Académique Documents

Professionnel Documents

Culture Documents

Understanding BARC

Transféré par

xerxeshakaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Understanding BARC

Transféré par

xerxeshakaDroits d'auteur :

Formats disponibles

Understanding Brewer Science’s

Bottom Anti-Reflective Coatings

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Overview

• Anti-reflective coating introduction

• Types of anti-reflective coating

• Advantages to anti-reflective coatings

• Advantages to bottom anti-reflective coatings

• Guide to products and compatibility

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Anti-Reflective Coating Introduction

• Anti-reflective coatings (ARC) can do several things

– Absorb light entering the material by light absorbing compounds in material.

– If ARC is the correct thickness can cause destructive interference of reflected light.

Exposure

Energy

ARC

Substrate

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Types of Anti-reflective Coatings

• Organic

– Applied like a photoresist

– Top anti-reflective coating (TARC)

– Applied after the photoresist

– Absorbs light to give little reflection at substrate/resist surface

– Bottom anti-reflective coating (BARC)

– Applied before the photoresist

– Absorbs light and uses destructive interference to give little reflection at the

resist/ARC interface

• Inorganic

– Deposited on substrate in special deposition chamber

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Organic and Inorganic ARC

Property Organic ARC Inorganic ARC

Reflectivity and swing ratio ++ +++

reduction - 1st minimum

Reflectivity and swing ratio +++ 0

reduction - 2nd and higher minima

Etch rate 0 or + +++

Coating conformity 0 ++

Thickness tolerance + 0

Plasma damage +++ --

Refr. index reproducibility +++ 0

Throughput ++ +

Cost of Ownership + 0

Stack issues +++ -

Planarization capability ++ --

Rework capability +++ --

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Advantages of Anti-Reflective Coatings

• Eliminates swing effect and standing waves in

photoresist

• Solves topography related lithography problems

• Provides ultimate critical dimension (CD)

control

• Expands process capabilities.

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Topography Related Lithography Problems

• Light reflecting off underlying substrate reduced or eliminated

– Backscattering

– Reflective notching

– Standing Waves

Exposure Energy Exposure Energy

Reflective Standing Resist

Notching Wave

Resist

ARC®

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Reflective Notching

Reflective Notching

Metal

Light Light line

Metal

Unexposed Line

photoresist Photoresist

Cross

Section

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Reflective Notching

0.4µm on 2500Å steps using 1844Å XHRi

Competitor BARC

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Swing Effects

• Dose to clear swing curve defined as the amount of light required

to completely expose photoresist

• Swing curves reduced with application of BARC

Dose to Clear Swing

100

95

90

No ARC

85

XHRi

80

Dose (mJ)

75

70

65

60

55

50

850 900 950 1000 1050

Resist Thickness (nm)

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

BARC Reflectivity Curve

1.00

0.90

0.80

Aluminum

0.70 GaAs

Poly

0.60 Tungsten

0.50

0.40

0.30

0.20

0.10

0.00

0 50 100 150 200 250 300

ARC®Thickness

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Resist Profiles on Topography

0.4µm with 2500Å Steps with 1844Å ARC XHRi

High Area

Low Area

Transition

Flat Area

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Advantages of organic BARC

• Can apply with existing photoresist application systems

• Do not need expensive deposition chambers

• Prevents chemical interaction between photoresist and substrate

– BARC acts as wall to nitrogen poisoning with chemically amplified photoresists

• Increases CD control

– Eliminates reflective notching

– Eliminates standing waves and scattered light

• Extends lithography process window

– Increases stepper focus latitude

– Maximizes photoresist exposure latitude

– Increases usage life of stepper.

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Example Spin Speed Curve

2000

1800

DUV42-6

1600 DUV42-8

DUV42-11

1400

1200

1000

800

600

400

200

0

1000 1500 2000 2500 3000 3500 4000 4500 5000

Spin Speed (RPM)

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Lines With or Without BARC

PEK-103 0.20µm L/S Resist on DUV42

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Guide to BSI BARC’s

• Exposure wavelength

– G-line, I-line, DUV, 193nm

• Planar or conformal BARC

– Worst case step height

– CD tolerances needed

• Wet or dry processing

– Depending on equipment availability, CD and wavelength

– Wet process BARC develops away with resist

– Dry process BARC requires a gas etcher

• Choose BARC based on resist chosen

– DUV resists have two chemistries

– ACETAL

– ESCAP/TBOC

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Planar vs Conformal BARC

EQUAL

RESIST

THICKNESS THIN

RESIST

RESIST RESIST RESIST RESIST

EQUIVALENT

BARC

THICKNESS

PLANAR BARC BARC

CONFORMAL

SUBSTRATE SUBSTRATE

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Wet or Dry Etch Processing

Inorganic Organic Organic

Developer Insoluble Developer Insoluble Developer Soluble

Exposure

Development

Etch

Stripping

Anti-reflective

Substrate Photoresist

Bottom coat

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

What is a Bake Window?

Stable Lines Spaces Clear

Space

Residue

CD Missing

Pattern

Bake Latitude

Stepper & Resist Resolution Limit

Bake Temperature

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Wet or Dry Etch Patterning

0.35 µm Dense Lines

177°C Bake 205°C Bake

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

BSI BARC Product Families

• G-line (broadband material) • DUV

– Wet or dry process – Dry Process Only

– XLT – ESCAP/TBOC compatable

– XLX – DUV30 (planar)

• I-line – DUV42 (conformal)

– Wet or dry process – ACETAL compatable

– WiDE – DUV32 (planar)

– Dry process only – DUV44 (conformal)

– XHRi

– XHRiA

Planar BARC gives superior photo performance

Conformal BARC gives superior etch performance

Various viscosities available in each family

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Etch Capabilities

• Successfully dry etched in various chemistries

– HBr

– O2

– Cl2, HCl

– CF4, C2F2

– N2

– Carrier gases: He, Ar

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

DUV42 Etch Performance

After He/O2 etch. After Cl2/O2 etch. After HBr/O2 etch.

∆CD = 0.024µm. ∆CD = 0.013µm. ∆CD = 0.026µm.

Selectivity = 1.04 Selectivity = 1.48 Selectivity = 0.85

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Cleaning/Stripping Capability

• BARC can be removed by common photoresist

stripping processes

– Oxidizing plasma or oxidizing solvent strip processes

– Ozone Plasma Strip

– O2 Plasma

– Piranha

– RCA Clean

Brewer Science Inc., Rolla MO, USA

Effective Date: 0X/0X/02 DCIF: MKT00XX Doc. Control#: F.6.6.010X.A

Vous aimerez peut-être aussi

- Toyota 1ZZ FE 3ZZ FE Engine Repair Manual RM1099E PDFDocument141 pagesToyota 1ZZ FE 3ZZ FE Engine Repair Manual RM1099E PDFJhorwind Requena87% (15)

- TALAT Lecture 5205: Plating On AluminiumDocument19 pagesTALAT Lecture 5205: Plating On AluminiumCORE Materials100% (1)

- TALAT Lecture 5205: Plating On AluminiumDocument19 pagesTALAT Lecture 5205: Plating On AluminiumCORE Materials100% (1)

- Hydraulic Fracturing Design For Optimum WellDocument33 pagesHydraulic Fracturing Design For Optimum WellAoun Fateh100% (2)

- OPERATORS GUIDE SURGICAL LIGHTSDocument117 pagesOPERATORS GUIDE SURGICAL LIGHTSClay MorrisPas encore d'évaluation

- RCDD Flash Cards - Chapter 1 Principle of TransmissionDocument286 pagesRCDD Flash Cards - Chapter 1 Principle of TransmissionTony Leonard80% (5)

- 7.overview of Filter Validation-K.michaelDocument62 pages7.overview of Filter Validation-K.michaelqhpuongPas encore d'évaluation

- Qualitative Analysis of AnionsDocument6 pagesQualitative Analysis of AnionsxerxeshakaPas encore d'évaluation

- Superhydrophobic Surface and ApplicationDocument28 pagesSuperhydrophobic Surface and ApplicationMaterials Research Institute100% (1)

- Advanced Carbonate Reservoir CharacterizationDocument5 pagesAdvanced Carbonate Reservoir CharacterizationAijaz AliPas encore d'évaluation

- Geological Storage Site Screening and ApprovalDocument56 pagesGeological Storage Site Screening and ApprovalIbukun OpeyemiPas encore d'évaluation

- Refractory DetailDocument23 pagesRefractory Detailsunil_supeda0% (1)

- Optimum Propeller Design Using Computerized MethodDocument10 pagesOptimum Propeller Design Using Computerized MethodPavan KishorePas encore d'évaluation

- HPLC Analysis of Metal ComplexesDocument15 pagesHPLC Analysis of Metal Complexesxerxeshaka100% (1)

- F838 15a Standard Test Method ForDocument6 pagesF838 15a Standard Test Method Forxerxeshaka100% (2)

- Hyperspectral Image Analysis For Mechanical and Chemical PropertiDocument31 pagesHyperspectral Image Analysis For Mechanical and Chemical PropertiPreetiPas encore d'évaluation

- Pr01, Pr02, Pr03: Vishay BccomponentsDocument19 pagesPr01, Pr02, Pr03: Vishay BccomponentsGabriel pedrosaPas encore d'évaluation

- Vishay - Resistors, Fixed - Metal OxideDocument5 pagesVishay - Resistors, Fixed - Metal OxideHari Sita RukminiPas encore d'évaluation

- X-Ray Diffraction Project Final Report, Fiscal Year 2006: October 2006Document12 pagesX-Ray Diffraction Project Final Report, Fiscal Year 2006: October 2006Tarun VarmaPas encore d'évaluation

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilPas encore d'évaluation

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilPas encore d'évaluation

- PAVCO Perú - Geotextil NT - NW011 - Marv - Abril - 13 Eng PDFDocument1 pagePAVCO Perú - Geotextil NT - NW011 - Marv - Abril - 13 Eng PDFArmandoPas encore d'évaluation

- Schott Borofloat Technical Data Sheet EnglishDocument1 pageSchott Borofloat Technical Data Sheet Englishlilian.agenaisPas encore d'évaluation

- Innovative Self Initiating PDFDocument9 pagesInnovative Self Initiating PDFkanand_7Pas encore d'évaluation

- Part Number 22211KEJW33, Spherical Roller Bearings - Steel CageDocument4 pagesPart Number 22211KEJW33, Spherical Roller Bearings - Steel CageXiaoYaiZiZaiPas encore d'évaluation

- Lanmark-Of Micro-Bundle Universal (6F-12F) Dca: DescriptionDocument3 pagesLanmark-Of Micro-Bundle Universal (6F-12F) Dca: DescriptionALLISON VANESSA DIAZ GUERREROPas encore d'évaluation

- Vishay Roederstein: FeaturesDocument15 pagesVishay Roederstein: Featuresiman wahyudinPas encore d'évaluation

- bc400 404 408 412 416 Data SheetDocument2 pagesbc400 404 408 412 416 Data SheetMario Javier GonzalesPas encore d'évaluation

- 7.DisenoSismicoPortEsp Part2Document34 pages7.DisenoSismicoPortEsp Part2Richard SantosPas encore d'évaluation

- Fea en Tile Datasheet Rockfon Artic D 02 20203Document4 pagesFea en Tile Datasheet Rockfon Artic D 02 20203sirikhwan wonganuntPas encore d'évaluation

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesXQPas encore d'évaluation

- Sick - WT34 - R220Document7 pagesSick - WT34 - R220M MPas encore d'évaluation

- 004 Diap. RT (Rev.2003)Document61 pages004 Diap. RT (Rev.2003)Armando Lujan VelazquezPas encore d'évaluation

- Opportunities and challenges in smart coatings manufacturingDocument33 pagesOpportunities and challenges in smart coatings manufacturingashna latheefPas encore d'évaluation

- Beam Displacer-WebDocument2 pagesBeam Displacer-Webdlgda1993Pas encore d'évaluation

- 400BPNM-C Product SpecificationsDocument4 pages400BPNM-C Product SpecificationsKoro SenpaiPas encore d'évaluation

- Titanium alloy propertiesDocument3 pagesTitanium alloy propertiesMarcionilo NeriPas encore d'évaluation

- Sa Stock ClearanceDocument5 pagesSa Stock ClearanceSatya RaoPas encore d'évaluation

- AWCCA-48R32 Series: Moisture Sensitivity Level (MSL) - MSL 1Document2 pagesAWCCA-48R32 Series: Moisture Sensitivity Level (MSL) - MSL 1cbdk71Pas encore d'évaluation

- Radial Metallized Polyester RC Network For Transient Suppression HighlightsDocument2 pagesRadial Metallized Polyester RC Network For Transient Suppression HighlightsMkt ConPas encore d'évaluation

- RO4500 Series Cost Performance Antenna Grade LaminatesDocument2 pagesRO4500 Series Cost Performance Antenna Grade LaminatesRodrigoFlorianPas encore d'évaluation

- T20B and Piranha T20 Dose Probes Technical SpecsDocument4 pagesT20B and Piranha T20 Dose Probes Technical SpecsDhoy GaviolaPas encore d'évaluation

- Smart ReologyDocument42 pagesSmart ReologyMarisol Martinez MaldonadoPas encore d'évaluation

- Datasheet WL24-2R240 1017858 enDocument8 pagesDatasheet WL24-2R240 1017858 enRachid MoussaouiPas encore d'évaluation

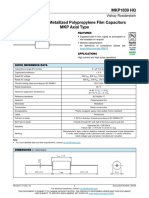

- MKP1839 HQ: Vishay RoedersteinDocument13 pagesMKP1839 HQ: Vishay RoedersteinSTE ABMCPas encore d'évaluation

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDocument2 pagesGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranPas encore d'évaluation

- Erosion-Corrosion in Slurry Service - NACE CalgaryDocument17 pagesErosion-Corrosion in Slurry Service - NACE Calgaryzerocool86Pas encore d'évaluation

- Schneider SwitchesDocument10 pagesSchneider Switchesing.cdpadillaPas encore d'évaluation

- MFA 4000 Lithography Process OverviewDocument46 pagesMFA 4000 Lithography Process OverviewPrakharPas encore d'évaluation

- Resistor 1k - Vishay - 0.6wDocument3 pagesResistor 1k - Vishay - 0.6wLEDPas encore d'évaluation

- Fabrock 30: Board Insulation For OEM ApplicationsDocument2 pagesFabrock 30: Board Insulation For OEM ApplicationsCristhian RangelPas encore d'évaluation

- Rogers MaterialDocument4 pagesRogers MaterialRobert ZmrzliPas encore d'évaluation

- Characteriza On of BiomaterialsDocument48 pagesCharacteriza On of BiomaterialsJT92Pas encore d'évaluation

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoPas encore d'évaluation

- Revitex VAC40: Sleevings For Thermal, Electrical, Mechanical & Emi ApplicationsDocument2 pagesRevitex VAC40: Sleevings For Thermal, Electrical, Mechanical & Emi ApplicationsJesus VerduzcoPas encore d'évaluation

- Part Number 22317EJW33, Spherical Roller Bearings - Steel CageDocument4 pagesPart Number 22317EJW33, Spherical Roller Bearings - Steel CageXiaoYaiZiZaiPas encore d'évaluation

- S SeriesDocument11 pagesS Series380665791408maksPas encore d'évaluation

- EcoSonic-VpCI-125-ESD-HP-UVDocument3 pagesEcoSonic-VpCI-125-ESD-HP-UVcongnghiephoachat01Pas encore d'évaluation

- Alloy 6061 Technical Data SheetDocument2 pagesAlloy 6061 Technical Data SheetSarat SrinivasPas encore d'évaluation

- Sheet Coil & Plate Alloy 6061Document2 pagesSheet Coil & Plate Alloy 6061Sarat SrinivasPas encore d'évaluation

- LOCTITEDocument2 pagesLOCTITEHrPas encore d'évaluation

- RD 360R3Document1 pageRD 360R3Rachmad Budi WPas encore d'évaluation

- Hanif Summary FinalDocument3 pagesHanif Summary FinalAmmara AminPas encore d'évaluation

- AEN033 OTDR Return Loss MeasurementDocument3 pagesAEN033 OTDR Return Loss MeasurementRenbozzPas encore d'évaluation

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraPas encore d'évaluation

- GHG 612 RCD Technical Specifications and Ordering InformationDocument3 pagesGHG 612 RCD Technical Specifications and Ordering Informationkhairalla mohamedPas encore d'évaluation

- PT. EASTERN Calibration Certificate for Proving RingDocument1 pagePT. EASTERN Calibration Certificate for Proving RingJannatun Amira Al AqilahPas encore d'évaluation

- SGG CLIMAPLUS STADIP SILENCE 66.1 Si (16 ARGON 90) 6Document1 pageSGG CLIMAPLUS STADIP SILENCE 66.1 Si (16 ARGON 90) 6Carlos Adolfo Salah FernandezPas encore d'évaluation

- SkyCiv Beam Analysis ReportDocument8 pagesSkyCiv Beam Analysis Reportpatel nikunj rPas encore d'évaluation

- Elix Essential Manual Millipore - Water-PurificationDocument54 pagesElix Essential Manual Millipore - Water-PurificationDino Sk100% (1)

- Waters XEO GC MSDocument4 pagesWaters XEO GC MSxerxeshakaPas encore d'évaluation

- FilterDocument8 pagesFilterxerxeshakaPas encore d'évaluation

- 2695 SpecificationDocument3 pages2695 SpecificationxerxeshakaPas encore d'évaluation

- AN1422EN00Document2 pagesAN1422EN00xerxeshakaPas encore d'évaluation

- Surface Engineering Industry GermanyDocument27 pagesSurface Engineering Industry GermanyxerxeshakaPas encore d'évaluation

- Sterilizing-grade Durapore® 0.22 μm Hydrophobic FiltersDocument8 pagesSterilizing-grade Durapore® 0.22 μm Hydrophobic FiltersxerxeshakaPas encore d'évaluation

- Capsules PDFDocument30 pagesCapsules PDFxerxeshakaPas encore d'évaluation

- The 58th Annual Meeting International Society of ElectrochemistryDocument102 pagesThe 58th Annual Meeting International Society of ElectrochemistryxerxeshakaPas encore d'évaluation

- Durapore Hydrophilic Filter Cartridges User Guide L PDFDocument52 pagesDurapore Hydrophilic Filter Cartridges User Guide L PDFxerxeshakaPas encore d'évaluation

- Determination of Hydrochloric and Nitric Acid in Etching Baths by Thermometric Titration PDFDocument3 pagesDetermination of Hydrochloric and Nitric Acid in Etching Baths by Thermometric Titration PDFxerxeshakaPas encore d'évaluation

- Corrosion Under Control? Mechanisms and Applications at Gordon ConferenceDocument18 pagesCorrosion Under Control? Mechanisms and Applications at Gordon ConferencexerxeshakaPas encore d'évaluation

- Minimum Bubble Point Specification for Sterilizing-Grade 0.22 μm Durapore® MembranesDocument8 pagesMinimum Bubble Point Specification for Sterilizing-Grade 0.22 μm Durapore® MembranesxerxeshakaPas encore d'évaluation

- 1992-New Kinetic Model For Resist DissolutionDocument3 pages1992-New Kinetic Model For Resist DissolutionxerxeshakaPas encore d'évaluation

- Surface and Interface Analysis Book - Surface Analytical MethodsDocument44 pagesSurface and Interface Analysis Book - Surface Analytical MethodsxerxeshakaPas encore d'évaluation

- E Prep 280 NCZDocument4 pagesE Prep 280 NCZxerxeshakaPas encore d'évaluation

- Top-Coats & Lubricants for Corrosion ProtectionDocument1 pageTop-Coats & Lubricants for Corrosion ProtectionxerxeshakaPas encore d'évaluation

- Determination of Hydrochloric and Nitric Acid in Etching Baths by Thermometric TitrationDocument3 pagesDetermination of Hydrochloric and Nitric Acid in Etching Baths by Thermometric TitrationxerxeshakaPas encore d'évaluation

- E Brite 50 Cu SdsDocument8 pagesE Brite 50 Cu SdsxerxeshakaPas encore d'évaluation

- Filter Systems: Out-Tank Models In-Tank ModelsDocument1 pageFilter Systems: Out-Tank Models In-Tank ModelsxerxeshakaPas encore d'évaluation

- Sinkral B 432eDocument2 pagesSinkral B 432exerxeshakaPas encore d'évaluation

- Antiprex® CEN Chelating AgentDocument1 pageAntiprex® CEN Chelating AgentxerxeshakaPas encore d'évaluation

- Cuprostar NC: Alkaline, Cyanide-Free Bright CopperDocument2 pagesCuprostar NC: Alkaline, Cyanide-Free Bright Copperxerxeshaka100% (1)

- Refrigerant Tracking User Guide 2013Document13 pagesRefrigerant Tracking User Guide 2013corrigomarketingPas encore d'évaluation

- App Disply Rgrming PDFDocument776 pagesApp Disply Rgrming PDFGnaneshwar Rao SirikondaPas encore d'évaluation

- Kollmorgen PMA Series CatalogDocument6 pagesKollmorgen PMA Series CatalogElectromatePas encore d'évaluation

- Second Year Hall Ticket DownloadDocument1 pageSecond Year Hall Ticket DownloadpanditphotohousePas encore d'évaluation

- 0111 Tension Load Cell Datasheet enDocument2 pages0111 Tension Load Cell Datasheet enJosipaPas encore d'évaluation

- Introduction to Philosophy Class Lesson PlansDocument3 pagesIntroduction to Philosophy Class Lesson PlansJennifer MagangoPas encore d'évaluation

- Orange Line Improvements Project PresentationDocument25 pagesOrange Line Improvements Project PresentationMetro Los AngelesPas encore d'évaluation

- Computer Organization & Assembly Language: 1 - An IntroductionDocument35 pagesComputer Organization & Assembly Language: 1 - An IntroductionAhmad NaeemPas encore d'évaluation

- 10-20 Belt Scale MT9101 8017.0113Document4 pages10-20 Belt Scale MT9101 8017.0113RickPas encore d'évaluation

- IssabelPBX AdministrationDocument9 pagesIssabelPBX AdministrationDaniel VieceliPas encore d'évaluation

- Versidrain 150: Green RoofDocument2 pagesVersidrain 150: Green RoofMichael Tiu TorresPas encore d'évaluation

- IPC-7351A & PCBL Land Pattern Naming ConventionDocument6 pagesIPC-7351A & PCBL Land Pattern Naming ConventionSri ramPas encore d'évaluation

- Account Statement 220422 210722Document14 pagesAccount Statement 220422 210722Meherun BibiPas encore d'évaluation

- Digital Circuit SimulatorDocument7 pagesDigital Circuit SimulatorPratik V PandharePas encore d'évaluation

- Catalogo 3wl lv10-1 2016 en PDFDocument116 pagesCatalogo 3wl lv10-1 2016 en PDF- witaratamaPas encore d'évaluation

- Proceeding 4th Ismei - FinalDocument412 pagesProceeding 4th Ismei - FinalAchmad NizarPas encore d'évaluation

- Piper Archer II Checklist GuideDocument8 pagesPiper Archer II Checklist GuideJosías GenemPas encore d'évaluation

- User Guide For Gateway NV57H / NV55SDocument1 087 pagesUser Guide For Gateway NV57H / NV55SAudrey D. ChatmanPas encore d'évaluation

- Mobil Nuto H Series TdsDocument2 pagesMobil Nuto H Series TdswindiPas encore d'évaluation

- The Kitchen Science of Crystals Lesson 4Document3 pagesThe Kitchen Science of Crystals Lesson 4api-239297797Pas encore d'évaluation

- Sa-Akx36Ph Sa-Akx36Pn: CD Stereo SystemDocument90 pagesSa-Akx36Ph Sa-Akx36Pn: CD Stereo SystemEdwin BerruetaPas encore d'évaluation

- Dyeing Process Guide: Types, Machines & OptimizationDocument3 pagesDyeing Process Guide: Types, Machines & OptimizationVipin Singh KandholPas encore d'évaluation

- Activities Plan - Assets Inventory (Lake House, Club Huis & Green Sport)Document8 pagesActivities Plan - Assets Inventory (Lake House, Club Huis & Green Sport)Customer ServicePas encore d'évaluation

- 01 Rude DoctypeDocument215 pages01 Rude DoctypeChristal Rae Tac-anPas encore d'évaluation

- Ford Pinto Case Study HandoutDocument2 pagesFord Pinto Case Study HandoutSteven Snitch TranPas encore d'évaluation