Académique Documents

Professionnel Documents

Culture Documents

Ac-Corroguard: Inhibitor Solution For Reinforcement Bar

Transféré par

bhagwatpatilDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ac-Corroguard: Inhibitor Solution For Reinforcement Bar

Transféré par

bhagwatpatilDroits d'auteur :

Formats disponibles

An ISO 9001 Certified Company

Direction for use

AC-CORROGUARD

Remove all loose rust / iron oxide remanants if

Inhibitor Solution for Reinforcement any on the rebar by using wire brush.

The treatment shall be given to reinforcement

Bar only after cutting and bending the same as per

Description the bar bending schedule.

Make a slurry of cement by adding inhibitor

solution to OPC in the ratio of 0.5 to 0.6 : 1

(Inhibitor Solution : OPC Cement)

AC-CORROGUARD is a specially formulated Apply uniform coat of slurry on surface of

corrosion inhibitor solution to increase chloride reinforcement, iron and steel by brushing or

threshold value, reducing corrosion rate, thereby dipping.

minimizing the corrosion & ensuring life of Keep coated bars for drying on the drying

reinforcement structure. platform. Apply second coat after 12 to 24 hrs

AC-CORROGUARD, corrosion inhibitor, is mixed interval and dry again.

type of inhibitor solution which retards anodic as

well as cathodic reactions and forms an

impervious layer on metal surface. Consumption

Approx. 10 to 15 kg per metric ton. (Consumption

depends on ambient temperature.)

Use

AC-CORROGUARD is used for the protection of Packaging

reinforcement bars before concreting. AC-CORROGUARD is supplied in 20 and

210 kg. drums

Advantages

Storage and Shelf life

AC-CORROGUARD needs to be protected from

1. It maintains high alkalinity around the

extremes of temperature. It must be thoroughly

metal surface in concrete, therefore

mixed before use.

controls corrosion due to carbonation.

AC-CORROGUARD has a minimum shelf life of 12

2. It increases the resistance of natural

months from manufacturing date, for original

passivating film on the metal surface from

sealed packaging provided temperature is kept

chloride attack.

within the range 5° C to 30° C.

3. It creates thin protective film on metal

surface

Technical Service

4. The passivating film blocks the contact of

"APPLE CHEMIE" provides technical support

chloride & Sulphate with metal surface.

service on mix design, admixture selection,

evaluation of trials, dispensing equipment etc.

Typical Properties Please contact the Technical department in

these cases.

Appearance : Clear Liquid. Cleaning: Spillages of AC-CORROGUARD

Sp Gravity : 1.04 ± 0.02 C. can be cleaned with plenty of water.

pH : 12.5 + 0.25

Safety precautions

Standards HEALTH AND SAFETY

AC-CORROGUARD is non-toxic. Any splashes

to the skin should be washed immediately with

AC-CORROGUARD complies with IS-9077 and water. Splashes to the eyes should be washed

JIS A-6205 immediately with water and medical advice

should be sought.

Fire : AC-CORROGUARD is non-flammable.

All possible precautions are taken to manufacture all APPLE CHEMIE PRODUCTS to ensure best quality standards. All products undergo

rigid quality test, however, no guarantee can be given because results depend on many other factors beyond our control. Any verbal or

written recommendation for the product application is intended to support the Buyer / User on the bases if our actual state of scientific and

practical knowledge. They are given in good faith and without any commitment, reserving the rights of third parties or foreign legal

provisions. They do not create any legal relations and no deed of convenient under a sales contract.

It is the Buyer’s / User’s responsibility to find out whether or not our product will fit for the intended use. All transactions shall be subject

to our terms of sale, delivery and payment. We reserve right of changing any / all specifications without any notice.

APPLE CHEMIE INDIA PVT. LTD. 24 ‘Abhang’, Ring Road, Near Chhatrapati Nagar Chowk, Nagpur 440 015. Ph.No. +91-712-2284942,

Fax No. +91-712-2284184 Email : sales@applechemie.com, Visit us at:www.applechemie.com

Vous aimerez peut-être aussi

- Bridge FinalDocument2 pagesBridge FinalRishil ShahPas encore d'évaluation

- Calculation of Decking Capacity &Document9 pagesCalculation of Decking Capacity &Waqar FaziPas encore d'évaluation

- Powder MetallurgyDocument24 pagesPowder MetallurgyMilan PanchalPas encore d'évaluation

- Chrome Ore Beneficiation Challenges & LISTODocument8 pagesChrome Ore Beneficiation Challenges & LISTOAlfredo V. Campa100% (1)

- A182 PDFDocument19 pagesA182 PDFالGINIRAL FREE FIRE100% (2)

- Guide To Types of Welding PDFDocument24 pagesGuide To Types of Welding PDFbhaskarjalanPas encore d'évaluation

- Dies1 2Document23 pagesDies1 2Ajay BabuPas encore d'évaluation

- Cracks in Immature Concrete PDFDocument2 pagesCracks in Immature Concrete PDForode franklynPas encore d'évaluation

- 2911 (Part 4) 2013Document16 pages2911 (Part 4) 2013Sangram keshari bejaPas encore d'évaluation

- Pile CatalogueDocument8 pagesPile CatalogueMohamad AmirulbaharudinPas encore d'évaluation

- BS Iso 4990Document23 pagesBS Iso 4990Thomas ValoPas encore d'évaluation

- Anker Schroeder - Anchors For Marine Structures PDFDocument28 pagesAnker Schroeder - Anchors For Marine Structures PDFlokeshras12Pas encore d'évaluation

- Cantilever Retaining Wall Design (3m)Document6 pagesCantilever Retaining Wall Design (3m)Dhukwan CivilPas encore d'évaluation

- 1881 208-96Document14 pages1881 208-96bhagwatpatil100% (1)

- 345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Document1 page345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Satya kaliprasad vangaraPas encore d'évaluation

- 1881 5-70Document27 pages1881 5-70bhagwatpatilPas encore d'évaluation

- SDADocument1 pageSDAFrans van der MerwePas encore d'évaluation

- WeldingDocument34 pagesWeldingManoj BallaPas encore d'évaluation

- FEED WATER TREATMENT FROM AVT (R) TO AVT (O) LDocument14 pagesFEED WATER TREATMENT FROM AVT (R) TO AVT (O) Lprakash100% (1)

- CPC-18 Measurement of Hardened Concrete Carbonation Depth: Rilem Recommendations Recommandations de La RilemDocument3 pagesCPC-18 Measurement of Hardened Concrete Carbonation Depth: Rilem Recommendations Recommandations de La RilemmanuelisantosPas encore d'évaluation

- Chemistry ProjectDocument10 pagesChemistry ProjectVineet Agarwal50% (4)

- CONSTRUCTION METHODOLOGY Embankment RailwaysDocument5 pagesCONSTRUCTION METHODOLOGY Embankment Railwaysvenkateswara rao PothinaPas encore d'évaluation

- (A) Open Caissons: These Are of Box-Shape, Open Both at The Top and The Bottom DuringDocument22 pages(A) Open Caissons: These Are of Box-Shape, Open Both at The Top and The Bottom DuringDilipKumarAkkaladeviPas encore d'évaluation

- Design of Prestressed Concrete Pile PDFDocument14 pagesDesign of Prestressed Concrete Pile PDFvindyavPas encore d'évaluation

- IS 2911 Part 2-Pages-4,8-19Document13 pagesIS 2911 Part 2-Pages-4,8-19Harsh TiwariPas encore d'évaluation

- Kerb and Channel Machine Placed Concrete PDFDocument6 pagesKerb and Channel Machine Placed Concrete PDFbala subramanyamPas encore d'évaluation

- Design and Construction of Reinforced Concrete Chimneys (ACI 307-98) PDFDocument17 pagesDesign and Construction of Reinforced Concrete Chimneys (ACI 307-98) PDFCristobal Jimenez MuchoPas encore d'évaluation

- Seismic Design NBC 105Document38 pagesSeismic Design NBC 105Shyam AwalPas encore d'évaluation

- Ultimate Limit State Design of Spread Foundations in The Case of UpliftDocument7 pagesUltimate Limit State Design of Spread Foundations in The Case of UpliftAndoPas encore d'évaluation

- Strip Footing Design Example PDFDocument6 pagesStrip Footing Design Example PDFJP ReddyPas encore d'évaluation

- Dome Structures. Saldome 2Document6 pagesDome Structures. Saldome 2Lidhia Fairuz HarlyPas encore d'évaluation

- Jersey Barrier DrawingDocument1 pageJersey Barrier DrawingShams Khattak100% (1)

- Rheofinish 288FU PDSDocument2 pagesRheofinish 288FU PDSpn0% (1)

- MoRTH 1100 Pile FoundationDocument22 pagesMoRTH 1100 Pile FoundationApurv Patel100% (1)

- Difference Between FIXED and ENFORCED Support - RAM - STAAD Wiki - RAM - STAAD - Bentley CommunitiesDocument3 pagesDifference Between FIXED and ENFORCED Support - RAM - STAAD Wiki - RAM - STAAD - Bentley CommunitiesHabib LajiliPas encore d'évaluation

- Fine Aggregate - M-SandDocument1 pageFine Aggregate - M-SandSudhir Mishra100% (1)

- Masterset Ac 100: Non-Chloride Hardening Accelerator For ConcreteDocument2 pagesMasterset Ac 100: Non-Chloride Hardening Accelerator For Concretemehrdad_so1981100% (1)

- Bailey Bridges - Guide To Inspection, Bridge Capacity Assessment & MaintenanceDocument19 pagesBailey Bridges - Guide To Inspection, Bridge Capacity Assessment & MaintenanceJames Ellis100% (1)

- Module 5: Design of Deep Foundations Lecture 20: Introduction (Section 20.1: Introduction) Objectives in This Section You Will Learn The FollowingDocument12 pagesModule 5: Design of Deep Foundations Lecture 20: Introduction (Section 20.1: Introduction) Objectives in This Section You Will Learn The FollowingmaizansofiaPas encore d'évaluation

- Renderoc RGDocument3 pagesRenderoc RGR.ThangarajPas encore d'évaluation

- Strip Chart StructureDocument5 pagesStrip Chart StructureBrijesh MishraPas encore d'évaluation

- List of Is Codes For Cement and ConcreteDocument6 pagesList of Is Codes For Cement and ConcreteAnand.5Pas encore d'évaluation

- Slab Deflection and DepthDocument10 pagesSlab Deflection and Depthsyed AffanPas encore d'évaluation

- 08 Chapter 9 - Sheet Pile WallsDocument65 pages08 Chapter 9 - Sheet Pile WallsHazem AlmasryPas encore d'évaluation

- Flat Slab Column SlendernessDocument5 pagesFlat Slab Column SlendernessDeepak GadkariPas encore d'évaluation

- Behavior of Sbr-Latex Modified Polypropylene Fibre Einforced Railway SleepersDocument7 pagesBehavior of Sbr-Latex Modified Polypropylene Fibre Einforced Railway SleepersHasnain BukhariPas encore d'évaluation

- Asphalt Concrete Report Final VersionDocument11 pagesAsphalt Concrete Report Final VersionLorraine Custodio100% (1)

- Static Cone Penetration TestDocument9 pagesStatic Cone Penetration TestRuchit GandhiPas encore d'évaluation

- Booklet PPC Jan19Document25 pagesBooklet PPC Jan19MAYURESH PATILPas encore d'évaluation

- CIVABTech81733Div A5rBrirAP - 11Document6 pagesCIVABTech81733Div A5rBrirAP - 11Rohit VermaPas encore d'évaluation

- Industrial-Structures - Question BankDocument14 pagesIndustrial-Structures - Question BankSherlin SibithaPas encore d'évaluation

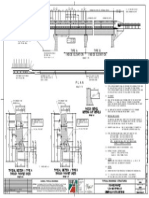

- Pile Cap of Abutment A1 & A2 (Takarma) - 1Document1 pagePile Cap of Abutment A1 & A2 (Takarma) - 1Nilay GandhiPas encore d'évaluation

- 400kv Sanand (Charal) - SBC ReportDocument65 pages400kv Sanand (Charal) - SBC Report400KVPas encore d'évaluation

- USSOR-2019 Earth Work SpecificationsDocument56 pagesUSSOR-2019 Earth Work SpecificationsrohitPas encore d'évaluation

- Course File RCC I Spring 2017newwwwDocument15 pagesCourse File RCC I Spring 2017newwwwMuhammad MurtazaPas encore d'évaluation

- Catalogo Freyssinet-122 Tendons PDFDocument11 pagesCatalogo Freyssinet-122 Tendons PDFJuan Jose QuevedoPas encore d'évaluation

- Block Shear Failure Seminar ReportDocument30 pagesBlock Shear Failure Seminar Reportpraxie88% (8)

- Temperature - 1Document2 pagesTemperature - 1ksshashidharPas encore d'évaluation

- Fabric Reinforcement SpecsDocument2 pagesFabric Reinforcement Specsabj7Pas encore d'évaluation

- IS-2911-part-1sec-1-2010-design-and Construction-Of-Pile-Foundation PDFDocument22 pagesIS-2911-part-1sec-1-2010-design-and Construction-Of-Pile-Foundation PDFRajan VAPas encore d'évaluation

- v2 TD S P 1002 1 F Shape Parapet 1 22m High Type A B General Layout and SectionsDocument1 pagev2 TD S P 1002 1 F Shape Parapet 1 22m High Type A B General Layout and SectionsSudathipTangwongchaiPas encore d'évaluation

- TDS - Polyalk CP 293+Document1 pageTDS - Polyalk CP 293+Anonymous ouZFaSBRPas encore d'évaluation

- Underpass Design ReportDocument23 pagesUnderpass Design ReportMuhammad MinhasPas encore d'évaluation

- Bridge Rules PDFDocument73 pagesBridge Rules PDFnrnnadigPas encore d'évaluation

- Method Statement For Laying of ACWC 20Document3 pagesMethod Statement For Laying of ACWC 20Fa DylaPas encore d'évaluation

- Tunnelling in Bukit Timah Granite Formation - Challenges in Tunnelling From Newton To Stevens StationDocument14 pagesTunnelling in Bukit Timah Granite Formation - Challenges in Tunnelling From Newton To Stevens StationfreezefreezePas encore d'évaluation

- Bitexco Article To UseDocument9 pagesBitexco Article To Useyamibarisonzi100% (1)

- Column Design - As Per BS8110Document16 pagesColumn Design - As Per BS8110Parthiban ArivazhaganPas encore d'évaluation

- Emaco S40 ZR - PDS - ASEAN - 300409 PDFDocument2 pagesEmaco S40 ZR - PDS - ASEAN - 300409 PDFEkoAndriAntoPas encore d'évaluation

- SR Coat CT - TDS-1Document2 pagesSR Coat CT - TDS-1dinescPas encore d'évaluation

- Carboguard 703Document2 pagesCarboguard 703Achraf BoudayaPas encore d'évaluation

- Ac Dur Sba G PDFDocument2 pagesAc Dur Sba G PDFbhagwatpatilPas encore d'évaluation

- Ac-Cure-R (MS)Document2 pagesAc-Cure-R (MS)bhagwatpatilPas encore d'évaluation

- Ac-Dur-Ie - LV PDFDocument2 pagesAc-Dur-Ie - LV PDFbhagwatpatilPas encore d'évaluation

- PENETRON PLUS Data Sheet PDFDocument2 pagesPENETRON PLUS Data Sheet PDFbhagwatpatilPas encore d'évaluation

- Ac Epoxy Joint GroutDocument2 pagesAc Epoxy Joint GroutbhagwatpatilPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationbhagwatpatilPas encore d'évaluation

- Kuwait SNF Results - 1Document1 pageKuwait SNF Results - 1bhagwatpatilPas encore d'évaluation

- Testing of Form OilDocument1 pageTesting of Form OilbhagwatpatilPas encore d'évaluation

- EOS-Titanium Ti64 Grade23 enDocument14 pagesEOS-Titanium Ti64 Grade23 ennicoleta.popa2093Pas encore d'évaluation

- 1) Fitting HammersDocument2 pages1) Fitting HammersKrako TramPas encore d'évaluation

- Equivalent Standards Tables: Automotive WorldwideDocument8 pagesEquivalent Standards Tables: Automotive WorldwideRafael MontanhinePas encore d'évaluation

- LADWER API 510 - API 571 April 2017Document12 pagesLADWER API 510 - API 571 April 2017Luthfi ArdiansyahPas encore d'évaluation

- High Silica Bauxite Review Atf-06-04Document42 pagesHigh Silica Bauxite Review Atf-06-04Matt SalinovichPas encore d'évaluation

- 0001y01091 en PDFDocument1 page0001y01091 en PDFvivekpattniPas encore d'évaluation

- L32A - RESISTANCE WeldingDocument37 pagesL32A - RESISTANCE WeldingArshpreet SinghPas encore d'évaluation

- Unilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Document6 pagesUnilet Conduit Outlet Bodies: FM7, FM8, Form 35 and Form 85Ciro LeonPas encore d'évaluation

- A 320 Â " A 320M Â " 01 - QTMYMC0WMQDocument7 pagesA 320 Â " A 320M Â " 01 - QTMYMC0WMQhPas encore d'évaluation

- EN19 - 709M40 Black (As Rolled, Forged or Heat Treated) (ALLOY STEEL) (Direct Hardening or Nitriding)Document1 pageEN19 - 709M40 Black (As Rolled, Forged or Heat Treated) (ALLOY STEEL) (Direct Hardening or Nitriding)Raja Sekaran SajjaPas encore d'évaluation

- Types of Arc WeldingDocument20 pagesTypes of Arc WeldingEhigiator JosephPas encore d'évaluation

- Table 1A (Cont'd) Section I Section III, Classes 2 and 3 Section VIII, Division 1 and Section XII Maximum Allowable Stress Values ( See Maximum Temperature Limits For Restrictions On Class)Document3 pagesTable 1A (Cont'd) Section I Section III, Classes 2 and 3 Section VIII, Division 1 and Section XII Maximum Allowable Stress Values ( See Maximum Temperature Limits For Restrictions On Class)Latif RadwanPas encore d'évaluation

- Para 302-3-5 Stress LimitsDocument4 pagesPara 302-3-5 Stress LimitsalvinchuanPas encore d'évaluation

- Copper CorrosionDocument2 pagesCopper CorrosionDonatas BertasiusPas encore d'évaluation

- Severe Plastic Deformation SPD Process For MetalsDocument21 pagesSevere Plastic Deformation SPD Process For MetalsMarian SuciuPas encore d'évaluation

- Hindalco SpecificationDocument15 pagesHindalco SpecificationRavi JainPas encore d'évaluation

- jt8d Engine PDFDocument2 pagesjt8d Engine PDFGreciaPas encore d'évaluation

- Super Invar: Ational Lectronic LloysDocument1 pageSuper Invar: Ational Lectronic LloysMuhlisaApriliaPas encore d'évaluation

- Review, Evolution, and Optimization of The Treatment of Kansanshi Mixed Copper OreDocument7 pagesReview, Evolution, and Optimization of The Treatment of Kansanshi Mixed Copper OreOnesime MutebaPas encore d'évaluation

- Linear Coefficients of ExpansionDocument12 pagesLinear Coefficients of ExpansionVBT1Pas encore d'évaluation

- Steel Grades en 10028 AstmDocument24 pagesSteel Grades en 10028 AstmYahya AljarokPas encore d'évaluation