Académique Documents

Professionnel Documents

Culture Documents

Simulation of Sand Production Prediction

Transféré par

Anonymous SEEyca1bRQCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Simulation of Sand Production Prediction

Transféré par

Anonymous SEEyca1bRQDroits d'auteur :

Formats disponibles

ISSN: 2456-9348

Vol (02) _Issue (09) Impact Factor: 4.520

International Journal of Engineering Technology Research & Management

SIMULATION OF SAND PRODUCTION PREDICTION IN GAS RESERVOIRS

Ibrahim Ayuba *1

H. Isma’il 2

T.S. Manasseh 3

M.S. Gwio 4

M.M. Aminu 5

*1, 2, 3, 4 & 5

Department of Petroleum Engineering, Bauchi, Nigeria

Ibrahimayuba08@gmail.com

ABSTRACT

Sand production due to result of unconsolidated grains in wellbore formations, as lead to many adverse effect,

such as plugging, accumulation in surface equipment, increase in skin and tubing roughness.

Sensitivity analysis using PROSPER software was run on different well parameters, (tubing roughness, skin)

and under free gas effect for an open hole completion to predict effect of sand production in life of the well. The

tubing and skin analysis shows a decline in well flow potential across the years, due to sand production. The

future performance indicate sand control remedy must be deploy to maintain and revive the well to it optimum

flow potential.

Analysis on free gas effect was used to determine the highest free gas value under the reservoir condition for

the well optimum production. (3.5 - 4.023) MMscf/day gave the optimal flow potential for the well. This

analysis shows the amount and condition of free gas in the well before the effect of sand production

.

Keywords: Unconsolidated grains, Sand production, Wellbore formations, Plugging, Accumulation, PROSPER

software, Tubing roughness, Open hole completion, Skin analysis, Free gas, Optimal flow potential.

INTRODUCTION

Sand prediction model have the capability to indicate whether initial sand production may take place somewhere

during the lifetime of an oil gas field. Prediction of maximum sand-free production rate provides information for

sand-control decisions and allows maximization of rate in those wells that are completed without sand control.

In this paper, filed data will be used for modelling and making this predictions.

A significant proportion of the world gas reserves is contained in weakly consolidated sandstone reservoirs and

hence is prone to sand production. Material degradation is a key process leading to sanding. Drilling operations,

cyclic effects of shut-in and start-up, operational conditions, reservoir pressure depletion, and strength-

weakening effect of water may gradually lead to sandstone degradation around the perforations and boreholes.

High pressure gradient due to fluid flow also facilitates the detachment of sand particles. In addition, fluid flow

is responsible for the transport and production of cohesionless sand particles or detached sand clumps to the

wellbore. Sand production is the cause of many problems in the oil industry and it affects the completion

adversely. These problems include, but are not limited to, plugging the perforations or production liner, wellbore

instability, failure of sand control completions

Sand-production problems can be experienced in various ways. In conventional oil wells, transient sand

production, where the sand production rate declines rapidly with time, is frequently experienced during the

clean-up period after processes such as perforating or acidizing, after rapid bean-up of production, or after water

breakthrough. It is assumed that sand production in these cases is merely the removal of weakened or sheared

and dilated sand. However, there are different “types” of sand-production behavior. Conventional-oil sand

production has been classified on the basis of distinct reservoir evolution stages:

The early transient sand-production period, when some of the perforation-induced damage has been

removed and the cavities may have a zone of reduced permeability around them, leading to a steep exit

gradient.

A stable production period with enlarged cavities, when the damaged zone and the permeability

impairment have been removed.

A general increase in sand influx after a water-cut increase, a process that is considered to be related to

capillary forces and is a type of flow-rate-induced sand production.

IJETRM (http://ijetrm.com/) [51]

ISSN: 2456-9348

Vol (02) _Issue (09) Impact Factor: 4.520

International Journal of Engineering Technology Research & Management

An unstable sand-production period because of reservoir pressure depletion, considered to arise when

large effective-stress increase causes straining, destroy cohesion, alter fabric, and induce almost-

continuous sanding.

Common Techniques Used in Sand Management Decisions

A number of approaches have been developed to predict or help to understand the sand production problem,

using physical model testing, analytical and empirical relationships, and numerical models Routine laboratory

tests can only predict the onset of sand production. More sophisticated Physical model could predict volumetric

sand production, they are also time-consuming and expensive. In addition, because of the small sizes of the

laboratory setup, the results are usually influenced by boundary effects. Analytical models are fast and easy to

use but they are only suitable to predict the onset of sand production and they have limitations. Most of them are

only valid for capturing a single mechanism of sanding and under simplified geometrical and boundary

conditions which are not usually the complicated field-scale problems. Numerical models are by far the most

powerful tools for predicting sand production. They can be combined with analytical correlations to obtain the

results more efficiently. Experimental results are also utilized to calibrate or validate a numerical model. Yet,

numerical models have their own limitations and extensive efforts have been made to improve them.

Discrete element method (DEM) is a useful tool to simulate sand production especially to understand the

mechanism of sanding. However, it cannot be used for large scale problems because of large computational time

required. (Thallak et al. 1991), have used discrete element models to predict the development of borehole

breakouts in an assemblage of spherical particles.

The calibration of the model is also difficult and involves several uncertainties as it is not possible to create a

model with the exact particle arrangement as the real material. Further, methodologies to directly measure

sandstone micro properties have not been developed yet. Presently, the micro-properties are obtained in

calibrating against the actual sand behavior. Therefore, continuum-based models are more popular especially for

field-scale problems. However, there can be advanced models which couple continuum and discontinuum

models together to take advantage of both methods, these are known as hybrid models.

Modeling of sand production requires coupling of two mechanisms, the first mechanism is mechanical

instability and degradation around the wellbore and the second one is hydro-mechanical instability due to low-

induced pressure gradient on degraded material surrounding the cavity (e.g perforation and open hole).

At larger perforation lengths, as for openhole production conditions, the effects of non-Darcy flow on rock

yielding are not very significant. This conclusion is consistent with the findings of (Wang and Peden, 1991).

In general, numerical methods in the mechanical modeling are categorized under continuum and discontinuum

approaches.

In the continuum approach, matters are treated as continuous in deriving the governing differential equations.

The assumption of continuity implies that the material cannot be separated or broken into smaller pieces. In the

case when there is a discontinuity, the magnitudes of deformation along or across the discontinuity are about the

same as the rest of the continuum.

Numerical models based on discontinuum approach sand production is a continuous and dynamic process that

occurs at the microscopic scale and the rock becomes a discontinuum in nature, discontinuum approach is

promising to simulate phenomena such as detachment of individual particles from the rock matrix.

Other techniques used for predicting sand includes; Formation Strength; Sonic Log; Formation Properties Log;

Porosity; Drawdown Finite Element Analysis; Time Dependence.

Formation Strength

Rock failure and/or degradation in commonly accepted as prerequisite for sanding. Failure of geo-materials is

usually associated with formation of shear bands which are narrow zones of concentrated plastic deformation.

This phenomenon, which is known as “deformation localization” or simply “localization,” is one of the key

parameters in sanding prediction models. Further details about this concept can be found in (Sulem et al.1999),

(Nouri et al.2009), and (Jafarpour et al.2012).

The general procedure followed by most operators considering whether or not sand control is required, is to

determine the hardness of the formation rock (i.e., the rock’s compressive strength). Since the rock’s

compressive strength has the same units as the pressure drawdown in the reservoir, the two parameters can be

compared on a one to one basis and drawdown limits for specific wells can be determined.

Finite Element Analysis

Probably the most sophisticated approach to predicting sand production is the use of geo-mechanical numerical

models developed to analyze fluid flow through the reservoir in relation to the formation strength. The effects of

IJETRM (http://ijetrm.com/) [52]

ISSN: 2456-9348

Vol (02) _Issue (09) Impact Factor: 4.520

International Journal of Engineering Technology Research & Management

formation stress associated with fluid flow in the immediate region around the wellbore are simultaneously

computed with finite element analysis. While this approach is by far the most rigorous, it requires an accurate

knowledge of the formation’s strength both in the elastic and plastic regions where the formation begins to fail.

The finite element analysis method is good from the viewpoint of comparing one interval with another;

however, the absolute values calculated may not represent actual formation behavior.

Drawdown

The pressure drawdown associated with production may be an indicator of potential formation sand production.

No sand production may occur with low pressure drawdown around the well whereas excessive drawdown can

cause formation material to be produced at unacceptable levels. The amount of pressure drawdown is normally

associated with the formation permeability and the viscosity of the produced fluids.

Sonic Log

The sonic log can be used as a way of addressing the sand production potential of wells. The sonic log records

the time required for sound waves to travel through the formation in microseconds. The porosity is related to the

sonic travel time. Short travel times, (for example, 50 microseconds) are indicative of low porosity and hard,

dense rock; while long travel times (for example, 95 microseconds or higher) are associated with softer, lower

density, higher porosity rock. A common technique used for determining if sand control is required in a given

geologic area is to correlate incidences of sand production with the sonic log readings.

Causes of Sand Production

The solid material produced from a well can consist of both formation fines (usually not considered part of the

formation’s mechanical framework) and load bearing solids. The production of fines cannot normally be

prevented and is actually beneficial.

The following list summarizes many of the factors that influence the tendency of a well to produce

Sand, these factors can be categorized into rock strength effects and fluid flow effects

Degree of consolidation

Reduction in pore pressure throughout the life of a well

Production rate

Reservoir fluid viscosity

Increasing water production throughout the life of a well

Degree of Consolidation

The ability to maintain open perforation tunnels is closely tied to how strongly the individual sand grains are

bound together. The cementation of a sandstone is typically a secondary geological process and as a general

rule, older sediments tend to be more consolidated than newer sediments. This indicates that sand production is

normally a problem when producing from shallow, geologically younger Tertiary sedimentary formations.

Young Tertiary formations often have little matrix material (cementation material) bonding the sand grains

together and these formations are generally referred to as being “poorly consolidated” or “unconsolidated.

Production Rate.

The production of reservoir fluids creates pressure differential and frictional drag forces that can combine to

exceed the formation compressive strength. This indicates that there is a critical flow rate for most wells below

which pressure differential and frictional drag forces are not great enough to exceed the formation compressive

strength and cause sand production.

Reservoir Fluid Viscosity.

The frictional drag force exerted on the formation sand grains is created by the flow of reservoir fluid. This

frictional drag force is directly related to the velocity of fluid flow and the viscosity of the reservoir fluid being

produced. High reservoir fluid viscosity will apply a greater frictional drag force to the formation sand grains

than will a reservoir fluid with a low viscosity.

IJETRM (http://ijetrm.com/) [53]

ISSN: 2456-9348

Vol (02) _Issue (09) Impact Factor: 4.520

International Journal of Engineering Technology Research & Management

Modelling

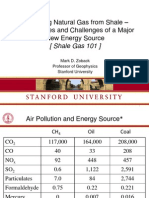

Figure 1: Inflow and Outflow Performance Plot.

The figure above shows the inflow performance relationship curve (IPR) and vertical lift performance (VLP) for

an open-hole completion. The well has an absolute open flow 22439.6 (STB/day) with a productivity index of

18.17 when the skin factor is 4 and reservoir pressure of 3242 (psig). Hence this implies deliverability of the

well performance is quite effective, (the fluid flow to the reservoir for production). Whereas, the outflow (VLP)

is the ability of the reservoir deliver fluid to the tubing to effectively convey to the surface, which will be used

to determine and predict the effect of produced sand in this paper work.

Sensitivity Analysis to Predict the Effect of Sand Production

IJETRM (http://ijetrm.com/) [54]

ISSN: 2456-9348

Vol (02) _Issue (09) Impact Factor: 4.520

International Journal of Engineering Technology Research & Management

Well Parameters under the effect of Sand Production

Years Tubing Roughness Free gas Skin Liquid rate Oil rate

(MMscf/day) STB/day STB/day

2016 0.0005 1.5 2 6368.9 4776.4

2017 0.0008 2.78 4 6127.3 4595.5

2018 0.001 4.023 6 5847.2 4385.4

2019 0.005 6.14 8 4956.6 3717.5

2020 0.01 8.55 10 4190.7 3143.0

Initial Condition without Sand

Free gas Liquid Oil

(STB/day)

(MMscf/day) (STB/day)

1.5 6160.8 4580.1

2.78 6222.0 4666.5

4.023 6299.0 4671.7

6.14 6115.9 4586.9

8.55 5894.8 4421.1

From the table above analysis were run on different well parameters under the influence of tubing roughness,

skin and the free gas at reservoir condition, for an open-hole production to predict the yearly future

performance, without any remedy for sand control.

Due to effect of sand production towards the years the tubing roughness and skin increases, which reduces the

flow potential of the well optimum productivity. This is clearly analyzed using the performance plot below.

IJETRM (http://ijetrm.com/) [55]

ISSN: 2456-9348

Vol (02) _Issue (09) Impact Factor: 4.520

International Journal of Engineering Technology Research & Management

Figure 2: Performance Plot across the Years.

It can be seen that the production rate declines over year, were a sharp decline was observed in 2018, the use of

sand control measure must be used to resolve this sand effect, for the well optimum production.

Condition without Sand

Analysis were run using the differences in free gas at initial well condition were skin and tubing roughness were

at fixed parameters without sand production effect, to determine the maximum value of gas that gave the

optimum production in the well condition.

Figure 3: Oil Production under Effect of free Gas

The free gas rate from (3.5 - 4.023) MMscf/day gave the highest production rate of 4671.7 (STB/day). This

shows the optimal value of free gas rate that will be available in the well for production without sand effect.

While the decline in oil production from 4MMscf, is an indication of the frictional pressure loss, were the gas

phase travels faster than the liquid phase, therefore leaving behind the oil phase, at this point, more gas will be

IJETRM (http://ijetrm.com/) [56]

ISSN: 2456-9348

Vol (02) _Issue (09) Impact Factor: 4.520

International Journal of Engineering Technology Research & Management

produced to oil, when the amount of gas exceed the production limit. This will help to convey unconsolidated

sand grains to surface during production.

Further analysis in PROSPER at a skin of 4 with different tubing roughness are shown below:

IJETRM (http://ijetrm.com/) [57]

ISSN: 2456-9348

Vol (02) _Issue (09) Impact Factor: 4.520

International Journal of Engineering Technology Research & Management

CONCLUSION

This paper analysis determines and present a model used to predict sand production, using the petroleum expert

software PROSPER, the following features were used to predict sand production, in the flow life of the well.

The sensitivity analysis on well parameters in predicting the future performance, shows decline in flow

potential of the well optimum productivity under the influence tubing roughness and skin, due to the

effect of sand production.

For the free gas effect in the well, analysis indicates (3.5 – 4.023) MMscf/day of free gas in optimizing

the well productivity optimally. Above the free gas limit, shows decline in production, due to effect of

frictional pressure loss (where the gas phase travels faster than the liquid phase) therefore the well

producing more of gas to oil. Hence causing the production of unconsolidated sand grains during cause

of production due to high gas rate.

Nomenclature

k = Permeability

h = Thickness

GOR = Gas Oil Ratio

MD = Measured Depth

THT = Tubing Head Temperature

THP = Tubing Head Pressure

IPR = Inflow Performance Relationship

VLP = Vertical Lift Performance

TVD = True Vertical Depth

SSSV = Subsurface Safety Valve

PROSPER = Production and Systems Performance Analysis Software

REFERENCES

[1]. A. Nouri, E. Kuru, and H. Vaziri, “Elastoplastic modelling of sand production using fracture energy

regularization method,”Journal of Canadian Petroleum Technology, vol. 48, no. 4, pp.64–71, 2009.

[2]. Boyun, G., (2007). Petroleum Production Engineering, A Computer-Assisted Approach, 1st Edition |

ISBN 9780750682701.

[3]. Liangwen Zhang and Maurice B. Dusseault, Porous Media Research Inst., U. of Waterloo Sand-

Production Simulation in Heavy-Oil Reservoirs SPE 89037.

[4]. Chukwunyere George (2016), Design of Continuous Flow Gas Lift, University of Miskolc Petroleum

and Natural Gas Institute.

[5]. PROSPER v.10 User Manual, Petroleum Experts. 2008.

[6]. Hossein Rahmati, Mahshid Jafarpour, Saman Azadbakht, Alireza Nouri, Hans Vaziri, Dave Chan, and

Yuxing Xiao. 2013, Review of Sand Production Prediction Models, Journal of Petroleum Engineering

Volume 2013, Article ID 864981.

[7]. Tixier, M.P., Loveless, G.W., Anderson, R.A., March 1975 “Estimation of Formation Strength from

the Mechanical-Properties Log”, Journal of Petroleum Technology.

[8]. Penberthy, W.L. and Shaughnessy, C.M., Sand Control, SPE Series on Special Topics, Volume 1,

1992.

[9]. Roberts, A., Geotechnology: An Introductory Text for Students and Engineers, Pergamon Press, New

York, New York, 1977.

[10]. Suman, G.O. Jr., Ellis, R.C., and Snyder, R.E., Sand Control Handbook, Second Edition, Gulf

Publishing Company, Houston, Texas, 1991.

[11]. P.J.Van den Hoek, SPE, and M.B Geiliman, Prediction of sand production in oil and gas reservoirs,

Field validation and Practical use. 9 -12 October 2005. SPE 95715.

[12]. J. Sulem, I. Vardoulakis, E. Papamichos, A. Oulahna, and J. Tronvoll, “Elasto-plastic modelling of Red

Wildmoor sandstone,” Journal of Mechanics of Cohesive-Frictional MaterialsNo, vol. 4, no. 3, pp.

215–245, 1999.

IJETRM (http://ijetrm.com/) [58]

ISSN: 2456-9348

Vol (02) _Issue (09) Impact Factor: 4.520

International Journal of Engineering Technology Research & Management

[13]. M. Jafarpour, H. Rahmati, S. Azadbakht, A. Nouri, D. Chan, and H. Vaziri, “Determination of

mobilized strength properties of degrading sandstone,” Journal of Soils and Foundations, vol. 52, no. 4,

pp. 658–667, 2012.

[14]. J.S. Weingarten, SPE, Arco Alaska Inc., and 1.K. Perkins, July 1995. Prediction of Sand Production in

Gas Wells.

[15]. P.J. McLellan, SPE, C.D. Hawkes. Sand Production Prediction for Horizontal Wells in Gas Storage

Reservoirs. , November 2000, SPE 65510.

[16]. Thallak, S., Rothenburg, L. and Dusseault, M.B.: “Analysis of borehole stability using discrete element

models,” Proc. Int. Congress on Rock Mechanics, Aachen, Germany (1991) 813.

[17]. Wang, Z. and Peden, J.M.: “The prediction of operating conditions to constrain sand production from a

gas well,” SPE 21681, Proc. Production Operations Symposium, Oklahoma City,

Oklahoma (1991) 447.

IJETRM (http://ijetrm.com/) [59]

ISSN: 2456-9348

Vol (02) _Issue (09) Impact Factor: 4.520

International Journal of Engineering Technology Research & Management

IJETRM (http://ijetrm.com/) [60]

Vous aimerez peut-être aussi

- Fundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyD'EverandFundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyPas encore d'évaluation

- A New and Practical Model For Amount and Rate of Sand Production Estimation OTC-26508-MSDocument18 pagesA New and Practical Model For Amount and Rate of Sand Production Estimation OTC-26508-MSNik Mohammad FadhlanPas encore d'évaluation

- Spe 39437 MSDocument14 pagesSpe 39437 MSAndrés Bojacá MatizPas encore d'évaluation

- Fundamentals and Applications of Bionic Drilling FluidsD'EverandFundamentals and Applications of Bionic Drilling FluidsPas encore d'évaluation

- Review of Sand ProductionDocument9 pagesReview of Sand ProductionFarqad AliPas encore d'évaluation

- Effect of Sand Invasion On Oil Well Production A Case Study of Garon Field in The Niger Delta PDFDocument9 pagesEffect of Sand Invasion On Oil Well Production A Case Study of Garon Field in The Niger Delta PDFTOÀN ĐỖ VIỆTPas encore d'évaluation

- Sand ControlDocument3 pagesSand ControlPaolo CavaioniPas encore d'évaluation

- Sand Control 2014Document8 pagesSand Control 2014ykefirPas encore d'évaluation

- SPE-180491-MS Customized Drilling & Completion Fluids Designed For Horizontal Wells To Address The Drilling and Production Challenges - Case HistoryDocument14 pagesSPE-180491-MS Customized Drilling & Completion Fluids Designed For Horizontal Wells To Address The Drilling and Production Challenges - Case HistoryKd FaPas encore d'évaluation

- Geothermal Drilling: A Baseline Study of Nonproductive Time Related To Lost CirculationDocument13 pagesGeothermal Drilling: A Baseline Study of Nonproductive Time Related To Lost CirculationForloradPas encore d'évaluation

- Well Commander BrochureDocument8 pagesWell Commander BrochureAlexandru NeaguPas encore d'évaluation

- As Ton Sun UmDocument44 pagesAs Ton Sun Umwahyu budiharjoPas encore d'évaluation

- An Integrated Drilling and Geomechanics Approach Helps To Successfully Drill Wells Along The Minimum Horizontal Stress Direction in Khuff Reservoirs PDFDocument13 pagesAn Integrated Drilling and Geomechanics Approach Helps To Successfully Drill Wells Along The Minimum Horizontal Stress Direction in Khuff Reservoirs PDFedenPas encore d'évaluation

- Casing LeaksDocument8 pagesCasing LeaksJames "Chip" NorthrupPas encore d'évaluation

- MCQDocument60 pagesMCQkushal100% (1)

- WebtocDocument10 pagesWebtocriobmPas encore d'évaluation

- Wellbore Stability, Stabilization and StrengtheningDocument14 pagesWellbore Stability, Stabilization and StrengtheningAshishPas encore d'évaluation

- Aerated DrillingDocument10 pagesAerated DrillingDen YogaPas encore d'évaluation

- 2-New Completion Technology4Document7 pages2-New Completion Technology4klibiPas encore d'évaluation

- 03 Stabilizing PDFDocument10 pages03 Stabilizing PDFJhon Jairo Maestre UribePas encore d'évaluation

- Master Thesis - Jose Maria MoratallaDocument80 pagesMaster Thesis - Jose Maria MoratallaorlandoPas encore d'évaluation

- Limpieza PozosDocument86 pagesLimpieza PozosDiego LeonPas encore d'évaluation

- Advanced DrillingDocument24 pagesAdvanced DrillingYUSUFPas encore d'évaluation

- Managing Challenges During Drilling OperationsDocument3 pagesManaging Challenges During Drilling OperationsRasakPas encore d'évaluation

- SPE-124295-PP New Integrated Approach For Updating Pore-Pressure Predictions During DrillingDocument11 pagesSPE-124295-PP New Integrated Approach For Updating Pore-Pressure Predictions During DrillingMarcelo Ayllón RiberaPas encore d'évaluation

- عرض تقديمي من Microsoft PowerPoint جديد Document29 pagesعرض تقديمي من Microsoft PowerPoint جديد AnasPas encore d'évaluation

- Key Aspects of Deepwater AppraisalDocument19 pagesKey Aspects of Deepwater Appraisalsanwang12345Pas encore d'évaluation

- Integration of Drilling, Geology and Geophysical Data - Develop. High Res Predill Wellbore Satablility For Ultra Deep Water Kumar2019Document15 pagesIntegration of Drilling, Geology and Geophysical Data - Develop. High Res Predill Wellbore Satablility For Ultra Deep Water Kumar2019Juan P MSPas encore d'évaluation

- Well CompletionDocument82 pagesWell CompletionFlorian Ananias ByarugabaPas encore d'évaluation

- Testing of Drilling Fluids: Mud DensityDocument9 pagesTesting of Drilling Fluids: Mud DensityMohammed Amin BenharkatPas encore d'évaluation

- MUDLOGGINGQUALITYCONTROLPOREPRESSUREPREDICTION AhmedSabry PHDDocument137 pagesMUDLOGGINGQUALITYCONTROLPOREPRESSUREPREDICTION AhmedSabry PHDbmnPas encore d'évaluation

- Riserless Drilling AppendixDocument2 pagesRiserless Drilling AppendixDr K GallowglaichPas encore d'évaluation

- Advanced Deepwater Kick DetectionDocument10 pagesAdvanced Deepwater Kick DetectionRakibul IslamPas encore d'évaluation

- Spe 103184 MSDocument7 pagesSpe 103184 MSRamanamurthy PalliPas encore d'évaluation

- SLB Oilfield Review - Sealing Fractures Advances in Lost Circulation Control Treatments PDFDocument10 pagesSLB Oilfield Review - Sealing Fractures Advances in Lost Circulation Control Treatments PDFpetropaoPas encore d'évaluation

- SPE 87130 Stress Cage AstonDocument8 pagesSPE 87130 Stress Cage AstonPTPas encore d'évaluation

- Abbreviations Updated 2007 - AugDocument15 pagesAbbreviations Updated 2007 - Augdaniel_iosif_glPas encore d'évaluation

- Sand Control To Improve Well PerformanceDocument10 pagesSand Control To Improve Well PerformanceDobrescu MariusPas encore d'évaluation

- Low Cost Deep Water Wells - by John Normann Gundersen - 2Document105 pagesLow Cost Deep Water Wells - by John Normann Gundersen - 2Amir O. Osho100% (1)

- Name: Stephany Kwoyiga INDEX NUMBER: UEB0506118Document3 pagesName: Stephany Kwoyiga INDEX NUMBER: UEB0506118Musah HarunaPas encore d'évaluation

- 383 AB Final Report Deepwater Kicks and BOP PerformanceDocument123 pages383 AB Final Report Deepwater Kicks and BOP Performancechandra sonarPas encore d'évaluation

- BaraBlend 665BaraLock 666russiaDocument2 pagesBaraBlend 665BaraLock 666russiaArun Raj LatchumananPas encore d'évaluation

- Sandface ScreenDocument1 pageSandface ScreenMoujahed FarésPas encore d'évaluation

- Scheer2021 Book SubsurfaceEnvironmentalModelliDocument232 pagesScheer2021 Book SubsurfaceEnvironmentalModelliRoger YuanPas encore d'évaluation

- Drilling and Complwtion FluidsDocument14 pagesDrilling and Complwtion FluidsvipmittalPas encore d'évaluation

- IADC/SPE 87122 Successful Horizontal Drilling in Western Siberia: Use of Appropriate, Cost-Effective Technology Solutions To Increase Well ProductivityDocument9 pagesIADC/SPE 87122 Successful Horizontal Drilling in Western Siberia: Use of Appropriate, Cost-Effective Technology Solutions To Increase Well ProductivitymsmsoftPas encore d'évaluation

- Drilling Problems Mitigation in Geothermal Environtment, Case Studies of Stuck Pipe and Lost Circulation (W.a. Nugroho, 2017)Document11 pagesDrilling Problems Mitigation in Geothermal Environtment, Case Studies of Stuck Pipe and Lost Circulation (W.a. Nugroho, 2017)Daniel TobingPas encore d'évaluation

- Spe 135704 MS PDFDocument9 pagesSpe 135704 MS PDFKd FaPas encore d'évaluation

- Spe 128602 PDFDocument10 pagesSpe 128602 PDFDaniel DamboPas encore d'évaluation

- SPE-57390-Underbalance or Extreme OverbalanceDocument10 pagesSPE-57390-Underbalance or Extreme Overbalancecv sabiraPas encore d'évaluation

- Well Completion Maintenance Abandonment Guideline April Release2013Document82 pagesWell Completion Maintenance Abandonment Guideline April Release2013Mayur PatelPas encore d'évaluation

- 2008 IPTC Conference Preview FINALDocument72 pages2008 IPTC Conference Preview FINALHing Chai ShingPas encore d'évaluation

- Geokniga Wells1967 PDFDocument154 pagesGeokniga Wells1967 PDFDamiánVillegasPas encore d'évaluation

- SPE 29259 An Innovative Model For Drilling Fluid HydraulicsDocument17 pagesSPE 29259 An Innovative Model For Drilling Fluid HydraulicsmucoPas encore d'évaluation

- MarkZoback ShaleGas101Document93 pagesMarkZoback ShaleGas101Elan YogeswarenPas encore d'évaluation

- Cementing Solid Expendable TubularDocument2 pagesCementing Solid Expendable Tubularlone_PEPas encore d'évaluation

- DW2005 User GuideDocument699 pagesDW2005 User GuideRoninPas encore d'évaluation

- PtrE 521 - Lecture 6 - Horizontal and Multilateral WellsDocument116 pagesPtrE 521 - Lecture 6 - Horizontal and Multilateral WellsGhoulemEllah Haithem IfrenePas encore d'évaluation

- Sand Mass Prediction in A North Sea Reservoir PDFDocument9 pagesSand Mass Prediction in A North Sea Reservoir PDFViệt Toàn ĐỗPas encore d'évaluation

- THE TRANSPORT OF ATOMIC DEBRIS FROM OPERATION UPSHOT-KNOTHOLE - U.S. Atomic Energy CommissionDocument201 pagesTHE TRANSPORT OF ATOMIC DEBRIS FROM OPERATION UPSHOT-KNOTHOLE - U.S. Atomic Energy Commissionscribd3Pas encore d'évaluation

- DOE Gasification Program OverviewDocument148 pagesDOE Gasification Program OverviewJohn DalkiaPas encore d'évaluation

- Aceiteka Chem3.o 2023Document6 pagesAceiteka Chem3.o 2023EMMANUEL BIRUNGIPas encore d'évaluation

- DKK1413 - Chapter 04-1Document37 pagesDKK1413 - Chapter 04-1Salini ShaPas encore d'évaluation

- Describes The Pattern in The Data?: Diagnostic Test (Grade 5)Document5 pagesDescribes The Pattern in The Data?: Diagnostic Test (Grade 5)Kristine torresPas encore d'évaluation

- Nuflo 1502 Weco Union Liquid Turbine Flow Meter DatasheetDocument3 pagesNuflo 1502 Weco Union Liquid Turbine Flow Meter DatasheetPad TruPas encore d'évaluation

- Sambungan LasDocument30 pagesSambungan LasMei'o KuroPas encore d'évaluation

- Electro-Optic and Acousto-Optic Laser Beam ScannerDocument12 pagesElectro-Optic and Acousto-Optic Laser Beam ScannerJános OrbánPas encore d'évaluation

- Bond AngleDocument2 pagesBond AngleMadhukar Singh67% (3)

- Doe Nuclear Physics and Reactor Theory Volume 2 of 2 Doe-Hdbk-10191-93Document128 pagesDoe Nuclear Physics and Reactor Theory Volume 2 of 2 Doe-Hdbk-10191-93Titer100% (3)

- Heat Transfer IES GATE IAS 20 Years Question and Answers by S K MondalDocument115 pagesHeat Transfer IES GATE IAS 20 Years Question and Answers by S K Mondalraju100% (1)

- 7.4 Center of Mass Cog TorqueDocument7 pages7.4 Center of Mass Cog TorqueWong SunPas encore d'évaluation

- Lattice VibrationDocument21 pagesLattice VibrationPandu lal100% (1)

- Crouse Hinds Rs RSM Rss Junction Boxes Catalog PageDocument1 pageCrouse Hinds Rs RSM Rss Junction Boxes Catalog Pagejose luisPas encore d'évaluation

- Grasshoppers Vs Microgravity22Document13 pagesGrasshoppers Vs Microgravity22maryam nusirPas encore d'évaluation

- Experimental Investigation On Hybrid Fibre Reinforced Concrete by Partial Replacement of MDocument33 pagesExperimental Investigation On Hybrid Fibre Reinforced Concrete by Partial Replacement of MAarthiPas encore d'évaluation

- Lithium Battery Catalogue 10-03-2024Document7 pagesLithium Battery Catalogue 10-03-2024ASHUTOSH MOHAPATRA ROLL 24 VIPas encore d'évaluation

- Einstein, Perrin, and The Reality of Atoms PDFDocument4 pagesEinstein, Perrin, and The Reality of Atoms PDFDiego PachecoPas encore d'évaluation

- Polymers: Year 11 RevisionDocument11 pagesPolymers: Year 11 RevisionGanta BooomPas encore d'évaluation

- Overview of The Availability and Utilization of Kaolin As A Potential Raw Material in Chemicals & Drugs Formulation in NigeriaDocument6 pagesOverview of The Availability and Utilization of Kaolin As A Potential Raw Material in Chemicals & Drugs Formulation in Nigeriawilolud6720100% (1)

- Chapter+4+ +Imperfections+in+CrystalsDocument25 pagesChapter+4+ +Imperfections+in+Crystalspramod_kPas encore d'évaluation

- ELECTRICITY NotesDocument62 pagesELECTRICITY Notesmallikammu12Pas encore d'évaluation

- Silver: This Article Is About The Chemical Element. For The Use of Silver As A Medication, See - For Other Uses, SeeDocument4 pagesSilver: This Article Is About The Chemical Element. For The Use of Silver As A Medication, See - For Other Uses, SeeEllainePas encore d'évaluation

- Unit1 Mod 3 Group IV ElementsDocument9 pagesUnit1 Mod 3 Group IV ElementsNkemzi Elias NzetengenlePas encore d'évaluation

- Tds-Antifoam Ew Defoamer Saw 2510Document1 pageTds-Antifoam Ew Defoamer Saw 2510kokotampanPas encore d'évaluation

- SJPO Special Round 2011 Sample PDFDocument10 pagesSJPO Special Round 2011 Sample PDFziwei_from_chinaPas encore d'évaluation

- TECKA Air Cooled Screw Chiller (Heat Pump) Unit - Brochure TECKA202103Document10 pagesTECKA Air Cooled Screw Chiller (Heat Pump) Unit - Brochure TECKA202103Guvanch MuradowPas encore d'évaluation

- Chemis Chap 4 (f4)Document2 pagesChemis Chap 4 (f4)Kai YuanPas encore d'évaluation

- Module 5: Failure Criteria of Rock and Rock MassesDocument5 pagesModule 5: Failure Criteria of Rock and Rock Massesفردوس سليمانPas encore d'évaluation