Académique Documents

Professionnel Documents

Culture Documents

Sop 1 Calibration Certificate Preparation 20180213

Transféré par

SKPACACopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sop 1 Calibration Certificate Preparation 20180213

Transféré par

SKPACADroits d'auteur :

Formats disponibles

SOP 1

Recommended Standard Operating Procedure

for

Calibration Certificate Preparation

1. Introduction

This publication is available free of charge from: https://doi.org/10.6028/NIST.IR.6969-2018

Calibration certificates are the visible outputs of the calibration laboratory that must be

prepared with utmost care to ensure that they accurately convey all information pertaining

to a calibration so that data may be used with maximum benefit by all concerned. Carefully

prepared calibration certificates must contain or refer to all information necessary to

justify the measurement results and must be thoroughly reviewed and authorized prior to

release.

A detailed reporting of results is preferred and often required by customers in accredited

and recognized laboratory systems, which includes a complete narrative describing and

documenting the calibration, including those for special calibrations or tests. According

to the ISO/IEC 17025 standard, calibration results may be reported in a simplified way

when agreed to by the customer. For weights and measures (legal metrology applications)

reporting of elements of metrological traceability for reference to the International System

of Units (SI), measurement results, and uncertainty results continue to be required with

few exceptions1. All information not provided to the customer must be maintained by the

laboratory and readily available.

The laboratory is responsible for all information provided within the calibration certificate,

except for information that was provided by the customer. When information is provided

by the customer, it shall be clearly identified. The calibration certificate will include a

disclaimer notifying users that information supplied by the customer can affect the validity

of results. When sampling is provided by the customer (e.g., the method sampling stage),

the calibration certificate shall state that the results apply to the sample as received from

the customer.

2. Content of calibration certificates.

Regardless of the final form, the calibration certificate must contain the basic information

described in this procedure (see also Section 7.8 of ISO/IEC 170252 and the attached template

Calibration Certificate Review Checklist, Appendix B).

1

See GMP 13, Ensuring Traceability, ISO/IEC 17025, Annex A, and International Laboratory Accreditation

Cooperation (ILAC) and accreditation body policies.

2

ISO/IEC 17025:2017, General Requirements for the Competence of Testing and Calibration Laboratories.

SOP 1 – 2018 Page 1 of 9

Each calibration certificate, supplied in hard copy or electronic format, shall contain the

following information to minimize the possibility of misunderstanding or misuse:

Title (e.g., “Calibration Certificate”).

Name and address of the laboratory where the calibration is performed (e.g., permanent

facility), including any alternative location where a calibration is performed (e.g.,

temporary, mobile, or alternative facility).

This publication is available free of charge from: https://doi.org/10.6028/NIST.IR.6969-2018

Unique identification that all calibration certificate components are recognized, and an

identification on each page to ensure that the page is recognized as part of the complete

document, and a clear identification of the end of the certificate. A unique calibration

number and page X of Y formatting are frequently used to uniquely identify the

components of a calibration certificate.

Customer name and contact information.

Method used –Cite the Standard Operating Procedure (SOP), including the full title or

description and the version date. In the absence of a nationally or internationally published

SOP, a brief but informative description of the methodology shall be included. When a

customer approves of an addition, deviation, or exclusion from the published method,

these departures shall also be included

Unambiguous identification and description of the calibration artifact, and when

necessary, the condition of the item. Serial numbers are assigned to items by the customer,

laboratory, or manufacturer to facilitate the internal control of the item during the

calibration process and subsequent use by the customer. Unique identification is verified

when an item is submitted to the laboratory for calibration.

Date(s) of:

Calibration item receipt;

Sampling, where critical to the validity and application of the results;

Calibration or laboratory activity performance; and

Certificate issuance.

Cite the sampling plan and methods used. Uniquely identify the items sampled. Include

the:

The date and location of sampling;

Environmental conditions during sampling that affect the interpretation of results;

and

Information related to the measurement uncertainty, where relevant.

Calibration results and corresponding units of measurement are clearly organized in a

tabular or other convenient format. When a calibration item has been repaired or adjusted,

the calibration results before and after repair or adjustment shall be reported. The

SOP 1 – 2018 Page 2 of 9

measurement units reported are typically related to the nominal value of the calibration

item. Measurement units may be selected to reflect an industry practice or a customer

request.

A statement of the measurement uncertainty, and corresponding measurement unit,

coverage factor, and estimated confidence interval shall accompany the measurement

result. The measurement uncertainty is reported in the same measurement units as the

measurement result (e.g., multiple or submultiple). Special care shall be used when the

coverage factor is not consistent for all calibrated items. The results table should be

This publication is available free of charge from: https://doi.org/10.6028/NIST.IR.6969-2018

formatted to clearly identify individual coverage factors when variations exist (e.g., an

additional column containing the corresponding coverage factors). When appropriate,

significant uncertainty components and the rationale for their inclusion are included.

Note: the use of standard industry practices or reporting units based on customer

requests is permitted.

Environmental or other conditions under which the calibrations were made that

influence the measurement results.

Clearly identify the person(s) performing the calibration and authorizing calibration

certificate by stating their corresponding name, title, and signature. Each authorized

signatory accepts responsibility for the technical accuracy and validity of the reported

results.

A statement to the effect that the results relate only to the items calibrated or sampled.

A statement identifying how the measurements are metrologically traceable (e.g., the

laboratory establishes metrological traceability to the International System of Units (SI)

and is recognized by NIST OWM). The inclusion of supplemental supporting

information may be requested by the customer.

When statement of compliance or non-compliance with requirements and/or

specifications (e.g., a conformity assessment), where relevant. Compliance refers to an

assessment of all criteria of a referenced documentary standard and not a limited

assessment of a portion or specific clauses (e.g., compliance to all specifications versus

only the tolerance specification). When a statement of conformity is made, the

laboratory must clearly identify to which results the statement of conformity applies

(e.g., all results or a specific portion of the results), which specifications, standards or

parts thereof are met or not met, and the decision rule applied (unless the decision rule

is inherent in the specification or documentary standard). When a statement of

conformity to a specification or documentary standard is made, the laboratory shall

document the decision rule applied, take into account the level of risk associated with

the decision rule employed (such as false accept, false reject, and statistical

assumptions), and apply the decision rule. Where decision rules regarding uncertainties

and tolerances are not part of the documentary standard, decision rules will be agreed to

by the customer and reported on the calibration certificate.

SOP 1 – 2018 Page 3 of 9

Opinions and interpretations, where appropriate and needed, shall be based on the

measurement results, clearly stated, and identified as such. Only technically competent

laboratory personnel are permitted to express opinions and interpretations (e.g., an

authorized signatory). When opinions and interpretations are directly communicated and

discussed with the customer, a record of the conversation shall be documented and

retained.

Results from external providers shall be clearly identified.

This publication is available free of charge from: https://doi.org/10.6028/NIST.IR.6969-2018

Additional information which may be required by specifications, specific methods,

customers, or groups of customers.

To ensure parts of the calibration certificate results are not taken out of context, a

statement specifying that the calibration certificate shall not be reproduced except in

full, without written approval of the laboratory may be included.

A calibration certificate or calibration label shall not include any recommended

calibration interval, except when required for legal applications or where requested and

agreed to by the customer.

3. Review and Issue to Customer.

A thorough technical and quality review of each calibration certificate should be

conducted according to laboratory Quality Management System before issuance to prevent

errors, recall, and certificate amendment.

Review measurement units and symbols according to the current edition of NIST Special

Publication (SP 811), The NIST Guide for the Use of the International System of Units

(https://www.nist.gov/physical-measurement-laboratory/special-publication-811).

The template Calibration Certificate Review Checklist may be used by the laboratory to

aid in multiple evaluation functions (Appendix B).

3.3.1 Review each calibration certificates before issue to the customer to ensure it meets

the requirements of this procedure.

3.3.2 Review external calibration certificates during the supplier evaluation process.

3.3.3 Review issued and/or template calibration certificates during a technical or quality

audit.

4. Calibration Certificate Amendment.

When a calibration certificate issued to a customer must be changed, amended, or re-

issued, the changed information shall be clearly identified. The reason for the change shall

be included in the report, when appropriate.

Amendments made after issue to the customer shall be made only in the form of a further

SOP 1 – 2018 Page 4 of 9

document or data transfer, which includes the statement “Amendment to Calibration

Certificate” or an equivalent form of wording.

When it is necessary to issue a completely new calibration certificate, it shall be uniquely

identified and contain a reference to the original calibration certificate that it replaces.

Amended calibration certificates shall meet all the requirements of this procedure.

This publication is available free of charge from: https://doi.org/10.6028/NIST.IR.6969-2018

5. Records

The laboratory shall file, organize, and retain all calibration certificates in a systematic

manner for ease of retrieval.

Retain legible copies of all issued and amended calibration certificates according to the

laboratory Quality Management System.

SOP 1 – 2018 Page 5 of 9

Calibration No.: TI-01-056

Appendix A – Example Certificate Page 1 of 2

COMPLIANT CALIBRATION LABORATORY

123 Some Ave.

City, State Mail code

XYZ Accreditation Body: 1234567890

This publication is available free of charge from: https://doi.org/10.6028/NIST.IR.6969-2018

CALIBRATION CERTIFICATE

FOR

1 kg to 10 mg kit

(Twenty-one weights)

Manufacturer: DENTROM LAKE SUBMITTED BY:

YOUR CUSTOMER, INC.

Serial No.: 27269

Customer’s Address

City, State Zip code

Phone/Email

Conventional Mass3 Expanded

Nominal Conventional Mass

Correction Uncertainty

(g) (g)

(mg) (mg)

1000 1000.000 82 0.82 0.92

500 500.000 71 0.71 0.53

300 299.999 87 - 0.13 0.27

200 200.000 67 0.67 0.18

100 100.000 411 0.411 0.091

50 50.000 318 0.318 0.051

30 30.000 117 0.117 0.028

20 19.999 987 - 0.013 0.023

10 10.000 011 0.011 0.018

5 5.000 022 0.022 0.015

3 3.000 112 0.112 0.013

2 1.999 965 - 0.035 0.012

1 1.000 117 0.117 0.010

0.500 0.500 013 2 0.013 2 0.005 1

0.300 0.300 022 3 0.022 3 0.004 8

0.200 0.200 001 7 0.001 7 0.004 3

0.100 0.100 001 3 0.001 3 0.004 2

0.050 0.050 001 8 0.001 8 0.004 0

0.030 0.030 001 1 0.001 1 0.003 7

0.020 0.020 000 9 0.000 9 0.003 3

0.010 0.009 999 7 - 0.000 3 0.003 1

The data in the above table applies only to those items specifically listed on this calibration certificate.

3

Conventional Mass: The conventional value of the result of weighing a body in air is equal to the mass of a standard, at

reference density 8.0 g/cm³, at a reference temperature 20 °C, which balances this body at this reference temperature in normal

air density 0.0012 g/cm3. See OIML D28 (2004), “Conventional value of the result of weighing in air.”

SOP 1 – 2018 Page 6 of 9

Calibration No.: TI-01-056

Uncertainty Statement:

Page 2 of 2

The combined standard uncertainty includes the standard uncertainty reported for the standard, the standard uncertainty for the measurement

process, the standard uncertainty for any uncorrected errors associated with buoyancy corrections, and a component of uncertainty to account for

any observed deviations from NIST values that are less than surveillance limits. The combined standard uncertainty is multiplied by a coverage

factor (k) of 2 to provide an expanded uncertainty, which defines a level of confidence of approximately 95 percent. The expanded uncertainty

presented in this report is consistent with the ISO/IEC Guide to the Expression of Uncertainty in Measurement (2008). The expanded uncertainty

is not to be confused with a tolerance limit for the user during application.

Traceability Statement:

The Standards of the Compliant Calibration Laboratory are traceable to the International System of Units (SI) through the National Institute of

This publication is available free of charge from: https://doi.org/10.6028/NIST.IR.6969-2018

Standards and Technology, and are part of a comprehensive measurement assurance program for ensuring continued accuracy and measurement

traceability within the level of uncertainty reported by this laboratory. The unique laboratory calibration number identified above shall be used in

referencing metrological traceability for artifacts identified only in this certificate.

Supplemental Information:

Description of Artifacts Submitted for Calibration:

Twenty one weights from 1 kg to 10 mg, marked ASTM E617 (2013), Standard Specification for Laboratory Weights and Precision Mass Standards,

Class 4. Weights from 1 kg to 1 g: two-piece weights, with assumed density of 8.0 g/cm3. Weights from 500 mg to 50 mg: sheet weights, with

assumed density of 16.6 g/cm3. Weights from 30 mg to 10 mg: sheet weights, with assumed density of 2.7 g/cm3.

Conditions of Artifacts Submitted for Calibration:

Artifacts showed evidence of improper handling. Fingerprints and dents were visible on the surface of the weights.

Treatment of Artifacts Prior to Calibration:

Artifacts were cleaned with cheesecloth and ethyl alcohol. Thermal equilibrium time/conditions: seven days next to balances in mass laboratory.

Procedure Used:

Double Substitution (NISTIR 6969, SOP 4, 2018)

Environmental Conditions at Time of Calibration:

Temperature: 20.1 C to 20.2 C Barometric Pressure: 752.7 mmHg Relative Humidity: 43.35 % to 43.40 %

Date Artifacts Received: January 5, 2018 Date Certificate Issued: January 13, 2018

Date of Calibration: January 12, 2018

Due Date (Requested by Customer): January 15, 2018

Josh Balani II

Calibration Performed by: Josh Balani II, Metrologist

This document does not represent or imply endorsement by the Accreditation Body of Compliant Calibration Laboratory or any agency of a state

and/or national government. This document may not be reproduced, except in full, without the written permission of the Compliant Calibration

Laboratory.

SOP 1 – 2018 Page 7 of 9

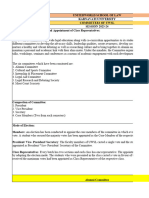

Appendix B - Calibration Certificate Review Checklist

ISO/IEC 17025:2017, Section 7.8 - Reporting of Results

This evaluation form may be used as an assessment tool for calibration certificates. Its use needs to include

objective evidence of the assessment (e.g., a marked-up certificate).

Criteria Guide Compliance

Reported accurately, clearly, unambiguously and objectively; in accordance with method instructions;

7.8.1.2 include all info requested by customer, necessary for interpretation of the results, & required by the

method

This publication is available free of charge from: https://doi.org/10.6028/NIST.IR.6969-2018

Calibration Certificate Core Requirements (Include at least the following information, unless valid reasons for

not)

7.8.2.1 a) Title

7.8.2.1 b,

Laboratory name & address and location where tests/calibrations performed

c)

Unique identification that allows the user recognize all the portions of the certificate. Clearly identify

7.8.2.1 d) document end (a way to recognize a complete report) For Example: page number and total number of

pages

7.8.2.1 e) Customer name and contact information

7.8.2.1 f,

Identify method used; additions, deviations, exclusions from the method

n)

7.8.2.1 g) Description and unambiguous identification of the item(s) calibrated and when necessary condition

7.8.2.1 h-

Dates: receipt, sampling if applicable, date(s) of performance of lab activity, certificate issue

j)

7.8.2.1 k) Reference to sampling plan and procedures used where relevant to validity or application of results

Statement to the effect that the results relate only to the calibrated items

7.8.2.1 l)

Note: Recommend statement shall not be reproduced except in full, without written lab approval

7.8.2.1

Calibration results with appropriate units of measurement, where appropriate

m)

7.8.2.1 o) Name(s), function(s) & signature(s) or equivalent ID of person(s) authorizing the certificate

Calibration Certificates (In addition to 7.8.2.1)

Uncertainty of the measurement result in the same unit as that of the measured item, or unit relative to

7.8.4.1 a)

item

7.8.4.1 b) Calibration conditions (e.g., environmental) that influence the measurement results

7.8.4.1 c) Statement on how the measurements are metrologically traceable

7.8.4.1 d) Before and after measurement results when adjustment or repair is made

7.8.4.1 e), If compliance statement is made: Identify to which results they apply, clauses met/not met, and account

7.8.6 for the decision rule (e.g., uncertainty)

7.8.4.3 No calibration interval on certificate/label except if customer agrees (superseded by legal regulations)

Sampling (7.8.5) Specific requirements noted in 7.8.3.2, 7.8.4.2

Sampling date, unique identify, material or product, location, diagrams, sketches, photographs;

7.8.5 a-f)

reference plan & procedures; environmental conditions; information for uncertainty evaluation

Opinions and Interpretations

7.8.4.1. f) Document basis of opinions and interpretations when included with reference to basis, performed by

7.8.7 authorized personnel only; clearly identify

Amendments

Amendments after issue made as further document/data transfer with statement, meet all requirements.

7.8.8

New certificate is uniquely identified, and reference to the original that it replaces

SOP 1 – 2018 Page 8 of 9

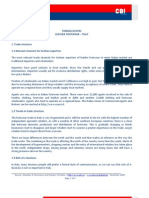

Appendix C - Calibration Certificate Review Checklist

ISO/IEC 17025:2017, Section 7.8 - Reporting of Results

This evaluation form may be used as an assessment tool for evaluating multiple calibration certificates; for example,

during an internal audit or during review of proficiency testing certificates. Its use needs to include objective

evidence of the assessment (marked-up certificates).

X = Nonconformity C = Comment

Lab Names or

Parameters:

7.8.1.2

This publication is available free of charge from: https://doi.org/10.6028/NIST.IR.6969-2018

Calibration Certificate Core Requirements (Include at least the following information, unless valid reasons for not)

7.8.2.1 a)

7.8.2.1 b, c)

7.8.2.1 d)

7.8.2.1 e)

7.8.2.1 f, n)

7.8.2.1 g)

7.8.2.1 h-j)

7.8.2.1 k)

7.8.2.1 l)

7.8.2.1 m)

7.8.2.1 o)

Calibration Certificates (In addition to 7.8.2.1)

7.8.4.1 a)

7.8.4.1 b)

7.8.4.1 c)

7.8.4.1 d)

7.8.4.1 e), 7.8.6

7.8.4.3

Sampling (7.8.5) Specific requirements noted in 7.8.3.2, 7.8.4.2

7.8.5 a-f)

Opinions and Interpretations

7.8.4.1. f), 7.8.7

Amendments to Test Reports and Calibration Certificates

7.8.8

* Participants that apply tolerances

SOP 1 – 2018 Page 9 of 9

Vous aimerez peut-être aussi

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1D'EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Évaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Environmental ConditionDocument7 pagesEnvironmental ConditionTammam AbourshaidPas encore d'évaluation

- ISO 17025 Accreditation RequirementsDocument41 pagesISO 17025 Accreditation Requirementssiddhi jadhavPas encore d'évaluation

- G133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Document9 pagesG133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Alberto Garcia100% (1)

- Procedure For RiskDocument2 pagesProcedure For RiskMayur KhalatkarPas encore d'évaluation

- Conformity Assessment of Temperature Measuring Devices Used in Forensic Science Laboratories Under Iso/iec 17025: 2017Document9 pagesConformity Assessment of Temperature Measuring Devices Used in Forensic Science Laboratories Under Iso/iec 17025: 2017IJAR JOURNALPas encore d'évaluation

- Form Q-15 Icc-Es Nonaccredited Laboratory Assessment ChecklistDocument5 pagesForm Q-15 Icc-Es Nonaccredited Laboratory Assessment ChecklistShaun HolderPas encore d'évaluation

- SASSCO Intermediate Check InstructionDocument4 pagesSASSCO Intermediate Check InstructionStudent ForeignPas encore d'évaluation

- 4.4 Review of Requests, Tenders and ContractsDocument1 page4.4 Review of Requests, Tenders and ContractsGajaNand MallickPas encore d'évaluation

- Kosaka Lab Scope CC 2611Document50 pagesKosaka Lab Scope CC 2611kumarPas encore d'évaluation

- 07 - Risk Based Approach 17025Document10 pages07 - Risk Based Approach 17025सागर फुकटPas encore d'évaluation

- DLAB Scientific Brochure 2016Document97 pagesDLAB Scientific Brochure 2016ThanhSơnHồPas encore d'évaluation

- Water Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - LiDocument46 pagesWater Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - Lilouis bothe100% (1)

- Quality Manual LTM-en PDFDocument80 pagesQuality Manual LTM-en PDFLokesh GandikotaPas encore d'évaluation

- Sop For Operation and Calibration of Analytical BalanceDocument2 pagesSop For Operation and Calibration of Analytical BalanceDolly BijaniPas encore d'évaluation

- Iso 17025 PDFDocument6 pagesIso 17025 PDFJhon Fredy RinconPas encore d'évaluation

- Technical Requirement For ISO 17025-2005-SanasDocument11 pagesTechnical Requirement For ISO 17025-2005-Sanasyouni_2005Pas encore d'évaluation

- Calibration Certificate Basic 315Document1 pageCalibration Certificate Basic 315Anonymous xnpIPaMoPas encore d'évaluation

- General Accreditation Criteria: Metrological Traceability PolicyDocument24 pagesGeneral Accreditation Criteria: Metrological Traceability Policyarli krisnandikaPas encore d'évaluation

- Iso 17025 - Corrective Action Request Form (Completed)Document1 pageIso 17025 - Corrective Action Request Form (Completed)JessePas encore d'évaluation

- NIST Stopwatch & Timer Calibrations 2009Document82 pagesNIST Stopwatch & Timer Calibrations 2009ririmonir100% (1)

- SOP Housekeeping&CleaningDocument3 pagesSOP Housekeeping&Cleaningmalik234everPas encore d'évaluation

- XYZ Laboratory: Iso/Iec 17025 Quality ManualDocument13 pagesXYZ Laboratory: Iso/Iec 17025 Quality ManualvictorPas encore d'évaluation

- Internal Quality Audit at Isuzu PlantDocument8 pagesInternal Quality Audit at Isuzu Plantgharba putraPas encore d'évaluation

- 1.SOP For Calibratioon of Pressure GaugesDocument3 pages1.SOP For Calibratioon of Pressure Gaugesget_engineer05100% (1)

- TOTL-SP02 Factilities and Environmental Conditions ProcedureDocument9 pagesTOTL-SP02 Factilities and Environmental Conditions ProcedureahmedPas encore d'évaluation

- NIST Procedure For Method Validation 20180101Document7 pagesNIST Procedure For Method Validation 20180101Tonio DimaculanganPas encore d'évaluation

- Nabl Doc ListDocument2 pagesNabl Doc ListhrtinubittuPas encore d'évaluation

- Whitepaper: When Recognition MattersDocument10 pagesWhitepaper: When Recognition MattersLuân Nguyễn QuỳnhPas encore d'évaluation

- Quality ManualDocument31 pagesQuality ManualKodhansPas encore d'évaluation

- TR 47-03 TR 47-03 - South African National Accreditation SystemDocument11 pagesTR 47-03 TR 47-03 - South African National Accreditation Systemviethuong96Pas encore d'évaluation

- New ISO 17025 and Decision RuleDocument4 pagesNew ISO 17025 and Decision RulesujudPas encore d'évaluation

- Requirement of Lab AccreditationDocument4 pagesRequirement of Lab AccreditationGajaNand MallickPas encore d'évaluation

- F ISO 17025Document51 pagesF ISO 17025Shishir MaharjanPas encore d'évaluation

- EPA Thermometer Calibration ProceduresDocument7 pagesEPA Thermometer Calibration ProceduresGilberto Andrés Jurado100% (1)

- Digital Display Voltmeter (Ammeter) Anual Operational Instruction MDocument4 pagesDigital Display Voltmeter (Ammeter) Anual Operational Instruction MCaterine CrespoPas encore d'évaluation

- QSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207Document34 pagesQSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207SureshPas encore d'évaluation

- Nabl 103Document55 pagesNabl 103hrtinubittu100% (1)

- Ba Tho 5000toce Full Calibration Sop en 58130094bDocument38 pagesBa Tho 5000toce Full Calibration Sop en 58130094bعبدالعزيز بدرPas encore d'évaluation

- Measurement Traceability PDFDocument7 pagesMeasurement Traceability PDFPrashansa ShresthaPas encore d'évaluation

- 3.LA 201-7 MS ISOIEC 17025-2017 Checklist Issue 5, 9 Aug 2019Document15 pages3.LA 201-7 MS ISOIEC 17025-2017 Checklist Issue 5, 9 Aug 2019jeyasekarPas encore d'évaluation

- Sadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionDocument10 pagesSadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionSuresh KumarPas encore d'évaluation

- A2LA Expalnations For ISO 17025 RequirementsDocument27 pagesA2LA Expalnations For ISO 17025 RequirementsgiamilliaPas encore d'évaluation

- Internal Audit ProcedureDocument4 pagesInternal Audit ProcedureAniruddha ChatterjeePas encore d'évaluation

- SOP For Management of Risk & OpportunityDocument4 pagesSOP For Management of Risk & OpportunityShreya Test House50% (2)

- Ifra Conformity Certificate - Passion Fruit 105Document3 pagesIfra Conformity Certificate - Passion Fruit 105David Coello CedeñoPas encore d'évaluation

- Sample Procedure For Method Validation 1.: Document Control: SAP - Approved 20161221 Page 1 of 7Document7 pagesSample Procedure For Method Validation 1.: Document Control: SAP - Approved 20161221 Page 1 of 7YAMA ENGINEERSPas encore d'évaluation

- EUROLAB Cook Book - Doc No 0 Tool For Transition From ISO 17025 2005 To 2017Document23 pagesEUROLAB Cook Book - Doc No 0 Tool For Transition From ISO 17025 2005 To 2017Eby Joy0% (2)

- Handbook of Weighting Applications PDFDocument32 pagesHandbook of Weighting Applications PDFiptPas encore d'évaluation

- Site ChecklistDocument18 pagesSite Checklistagus kurniawanPas encore d'évaluation

- LAB 48 Decision Rules and Statements of ConformityDocument47 pagesLAB 48 Decision Rules and Statements of ConformityNirja ParmarPas encore d'évaluation

- Astm d4448-01 Standard Guide For Sampling Ground Water Monitoring WellsDocument343 pagesAstm d4448-01 Standard Guide For Sampling Ground Water Monitoring WellsEdson MoscosoPas encore d'évaluation

- Chlorine Test: SpectroquantDocument1 pageChlorine Test: Spectroquantanica moldovanPas encore d'évaluation

- Template For Intermediate Check Sheet For Deadweight TesterDocument1 pageTemplate For Intermediate Check Sheet For Deadweight Testervasudeva yasasPas encore d'évaluation

- Sop-1-Calibration-Certificate-Preparation-20190506 Checklist para Laboratorio de CalibraciónDocument10 pagesSop-1-Calibration-Certificate-Preparation-20190506 Checklist para Laboratorio de CalibraciónfcoespinosaPas encore d'évaluation

- Sop 1 Recommended Standard Operating Procedure For Calibration Certificate PreparationDocument10 pagesSop 1 Recommended Standard Operating Procedure For Calibration Certificate PreparationEileen OngPas encore d'évaluation

- ISO/IEC 17025 Requirements for Calibration LaboratoriesDocument22 pagesISO/IEC 17025 Requirements for Calibration LaboratoriesAli ZafarPas encore d'évaluation

- D1 CNEY7 ONq SDocument137 pagesD1 CNEY7 ONq SSKPACAPas encore d'évaluation

- Statistics For AnalystDocument11 pagesStatistics For AnalystSKPACAPas encore d'évaluation

- 2018 Annual CalendarDocument1 page2018 Annual CalendarSKPACAPas encore d'évaluation

- Fme Written Communications ChecklistDocument1 pageFme Written Communications ChecklistLATIFPas encore d'évaluation

- Iso 17025Document11 pagesIso 17025SKPACA100% (1)

- White Paper 026 - Leachables - Minimizing The Influence of Plastic Consumables On The Laboratory WorkflowsDocument6 pagesWhite Paper 026 - Leachables - Minimizing The Influence of Plastic Consumables On The Laboratory WorkflowsSKPACAPas encore d'évaluation

- Understanding and Implementing ISOIEC 17025Document64 pagesUnderstanding and Implementing ISOIEC 17025hesham_tm3658Pas encore d'évaluation

- Oecd Principles of GLP AND ISO/IEC 17025: Oecd Position Paper Regarding The Relationship Between TheDocument7 pagesOecd Principles of GLP AND ISO/IEC 17025: Oecd Position Paper Regarding The Relationship Between TheSKPACAPas encore d'évaluation

- Exemple Mind MapDocument1 pageExemple Mind MapSKPACAPas encore d'évaluation

- PCR Detection of Microbial Pathogens Real-Time PCR in Food Science: Current Technology and ApplicationsDocument1 pagePCR Detection of Microbial Pathogens Real-Time PCR in Food Science: Current Technology and ApplicationsSKPACAPas encore d'évaluation

- Titres Books Biologie MoléculaireDocument8 pagesTitres Books Biologie MoléculaireSKPACAPas encore d'évaluation

- EFSA European Food Safety AuthorityDocument5 pagesEFSA European Food Safety AuthoritySKPACAPas encore d'évaluation

- Document summary for legal assistant job postingDocument1 pageDocument summary for legal assistant job postingSKPACAPas encore d'évaluation

- Squared Up13Document1 pageSquared Up13SKPACAPas encore d'évaluation

- QIAGEN LongRange PCR HandbookDocument44 pagesQIAGEN LongRange PCR HandbookSKPACAPas encore d'évaluation

- Jene Sys 2016 ApplicationformDocument4 pagesJene Sys 2016 ApplicationformReva WiratamaPas encore d'évaluation

- Paul of Aegina LaminectomyDocument9 pagesPaul of Aegina LaminectomypepepartaolaPas encore d'évaluation

- The Contemporary Contrabass. by Bertram TuretzkyDocument5 pagesThe Contemporary Contrabass. by Bertram TuretzkydoublepazzPas encore d'évaluation

- Committees of UWSLDocument10 pagesCommittees of UWSLVanshika ChoudharyPas encore d'évaluation

- Why the Seventh Day, Not the First, Should Be Observed as the SabbathDocument8 pagesWhy the Seventh Day, Not the First, Should Be Observed as the SabbathMarcos Silva100% (1)

- Getting More Effective: Branch Managers As ExecutivesDocument38 pagesGetting More Effective: Branch Managers As ExecutivesLubna SiddiqiPas encore d'évaluation

- Activity-Sheet-Module 1 Relation and FunctionDocument7 pagesActivity-Sheet-Module 1 Relation and FunctionNeah Neoh NeohnPas encore d'évaluation

- Assignment of English Spesialization Biography of B. J. HabibieDocument3 pagesAssignment of English Spesialization Biography of B. J. HabibieFikri FauzanPas encore d'évaluation

- An Adaptive Memoryless Tag Anti-Collision Protocol For RFID NetworksDocument3 pagesAn Adaptive Memoryless Tag Anti-Collision Protocol For RFID Networkskinano123Pas encore d'évaluation

- Eichhornia Crassipes or Water HyacinthDocument5 pagesEichhornia Crassipes or Water HyacinthJamilah AbdulmaguidPas encore d'évaluation

- RMET Score Sheet AnalysisDocument1 pageRMET Score Sheet AnalysisJohnPas encore d'évaluation

- AVD 370 Installation Manual WEBDocument72 pagesAVD 370 Installation Manual WEBLuis Anselmo CastilloPas encore d'évaluation

- Complex Number Exercise Book PDFDocument26 pagesComplex Number Exercise Book PDFRitik KumarPas encore d'évaluation

- Piaget'S Legacy As Reflected In: The Handbook of Child Psychology (1998 Edition)Document23 pagesPiaget'S Legacy As Reflected In: The Handbook of Child Psychology (1998 Edition)Melati SenjaPas encore d'évaluation

- GE Oil & Gas Emails Discuss Earthing Cable SpecificationsDocument6 pagesGE Oil & Gas Emails Discuss Earthing Cable Specificationsvinsensius rasaPas encore d'évaluation

- Experiment 1 Tensile Testing (Universal Tester) : RD THDocument23 pagesExperiment 1 Tensile Testing (Universal Tester) : RD THShangkaran RadakrishnanPas encore d'évaluation

- Finding Buyers Leather Footwear - Italy2Document5 pagesFinding Buyers Leather Footwear - Italy2Rohit KharePas encore d'évaluation

- HST.582J / 6.555J / 16.456J Biomedical Signal and Image ProcessingDocument23 pagesHST.582J / 6.555J / 16.456J Biomedical Signal and Image ProcessingEduardo AlvarezPas encore d'évaluation

- EHV AC Transmission System Design and AnalysisDocument104 pagesEHV AC Transmission System Design and Analysispraveenmande100% (1)

- Hrm-Group 1 - Naturals Ice Cream FinalDocument23 pagesHrm-Group 1 - Naturals Ice Cream FinalHarsh parasher (PGDM 17-19)Pas encore d'évaluation

- Crema Coffee Garage - Understanding Caffeine Content of Popular Brewing Methods Within The Australian Coffee Consumer MarketDocument33 pagesCrema Coffee Garage - Understanding Caffeine Content of Popular Brewing Methods Within The Australian Coffee Consumer MarketTDLemonNhPas encore d'évaluation

- ACE Personal Trainer Manual Chapter 13Document59 pagesACE Personal Trainer Manual Chapter 13Đạt NguyễnPas encore d'évaluation

- Parameter ranges and attenuation values for RRH configurationsDocument121 pagesParameter ranges and attenuation values for RRH configurationscharantejaPas encore d'évaluation

- Sovtek 5881 Wxt/6L6 WGC Tube GuideDocument8 pagesSovtek 5881 Wxt/6L6 WGC Tube GuideKon GekasPas encore d'évaluation

- Enclosure No. 6.7: Parental ConsentDocument3 pagesEnclosure No. 6.7: Parental ConsentRhea CarinoPas encore d'évaluation

- SeminarDocument30 pagesSeminarRahul prajapatiPas encore d'évaluation

- Form 2 Physics HandbookDocument90 pagesForm 2 Physics Handbookmosomifred29Pas encore d'évaluation

- The Heart of Arabia - A Record of Travel & ExplorationDocument503 pagesThe Heart of Arabia - A Record of Travel & ExplorationAltug100% (1)

- (Ebook - PDF - Cisco Press) DNS, DHCP and IP Address ManagementDocument29 pages(Ebook - PDF - Cisco Press) DNS, DHCP and IP Address ManagementRachele AlbiottiPas encore d'évaluation

- Solid Waste Management Center RevisedDocument44 pagesSolid Waste Management Center RevisedPrimo Ernesto CanoyPas encore d'évaluation