Académique Documents

Professionnel Documents

Culture Documents

Microbial and Physico-Chemical Qualities of Retort Pouch Processed

Transféré par

Journal of Environment and Bio-SciencesTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Microbial and Physico-Chemical Qualities of Retort Pouch Processed

Transféré par

Journal of Environment and Bio-SciencesDroits d'auteur :

Formats disponibles

J. Env. Bio-Sci., 2015: Vol.

29 (2):561-565

(561) ISSN 0973-6913 (Print), ISSN 0976-3384 (On Line)

MICROBIAL AND PHYSICO-CHEMICAL QUALITIES OF RETORT POUCH PROCESSED

CHETTINAD STYLE CHICKEN USING DESI AND BROILER MEAT

P. Nalini*, Robinson J.J. Abraham, V. Appa Rao, R. Narendra Babu and R. Ilavarasan

Department of Meat Science and Technology, Madras Veterinary College, TANUVAS, Chennai-600 007, India

[Correspondence author E-mail*: aishvet@gmail.com]

Received: 29-05-2015 Accepted: 21-06-2015

This study was undertaken to assess the microbial qualities of retort pouch processed chettinad chicken using meat derived

from desi and broiler breeds of chicken (Gallus gallus domesticus) at room temperature. Chettinad chicken was prepared using

desi and broiler meat packed in retort pouches (250 g) and processed in retort at the product temperature of 121.1 °C and the

corresponding F0 value of 5.2. Total viable count was 1.44 ± 0.01 in desi and 1.43 ± 0.01 in broiler on‘0’ day which increased

significantly on 90th day to 1.65 ± 0.01 and 1.66 ± 0.02 log cfu in desi and broiler meat respectively but E.coli, Salmonella spp,

Clostridium spp., Staphylococcus spp., and yeast and mould could not be detected till 90th day of storage. It was concluded that

the retort processed Chettinad chicken prepared from both desi and broiler meat can be safely stored up to 90 days at room

temperature.

Chicken meat contributed 36.68% (2.30 million tons) to the resistance and most importantly, prevents recontamination

total meat production in India1. Poultry meat is gaining wide and production of toxins during storage2. In total, thermal

acceptance by consumers and growing 10-15% annually. This processing persists as the most widely used method of meat

growth is expected more in near future due to popularity, low preservation by extending its shelf life.

price, easy availability, no religious taboos and more desirable Retortable flexible containers are laminate structures that are

characteristics in poultry meat. There is a growing demand in thermally processed like a can and are shelf-stable and also

India for hygienic meat. The consumer’s have also started have the convenience of freezing and boiling in the bag with

accepting frozen and ready-to-eat meat and meat products. the products, less weight, needs less storage space, ease of

This is mainly due to increased income, urbanization and opening and preparation. In conventional canning, meat must

nutritional awareness by the new generation. In India only 1- be cooked approximately twice as long as the retort pouch

2% of total meat is processed into products for trade as processed meat. This reduced heat exposure would results

compared to more than 60% in the developed countries. in improved quality and in economy packaging. Traditional or

Marketing of the processed meat products have some ethnic dishes are important due to their delicacy. These

difficulties because they have to be maintained in cold chain products have an authenticity that is unique to the region of

for quality standards. Due to the high perishable nature of their origin. These recipes are safely guarded and usually

meat, various preservation methods like drying, curing, passed on orally. As there is a great demand for these products

canning, freezing etc have been evolved over the period of in the domestic and international market the present study

time. Although each has method own advantages and was undertaken to standardize a shelf stable ready-to-eat

disadvantages, these preservation methods are aimed at traditional product (Chettinad Chicken) in retort pouches.

preventing undesirable changes in the wholesomeness,

nutritive value and sensory quality of meat by controlling growth

of microorganisms and obviating contamination by adopting MATERIAL AND METHODS

economic methods.

Three experiments were conducted. First experiment was

Thermal processing is a method of meat processing which

conducted to determine the suitable recipe formulation using

involves the application of heat that is sufficient to destroy

meat of desi and broiler chicken (Gallus gallus domesticus)

microbes which would spoil the meat and cause diseases to

based on the various references and preliminary trials (pilot

consumers. The hermetic seal maintains an environment inside

study). In the second experiment, suitable retort processing

the container that prevents the growth of microbes with higher

temperature was standardized with both desi and broiler meat

NAAS Rating (2016)-4.20

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

MICROBIAL AND PHYSICO-CHEMICAL QUALITIES OF RETORT POUCH (562)

prepared as in the graph 1 & 2. In the third experiment, shelf- determined by the method described by American Public

life studies (microbiological, physico-chemical composition Health Association4.

and sensory characters) were studied under ambient

temperature (32 ± 2o C) up to 3 months of period. Preparation of sample: Five gram of sample was taken

aseptically and homogenized with 45 ml of 0.1 percent sterile

Source of meat: Deboned meat of desi and broiler chicken peptone water in a stomacher to obtain an initial dilution of

(Gallus gallus domesticus) were bought from the local market 10-1. Serial ten-fold dilutions were made up to 10-6 in pre-

in Vepery, Chennai - 07. sterilized tubes containing 9 ml of 0.1 percent peptone water.

The sample preparation and plating were carried out under

Preparation of chettinad chicken : The clean dried spices

laminar air flow.

were fried in dry heat and were ground to a fine powder and

stored at room temperature for subsequent use. Ginger and Physico-chemical characteristics: The pH of the Chettinad

garlic were ground to fine paste and used. Composition of chicken products were measured with the use of digital pH

dried spices and green condiments is given in Table-1. meter. The extract release volumes were determined as

Chettinad chicken gravy was prepared separately by frying described by Pearson, thio-barbituric acid number and

fenugreek and poppy seeds in refined sunflower oil and then tyrosine values were determined as by Strange with slight

chopped onion was added and fried till it reach golden yellow modifications5-6.

colour. The sliced tomato was added and fried in mild heat for

4 minutes and then freshly prepared ginger garlic paste was

added and heated for 2 minutes. Spice mix was added and RESULTS AND DISCUSSION

sauted for 1 minute; finally potable water and common salt

The microbial count and the physic-chemical parameters of

were added and heated for 7 minutes. The whole process

Chettinad chicken products using desi and broiler meat are

was completed within 20 minutes.

presented in Table-2 and 3.

Filling, sealing and retorting of the product in the

MICROBIAL STUDY: Total viable count was 1.44 ± 0.01 in

pouches : Freshly chopped boneless desi meat of 100 gram

desi and 1.43 ± 0.01 in broiler meat which increased

and chettinad chicken gravy of 150 gram was packed into the

significantly on 90th day to 1.65 ± 0.01 and 1.66 ± 0.02 log cfu

retort pouch using stainless steel funnel. Headspace air was

in desi and broiler meat respectively. The results were within

removed from the pouch using a modified steam flush

the limits and standard of total viable count of log7,

technique and then pouch was sealed immediately by using

psychrotrophic count of log4 and coliforms count of log3 in

a single jaw high pressure impulse sealing machine. Adequate

meat products7-8. Anaerobic counts, E.colli, Salmonella spp,

numbers of pouches were fixed with glands and thermocouples

Clostridium spp, Staphylococca spp and yeast and mould

to the core of the desi meat to study the retort controlling

were absent on ‘0’ and 90th day. Microbial load in retort

parameters. The filled and sealed pouches were laid flat on

processed fish paste after one year (E. coil, Staphylococcus.

the trays in the over pressure autoclave/retort and the product

V. cholera and Salmonella) were absent9. Also no anaerobic

was retorted up to standardized temperature as in Fig.-1.

colonies in buffalo and goat meat which were processed in

Same procedure was followed for broiler meat but the product

retort and suggesting that the thermal processing was

was retort at the standardized temperature as in Fig.-2.

efficiently done10-11.

Commercial sterility test (is: 2168-1971): The commercial

PHYSICO-CHEMICAL PARAMETERS

sterility study was done according to the Bureau of Indian

Standards3. pH: The pH of desi and broiler meat on ‘0’ day was 5.40 ±

0.03 and 5.44 ± 0.04 respectively and on 90th day was 5.31 ±

Microbial analysis: Total viable count, anaerobic counts,

0.03 and 5.36 ± 0.03 respectively, which were decreased

E.coli, Salmonella spp, Staphylococcus spp, Clostridium spp

slightly during storage but it was not significant. The results

and yeast and mould counts of processed samples were

of the pH are similar in buffalo meat block, chettinad goat

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

(563) NALINI, ABRAHAM, RAO, BABU AND ILAVARASAN

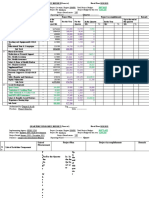

Table-1. Recipe for Chettinad chicken

Figure-1. Standardized Retort processing data of

chettinad chicken-desi meat

Chettinad chicken -Broiler

140 9

T 8 F

120

e 7 0

m 100

6

p 80 5 v

e 4 a

60

r 3 l

a 40 2 u

t 20 1 e

u

0 0

r

1 4 7 10 13 16 19 22 25 28 31 34 37 40 43 46 49 52

e

Time (min)

Retort temperature(0C) Product temperature(0C) F0 value

meat prepared by retort processing and north Indian style

rohu curry stored in cans for 6 months10-12. Decrease in pH Figure-2. Standardized Retort processing data of

might be due to degradation of proteins and liberation of free chettinad chicken-broiler meat

amino acids.

meat to the fill oils or loss to the aqueous exudates from the

THIO-BARBITURIC ACID NUMBER (TBA): Thio-barbituric meat and also heating of fish muscle results in fall in TBA

acid number of desi and broiler meat on ‘0’ day was 0.38 value13-14.

±0.01 and 0.38 ± 0.01, respectively which showed slight

TYROSINE VALUE: Tyrosine value of desi and broiler meat

increase on 15 th day and then started decreasing (not

on ‘0’ day was 6.11 ± 0.03 and 6.11 ± 0.05, respectively which

significantly in desi meat whereas significantly in broiler meat)

increased on storage but not significantly. Tyrosine value of

up to 90 days of storage. TBA number of desi and broiler on

desi and broiler meat on 90th day was 6.89 ± 0.04 and 6.89 ±

90th day was 0.35 ± 0.05 and 0.38 ± 0.01 respectively. TBA

0.03, respectively. Tyrosine value of meat increased with

number initially increased upto 15 days and then started to

storage until deamination of amino acid limited the formation

decrease. Highest value of TBA was noticed on 15th day and

of free amino acid15-16. Similar results were reported in sterile

lowest value was noticed on 90th day. Decrease in TBA number

and inoculated beef samples and also in buffalo meat patties17-18.

in canned fish meat might be due to dilution of secondary

Tyrosine value of 47.7 mg percent in fresh beef and 69.2 mg

oxidation product by filling oils or their extraction from the

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

MICROBIAL AND PHYSICO-CHEMICAL QUALITIES OF RETORT POUCH (564)

Table-2. Microbial Quality Of Chettinad Chicken

N= 6 observations, ND- Not Detected * - significant (P<0.05) difference, ** - highly significant (P<0.01) difference

Table-3. Physico-chemical characteristics with desi and broiler meat–chettinad chicken

n= 6 observations, * - significant (P<0.05) difference, ** - highly significant (P<0.01) difference , NS - No significant (P 0.05)

difference

percent in just spoiled meat, whereas, the tyrosine value in during the entire storage period of 90 days at room temperature.

this study ranged from 6.11 to 6.89.

ACKNOWLEDGEMENT

CONCLUSION

The financial support and facilities provided by the Tamil Nadu

The results obtained in this study were within the standard Veterinary and Animal Sciences University, Chennai, India is

value and it indicating that the products were hygienically duly acknowledged. The authors are thankful to the Dean of

prepared, adequate thermal processing was done and may Madras Veterinary College, Tamil Nadu Veterinary and Animal

also be due to herbals, spices, condiments like cloves, fennel, Sciences University, Chennai-600 051, India for providing

garlic, ginger and turmeric which have antibacterial property. necessary facilities to carry out research work.

Thus it can be concluded that the retort pouch processed

Chettinad chicken meat products using desi and broiler meat

remained microbiologically and physico-chemically safe

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

(565) NALINI, ABRAHAM, RAO, BABU AND ILAVARASAN

REFERENCES Veterinary Research Institute, Deemed University, Bareilly, India.

11. Rajkumar, V., Dushyanthan, K. and Das, A.K. (2010). Journal

1. FAO, (Food and Agricultural Organization) (2012). In: Production of Food Science and Technology, 47: 372.

Year Book. Rome, Itay. 12. Mallick, A.K., Srinivasa Gopal T.K., Ravishankar C.N. and

2. Awuah G.B., Ramaswamy H.S. and Economides A, ( 2007). Vijayan P.K. (2006). Food Science and Technology Internatioal,

Chemical Engineering Process, 47: 584. 12(6):539.

3. IS: 2168- (1971). Indian Standard Institute, Manak Bhavan, 9 13. Aubourg, S., Medina, I., and Perez-Martin, R, (1995). Journal

Bahadur Saha Zafar Marg, New Delhi-1. of Science of Food and Agriculture, 200: 25.

4. APHA (Americ an Public Health As sociation), (1984). 14. Chai, T., Pace, J. and Cossaboom, T. (1984). Journal of Food

Compendium of Methods for the Mcrobioogical Examination of Science, 49: 311.

Foods, 2nd Edn. (Ed) M. L. Speck. American Public Health 15. Dushyanthan, K., Shanmugam, A.M. and Venkataramanujam,V.

Association, W ashington, DC (2001). Indian Journal of Animal Science, 71: 573.

5. Pearson, D, (1968). Journal of Science Food Agriculture, 19: 16. Rajkumar, V., Agnihotri, M.K. and Sharma,N. (2004). Asian

366. Australian Journal of Animal Sciences, 17: 548.

6. Strange, E.D., Benedict,R.C., Smith, J.C. and Swift,C.E. (1977). 17. Morrissey, P.A., Buckley, D.J. and Daly, M.C. (1980). Irish Journal

Journal of Food Protection, 40: 843. of Food Science and Technology, 4: 1.

7. Wehr, H.M., (1978). Food Technology Champaign, 24: 189. 18. Kulkarni, V.V., Kowale,B.N., Kesava Rao, V. and Murthy,T.R.K.

8. Jay, J.M., (1972). Journal of Milk and Food Technology., 35: (1993). Journal of Food Science and Technology, 30: 169.

467.

9. Thankamma. R., Gopal, T.K.S. and Iyer, T.S.G. (1998). Centrel

Institute of Fisheries Technology, Cochin, 246 .

10. Devadason, P., (2004). In: Ph.D Thesis submitted to Indian

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

Vous aimerez peut-être aussi

- ECR Bluebook TraceabilityDocument77 pagesECR Bluebook Traceabilityd023038Pas encore d'évaluation

- The Universe of Food QualityDocument6 pagesThe Universe of Food QualityAlexRiveraPas encore d'évaluation

- 1Document198 pages1RoodyP00Pas encore d'évaluation

- Mango SeedDocument8 pagesMango SeedAisha AkramPas encore d'évaluation

- Water Activity PDFDocument9 pagesWater Activity PDFlalitk02Pas encore d'évaluation

- Naturland Processing StandardsDocument69 pagesNaturland Processing StandardsMarius VrajaPas encore d'évaluation

- ECR-Global Score Card PWCDocument28 pagesECR-Global Score Card PWCliberrimoPas encore d'évaluation

- Gap PDFDocument201 pagesGap PDFREXIL M. LADIGOHONPas encore d'évaluation

- Food Fraud (Guía NSF)Document172 pagesFood Fraud (Guía NSF)Natalia LizamaPas encore d'évaluation

- Consumer Behavioral Patterns in The Food Industry in Sunyani MunicipalityDocument28 pagesConsumer Behavioral Patterns in The Food Industry in Sunyani MunicipalityJEASH JOURNALPas encore d'évaluation

- Global RetailingDocument41 pagesGlobal RetailingPink100% (1)

- 0959-0962 (2022) MICROBIOLOGICAL PROCEDURES FOR ABSENCE OF SPECIFIED MICROORGANISMSةزNUTRITIONAL AND DIETARY SUPPLEMENTSDocument7 pages0959-0962 (2022) MICROBIOLOGICAL PROCEDURES FOR ABSENCE OF SPECIFIED MICROORGANISMSةزNUTRITIONAL AND DIETARY SUPPLEMENTSDr usama El ShafeyPas encore d'évaluation

- Environmental AccountingDocument27 pagesEnvironmental AccountingFaresh Haroon100% (1)

- Unit 2 Marketing Environment and Market SegmentationDocument22 pagesUnit 2 Marketing Environment and Market Segmentationparshwa02 gandhiPas encore d'évaluation

- Ajanta Pharma LTDDocument4 pagesAjanta Pharma LTDhemantPas encore d'évaluation

- San Miguel PurefoodsDocument128 pagesSan Miguel PurefoodsSanta Anna SinagaPas encore d'évaluation

- CHR Hansen Q3 Roadshow Presentation 201819 PDFDocument38 pagesCHR Hansen Q3 Roadshow Presentation 201819 PDFAravind100% (1)

- AllergenDocument7 pagesAllergenchocoboomPas encore d'évaluation

- Household ProductsDocument7 pagesHousehold ProductsRenu KapoorPas encore d'évaluation

- Final - Lucid Timber Liquid Wax Feasib UpdatedDocument518 pagesFinal - Lucid Timber Liquid Wax Feasib UpdatedCristofer MatunogPas encore d'évaluation

- Pet Food Code 20102011 1en PDFDocument63 pagesPet Food Code 20102011 1en PDFDhika LesmanaPas encore d'évaluation

- S&B - Kombucha Market - Global Forecast To 2020Document25 pagesS&B - Kombucha Market - Global Forecast To 2020anomenusPas encore d'évaluation

- WTW Catalog+ Lab - 106 - 137 - Photometry - 1493-kb - US PDFDocument32 pagesWTW Catalog+ Lab - 106 - 137 - Photometry - 1493-kb - US PDFCorina StanculescuPas encore d'évaluation

- Food-Report Statistics PDFDocument162 pagesFood-Report Statistics PDFТатьяна КасимоваPas encore d'évaluation

- 12 Steps To HACCP Defined by The Codex Alimentarius - EnglishDocument1 page12 Steps To HACCP Defined by The Codex Alimentarius - EnglishDiana RestrepoPas encore d'évaluation

- Final Citrosuco in FranceDocument15 pagesFinal Citrosuco in FranceRenzo Mendizábal PiaggioPas encore d'évaluation

- Food Processing IndustryDocument202 pagesFood Processing IndustryAun GoveasPas encore d'évaluation

- Oil-Guide-Food en v01 PDFDocument25 pagesOil-Guide-Food en v01 PDFmeethi_andreaPas encore d'évaluation

- Risk Assessment 2012-11-6 FDA GuidanceDocument95 pagesRisk Assessment 2012-11-6 FDA GuidancedahearnPas encore d'évaluation

- Biscuit Industry Parle GDocument53 pagesBiscuit Industry Parle GspvarmaPas encore d'évaluation

- Group 1 PresentationDocument41 pagesGroup 1 Presentationtinashe tagariraPas encore d'évaluation

- Food Safety and Compliance With High Performance Weighing and Inspection 1240364414Document112 pagesFood Safety and Compliance With High Performance Weighing and Inspection 1240364414Luthfa Umi AzizahPas encore d'évaluation

- Integrating Productivity and Quality Management (PDFDrive)Document658 pagesIntegrating Productivity and Quality Management (PDFDrive)Lê Hoàng MinhPas encore d'évaluation

- Sunett Quality Information PackDocument36 pagesSunett Quality Information PackABI Alco QAPas encore d'évaluation

- Carne Madurada (16202)Document4 pagesCarne Madurada (16202)Fernando FernandezPas encore d'évaluation

- 2017 Restructured Chicken ChunksDocument14 pages2017 Restructured Chicken Chunksdilipgupta66Pas encore d'évaluation

- RP PagadanDocument19 pagesRP PagadanEujay Martirez AnietePas encore d'évaluation

- 17676-Article Text-99039-1-10-20140404Document6 pages17676-Article Text-99039-1-10-20140404ajengPas encore d'évaluation

- IOSR JournalsDocument8 pagesIOSR JournalsInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Muhfathul,+journal+manager,+2 +Muhammad+Husein+ (66-74)Document9 pagesMuhfathul,+journal+manager,+2 +Muhammad+Husein+ (66-74)itaakavitaPas encore d'évaluation

- Survival: of Aerobic Anaerobic Chicken Freeze-DehydrationDocument5 pagesSurvival: of Aerobic Anaerobic Chicken Freeze-DehydrationLyka BartolabacPas encore d'évaluation

- MT 60-01 1 Jelena Janjic - InddDocument7 pagesMT 60-01 1 Jelena Janjic - InddmiskoscribdPas encore d'évaluation

- Masa Simpan Daging AyamDocument8 pagesMasa Simpan Daging AyamRiri JuniartiPas encore d'évaluation

- Meat, Poultry and Egg Processing Submitted To: Miss Saniya Tayyab Submitted By: Laiba KhanDocument11 pagesMeat, Poultry and Egg Processing Submitted To: Miss Saniya Tayyab Submitted By: Laiba KhanAmmar KhanPas encore d'évaluation

- In Packaged Low-Fat Ready-to-Eat Turkey Bologna Subjected To A Surface Pasteurization TreatmentDocument6 pagesIn Packaged Low-Fat Ready-to-Eat Turkey Bologna Subjected To A Surface Pasteurization TreatmentJhonatan CáceresPas encore d'évaluation

- The Effect of Oven Time Using Household OvenDocument12 pagesThe Effect of Oven Time Using Household OvenafikPas encore d'évaluation

- Application of Static Retort Thermal Processing Technology For RendangDocument8 pagesApplication of Static Retort Thermal Processing Technology For RendangOz NingratPas encore d'évaluation

- Determination of Thermal Lethality of Listeria Monocytogenes in Fully Cooked Chicken Breast Fillets and Strips During Postcook In-Package PasteurizationDocument6 pagesDetermination of Thermal Lethality of Listeria Monocytogenes in Fully Cooked Chicken Breast Fillets and Strips During Postcook In-Package PasteurizationsdfsdfsdfdPas encore d'évaluation

- Coating MeatDocument6 pagesCoating MeatHuỳnh Như Đặng ThụyPas encore d'évaluation

- Berbagai Lama Penyimpanan Daging Ayam Broiler Segar Dalam Kemasan Plastik Pada Lemari Es (Suhu 4oc) Dan Pengaruhnya Terhadap Sifat Fisik Dan OrganoleptikDocument10 pagesBerbagai Lama Penyimpanan Daging Ayam Broiler Segar Dalam Kemasan Plastik Pada Lemari Es (Suhu 4oc) Dan Pengaruhnya Terhadap Sifat Fisik Dan OrganoleptikmichabcdePas encore d'évaluation

- A Study On The Shelf Life of The Spent Hen Meat Puffed Product (SHPP) Stored at Ambient TemperatureDocument6 pagesA Study On The Shelf Life of The Spent Hen Meat Puffed Product (SHPP) Stored at Ambient TemperatureDr Sarvadnya GhongdePas encore d'évaluation

- 2004 Journal of Food Protection, 67, 10, 2337-2341 Effects of Preparation Methods On The Microbiological SafetyDocument5 pages2004 Journal of Food Protection, 67, 10, 2337-2341 Effects of Preparation Methods On The Microbiological SafetyDiego CómbitaPas encore d'évaluation

- Bacteriological Assessment of Some Ready-To-Eat Foods: Naglaa, S. Hassan Seham, A. Esmail and Mahmoud, A. HDocument14 pagesBacteriological Assessment of Some Ready-To-Eat Foods: Naglaa, S. Hassan Seham, A. Esmail and Mahmoud, A. HSyed Ali Akbar BokhariPas encore d'évaluation

- Meat Quality and Storage Characteristics of Pork Loin Marinated in Grape PomaceDocument9 pagesMeat Quality and Storage Characteristics of Pork Loin Marinated in Grape PomacemariaPas encore d'évaluation

- New Technology C27-1 Report FY2003 PDFDocument25 pagesNew Technology C27-1 Report FY2003 PDFantonio escuderoPas encore d'évaluation

- Research Article The Effect of Chitosan and Rosemary Essential Oil On The Quality Characteristics of Chicken Burgers During StorageDocument8 pagesResearch Article The Effect of Chitosan and Rosemary Essential Oil On The Quality Characteristics of Chicken Burgers During StorageAryaf alotibiPas encore d'évaluation

- JVMR Volume 26 Issue 2 Pages 151-163Document13 pagesJVMR Volume 26 Issue 2 Pages 151-163sheila antonio mapossePas encore d'évaluation

- Jurnal Sains Dan Teknologi Peternakan: (Chemical Quality of Broiler Chicken Meat at Different Breeding Temperature)Document6 pagesJurnal Sains Dan Teknologi Peternakan: (Chemical Quality of Broiler Chicken Meat at Different Breeding Temperature)Langgeng NUgrahaPas encore d'évaluation

- Physicochemical Properties and Its Relations of Beef Rendang-2018Document10 pagesPhysicochemical Properties and Its Relations of Beef Rendang-2018Oz NingratPas encore d'évaluation

- Exp 4 Heat Sterilization of Canned Chicken in Prepared SauceDocument4 pagesExp 4 Heat Sterilization of Canned Chicken in Prepared SauceNurul Syafiqah0% (1)

- Susceptibility of Differential Leucocyte Counts of The Fresh Water CatfishDocument9 pagesSusceptibility of Differential Leucocyte Counts of The Fresh Water CatfishJournal of Environment and Bio-SciencesPas encore d'évaluation

- Spectral and Biological Profile of ComplexesDocument12 pagesSpectral and Biological Profile of ComplexesJournal of Environment and Bio-SciencesPas encore d'évaluation

- Studies On Ichthyofaunal Diversity of Kali Sindh River Near Jetpura Village Jhalawar Rajasthan BAnyalDocument4 pagesStudies On Ichthyofaunal Diversity of Kali Sindh River Near Jetpura Village Jhalawar Rajasthan BAnyalJournal of Environment and Bio-SciencesPas encore d'évaluation

- Heavy Metal and Physicochemical Characteristics of River GangaDocument8 pagesHeavy Metal and Physicochemical Characteristics of River GangaJournal of Environment and Bio-Sciences100% (1)

- Removal of Phosphate From Aqueous Solutions Using Egg Shell Podwer As An Adsorbent Neetu RaniDocument6 pagesRemoval of Phosphate From Aqueous Solutions Using Egg Shell Podwer As An Adsorbent Neetu RaniJournal of Environment and Bio-SciencesPas encore d'évaluation

- Diversity Abundance and Composition of Non Human PrimatesDocument6 pagesDiversity Abundance and Composition of Non Human PrimatesJournal of Environment and Bio-SciencesPas encore d'évaluation

- Effect of Karanj Oil On The Population Dynamics of Rhizopertha DominicaDocument3 pagesEffect of Karanj Oil On The Population Dynamics of Rhizopertha DominicaJournal of Environment and Bio-SciencesPas encore d'évaluation

- Assessment of Seasonal and Altitudinal Variation in Population Density and Biomass of BeetlesDocument12 pagesAssessment of Seasonal and Altitudinal Variation in Population Density and Biomass of BeetlesJournal of Environment and Bio-SciencesPas encore d'évaluation

- Development of Symbiotic Cottage Cheese Using Lactobacillus Acidophilus La 5 and Pectin.Document4 pagesDevelopment of Symbiotic Cottage Cheese Using Lactobacillus Acidophilus La 5 and Pectin.Journal of Environment and Bio-SciencesPas encore d'évaluation

- Diversity and Abundance of Coleoptera in An Oak Forest of Kumaun Himalaya.Document8 pagesDiversity and Abundance of Coleoptera in An Oak Forest of Kumaun Himalaya.Journal of Environment and Bio-SciencesPas encore d'évaluation

- Impact of Farakka Barrage On The Fishery of River PadmaDocument9 pagesImpact of Farakka Barrage On The Fishery of River PadmaJournal of Environment and Bio-SciencesPas encore d'évaluation

- Biochemical Analysis of Kund Water of RajgrihDocument6 pagesBiochemical Analysis of Kund Water of RajgrihJournal of Environment and Bio-SciencesPas encore d'évaluation

- Bio-Efficacy of Emamectin Benzoate 5-wg Against Pigeonpea Pod Borer, Helicoverpa Armigera (Hub.) Under Field Condition in Steppe Climate of HK Region.Document4 pagesBio-Efficacy of Emamectin Benzoate 5-wg Against Pigeonpea Pod Borer, Helicoverpa Armigera (Hub.) Under Field Condition in Steppe Climate of HK Region.Journal of Environment and Bio-SciencesPas encore d'évaluation

- Distribution of Earthworms in Different SoilsDocument5 pagesDistribution of Earthworms in Different SoilsJournal of Environment and Bio-SciencesPas encore d'évaluation

- Distribution Pattern of Birds of Kangra Valley (Himachal Pradesh) .Document12 pagesDistribution Pattern of Birds of Kangra Valley (Himachal Pradesh) .Journal of Environment and Bio-SciencesPas encore d'évaluation

- A Study of Minor Limno-Biotic Components of River Bhagirathi From Garhwal Himalaya.Document6 pagesA Study of Minor Limno-Biotic Components of River Bhagirathi From Garhwal Himalaya.Journal of Environment and Bio-SciencesPas encore d'évaluation

- Test Questions For Oncologic DisordersDocument6 pagesTest Questions For Oncologic Disorderspatzie100% (1)

- Post Traumatic Stress DisorderDocument2 pagesPost Traumatic Stress Disorderapi-188978784100% (1)

- Rar Vol11 Nro3Document21 pagesRar Vol11 Nro3Valentine WijayaPas encore d'évaluation

- 13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaDocument9 pages13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaArick Frendi AndriyanPas encore d'évaluation

- TelfastDocument3 pagesTelfastjbahalkehPas encore d'évaluation

- Mental Status ExaminationDocument34 pagesMental Status Examinationkimbomd100% (2)

- Practical Cookery 14th Edition SAMPLEDocument16 pagesPractical Cookery 14th Edition SAMPLETendaiPas encore d'évaluation

- Tomography: Tomography Is Imaging by Sections or Sectioning Through The Use of AnyDocument6 pagesTomography: Tomography Is Imaging by Sections or Sectioning Through The Use of AnyJames FranklinPas encore d'évaluation

- INTELLECTUAL DISABILITY NotesDocument6 pagesINTELLECTUAL DISABILITY Notesshai gestPas encore d'évaluation

- Quarterly Progress Report FormatDocument7 pagesQuarterly Progress Report FormatDegnesh AssefaPas encore d'évaluation

- Erich FrommDocument2 pagesErich FrommTina NavarroPas encore d'évaluation

- Chapter 54 - Drugs Acting On The Upper Respiratory TractDocument13 pagesChapter 54 - Drugs Acting On The Upper Respiratory TractJonathonPas encore d'évaluation

- Brachiocephalic TrunkDocument3 pagesBrachiocephalic TrunkstephPas encore d'évaluation

- Monitoring AlkesDocument41 pagesMonitoring AlkesEndangMiryaningAstutiPas encore d'évaluation

- US Army Medical Course MD0722-100 - Microbiology For The Veterinary SpecialistDocument114 pagesUS Army Medical Course MD0722-100 - Microbiology For The Veterinary SpecialistGeorges100% (2)

- Soal 2-3ADocument5 pagesSoal 2-3Atrinanda ajiPas encore d'évaluation

- Biomolecules ExtractionDocument6 pagesBiomolecules ExtractionBOR KIPLANGAT ISAACPas encore d'évaluation

- MAIZEDocument27 pagesMAIZEDr Annie SheronPas encore d'évaluation

- Poisoned NeedleDocument147 pagesPoisoned NeedleMark Cooper100% (3)

- Drug AbuseDocument33 pagesDrug AbuseharshulnmimsPas encore d'évaluation

- E3sconf 2F20187307002Document4 pagesE3sconf 2F20187307002Nguyễn Thành VinhPas encore d'évaluation

- BlackCat ManualDocument14 pagesBlackCat ManualNestor Marquez-DiazPas encore d'évaluation

- Durock Cement Board System Guide en SA932Document12 pagesDurock Cement Board System Guide en SA932Ko PhyoPas encore d'évaluation

- Aliant Ommunications: VCL-2709, IEEE C37.94 To E1 ConverterDocument2 pagesAliant Ommunications: VCL-2709, IEEE C37.94 To E1 ConverterConstantin UdreaPas encore d'évaluation

- What Is Emergency ManagementDocument8 pagesWhat Is Emergency ManagementHilina hailuPas encore d'évaluation

- Gintex DSDocument1 pageGintex DSRaihanulKabirPas encore d'évaluation

- Poster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselDocument1 pagePoster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselcxmzswPas encore d'évaluation

- Variable Compression Ratio Engines A Literature Review: December 2018Document15 pagesVariable Compression Ratio Engines A Literature Review: December 2018Er Samkit ShahPas encore d'évaluation

- High School Students' Attributions About Success and Failure in Physics.Document6 pagesHigh School Students' Attributions About Success and Failure in Physics.Zeynep Tuğba KahyaoğluPas encore d'évaluation

- The Benefits of RunningDocument1 pageThe Benefits of Runningefendi odidPas encore d'évaluation