be labelled as

spares at either end.

Spare cores are not to be cut short. There must be enough

length, on each spare core, to reach any terminal on the

associated rail. They are to remain in the duct with the ends

covered in heat shrink. Each spare core shall be labelled with the

cable number. The wire is then to be laid back and neatly secured

to the parent cable. The wires do not need to be bonded to earth;

however they must be untwisted from the group of cores to allow

easy access for future work.

Where practicable, wires shall be contained within the ducts and

exit closest to the connection point on the panel equipment.

In this situation, wires have not been passed through the

corresponding holes in the cable ducts. This is not acceptable.

Panel wiring shall be grey PVC insulated 2.5 mm2 for CT and VT

circuits and 1.5 mm2 for all other wiring (excluding bus wiring)

Wire Size unless otherwise specified.

Earth wiring to be 2.5 mm2 green / yellow unless otherwise

specified.

Wires shall be routed in a neat, easy to trace manner. They

should travel through the ducts and exit at the appropriate point.

Sufficient length of wiring is required such that replacing a panel

component shall neither require disconnecting wiring from other

equipment on the rack or in the panel, nor disturbing wiring in the

ducts or looms. See additional picture below.

Page 5 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

Cable tidies and cable entry plate (with brush insert) shall be

utilised where wiring is required on the front of panels.

Wires shall be grouped together with cable ties where multiple

wires travel on the same path. They are not to be left loose.

Spiral binding or split loom tubing is acceptable instead of cable

ties.

Old cable ties shall be removed if additional wiring is added to a

loom.

Where a frame is available, the wire shall be secured to the inside

to minimise the possibility of damage from knocks.

Note in this situation the wires have neither been secured

together, nor secured on the inside of the rail. The earth wire has

also been left with a loose loop.

Page 6 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

Plastic cable ties shall be used for indoor cables. Outdoor cables

shall be tied with stainless steel cable ties. UV resistant plastic

cable ties are also acceptable.

Cables entering a terminal from a duct shall enter the terminal

strip on the side closest to the duct. All field cables entering the

Control Cable Orientation

panel shall terminate on the side of the terminal furthest from the

front of the panel.

Wires shall be grouped and loomed as shown when it leaves the

duct to provide a neat wire layout and adequate additional slack

to be able to remove and replace wiring for testing without

disturbing other wiring.

Wiring to CT secondary terminal blocks or ratio selection

Wiring to CT Secondary

terminals shall have sufficient length so that any secondary ratio

Terminal Blocks

or polarity can be connected.

Wires are not to stick out of the ducts. Once inside a cable duct

they are to follow the cable duct paths without cutting through

corners.

Ducts shall be chosen of sufficient size for the amount of cables

travelling through them. The duct lid must be able to fit on the

ducts.

Wires must fit neatly inside the cable ducts with the tops on.

Page 7 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

If there are too many cables for the duct, it is acceptable to cut

the cover short to allow the majority of the duct to be covered.

All cable cores shall be straightened, removing all kinks and

twists when laid out. This reduces the amount of space occupied

by cores in the cable ducts. It also makes wiring to other sections

of the panel easier in the future.

If vertical mounting is specified, CT sliders shall be installed so

that if the slide was to fall it would close links and not open circuit

the CT secondary.

CT and VT Sliders

If vertical mounting is specified, VT sliders shall be installed, the

opposite to CT sliders, such that if VT sliders fall it will open the

links.

No exposed mains wiring is acceptable within the equipment

Mains Power

cubicle.

Optical fibre patch cables shall not be run externally to cubicles,

between cubicles, or to a wall mounted Optical Termination Panel

unless they are protected within a dedicated optical fibre duct or

conduit or of heavy-duty construction and installed in a separate

cable tray (communications cable tray) from the control cables.

Excess length in fibre optic patch cables shall be neatly loomed

and fastened in a position where it is not exposed to damage.

BRIDGING

Bridging within Terminal Blocks

Any bridging within a terminal shall be done with terminal block

solid bar bridges if specified on the design drawings. Substitution

with a wire loop is not permitted.

Suitable insulating inserts must be used when bridging adjacent

terminal blocks to avoid shorting.

Where the terminal does not allow a link bar to be used, or the

design drawing permits, wires can be used to neatly loop

between links.

Page 8 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

LABELLING

Wire Numbers

Wire number ferrules shall be placed near the termination on

either end of the wire. The wire number must be legible, and

placed in a location where it can be read without disturbing other

wires.

Wire numbers on horizontal wires shall read left to right.

Wire numbers on vertical wires shall read bottom to top.

Wire numbers shall all be legible. They must all be read from left

to right or bottom to top. They are not to be misaligned.

Handwritten wire or cable numbers are not acceptable.

A single wire number ferrule may be placed in the centre of the

wire if the wire is sufficiently short such that both terminations of

the wire can easily be seen.

A wire number ferrule is not required when the bridging wire is too

short to fit the ferrule.

Insulation tape shall not be used for cable identification.

Page 9 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

Terminal Blocks

Individual terminal blocks shall be labelled.

Each terminal group shall be labelled.

Unless otherwise specified, manufacturer proprietary accessories

Manufacturer Accessories

such as end plates and bridging links shall be used.

In this situation the terminals have not been numbered, nor have

the cables entered the correct holes in the ducting. This is not

acceptable.

Cable Numbers

Stainless Steel labels (or alternative permanent marking system)

shall be placed around the sheathing of cables close to where the

sheathing has been stripped. Control cable numbers must be

fitted where the cable enters the panel or cubicle.

Page 10 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

All cables shall be labelled.

The cable number shall be mounted external to switchboards or

cubicles when the terminated end of the cable cannot be seen

due to physical barrier.

The cables have not been labelled with the appropriate labels.

Temporary labels are permitted for construction use only, and

must be removed and replaced with permanent labels before

commissioning occurs.

Labelling cables with a pen either directly on the cable or on tape

is not acceptable.

Relays and Devices

Identification labels must be applied adjacent to the relay or

devices. They are not to be placed on covers or the device itself

unless accompanied by an adjacent label.

Handwritten or other temporary labels are not to be used.

Page 11 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

Cubicle and Rack

Where possible, labels shall be fitted to the front and rear of each

Cubicle Labels

cubicle in a central top position.

Where specified, unused rack space shall have blanking panels

Spare Rack Space

fitted.

PLACEMENT

Where practicable, a minimum spacing of 40 mm between terminal

blocks and main ducts shall be used.

All equipment shall be installed into cubicles in accordance with the

manufacturers’ installation instructions.

Supports Equipment shall be fixed into the 19-inch racks using a minimum of four

(4) M6 setscrews and corresponding captive nuts. Heavy equipment

shall be supported by extra side rails or shelves as required.

Equipment with nameplate information attached to the device must be

installed with the information visible. It should also be placed in the most

practical installation position.

This optical isolator was placed back to front, covering the device

specific information. It was not centred when attached to the cable tray.

Had it been centred, the cable numbers on both cables could be placed

close to their ends.

COVERS

Unused Ports

Any unused fuse places on the front of panels will have their

holes covered with suitable plugs.

Blanking plates must be installed on unused ports. Covering with

duct tape is not acceptable.

Page 12 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

Shrouding Contacts

Dangerous live elements must be shrouded and labelled

accordingly.

No label

EARTHING

Earth wires shall be clearly labelled and individually attached to an

earthing bar. Earth wires are not to be stacked with multiple connections

to the one point on new installations. Earthing conductors shall be

terminated by means of crimped lugs unless approved terminals or

clamping devices are provided.

Control cable screens shall be earthed at both ends of the cable,

Control Cable Screens excluding signal cables (such as Decron) which are earthed at one end

only (preferably where the signal equipment is earthed, i.e. at the RTU).

Page 13 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Construction and Wiring Guidelines for

Ergon Energy Substation Panels

CABLE CONDUITS

Open ends of cable conduits shall not be left unfilled.

A suitable fill must be used on the ends of cable conduits. The fill must

be a fire and oil resistant breakable sealant material. In outdoor

applications the fill must be resistant to UV degradation – expanding

foam is not suitable (even if painted).

A grout cap is the preferred fill for outdoor situations.

Where entry or exit points are required from the side or bottom of closed

mesh or perforated trays, neat round or rectangular holes shall be cut

Edge Protection

with the edges de-burred and provided with edge protection such as

grommet strip or similar.

CABLE TRAYS AND LADDERS

All cable trays and ladders shall have a spare capacity of at least 25% of

Spare Capacity

tray or ladder width after all cables are installed.

In a stacked cable tray system the cables shall be arranged with power

Orientation

cables positioned above control and instrumentation cables.

Where cable trays and ladders are installed in plant rooms or across

Minimum Height walkways, the minimum clear height from floor or ground level to

underside of tray or ladder is 2.1 metres.

Cables which can be exposed to direct sunlight or are vulnerable to

Cable Protection damage from falling objects or build-up of spillage material must have a

continuous galvanised steel cable tray or ladder covers fitted.

CABLE PENETRATION FIRESTOPS AND FIRE BREAKS

Firestops shall be used to prevent fire propagation along a cable

system. The firestop shall have a fire rating equal to or greater than the

wall or floor it penetrates.

Modifications or additions of cables shall not compromise the integrity of

Firestops the firestop. Cable firestops must be used when sleeve or tray

penetrations are used beneath control panels or other panels.

Removable firestop bags or similar may be used as a temporary

measure during installation, but at the completion of the installation,

permanent firestops shall be applied.

Page 14 of 14 Reference MN000301R166 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- "Classic Range" Aluminium Connectors - 63/220 KV: Simel ProductsDocument4 pages"Classic Range" Aluminium Connectors - 63/220 KV: Simel ProductsThành DanhPas encore d'évaluation

- LTD245E1-Tech Data - 220kV Trang Bang Sub-ChinaDocument6 pagesLTD245E1-Tech Data - 220kV Trang Bang Sub-ChinaThành DanhPas encore d'évaluation

- Circuit Breaker Configuration of LTB245E1-1PDocument2 pagesCircuit Breaker Configuration of LTB245E1-1PThành Danh100% (1)

- LTB EnglishDocument20 pagesLTB EnglishThành DanhPas encore d'évaluation

- Technical Datasheet of 3AP1FI-245kVDocument2 pagesTechnical Datasheet of 3AP1FI-245kVThành DanhPas encore d'évaluation

- Product Test Report: Bosch Autodome Ip 5000 IrDocument3 pagesProduct Test Report: Bosch Autodome Ip 5000 IrThành DanhPas encore d'évaluation

- High Voltage Circuit Breakers 3AP Type 72.5 KV To 800 KV: Answers For EnergyDocument12 pagesHigh Voltage Circuit Breakers 3AP Type 72.5 KV To 800 KV: Answers For EnergyThành DanhPas encore d'évaluation

- Siemens Slide 2008Document53 pagesSiemens Slide 2008Thành DanhPas encore d'évaluation

- L90 Ge Protection RelayDocument8 pagesL90 Ge Protection RelayThành DanhPas encore d'évaluation

- Design Features of GIS: A. Development and ManufacturingDocument4 pagesDesign Features of GIS: A. Development and ManufacturingThành DanhPas encore d'évaluation

- Grid AIS L3 HYpact 0124 2017 - 02 ENDocument24 pagesGrid AIS L3 HYpact 0124 2017 - 02 ENThành DanhPas encore d'évaluation

- GL312F1 DrawingsDocument2 pagesGL312F1 DrawingsThành DanhPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- BT7000 PartsDocument123 pagesBT7000 PartsPilaquinga DiegoPas encore d'évaluation

- En-JV Catalogue - 2 Konversi China StandardDocument58 pagesEn-JV Catalogue - 2 Konversi China StandardRUKIPas encore d'évaluation

- Rigging TestDocument49 pagesRigging Testvasucristal67% (3)

- Cable Bending Radius GuideDocument4 pagesCable Bending Radius GuideOctober EchoPas encore d'évaluation

- ENG-Cable LubricationDocument2 pagesENG-Cable LubricationMhmd HnffPas encore d'évaluation

- Section 8 GposDocument14 pagesSection 8 GposDangolPas encore d'évaluation

- Mgv34Range: Installation, Use and Maintenance GearlessDocument36 pagesMgv34Range: Installation, Use and Maintenance Gearlessعادل شريفPas encore d'évaluation

- 5th Ed GW NA Catalog Final-WebsiteDocument24 pages5th Ed GW NA Catalog Final-WebsiteYousef ShishaniPas encore d'évaluation

- 50650.installation Guide 2061303Document39 pages50650.installation Guide 2061303curzPas encore d'évaluation

- IGC 3 - Management Report - IGC 3 SampleDocument4 pagesIGC 3 - Management Report - IGC 3 SampleHariKN68% (25)

- General Instruction Gi 7 029Document8 pagesGeneral Instruction Gi 7 029mohamedPas encore d'évaluation

- Annexure-10 Dropper SpecificationDocument1 pageAnnexure-10 Dropper SpecificationAnkit AgarwalPas encore d'évaluation

- Gaylin Ropes Catalogue - 25102012Document36 pagesGaylin Ropes Catalogue - 25102012migescu100% (1)

- WireRopeHoist - InstructionManualDocument94 pagesWireRopeHoist - InstructionManualsriguruprasathsPas encore d'évaluation

- Saej697v001 SAFETY CHAIN OF FULL TRAILERS OR CONVERTER DOLLIESDocument4 pagesSaej697v001 SAFETY CHAIN OF FULL TRAILERS OR CONVERTER DOLLIESDaniel FarfanPas encore d'évaluation

- Equipment Number Calculation Rules - IRSDocument5 pagesEquipment Number Calculation Rules - IRSmaaathanPas encore d'évaluation

- Slingmax CatalogDocument44 pagesSlingmax CatalogmaomontesPas encore d'évaluation

- Me-605 ADocument7 pagesMe-605 AEmperorPas encore d'évaluation

- PARTS MANUAL TIL RT630-C Part 1Document150 pagesPARTS MANUAL TIL RT630-C Part 1Md Iftekhar AhamedPas encore d'évaluation

- 9 WinchesDocument28 pages9 WinchesJAMAL JIBRILPas encore d'évaluation

- Katalog 2006Document41 pagesKatalog 2006Zhao PhilipPas encore d'évaluation

- Cannon Cable PrinterDocument6 pagesCannon Cable PrinterOliver HermosaPas encore d'évaluation

- Instruction Book Xa (H) S 38-88 (G) KD S3a App 2954 9520 02 enDocument92 pagesInstruction Book Xa (H) S 38-88 (G) KD S3a App 2954 9520 02 enYERKO OVIEDOPas encore d'évaluation

- Scully ST-47C Groundhog Technical ManualDocument32 pagesScully ST-47C Groundhog Technical ManualOscar Moreno100% (1)

- Installation Instructions: Product DescriptionDocument4 pagesInstallation Instructions: Product DescriptionHữu Khánh NguyễnPas encore d'évaluation

- Data Sheet FIBERLIGN - Dielectric - Dead-EndDocument8 pagesData Sheet FIBERLIGN - Dielectric - Dead-EndARCC2030Pas encore d'évaluation

- S-409 Cold Tuff ButtonsDocument1 pageS-409 Cold Tuff Buttonssaddam4everPas encore d'évaluation

- RRL 2Document2 pagesRRL 2Jessie BasasPas encore d'évaluation

- RD20 Operation ManualDocument551 pagesRD20 Operation Manualocto trianto100% (2)

- Cobra 5500 Product ManualDocument58 pagesCobra 5500 Product ManualBengkel Kayu MakassarPas encore d'évaluation