Académique Documents

Professionnel Documents

Culture Documents

Otisonic

Transféré par

senthilrsenthilCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Otisonic

Transféré par

senthilrsenthilDroits d'auteur :

Formats disponibles

.

book Page 1 Tuesday, August 18, 2009 1:26 PM

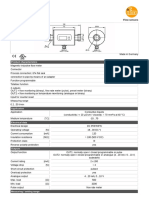

OPTISONIC 6300 Technical Datasheet

Ultrasonic clamp-on flowmeter

• Robust industrial clamp-on construction

• Immediate start-up

• All in one concept

© KROHNE 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 2 Tuesday, August 18, 2009 1:26 PM

CONTENTS OPTISONIC 6300

1 Product features 3

1.1 Clamp-on technology ....................................................................................................... 3

1.2 Variants............................................................................................................................. 5

1.3 Measuring principle.......................................................................................................... 8

2 Technical data 9

2.1 Technical data................................................................................................................... 9

2.2 Dimensions and weights ................................................................................................ 17

2.2.1 Clamp-on sensor and cable box ........................................................................................... 17

2.2.2 Housing ................................................................................................................................. 19

2.2.3 Mounting plate, field housing ............................................................................................... 20

2.2.4 Mounting plate, wall-mounted housing ............................................................................... 20

3 Installation 21

3.1 Intended use ................................................................................................................... 21

3.2 Environmental requirements ......................................................................................... 21

3.3 Installation requirements signal converter ................................................................... 21

3.4 Installation requirements sensor .................................................................................. 21

3.4.1 Inlet, outlet and recommended mounting area ................................................................... 22

3.4.2 Long horizontal pipes ........................................................................................................... 22

3.4.3 Open feed or discharge......................................................................................................... 23

3.4.4 Down going pipeline over 5 m /16 ft length.......................................................................... 23

3.4.5 Position of control valve........................................................................................................ 23

3.4.6 Position of pump ................................................................................................................... 24

4 Electrical connections 25

4.1 Signal cable and power supply signal converter ........................................................... 25

4.2 Inputs and outputs, overview ......................................................................................... 27

4.2.1 Fixed, non-alterable input/output versions.......................................................................... 27

4.2.2 Alterable input/output versions............................................................................................ 29

5 Application form 30

2 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

Product features

.book Page 3 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 PRODUCT FEATURES 1

1.1 Clamp-on technology

The OPTISONIC 6300 stands for continuity and long term reliability. Flow measurement can be

done anywhere and start-up is immediate. The new OPTISONIC 6300 clamp-on flowmeter for

liquids with its robust industrial construction and regreasing concept provides a revolutionary

solution for easy handling. It can be fitted on the outside of piping to measure the flow rate of

liquids.

The clamp-on flowmeter is a combination of one up to two OPTISONIC 6000 clamp-on sensor(s)

and one UFC 300 ultrasonic signal converter.

The overall functionality of the clamp-on flowmeter is the continuous measurement of actual

volume flow, mass flow, flow speed, velocity of sound, gain, SNR and diagnosis value.

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 3

.book Page 4 Tuesday, August 18, 2009 1:26 PM

1 PRODUCT FEATURES OPTISONIC 6300

Highlights

• Minimised uncertainty

• Optimised reliability

• Minimal maintenance

• Efficient regreasing concept

• Easy sensor mounting

• Installation wizard

• All in one system

Industries

• Chemicals

• Petrochemicals

• Power plants

• Water

• Oil & Gas

• Semi-conductor

• Food & Beverages

• Pharmaceuticals

Applications

• Chemical addition

• General process control

• Cooling water circuits

• Broad range of refined hydrocarbons

• Potable water

• De-ionized and demineralized water

• Sanitary flow rate measurements

• Purified water

4 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 5 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 PRODUCT FEATURES 1

1.2 Variants

The OPTISONIC 6300 is an ultrasonic clamp-on flowmeter that can be fitted on the outside of

piping to measure the flowrate of liquids. The flowmeters consists of a combination of one or two

clamp-on sensor(s) and one ultrasonic signal converter:

OPTISONIC 6000 + UFC 300 = OPTISONIC 6300

Different versions and some general examples

Small version (aluminum, including cover)

• chemical addition applications

• cooling circuits

Medium version (aluminum, including cover)

• purified water applications

• hydrocarbons

Large version (aluminum, including cover)

• all water applications

• especially for large pipe sizes

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 5

.book Page 6 Tuesday, August 18, 2009 1:26 PM

1 PRODUCT FEATURES OPTISONIC 6300

Optional stainless steel sensor (small / medium)

• for corrosive environments

• off-shore

• nuclear power plants

Optional eXtended Temperature sensor (XT, small /

medium)

• refineries

• chemical plants

• energy applications

• food and beverage

6 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 7 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 PRODUCT FEATURES 1

UFC 300 ultrasonic signal converter

UFC 300 W

• wall mounted

• Polyamide-polycarbonate housing

• non-Ex

• IP65

UFC 300 F

• field version

• die-cast aluminum or stainless steel housing

• (non-)Ex

• IP66/67

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 7

.book Page 8 Tuesday, August 18, 2009 1:26 PM

1 PRODUCT FEATURES OPTISONIC 6300

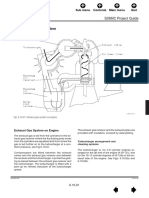

1.3 Measuring principle

• Like canoes crossing a river, acoustic signals are transmitted and received along a diagonal

measuring path.

• A sound wave going downstream with the flow travels faster than a sound wave going

upstream against the flow.

• The difference in transit time is directly proportional to the mean flow velocity of the medium.

Figure 1-1: Measuring principle

1 Transducer A

2 Transducer B

3 Flow velocity

4 Transit time from transducer A to B

5 Transit time from transducer B to A

8 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

Technical data

.book Page 9 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 TECHNICAL DATA 2

2.1 Technical data

• The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local representative.

• Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

Measuring system

Measuring principle Ultrasonic transit time

Application range Flow measurement of liquids

Measured value

Primary measured value Transit time

Secondary measured value Volume flow, mass flow, flow speed, flow direction, speed of sound,

gain, signal to noise ratio, diagnosis value, reliability of flow

measurement, quality of acoustic signal

Design

The measurement system consists of a measuring sensor and a

signal converter. It is only available as separate version.

Signal converter

Wall-mounted housing (W) - UFC 300 W (general purpose)

remote version

Field housing (F) - remote UFC 300 F (Option: Ex version)

version

Measuring sensor

Standard Small, medium or large version in aluminum

Optional Small / medium stainless steel version

Small / medium XT (eXtended Temperature).

Diameter ranges

Small DN15...100 / ½…4"

Outer diameter must be at least 20 mm / 0.79".

Medium DN50...400 / 2…16"

Large DN200...4000 / 8…160"

Outer diameter must be smaller than 4300 mm / 169.29".

Options

Inputs / outputs Current (incl. HART®), pulse, frequency and/or status output, limit

switch and/or control input (depending on the I/O version)

Counters 2 internal counters with a max. of 8 counter places (e.g. for counting

volume and/or mass units)

Self diagnostics Integrated verification, diagnosis functions: flowmeter, process,

measured value, empty pipe detection, bargraph

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 9

.book Page 10 Tuesday, August 18, 2009 1:26 PM

2 TECHNICAL DATA OPTISONIC 6300

Display and user interface

Graphic display LC display, backlit white

Size: 128x64 pixels, corresponds to 59x31 mm = 2.32"x1.22"

Display turnable in 90° steps

The readability of the display could be reduced at ambient

temperatures below -25°C / -13°F.

Operator input elements 4 optical keys for operator control of the signal converter without

opening the housing.

Option: Infrared interface (GDC)

Remote control PACTware® including Device Type Manager (DTM)

All DTM's and drivers are available at the internet homepage of the

manufacturer.

Display functions

Menu Programming of parameters at 2 measured value pages, 1 status

page, 1 graphic page (measured values and descriptions adjustable

as required)

Language of display texts English, French, German

Units Metric, British and US units selectable from list / free unit

Measuring accuracy

Reference conditions Medium: water

Temperature: 20°C / 68°F

Straight inlet section: 10 DN

Maximum measuring error ±1% of the measured value

for DN≥50 mm / 2" and v > 0.5 m/s / 1.5 ft/s

±3% of the measured value

for DN<50 mm / 2" and v > 0.5 m/s / 1.5 ft/s

Repeatability <±0.2%

Operating conditions

Temperature

Process temperature Standard version: -40...+120°C / -40...+248°F

XT version: -40...+200°C / -40...+392°F

Ambient temperature Sensor: -40...+70°C / -40...+158°F

Signal converter: -40…+60°C / -40…+140°F

(ambient temperature 55°C / 131°F and higher: protect electronics

against self-heating, because an increase in the electronics

temperature in 10°C / 50°F steps leads to a corresponding reduction

of the electronics' service life by a factor of two).

Storage temperature -50…+70°C / -58…+158°F

Pipe specifications

Material Metal, plastic, ceramic, asbestos cement, internal / external coated

pipes (coatings and liners fully bonded to pipe wall)

Pipewall thickness < 200 mm / 7.87"

Liner thickness < 20 mm / 0.79"

10 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 11 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 TECHNICAL DATA 2

Media properties

Physical condition Liquids

Viscosity < 100 cSt (general guideline)

For detailed information please contact your local representative.

Permissible gas content (volume) ≤ 2%

Permissible solid content ≤ 5%

(volume)

Recommended flow velocity 0.5...20 m/s

Other conditions

Protection category acc. to W (Wall) version signal converter:

IEC 529 / EN 60529 IP 65 (acc. to NEMA 4/4x)

F (Field) version signal converter:

IP 66/67 (acc. to NEMA 4x/6)

All sensors:

IP 67 (acc. to NEMA 6)

Vibration resistance IEC 68-2-64

Shock resistance IEC 60068-2-27

Installation condititions

Measurement configuration Single path, single pipe or dual path / dual pipe

Inlet run ≥ 10 DN straight length

Outlet run ≥ 5 DN straight length

Dimensions and weights See chapter "Dimensions and weights"

Materials

Sensor Standard

Anodised aluminum

Option stainless steel / eXtended Temperature (small / medium

version)

Rail construction: 1.4404 (AISI 316L)

Cable connection:1.4404, PSU with FKM O-ring

Converter Standard

F version: die-cast aluminum, polyurethane coated

W version: polyamide-polycarbonate

Option

F version: stainless steel 316 L (1.4408)

Electrical connections

Voltage Standard: 100…230 VAC (-15% / +10%), 50/60 Hz

Option: 24 VAC/DC (AC: -15% / +10%; DC: -25% / +30%)

Power consumption AC: 22 VA

DC: 12 W

Signal cable double shielded, 2 internal triax, available lengths:

5 m / 15 ft (standard), maximum length 30 m / 90 ft

Cable entries Standard: M20 x 1.5

Option: ½" NPT, PF ½

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 11

.book Page 12 Tuesday, August 18, 2009 1:26 PM

2 TECHNICAL DATA OPTISONIC 6300

Inputs and outputs

General All in- and outputs are galvanically isolated from each other and from

all other circuits

Description of used abbreviations Uext = external voltage; RL = load + resistance; Uo = terminal voltage;

Inom = nominal current

Current output

Output data Measurement of volume and mass (at constant density), HART®

communication

Settings Without HART®

Q = 0%: 0…20 mA; Q = 100%: 10…21.5 mA

Error identification: 0…22 mA

With HART®

Q = 0%: 4…20 mA; Q = 100%: 10…21.5 mA

Error identification: 3.5…22 mA

Operating data Basic I/Os Modular I/Os Ex-i

Active Uint,nom = 24 VDC Uint,nom = 20 VDC

I ≤ 22 mA I ≤ 22 mA

RL ≤ 1 kΩ RL ≤ 450 Ω

U0 = 21 V

I0 = 90 mA

P0 = 0.5W

C0 = 90 nF /

L0 = 2 mH

C0 = 110 nF /

L0 = 0.5 mH

Passive Uext ≤ 32 VDC Uext ≤ 32 VDC

I ≤ 22 mA I ≤ 22 mA

U0 ≥ 1.8 V at I = 22 mA U0 ≥ 4 V

RL ≤(Uext - Uo) / Imax

UI = 30 V

II = 100 mA

PI = 1 W

CI = 10 nF

LI ~ 0 mH

HART®

Description HART® protocol at active and passive current output

HART® version: V5

Universal HART® parameter fully integrated

Load ≥ 250 Ω

Please observe maximum value for current output

Multidrop Yes, current output = 4 mA

Multidrop addresses programmable in menu 1...15

Device drivers FDT/DTM

12 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 13 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 TECHNICAL DATA 2

Pulse or frequency output

Output data Volume or mass counting

Function Can be set as a pulse output or frequency output

Settings For Q = 100%: 0.01...10000 pulses per second or pulses per unit

volume

Pulse width: setting automatic, symmetric or fixed (0.05...2000 ms)

Operating data Basic I/Os Modular I/Os Ex-i

Active - Unom = 24 VDC -

fmax ≤ 100 Hz:

I ≤ 20 mA

open: I ≤ 0.05 mA

closed:

U0,nom = 24 V at

I = 20 mA

100 Hz < fmax ≤ 10

kHz:

I ≤ 20 mA

open: I ≤ 0.05 mA

closed:

U0,nom = 22.5 V at

I = 1 mA

U0,nom = 21.5 V at

I = 10 mA

U0,nom = 19 V at

I = 20 mA

Passive Uext ≤ 32 VDC -

fmax ≤ 100 Hz:

I ≤ 100 mA

open:

I ≤ 0.05 mA at Uext = 32 VDC

closed:

U0, max = 0.2 V at I ≤ 10 mA

U0, max = 2 V at I ≤ 100 mA

100 Hz < fmax ≤ 10 kHz:

I ≤ 20 mA

open:

I ≤ 0.05 mA at Uext = 32 VDC

closed:

U0, max = 1.5 V at I ≤ 1 mA

U0, max = 2.5 V at I ≤ 10 mA

U0, max = 5.0 V at I ≤ 20 mA

NAMUR - Passive to Passive to

EN 60947-5-6 EN 60947-5-6

open: Inom = 0.6 mA open: Inom = 0.43 mA

closed: Inom = 3.8 mA closed: Inom = 4.5 mA

UI = 30 V

II = 100 mA

PI = 1 W

CI =10 nF

LI ~ 0 mH

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 13

.book Page 14 Tuesday, August 18, 2009 1:26 PM

2 TECHNICAL DATA OPTISONIC 6300

Status output / limit switch

Function and settings Settable as automatic measuring range change, indicator for

direction of flow, overflow, error, operating point or empty pipe

detection

Valve control with activated dosing function

Status and/or control: ON or OFF

Operating data Basic I/Os Modular I/Os Ex-i

Active - Uint = 24 VDC -

I ≤ 20 mA

open: I ≤ 0.05 mA

closed:

U0, nom = 24 V at

I = 20 mA

Passive Uext ≤ 32 VDC Uext = 32 VDC -

I ≤ 100 mA I ≤ 100 mA

open: RL, max = 47 kΩ

I ≤ 0.05 mA at open:

Uext = 32 VDC I ≤ 0.05 mA at

closed: Uext = 32 VDC

U0, max = 0.2 V at closed:

I ≤ 10 mA U0, max = 0.2 V at

U0, max = 2 V at I ≤ 10 mA

I ≤ 100 mA U0, max = 2 V at

I ≤ 100 mA

NAMUR - Passive to Passive to

EN 60947-5-6 EN 60947-5-6

open: Inom = 0.6 mA open: Inom = 0.43 mA

closed: Inom = 3.8 mA closed: Inom = 4.5 mA

UI = 30 V

II = 100 mA

PI = 1 W

CI =10 nF

LI = 0 mH

14 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 15 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 TECHNICAL DATA 2

Control input

Function Hold value of the outputs (e.g. for cleaning work), set value of the

outputs to "zero", counter and error reset, range change.

Start of dosing when dosing function is activated.

Operating data Basic I/Os Modular I/Os Ex-i

Active - Uint = 24 VDC -

Terminals open:

U0, nom = 22 V

Terminals bridged:

Inom = 4 mA

On:

U0 ≥ 12 V with

Inom = 1.9 mA

Off:

U0 ≤ 10 V with

Inom = 1.9 mA

Passive 8 V ≤ Uext ≤ 32 VDC 3 V ≤ Uext ≤ 32 VDC Uext ≤ 32 VDC

Imax = 6.5 mA Imax = 9.5 mA at I ≤ 6 mA at Uext = 24 V

at Uext ≤ 24 VDC Uext ≤ 24 V I ≤ 6.6 mA at

Imax = 8.2 mA Imax = 9.5 mA at Uext = 32 V

at Uext ≤ 32 VDC Uext ≤ 32 V On:

Contact closed (On): Contact closed (On): U0 ≥ 5.5 V or I ≥ 4 mA

U0 ≥ 8 V U0 ≥ 3 V Off:

with Inom = 2.8 mA with Inom = 1.9 mA U0 ≤ 3.5 V or

Contact open (Off): Contact open (Off): I ≤ 0.5 mA

U0 ≤ 2.5 V U0 ≤ 2.5 V UI = 30 V

with Inom = 0.4 mA with Inom = 1.9 mA II = 100 mA

PI = 1 W

CI = 10 nF

LI = 0 mH

NAMUR - Active to EN 60947-5- -

6

Contact open:

U0, nom = 8.7 V

Contact closed (On):

Inom = 7.8 mA

Contact open (off):

U0, nom = 6.3 V with

Inom = 1.9 mA

Identification for

open terminals:

U0 ≥ 8.1 V with

I ≤ 0.1 mA

Identification for

short circuited

terminals:

U0 ≤ 1.2 V with

I ≥ 6.7 mA

Low-flow cutoff

On 0...±9.999 m/s; 0...20.0%, settable in 0.1% steps, separately for each

current and pulse output

Off 0...±9.999 m/s; 0...19.0%, settable in 0.1% steps, separately for each

current and pulse output

Time constant

Function Can be set together for all flow indicators and outputs, or separately

for: current, pulse and frequency output, and for limit switches and

the 3 internal counters

Time setting 0…100 seconds, settable in 0.1 second steps

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 15

.book Page 16 Tuesday, August 18, 2009 1:26 PM

2 TECHNICAL DATA OPTISONIC 6300

Approvals and certificates

Hazardous areas

ATEX Sensor:

PTB 06 ATEX 2045 X

II 2 G Ex ia IIC T6...T4 (XT Version: II 2 G Ex ia IIC T6...T2)

Converter (F version only):

PTB 06 ATEX 2046 X

II 2(1) G Ex de [ia] IIC T6 or II 2 G Ex de [ia] IIC T6

II 2(1) G Ex d [ia] IIC T6 or II 2 G Ex d [ia] IIC T6

FM - Class I, DIV 1/2 Option (F version): approval ID = 3029326

Pending for stainless steel / eXtended Temperature version.

CSA - GP / Class I, Option (F version): approval certificate = 1956404 (LR 105802)

DIV 1/2

Pending for stainless steel / eXtended Temperature version.

Other approvals and standards

Electromagnetic compatibility Directive: 89/336/EEC, NAMUR NE21/04

Harmonized standard: EN 61326-1: 2006

Low Voltage Directive Directive: 2006/95/EC

Harmonized standard: EN 61010: 2001

16 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 17 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 TECHNICAL DATA 2

2.2 Dimensions and weights

2.2.1 Clamp-on sensor and cable box

Version Dimensions [mm] Approx. weight

(without cable /

L H W strip) [kg]

Small 496.3 71 63.1 2.7

Medium 826.3 71 63.1 3.6

Large 496.3 1 71 1 63.1 1 2.7 1

Small - stainless 493 65.5 48 2.1

steel / XT 2

Medium - stainless 823 65.5 48 2.7

steel / XT 2

1 value for one of the 2 delivered rails

2 delivered without cover

Version Dimensions [inches] Approx. weight

(without cable /

L H W strip) [lbs]

Small 19.5 2.8 2.5 6.0

Medium 32.5 2.8 2.5 7.9

Large 19.5 1 2.8 1 2.5 1 6.0 1

Small - stainless 19.4 2.6 1.9 4.6

steel / XT 2

Medium - stainless 32.4 2.6 1.9 6.0

steel / XT 2

1 value for one of the 2 delivered rails

2 delivered without cover

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 17

.book Page 18 Tuesday, August 18, 2009 1:26 PM

2 TECHNICAL DATA OPTISONIC 6300

Dimensions [mm] Approx. weight

without

a b c cable/metal [kg]

Cable box 102 197 67 0.85

Dimensions [inches] Approx. weight

without

a b c cable/metal [lbs]

Cable box 4.01 7.76 2.64 1.87

18 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 19 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 TECHNICAL DATA 2

2.2.2 Housing

1 Field housing (F) - remote version

2 Wall-mounted housing (W) - remote version

Dimensions and weights in mm and kg

Version Dimensions [mm] Weights

[kg]

a b c g h

F 202 120 155 295.8 277 5.7

W 198 138 299 - - 2.4

Dimensions and weights in inches and lbs

Version Dimensions [inches] Weights

[lbs]

a b c g h

F 7.75 4.75 6.10 11.60 10.90 12.60

W 7.80 5.40 11.80 - - 5.30

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 19

.book Page 20 Tuesday, August 18, 2009 1:26 PM

2 TECHNICAL DATA OPTISONIC 6300

2.2.3 Mounting plate, field housing

Dimensions in mm and inches

[mm] [inches]

a 60 2.4

b 100 3.9

c Ø9 Ø0.4

2.2.4 Mounting plate, wall-mounted housing

Dimensions in mm and inches

[mm] [inches]

a Ø9 Ø0.4

b 64 2.5

c 16 0.6

d 6 0.2

e 63 2.5

f 4 0.2

g 64 2.5

h 98 3.85

20 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

Installation

.book Page 21 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 INSTALLATION 3

3.1 Intended use

The overall functionality of the clamp-on flowmeter is the continuous measurement of actual

volume flow, mass flow, flow speed, velocity of sound, gain, SNR and diagnosis value.

3.2 Environmental requirements

• Pollution degree 2

• Protection class I

• Humidity: 5...80 % RH

• Temperature: –40…+60°C / -40…+140°F operating and –50…+70°C / -58…+158°F storage

• Suitable for indoor and outdoor use and certified for operating up to an altitude of

2000 m / 6562 ft

• IP class 66/67

The device should be protected from corrosive chemicals or gases and dust / particles

accumulation.

3.3 Installation requirements signal converter

• Allow 10…20 cm / 3.9…7.9" of space at the sides and rear of the signal converter to permit

free air circulation.

• Protect signal converter against direct solar radiation, install a sunshield if necessary.

• Signal converters installed in switchgear cabinets require adequate cooling, e.g. by fan or

heat exchanger.

• Do not expose the signal converter to intense vibration.

3.4 Installation requirements sensor

To avoid measuring errors and malfunctioning of the flowmeter due to gas or air inclusions or an

empty pipe, please observe the following precautions.

Since gas will collect at the highest point of a pipe, installation of the flowmeter at that location

should be avoided at all times. Also installation in a down going pipe should be avoided since a

completely filled pipe may not be guaranteed due to cascading effects. Additionally flow profile

distortion is possible.

If you program the diameter, please note that you use the outer diameter of the pipe.

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 21

.book Page 22 Tuesday, August 18, 2009 1:26 PM

3 INSTALLATION OPTISONIC 6300

3.4.1 Inlet, outlet and recommended mounting area

Figure 3-1: Inlet, outlet and recommended mounting area

1 Min. 10 DN

2 Min. 5 DN

3 OK, 120°

Especially for XT (eXtended Temperature) versions:

• Always install the sensor at a non-insulated part of the pipe. Remove any insulation if

necessary!

• Bend radius of cable plus connection box needs 10 cm / 4" additional non insulated pipe

section.

• Always wear protections gloves.

3.4.2 Long horizontal pipes

• Install on slightly ascending pipe section.

• If not possible, ensure adequate velocity to prevent air, gas or vapor from collecting in upper

part.

• In partially filled pipes, the clamp-on flowmeter will report incorrect flow rates, or not

measure.

Figure 3-2: Long horizontal pipes

22 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 23 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 INSTALLATION 3

3.4.3 Open feed or discharge

Install meter on a lowered section of the pipe to ensure a full pipe condition through the meter.

Figure 3-3: Open feed or discharge

3.4.4 Down going pipeline over 5 m /16 ft length

Install air vent downstream of the flow meter to prevent vacuum. Although this will not harm the

meter, it may cause gases to come out of solution (cavitate) and interfere with proper

measurements.

Figure 3-4: Down going pipeline over 5 m /16 ft length

3.4.5 Position of control valve

Always install control valves downstream of flowmeter in order to avoid cavitation or distortion

of flow profile.

Figure 3-5: Position of control valve

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 23

.book Page 24 Tuesday, August 18, 2009 1:26 PM

3 INSTALLATION OPTISONIC 6300

3.4.6 Position of pump

Never install flowmeter at a pump suction side in order to avoid cavitation or flashing in the

flowmeter.

Figure 3-6: Position of pump

24 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

Electrical connections

.book Page 25 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 ELECTRICAL CONNECTIONS 4

4.1 Signal cable and power supply signal converter

The power terminals in the terminal compartments are equipped with additional hinged lids to

prevent accidental contact.

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

Figure 4-1: Construction of wall version

1 Connect blue cable to 1U (to 2U for 2nd sensor) and the green cable to 1D (2D for 2nd sensor)

2 Communication I/O

3 Power supply: 24 VAC/DC or 100...240 VAC

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 25

.book Page 26 Tuesday, August 18, 2009 1:26 PM

4 ELECTRICAL CONNECTIONS OPTISONIC 6300

Figure 4-2: Construction (field version)

1 Cover, electronics compartment

2 Cover, terminal compartment for power supply and inputs/outputs

3 Cable entry for power

4 Cable entry for inputs/outputs

5 Cable entry for sensor cable

6 Cover, sensor terminal compartment

100…230 VAC (-15% / +10%)

• Connect the protective ground conductor PE of the mains power supply to the separate

terminal in the terminal compartment of the signal converter.

• Connect the live conductor to the L terminal and the neutral conductor to the N terminal.

24 VAC/DC (-15% / +10%)

• For reasons to do with the measurement process, connect a functional ground FE to the

separate U-clamp terminal in the terminal compartment of the signal converter.

• When connecting to functional extra-low voltages, provide a facility for protective separation

(PELV) (VDE 0100 / VDE 0106 and/or IEC 364 / IEC 536 or relevant national regulations).

26 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 27 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 ELECTRICAL CONNECTIONS 4

4.2 Inputs and outputs, overview

4.2.1 Fixed, non-alterable input/output versions

This measuring transducer is available with various input/output combinations.

CG-No. Connection terminals

A+ A A- B B- C C- D D-

Basic input/output (I/O) standard

100 Ip + HART® passive 1 Sp / Cp passive 2 Sp passive Pp / Sp passive 2

Ia + HART® active 1

EEx-i inputs/outputs (I/Os) option

200 Ia + HART® active PN / SN NAMUR 2

300 Ip + HART® passive PN / SN NAMUR 2

210 Ia active PN / SN NAMUR Ia + HART® active PN / SN NAMUR 2

Cp passive 2

310 Ia active PN / SN NAMUR Ip + HART® passive PN / SN NAMUR 2

Cp passive 2

220 Ip passive PN / SN NAMUR Ia + HART® active PN / SN NAMUR 2

Cp passive 2

320 Ip passive PN / SN NAMUR Ip + HART® passive PN / SN NAMUR 2

Cp passive 2

1 function changed by reconnection

2 changeable

• The grey boxes in the tables denote unassigned or unused connection terminals.

• Connection terminal A+ is only operable in the basic input/output version.

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 27

.book Page 28 Tuesday, August 18, 2009 1:26 PM

4 ELECTRICAL CONNECTIONS OPTISONIC 6300

Description of abbreviations and CG identifier for possible optional modules

on terminals A and B

Abbreviation Identifier for CG No. Description

Ia A Active current output (including HART = HART® capability)

Ip B Passive current output (including HART = HART® capability)

Pa / Sa C Active pulse, frequency, status output or limit switch (changeable)

Pp / Sp E Passive pulse, frequency, status output or limit switch (changeable)

PN / SN F Passive pulse, frequency, status output or limit switch according to

NAMUR (changeable)

Ca G Active control input

Cp K Passive control input

CN H Active control input to NAMUR

Signal converter monitors cable breaks and short circuits as per EN

60947-5-6. Errors indicated on LCD display. Error messages possible via

status output.

IIna P Active current input

IInp R Passive current input

- 8 No additional module installed

- 0 No further module possible

28 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 29 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 ELECTRICAL CONNECTIONS 4

4.2.2 Alterable input/output versions

The signal converter is available with various input/output combinations.

CG-No. Connection terminals

A+ A A- B B- C C- D D-

Modular inputs/outputs option

4__ max. 2 option modules for term. A + B Ia + HART® active Pa / Sa active 1

8__ max. 2 option modules for term. A + B Ip + HART® passive Pa / Sa active 1

6__ max. 2 option modules for term. A + B Ia + HART® active Pp / Sp passive 1

B__ max. 2 option modules for term. A + B Ip + HART® passive Pp / Sp passive 1

7__ max. 2 option modules for term. A + B Ia + HART® active PN / SN NAMUR 1

C__ max. 2 option modules for term. A + B Ip + HART® passive PN / SN NAMUR 1

1 changeable

Description of abbreviations and CG identifier for possible optional modules

on terminals A and B

Abbreviation Identifier for CG No. Description

Ia A Active current output (including HART = HART® capability)

Ip B Passive current output (including HART = HART® capability)

Pa / Sa C Active pulse, frequency, status output or limit switch (changeable)

Pp / Sp E Passive pulse, frequency, status output or limit switch (changeable)

PN / SN F Passive pulse, frequency, status output or limit switch according to

NAMUR (changeable)

Ca G Active control input

Cp K Passive control input

CN H Active control input to NAMUR

Signal converter monitors cable breaks and short circuits as per EN

60947-5-6. Errors indicated on LCD display. Error messages possible via

status output.

IIna P Active current input

IInp R Passive current input

- 8 No additional module installed

- 0 No further module possible

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 29

Application form

.book Page 30 Tuesday, August 18, 2009 1:26 PM

5 APPLICATION FORM OPTISONIC 6300

Please fill in this form and fax or email it to your local representive. Please include a sketch of

the pipe layout as well, including the X, Y, Z dimensions.

Customer information

Date

Submitted by

Company

Address

Telephone

Fax

E-mail

Flow application data

Reference information (name, tag etc)

New application

Existing application, currently using:

Measurement objective:

Fluid:

Flowrate

Normal:

Minimum:

Maximum:

Temperature

Normal:

Minimum:

Maximum:

Viscosity

Normal:

Maximum:

Continuous / pulsating flow. Description:

Entrained air percentage (volume):

Eintrained solids percentage (volume):

Emulsion present (e.g. oil / water):

Emulsion percentage product A:

Emulsion percentage product B:

30 www.krohne.com 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en

.book Page 31 Tuesday, August 18, 2009 1:26 PM

OPTISONIC 6300 APPLICATION FORM 5

Piping details

Nominal pipe size:

Outer diameter:

Wall thickness / schedule:

Pipe material:

Pipe condition (old / new / painted /

internal scaling / exterior rust):

Liner material:

Liner thickness:

Straight inlet / outlet section (DN):

Upstream situation (elbows, valves,

pumps):

Flow orientation (vertical up / horizontal

/ vertical down / other):

Environment details

Corrosive atmosphere:

Sea water:

High humidity (% R.H.)

Nucleair (radiation):

Hazardous area:

Additional details:

Hardware requirements:

Accuracy requested (percentage of

rate):

Power supply (voltage, AC / DC):

Analog output (4-20 mA)

Pulse (specify minimum pulse width,

pulse value):

Digital protocol:

Options:

Remote mounted signal converter:

specify cable length:

Accessories

07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en www.krohne.com 31

.book Page 32 Tuesday, August 18, 2009 1:26 PM

K K

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

© KROHNE 07/2009 - 4000255303 - TD OPTISONIC 6300 R05 en - Subject to change without notice.

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Measuring systems for the oil and gas industry

• Measuring systems for sea-going tankers

Head Office KROHNE Messtechnik GmbH & Co. KG

Ludwig-Krohne-Str. 5

D-47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Vous aimerez peut-être aussi

- Optisonic 3400 Optisonic 3400 Optisonic 3400 Optisonic 3400Document52 pagesOptisonic 3400 Optisonic 3400 Optisonic 3400 Optisonic 3400Didik WahyudiPas encore d'évaluation

- Ultrasonico Krohne 3400Document52 pagesUltrasonico Krohne 3400Fer PabPas encore d'évaluation

- Optimass 7000Document36 pagesOptimass 7000Nazim GhaffarPas encore d'évaluation

- TD OPTISONIC7300 en 180907 4001344705 R05Document40 pagesTD OPTISONIC7300 en 180907 4001344705 R05Didik WahyudiPas encore d'évaluation

- TD OPTISONIC4400 en 170320 4003958501 R01Document48 pagesTD OPTISONIC4400 en 170320 4003958501 R01Didik WahyudiPas encore d'évaluation

- Optimass 1400 Tech DatasheetDocument32 pagesOptimass 1400 Tech DatasheetAbid Hossain RupamPas encore d'évaluation

- Optibar DP 7060 Optibar DP 7060 Optibar DP 7060 Optibar DP 7060Document52 pagesOptibar DP 7060 Optibar DP 7060 Optibar DP 7060 Optibar DP 7060SafiaMohamedPas encore d'évaluation

- Da Optibatch4011cDocument24 pagesDa Optibatch4011cCharles RodriguezPas encore d'évaluation

- Optiswirl 4200 Optiswirl 4200 Optiswirl 4200 Optiswirl 4200: Vortex FlowmeterDocument38 pagesOptiswirl 4200 Optiswirl 4200 Optiswirl 4200 Optiswirl 4200: Vortex FlowmeterJavier CarrizoPas encore d'évaluation

- Mass Flow MeterDocument32 pagesMass Flow MeterClash KingPas encore d'évaluation

- Optisonic 6300 P Optisonic 6300 P Optisonic 6300 P Optisonic 6300 PDocument32 pagesOptisonic 6300 P Optisonic 6300 P Optisonic 6300 P Optisonic 6300 PCristina GrecuPas encore d'évaluation

- Optibar DP 7060 Optibar DP 7060 Optibar DP 7060 Optibar DP 7060Document52 pagesOptibar DP 7060 Optibar DP 7060 Optibar DP 7060 Optibar DP 7060Luz Stella Calixto GomezPas encore d'évaluation

- Krohne mfc400 DatasheetDocument32 pagesKrohne mfc400 DatasheetArnezPas encore d'évaluation

- MFC 400 MFC 400 MFC 400 MFC 400: Signal Converter For Mass FlowmetersDocument36 pagesMFC 400 MFC 400 MFC 400 MFC 400: Signal Converter For Mass FlowmetersCharles RodriguezPas encore d'évaluation

- Optiflux 5000 Optiflux 5000 Optiflux 5000 Optiflux 5000: Electromagnetic Flowmeter in Sandwich VersionDocument28 pagesOptiflux 5000 Optiflux 5000 Optiflux 5000 Optiflux 5000: Electromagnetic Flowmeter in Sandwich VersionJavierLugoPas encore d'évaluation

- TD OPTIMASS2000 en 101122 4000228104 R04Document28 pagesTD OPTIMASS2000 en 101122 4000228104 R04eka pramudia santosoPas encore d'évaluation

- TD Optiflux4000 enDocument44 pagesTD Optiflux4000 enVasilePas encore d'évaluation

- TD OPTIBAR LC1010C en 160318 4005075701 R01 PRT 1000346341 1Document20 pagesTD OPTIBAR LC1010C en 160318 4005075701 R01 PRT 1000346341 1sgangaraj093010Pas encore d'évaluation

- TD OPTIFLUX4000 en 220106 4000525107 R10Document48 pagesTD OPTIFLUX4000 en 220106 4000525107 R10AugustoPas encore d'évaluation

- TD OPTISONIC 3400 MID en 160304 4004547101 R01 1000342931 1 ADocument32 pagesTD OPTISONIC 3400 MID en 160304 4004547101 R01 1000342931 1 ABsd FareedPas encore d'évaluation

- TD OPTIFLUX4000 en 140218 4000525103 R06 PDFDocument40 pagesTD OPTIFLUX4000 en 140218 4000525103 R06 PDFJahidul IslamPas encore d'évaluation

- Gifghig464 PDFDocument24 pagesGifghig464 PDFahmed nawaz100% (1)

- Krohne WATERFLUX3000 DatasheeDocument36 pagesKrohne WATERFLUX3000 DatasheeAllan FurukawaPas encore d'évaluation

- TD OPTIMASS2400 en 170223 4003534002 R02Document32 pagesTD OPTIMASS2400 en 170223 4003534002 R02M Alim Ur RahmanPas encore d'évaluation

- Optiflux 4000Document32 pagesOptiflux 4000jufrejjPas encore d'évaluation

- TD - OPTIFLUX 1000 - en - 120927 - 4000690403 - R03Document24 pagesTD - OPTIFLUX 1000 - en - 120927 - 4000690403 - R03Javier vaca villalbaPas encore d'évaluation

- TD OPTISYS-SLM 2100 en 200730 4002737406 R06Document44 pagesTD OPTISYS-SLM 2100 en 200730 4002737406 R06Ema LhtPas encore d'évaluation

- Field Devices - Flow Product SpecificationsDocument40 pagesField Devices - Flow Product SpecificationsschreyarPas encore d'évaluation

- Krohne OPTISONIC6300 Quick Start GuideDocument56 pagesKrohne OPTISONIC6300 Quick Start GuidelancasaPas encore d'évaluation

- H250 M40 H250 M40 H250 M40 H250 M40: Variable Area FlowmeterDocument48 pagesH250 M40 H250 M40 H250 M40 H250 M40: Variable Area FlowmeterAbel VegaPas encore d'évaluation

- Sodium Monitor: User Guide IM/8037 Rev. KDocument44 pagesSodium Monitor: User Guide IM/8037 Rev. KTiennghia BuiPas encore d'évaluation

- Medidor de FlujoDocument14 pagesMedidor de FlujoAngel LozaPas encore d'évaluation

- Safety ManualDocument28 pagesSafety ManualsindupwPas encore d'évaluation

- Optimass / 400 Optimass / 400 Optimass / 400 Optimass / 400Document44 pagesOptimass / 400 Optimass / 400 Optimass / 400 Optimass / 400samueloluwaseyi68Pas encore d'évaluation

- KROHNE OPTISONIC 3400 Quick Start GuideDocument42 pagesKROHNE OPTISONIC 3400 Quick Start GuideImpresora RabighPas encore d'évaluation

- Manual Optris CS LTDocument54 pagesManual Optris CS LTsduran2012Pas encore d'évaluation

- TD OPTIFLUX4000 en 190921 4000525106 R09Document44 pagesTD OPTIFLUX4000 en 190921 4000525106 R09Edwique Kudzai MukuzePas encore d'évaluation

- Pss - 1-6h7a - A 8400A (PFA)Document28 pagesPss - 1-6h7a - A 8400A (PFA)schreyarPas encore d'évaluation

- SA-20 User ManualDocument15 pagesSA-20 User ManualBiosistem-mld SRL100% (1)

- OP - UKK .MLE .MPS .TR .21.rev .3.11Document17 pagesOP - UKK .MLE .MPS .TR .21.rev .3.11Mario Lizano janampaPas encore d'évaluation

- BIOBASE Vertical Laminar Flow Cabinet BBS-DDC'SDC User Manual 202109Document25 pagesBIOBASE Vertical Laminar Flow Cabinet BBS-DDC'SDC User Manual 202109SACO QCPas encore d'évaluation

- Optiwave 7300 C Optiwave 7300 C Optiwave 7300 C Optiwave 7300 CDocument52 pagesOptiwave 7300 C Optiwave 7300 C Optiwave 7300 C Optiwave 7300 CraisPas encore d'évaluation

- Instruction Manual: Ion-Selective Electrode MonitorDocument44 pagesInstruction Manual: Ion-Selective Electrode MonitorAnuta CosminPas encore d'évaluation

- ABB Bulaniklik Olcum SistemiDocument52 pagesABB Bulaniklik Olcum SistemiLong Nguyễn VănPas encore d'évaluation

- Industrial Flow Measurement PracticeDocument251 pagesIndustrial Flow Measurement Practicepneuma110Pas encore d'évaluation

- Position Feedback For Motor Control Using Magnetic SensorDocument17 pagesPosition Feedback For Motor Control Using Magnetic SensorPablo TapiaPas encore d'évaluation

- Hydro-Probe Orbiter User Guide - Model ORB1Document51 pagesHydro-Probe Orbiter User Guide - Model ORB1John SmittPas encore d'évaluation

- HB OPTISONIC7060 en 070323Document52 pagesHB OPTISONIC7060 en 070323AzariasPas encore d'évaluation

- Practical Machinery Vibration Analysis and Predictive MaintenanceD'EverandPractical Machinery Vibration Analysis and Predictive MaintenanceÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Krohne Flow Meter PDFDocument40 pagesKrohne Flow Meter PDFavabhyankar9393Pas encore d'évaluation

- SLA Series ManualDocument10 pagesSLA Series ManualPrateek PandeyPas encore d'évaluation

- KR 800 RM 800 User ManualDocument74 pagesKR 800 RM 800 User ManualJosePas encore d'évaluation

- KR 800 Manual enDocument74 pagesKR 800 Manual enCristianPas encore d'évaluation

- 000-1533A OM3 User Guide PDFDocument52 pages000-1533A OM3 User Guide PDFJavierPas encore d'évaluation

- Ka01418den 0221-00Document56 pagesKa01418den 0221-00Meng PamplonaPas encore d'évaluation

- VFD CU24025 datasheet and ANDocument24 pagesVFD CU24025 datasheet and ANCarlos ChuekePas encore d'évaluation

- Ma Optimass Mfc400 Haz - Areas - enDocument28 pagesMa Optimass Mfc400 Haz - Areas - enFranzKafkaPas encore d'évaluation

- TD WATERFLUX3070 V3 en 220502 4005198103 R03Document52 pagesTD WATERFLUX3070 V3 en 220502 4005198103 R03ธนาชัย เต็งจิรธนาภาPas encore d'évaluation

- CryoLine User Manual Eng PDFDocument47 pagesCryoLine User Manual Eng PDFsantalusi0% (1)

- Fisher 249 Sensor Level Controller and Transmitter Dimensions en 124806Document20 pagesFisher 249 Sensor Level Controller and Transmitter Dimensions en 124806GOKUL PRASADPas encore d'évaluation

- Orifice Plate Data For Socia Line: Sr. No. Description Size / Type / Material CommentDocument1 pageOrifice Plate Data For Socia Line: Sr. No. Description Size / Type / Material CommentsenthilrsenthilPas encore d'évaluation

- Gas Detection SchematicDocument1 pageGas Detection SchematicsenthilrsenthilPas encore d'évaluation

- 107 Differential Pressure Switch Cat459Document4 pages107 Differential Pressure Switch Cat459senthilrsenthilPas encore d'évaluation

- Influenza Ac Cute Viral ConditionsDocument16 pagesInfluenza Ac Cute Viral ConditionssenthilrsenthilPas encore d'évaluation

- Asco Quick Exhaust CatalogDocument2 pagesAsco Quick Exhaust CatalogsenthilrsenthilPas encore d'évaluation

- RC5 Data Sheet TV606 @enDocument2 pagesRC5 Data Sheet TV606 @ensenthilrsenthilPas encore d'évaluation

- DS TE6540 en Co 2045Document13 pagesDS TE6540 en Co 2045senthilrsenthilPas encore d'évaluation

- RC5 Data Sheet TV8 @enDocument2 pagesRC5 Data Sheet TV8 @ensenthilrsenthilPas encore d'évaluation

- 70D4AVSA4X20Document8 pages70D4AVSA4X20senthilrsenthilPas encore d'évaluation

- TXDIN70Document1 pageTXDIN70senthilrsenthilPas encore d'évaluation

- Homeopathic Materia Medica Volume 2: Understanding Human IdiosyncrasiesDocument216 pagesHomeopathic Materia Medica Volume 2: Understanding Human IdiosyncrasiesRavi Ranjan Jha100% (1)

- ZV - V Shape ThermometerDocument2 pagesZV - V Shape ThermometersenthilrsenthilPas encore d'évaluation

- TT411CEDocument2 pagesTT411CEsenthilrsenthilPas encore d'évaluation

- General Guidance 5th Sg-1008-0eDocument40 pagesGeneral Guidance 5th Sg-1008-0esenthilrsenthilPas encore d'évaluation

- UP4 Din BrochureDocument2 pagesUP4 Din BrochuresenthilrsenthilPas encore d'évaluation

- LX5000Document6 pagesLX5000senthilrsenthilPas encore d'évaluation

- Influenza Ac Cute Viral ConditionsDocument16 pagesInfluenza Ac Cute Viral ConditionssenthilrsenthilPas encore d'évaluation

- SaltsDocument3 pagesSaltssenthilrsenthilPas encore d'évaluation

- Honeywell CableCatalogDocument94 pagesHoneywell CableCatalogsenthilrsenthilPas encore d'évaluation

- 556 Series Pneumatic Analog Computer: Product SpecificationsDocument4 pages556 Series Pneumatic Analog Computer: Product SpecificationssenthilrsenthilPas encore d'évaluation

- FLUDocument61 pagesFLUIsh Vadgama100% (1)

- Boiler Level Guidebook 01Document26 pagesBoiler Level Guidebook 01karthikeashwar100% (1)

- ISA 75.02 Control Valve Capacity Test ProcedureDocument28 pagesISA 75.02 Control Valve Capacity Test ProcedureSIVA100% (3)

- 120 BDocument28 pages120 BsenthilrsenthilPas encore d'évaluation

- DS PM232 25 en Us 15601Document2 pagesDS PM232 25 en Us 15601senthilrsenthilPas encore d'évaluation

- DS PM 23X 34 en Us 15712 PDFDocument2 pagesDS PM 23X 34 en Us 15712 PDFsenthilrsenthilPas encore d'évaluation

- 21X 34Document2 pages21X 34senthilrsenthilPas encore d'évaluation

- 1279 RCVR SpecDocument1 page1279 RCVR SpecsenthilrsenthilPas encore d'évaluation

- Venturi MeterDocument21 pagesVenturi MeterMuhammad AshirPas encore d'évaluation

- Disposable Infusion PumpsDocument20 pagesDisposable Infusion PumpsRaul SosaPas encore d'évaluation

- 353.1 HEN E5 Manual Design PDFDocument288 pages353.1 HEN E5 Manual Design PDFmazhar955Pas encore d'évaluation

- Flow Measurement by Drag Effects: RotameterDocument3 pagesFlow Measurement by Drag Effects: RotameterjehadyamPas encore d'évaluation

- Unit 1 ProblemsDocument3 pagesUnit 1 Problemsgrace_juganPas encore d'évaluation

- Air Sampling BrochureDocument40 pagesAir Sampling BrochureAmar ElezovicPas encore d'évaluation

- Alicat U Theory Pressure FlowDocument4 pagesAlicat U Theory Pressure FlowqaedmahmoodPas encore d'évaluation

- ADA Considerations For ANSIISEAZ358!1!2014Document37 pagesADA Considerations For ANSIISEAZ358!1!2014naveen_86Pas encore d'évaluation

- PCCFL001Document16 pagesPCCFL001Hermann KlierPas encore d'évaluation

- MAN B&W Diesel A/S S26MC Project Guide: 6.10 Exhaust Gas SystemDocument10 pagesMAN B&W Diesel A/S S26MC Project Guide: 6.10 Exhaust Gas SystemMuhammad Ihsan KamilPas encore d'évaluation

- A Two-Tier Approach To The Mass Balance of Multi-Level Mineral Processing Data. Part 1: Performance Index and Local Balance Around A NodeDocument15 pagesA Two-Tier Approach To The Mass Balance of Multi-Level Mineral Processing Data. Part 1: Performance Index and Local Balance Around A Nodesebas panezPas encore d'évaluation

- PIPES ParallelDocument27 pagesPIPES ParallelSalman100% (1)

- AD FlightTestInstrumentationEngineering2Document288 pagesAD FlightTestInstrumentationEngineering2ilter79Pas encore d'évaluation

- CP1 (2020) Commissioning of Space HeatingDocument8 pagesCP1 (2020) Commissioning of Space HeatingKaterinaPas encore d'évaluation

- Three Way Valve Technical OverviewDocument8 pagesThree Way Valve Technical OverviewWalter JosephPas encore d'évaluation

- Chap 3Document12 pagesChap 3Kevin John VelascoPas encore d'évaluation

- Micronics U3000/4000: Ultrasonic Flowmeter User ManualDocument66 pagesMicronics U3000/4000: Ultrasonic Flowmeter User ManualmubashirhasanPas encore d'évaluation

- Orifice Meter Gas Flow Calculations SiDocument94 pagesOrifice Meter Gas Flow Calculations Siadma10% (1)

- IFM - SM7000 - Debitmetre - Sortie AnalogiqueDocument4 pagesIFM - SM7000 - Debitmetre - Sortie Analogiquenapnap5Pas encore d'évaluation

- Doe Fundamentals Handbook Instrumentation and ControlDocument34 pagesDoe Fundamentals Handbook Instrumentation and Controlmoath1Pas encore d'évaluation

- Numerical and Experimental Analysis of AdditiveDocument5 pagesNumerical and Experimental Analysis of Additive111Neha SoniPas encore d'évaluation

- ADSORPTION COLUMN DESIGNDocument61 pagesADSORPTION COLUMN DESIGNalimisaghian62100% (2)

- Instrument Symbols GuideDocument1 pageInstrument Symbols GuidezhangPas encore d'évaluation

- High Precision Instruments for Hydropower and Water Control ApplicationsDocument4 pagesHigh Precision Instruments for Hydropower and Water Control ApplicationsAjit SinghPas encore d'évaluation

- Field Testing Procedures FOR Curtainwalls, Windows and Façade ElementsDocument56 pagesField Testing Procedures FOR Curtainwalls, Windows and Façade ElementsMohammad TaushifPas encore d'évaluation

- Material Sourcing List: China Electrical & InstrumentationDocument239 pagesMaterial Sourcing List: China Electrical & InstrumentationAnonymous dbNMpuPbVA73% (11)

- 4A104C Excel-Template - Heat-exchanger-Design p1 Si UnitsDocument1 page4A104C Excel-Template - Heat-exchanger-Design p1 Si UnitsGOWTHAMPas encore d'évaluation

- VEGA T For Terminal Version 1.0 - 8639080e2eDocument6 pagesVEGA T For Terminal Version 1.0 - 8639080e2eProcurement PardisanPas encore d'évaluation

- OMNI 3000 - 6000 Specification Sheet SEP - 2017Document19 pagesOMNI 3000 - 6000 Specification Sheet SEP - 2017abbutalibbPas encore d'évaluation

- Operating Instruction: RE 250 Variable Area FlowmeterDocument32 pagesOperating Instruction: RE 250 Variable Area Flowmeterza3amPas encore d'évaluation