Académique Documents

Professionnel Documents

Culture Documents

Astm 537 CL.1 WPS

Transféré par

audiihussainDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Astm 537 CL.1 WPS

Transféré par

audiihussainDroits d'auteur :

Formats disponibles

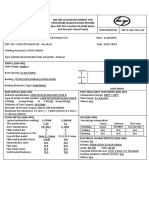

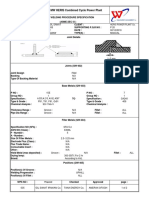

WELDING PROCEDURE SPECIFICATIONS (WPS)

QW-482

SEE QW-200.1, Section IX ASME Bolier & Pressure Vessal Code

PROJECT : BAIRA SIUL H.E.PROJECT

Company Name : M/s OM METALS INFRAPROJECT LTD Page:01 of 02

Welding Procedure Spec. No. WPS/BSHEP/01 Date: 08.NOV. 2018 REV.: 0

Supporting PQR No. ------------- Date: --------------

Welding Process(es) SMAW Type(s): MANUAL

(Automatic, Manual, Machine, or Semi-Auto)

CODE

ASME IX X API 1104 ANSI B31.3 AWS D 1.1 OTHER

JOINTS (QW-402)

Joint Design SINGLE VEE GROOVE

45°

Backing YES Type : WELD METAL/IS 2062

Inside

T t

2

Outside

APPLICABLE TO FILLET WELD. 8 mm

BASE METALS (QW-403)

P-No. P1 Group No.: 2 to P-No. P1 Group No.: 2

OR

Specification Type and Grade ASTM 537 CL.1

to Specification Type and Grade ASTM 537 CL.1

Base Metal Thickness Range : Groove 5MM TO 200MM Fillet ALL

Pipe Dia. Range : Groove OVER 25MM Ø Fillet ALL

Other: NO SINGLE PASS THICKNESS GREATER THAN 10 MM ALLOWED

FILLER METALS (QW-404)

F-No. 4 Other N/A

A-No. 1 Other N/A

Spec. No. (SFA) 5.1

AWS No (Class) 7018-1

Size of filler metals 3.15/4 MM

Electrode - Flux (Class) N/A

Flux and/or Electrode Trade Name ADORE/ESSAR/D& H OR EQUIVALENT

Consumable Insert N/A

Other: N/A

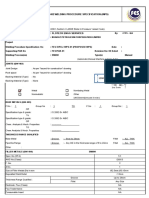

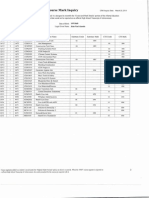

Page:02 of 02

POSITION ( QW-405) PREHEAT (QW-406)

Position(s) of Groove 3G Preheat Temp. Range. Not applicable

Interpass Temp Not applicable

Welding Progression: UPHILL X FORWARD Preheat Maintenance Not applicable

Position(s) of fillet ALL

POSTWELD HEAT TREATMENT (QW-407) GAS (QW-408)

Temparature Range N/A Percent Composition

Time Range N/A Gas(es) Mixture Flow Rate

Heating Rate N/A Cooling Rate: N/A Shielding N/A N/A N/A

Others: NONE Trailing N/A N/A N/A

Backing N/A N/A N/A

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC DC

: Polarity : DCRP

Amps (Range) : As shown on the table-1 Volts (Range) : As shown on the table-1

(Amps and Volts range should be recorded for each electrode size, position and thickness, etc. This information should be

listed in the tabular form show below.)

Heat Input Max : As shown on the Table-1

Tungsten Electrode Size and Type : N/A

Mode of Metal Transfer for GMAW : N/A

(spray arc, short circuiting arc, etc.)

Electrode Wire Feed Speed Range : N/A

TECHNIQUE (QW-410)

Stringer or Weave Bead: BOTH Max. Weave Width 2.5X electrode dia

Orifice or Gas Cup Size: N/A

Initial and Interpass Cleaning (Brushing, Grinding, etc.): WIRE BRUSHING/GRINDING

Method of Back Gouging: GRINDING

Oscillation: 2.5 times of electrode dia

Contact Tube to Work Distance: NONE `

Multiple or Single Pass (per side): MULTIPLE

Multiple or Single Electrodes: SINGLE

Travel Speed (Range): REFER TABLE

Peening: NOT PERMITTED

Other: NONE

Weld Filler Metal Current Voltage Travel Heat Input

Layer(s) Process Class. Dia. Type Amp. Volts Speed KJ/MM

Polarity Range Range Range(MM/MIN) ( Max. )

ROOT RUN SMAW 7018-1 3.15MM DCRP 100-140 22-24 68-69 2.53

FILL UP SMAW 7018-1 3.2.MM DCRP 122-155 22-26 125-142 1.69 to 2.37

CAPPING SMAW 7018-1 3.2MM DCRP 100-140 22-24 68-69 2.53

ELECTRODE CONTROL:

1. Storage temperaure and Humidity as per procedure.

2. Electrode backing and holding temperature as per procedure.

3. Hand oven holding temperaure as per procedure.

Prepared by - Anurag Shukla Checked By- Anurag Shukla Approved BY- QA

Vous aimerez peut-être aussi

- The Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDocument30 pagesThe Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDusen VanPas encore d'évaluation

- Bolt Tightening Torque CalculationDocument4 pagesBolt Tightening Torque CalculationaudiihussainPas encore d'évaluation

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertPas encore d'évaluation

- WPSDocument6 pagesWPSYASH BARDHAN SinghPas encore d'évaluation

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikPas encore d'évaluation

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanPas encore d'évaluation

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Flange 10 & 12 InchDocument2 pagesFlange 10 & 12 InchreniPas encore d'évaluation

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinPas encore d'évaluation

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraPas encore d'évaluation

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviPas encore d'évaluation

- HUMSS - Introduction To World Religions & Belief Systems CGDocument13 pagesHUMSS - Introduction To World Religions & Belief Systems CGAliuqus SirJasper89% (18)

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenPas encore d'évaluation

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourPas encore d'évaluation

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191Pas encore d'évaluation

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinPas encore d'évaluation

- Clad PQRDocument5 pagesClad PQRRinshadPas encore d'évaluation

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikPas encore d'évaluation

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberPas encore d'évaluation

- Electrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsDocument1 pageElectrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsJlkKumar100% (1)

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoPas encore d'évaluation

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshPas encore d'évaluation

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajPas encore d'évaluation

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshPas encore d'évaluation

- Safety Valve Sizing Calculations As Per IBR 1950Document2 pagesSafety Valve Sizing Calculations As Per IBR 1950santoshmane2389% (9)

- Dry Compressing Vacuum PumpsDocument62 pagesDry Compressing Vacuum PumpsAnonymous zwSP5gvPas encore d'évaluation

- Leadership and Management in Different Arts FieldsDocument10 pagesLeadership and Management in Different Arts Fieldsjay jayPas encore d'évaluation

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Api 571 CorrosionDocument5 pagesApi 571 CorrosionArun GuptaPas encore d'évaluation

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganPas encore d'évaluation

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- SubaruDocument7 pagesSubaruclaude terizlaPas encore d'évaluation

- PQR For Gmaw Saw 15.88Document3 pagesPQR For Gmaw Saw 15.88Kumawat PrakashPas encore d'évaluation

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 pagesQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীPas encore d'évaluation

- Edr 01 Dec 2018Document21 pagesEdr 01 Dec 2018AMALENDU PAULPas encore d'évaluation

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- 3.6 Technical Specifications For Procurement of Generating Equipment PDFDocument156 pages3.6 Technical Specifications For Procurement of Generating Equipment PDFaudiihussainPas encore d'évaluation

- E021-Checklist LT PanelDocument1 pageE021-Checklist LT Panelaudiihussain67% (3)

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaPas encore d'évaluation

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouPas encore d'évaluation

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedPas encore d'évaluation

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiPas encore d'évaluation

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyPas encore d'évaluation

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaPas encore d'évaluation

- 1035 03Document2 pages1035 03Anuj ShahiPas encore d'évaluation

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaPas encore d'évaluation

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelPas encore d'évaluation

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011Pas encore d'évaluation

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaPas encore d'évaluation

- PQWDocument3 pagesPQWcorey jacobsPas encore d'évaluation

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriPas encore d'évaluation

- WPQDocument10 pagesWPQayoki100% (3)

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- 131.4.1-1 Temperaturas de PreaquecimentoDocument1 page131.4.1-1 Temperaturas de PreaquecimentoRodrigo CarneiroPas encore d'évaluation

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabPas encore d'évaluation

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanPas encore d'évaluation

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarPas encore d'évaluation

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lPas encore d'évaluation

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadPas encore d'évaluation

- PQR REV. 2010a Interactive FormDocument2 pagesPQR REV. 2010a Interactive FormcosmicbunnyPas encore d'évaluation

- WPS-035 - (Pno.15e To Pno.7) - 2Document2 pagesWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamPas encore d'évaluation

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisPas encore d'évaluation

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalPas encore d'évaluation

- Penstock Quality ManagementDocument7 pagesPenstock Quality ManagementaudiihussainPas encore d'évaluation

- Beam PropertiesDocument14 pagesBeam PropertiesaudiihussainPas encore d'évaluation

- 4403 SNL Plummer Block HousingsDocument74 pages4403 SNL Plummer Block HousingsaudiihussainPas encore d'évaluation

- Electro Hydraulic Thrustors: Questionnaire For Elektromag ThrustorsDocument2 pagesElectro Hydraulic Thrustors: Questionnaire For Elektromag ThrustorsaudiihussainPas encore d'évaluation

- Structure CalculationDocument27 pagesStructure CalculationaudiihussainPas encore d'évaluation

- Beam PropertiesDocument15 pagesBeam PropertiesaudiihussainPas encore d'évaluation

- Is 2026 1 2011 PDFDocument31 pagesIs 2026 1 2011 PDFAravind Sampath100% (2)

- Kvf433V: TransformersDocument1 pageKvf433V: TransformersaudiihussainPas encore d'évaluation

- Nizkor Project Fallacies - LabossierDocument77 pagesNizkor Project Fallacies - Labossierapi-3766098100% (1)

- WWW Studocu Com in N 29646569 Sid 01682568219Document1 pageWWW Studocu Com in N 29646569 Sid 01682568219Nivetha SelvamuruganPas encore d'évaluation

- The Rise of Australian NovelDocument412 pagesThe Rise of Australian NovelSampath Kumar GummadiPas encore d'évaluation

- Img 20150510 0001Document2 pagesImg 20150510 0001api-284663984Pas encore d'évaluation

- Virtual WorkDocument12 pagesVirtual Workdkgupta28Pas encore d'évaluation

- CFD Turbina Michell BankiDocument11 pagesCFD Turbina Michell BankiOscar Choque JaqquehuaPas encore d'évaluation

- Ej. 1 Fin CorpDocument3 pagesEj. 1 Fin CorpChantal AvilesPas encore d'évaluation

- СV Nestor RodriguezDocument28 pagesСV Nestor RodriguezKate BrownPas encore d'évaluation

- A Literature Review of Retailing Sector and BusineDocument21 pagesA Literature Review of Retailing Sector and BusineSid MichaelPas encore d'évaluation

- IR2153 Parte6Document1 pageIR2153 Parte6FRANK NIELE DE OLIVEIRAPas encore d'évaluation

- Arithmetic QuestionsDocument2 pagesArithmetic QuestionsAmir KhanPas encore d'évaluation

- A P P E N D I X Powers of Ten and Scientific NotationDocument5 pagesA P P E N D I X Powers of Ten and Scientific NotationAnthony BensonPas encore d'évaluation

- XII CS Material Chap7 2012 13Document21 pagesXII CS Material Chap7 2012 13Ashis PradhanPas encore d'évaluation

- RARE Manual For Training Local Nature GuidesDocument91 pagesRARE Manual For Training Local Nature GuidesenoshaugustinePas encore d'évaluation

- Imabalacat DocuDocument114 pagesImabalacat DocuJänrëýMåmårìlSälängsàngPas encore d'évaluation

- Is 2 - 2000 Rules For Rounded Off For Numericals PDFDocument18 pagesIs 2 - 2000 Rules For Rounded Off For Numericals PDFbala subramanyamPas encore d'évaluation

- Pediatrics: The Journal ofDocument11 pagesPediatrics: The Journal ofRohini TondaPas encore d'évaluation

- Worst of Autocall Certificate With Memory EffectDocument1 pageWorst of Autocall Certificate With Memory Effectapi-25889552Pas encore d'évaluation

- AE Notification 2015 NPDCLDocument24 pagesAE Notification 2015 NPDCLSuresh DoosaPas encore d'évaluation

- Angle Modulation: Hệ thống viễn thông (Communication Systems)Document41 pagesAngle Modulation: Hệ thống viễn thông (Communication Systems)Thành VỹPas encore d'évaluation

- Five Reasons Hazards Are Downplayed or Not ReportedDocument19 pagesFive Reasons Hazards Are Downplayed or Not ReportedMichael Kovach100% (1)

- The Turning Circle of VehiclesDocument2 pagesThe Turning Circle of Vehiclesanon_170098985Pas encore d'évaluation

- Job Satisfaction VariableDocument2 pagesJob Satisfaction VariableAnagha Pawar - 34Pas encore d'évaluation

- Total Physical Response (G4)Document3 pagesTotal Physical Response (G4)Aq Nadzrul LarhPas encore d'évaluation

- Financial Market - Bsa 2A Dr. Ben E. Bunyi: Imus Institute of Science and TechnologyDocument3 pagesFinancial Market - Bsa 2A Dr. Ben E. Bunyi: Imus Institute of Science and TechnologyAsh imoPas encore d'évaluation