Académique Documents

Professionnel Documents

Culture Documents

Motoranalyzer1: Universal Tester For Electric Motors and Windings

Transféré par

MohamedTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Motoranalyzer1: Universal Tester For Electric Motors and Windings

Transféré par

MohamedDroits d'auteur :

Formats disponibles

top100.de top100.

de

Top-Innovator Top-Innovator

2014 2016

top100.de

MotorAnalyzer1

Universal tester for electric motors and windings

Made in Germany Expect more.

1

EN Winding testers

The MotorAnalyzer1 – Surge voltage

High-voltage DC up to 4 kV

a universal tool

Insulation up to 100 GΩ

The MotorAnalyzer1 is a universal tester for testing electric motors

and windings. It combines 10 different test methods in a user-friendly

and mobile device. The combination of test methods, the compact ROBUST Resistance | 4-wire method

design and the battery operation make the MotorAnalyzer1 an ideal

tool for on-site use – even if the DUT is difficult to access. INDUSTRIAL Battery operation

For testing a three-phase motor, the three winding leads and the STANDARD Automatic switch-overs

motor frame are connected to the tester. With surge and resistance

test, the MotorAnalyzer1 now analyzes the motor fully automatically.

After that, a high-voltage test is performed at the motor, allowing to

Made in Germany

evaluate the motor in a fast and reliable manner.

KEY FACTS

• Ten test methods

• High-voltage up to 4000 V

• Fully-automatic fault analysis

• Automatic switch-over between the 3 motor-connection leads

• Manual and automatic tests

• Locating winding faults Delivery extent MotorAnalyzer1

• Working with AC power and/or battery power

• 9 test leads with alligator clip

• Light weight

• Test probe HV

• Rotary switch for a fast selection of test methods

• Test probe GND

• Integrated result storage for transmission via RS232 or

• External charger

USB interface

• Calibration certificate

• Storing and printing test results via PrintCom

• Operating manual

2 Further information: www.schleich.com/en/motoranalyzer1 3

Test methods

1 Automatic analysis 2 Surge test 3 Resistance test 4 4 High-voltage test DC 5 Polarization-index test 6 Insulation-resistance test

For the automatic test of a three-phase For inductive winding tests, the The resistance test is performed with high- For the high-voltage test, the For the DAR and polarization-index test, For the insulation-resistance test, the

motor, the three winding leads and the MotorAnalyzer1 generates low-level surge precision four-wire method. The symmetry MotorAnalyzer1 generates an extremely the MotorAnalyzer1 generates an stable MotorAnalyzer1 generates an extremely

motor frame are connected to the testing voltages. The patented, automatic surge evaluation of the three winding resistances stable test voltage between 50 and 4000 V extremely test voltage between 50 and stable test voltage between 50 and 4000 V

device. With surge and resistance test, the voltage comparison between the windings or the comparison to a default value is DC. The voltage is adjusted manually via 4000 V DC. The voltage is adjusted manually DC. The voltage is adjusted manually via

MotorAnalyzer1 now analyzes the motor or to a reference DUT delivers precise performed automatically. If required, a the rotary knob. Alternatively, it can be via the rotary knob. Alternatively, it can be the rotary knob. Alternatively, it can be

fully automatically. It is checked, whether information about the symmetry of the temperature compensation converts the automatically adjusted to a programmable automatically adjusted to a programmable automatically adjusted to a programmable

the winding is ohmic and inductively windings. Asymmetries are detected by copper resistance to 20° C/68° F. This value. value. value. A step voltage measurement is

symmetrical. If the deviations between the the MotorAnalyzer1 automatically. requires an additional ambient-temperature possible, as well.

three phases are too large, the motor is sensor.

defective.

7 PE/GB-resistance test 8 Neutral-zone adjustment 9 Rotary-field test at stators and motors 10 Detection of turn-to-turn faults

The PE/GB-resistance test is performed with Graphically displaying the incorrect position While turning the shaft of a single-phase At stators or armatures, you can locate the

DC and high-precision four-wire method. of the brush holder facilitates the adjustment or a three-phase motor manually, it is slots with turn-to-turn faults by means of an

of the ”neutral zone” at DC motors. The indicated, whether the operator turns the induction test probe. The probe also serves

MotorAnalyzer1 guarantees a user-friendly shaft to the right or to the left. Via a for detecting bar-to-bar faults at squirrel-

and comfortable adjustment. Via a bar chart rotary-field probe in the stator and with cage rotors.

with center, the operator can directly see, externally applied voltage, you can detect

whether the brush holder is in the “neutral the rotary field at a stator.

zone” respectively in which direction he

needs to turn it.

4 Weitere Informationen: www.schleich.com/de/motoranalyzer1 5

Test protocol with PrintCom7 KEY FACTS

• Customizable protocol with your company data and your logo

• Editable Excel® protocol forms

With the PrintCom7 software, you can export all test results from the number of forms that can easily be adapted. Of course, you can also • Representative test protocol with test values and graphics

MotorAnalyzer1 to a PC. The test results can be printed directly after create completely new protocols. • Printing on all Windows-compatible printers

the test or at a later time. • Creating PDF-files

PrintCom7 is the ideal tool for creating test protocols containing all • Test protocols in various languages

The test results are stored in Excel® format – based on Excel® necessary information in no time at all.

protocol forms preconfigured by us.

By adding additional information or through an individual design,

e.g. with your logo, PrintCom7 allows you to adapt the test protocol

to your requirements. The delivery extent already includes a large

Test protocol

Editable field with your company logo

and your address Your Logo

PrintCom RESULTS General motor data, date and time,

etc.

Overview of all test results

6 Further information: www.schleich.com/en/motoranalyzer1 7

Technical data Insulation resistance | PI & DAR

Test methods

insulation

resistance

KV

GΩ

Test voltage max. 4 kV

Surge voltage Test-voltage selection manual potentiometer 300 degrees

Test-voltage selection yes

surge voltage

Insulation resistance max. 100 GΩ

Accuracy

Test voltage 250 V < 500 kΩ without specification

Test voltage 12 V 500 kΩ to 200 MΩ ±5 %

Evaluations Correlation (SCHLEICH patent) 200 MΩ to 1 GΩ ±7.5 %

Display of deviations in % > 1 GΩ outside measuring range

Comparison method between the phases Test voltage 500 V < 500 kΩ without specification

Automatic switch-over of test connections yes 500 kΩ to 200 MΩ ±2.5 %

200 MΩ to 1 GΩ ±10 %

Resistance 1 GΩ to 10 GΩ ±25 %

10 GΩ to 20 GΩ ±50 %

resistance

> 20 GΩ outside measuring range

Ω

Test voltage 1000 V < 1 MΩ without specification

1 MΩ to 10 GΩ ±2.5 %

Measuring range 2 mΩ to 500 kΩ 10 GΩ to 50 MΩ ±30 %

Resolution 1 µΩ 50 GΩ to 100 MΩ ±50 %

Accuracy 1 mΩ - 499 kΩ ±0.5% of test value ±1digit > 100 MΩ outside measuring range

Display of deviations/asymmetries in % Test voltage 3000 V < 10 MΩ without specification

Comparison method between the phases 10 MΩ to 10 GΩ ±2.5 %

Test current max. 1A 10 GΩ to 50 GΩ ±20 %

Test time manual without test time 50 GΩ to 100 GΩ ±50 %

automatic cycle presettable > 100 GΩ outside measuring range

4-wire method yes Polarization index (PI) yes

Automatic switch-over of test connections yes Dielectric absorption ratio (DAR) yes

Temperature compensation to 20°C/68°F (25°C / 77°F) yes* Current max. 3 mA

Measurement between 2 test probes yes – up to 4 KV

* The ambient-temperature sensor needs to be ordered separately (part number 403109) With graphic progress display yes

Test time manual without test time

High-voltage DC automatic process presettable

high-voltage

DC

KV

mA

GΩ Technical data – testing device

Test voltage | measurement between two test probes max. 4 kV Line voltage external plug-in charger 230V or 110V

Current max. 1 mA Battery lead-acid 12 V, 1.2 Ah

Test time manual without test time Battery charging time 4 h, fully charged

automatic process presettable Battery operating time 0.5 to 4 h, depending on the tests

Interface RS232 / optional USB

Storage capacity 128 individual test values

Dimensions (W x D x H) 280 x 170 x 95 mm (11.0” x 6.7” x 3.7”)

Weight 2.7 kg (6 lbs)

8 Further information: www.schleich.com/en/motoranalyzer1 9

Accessories

Robust Kelvin clamps Start/Stop button for 4-wire test probes Rotary-field probe to measure the sense of rotation of stators

Robust 4-wire Kelvin clamps for Ideally suited for starting and The sense of rotation of a stator is

high-precision resistance tests stopping the test, while holding detected by means of a Hall rotary

both test probes. field probe. In the test field, the stator

is operated with a low rotary-field

voltage and the rotary-field probe is

placed in the stator to be tested.

Cable length 3.2 m

Cable length 3m

Part # 403111

Type small medium large Part # 403103

Opening width 10 mm 20 mm 33 mm Note: suitable for test probe 4000395.

Pressure force 20 N 30 N 100 N Motor-direction measuring lead

Induction probes for fault location

4-wire method yes yes yes

This connection lead is required to

Test lead pluggable yes yes yes 1 determine the direction of the motor.

Probe for testing stator and armature

The de-energized, assembled and

Dimensions (L x H x W) 90 x 35 x 13 mm 165 x 65 x 20 mm 255 x 95 x 25 mm windings according to the induction

connected 3-phase motor (squirrel-

method. The probes serve to locate

Part # 4023184 4023122 4023109 cage rotor) is connected to the tester

turn-to-turn faults.

and the motor shaft is turned by hand.

Note: the Kelvin clamps require additional connection leads. 2

Robust Kelvin clamp for the pins of terminal boards Set of Kelvin clamps Cable length 1.5 m

Part # 403112

Special Kelvin clamp for Set consisting of 3 Kelvin

clamps for high-precision 3

contacting terminal boards

resistance measurement incl. Foot switch for starting the test

connection cables – the set is

part of the delivery extent.

Pin diameter 4-10 mm 8-14 mm Slot distance 1 19 mm 2 9 mm flexible 3 9 mm

4-wire method yes yes Dimensions

Part # 40001182 40001183 (L x H x W) 130 x 30 x 25.5 mm 115 x 40 x 20 mm 120 x 20 x 25.5 mm

Note: the Kelvin clamps require additional connection leads. Cable length 3m 3m 3m

Part # 403107 403123 403106 Cable length 2m

Connection cables Cable length 1.1 m Part # 4010611

Opening width approx. 20 mm Neutral-zone measuring lead

Connection cable per

4-wire method yes Software

robust Kelvin clamp

Part # 40001100

PrintCom allows you to log and

store your test results in a fast and

convenient manner.

4-wire test probe

PrintCom RESULTS

Cable length 2m

Part # (1 piece) 403154

Part # 4018182

The connection cables can be plugged into the

Kelvin clamps (4023184, 4023122 and 4023109)! SCHLEICH.Care for service abroad

For testing, you require 3 connection cables. For high-precision resistance measurement, e.g. at DC-motor bars

Within Germany, our testers are delivered

To adjust the neutral zone of DC-motors, the field and the armature including a full warranty. With SCHLEICH.

Cable length 3m (the carbon brushes) are connected to the MotorAnalyzer. Care, you can get this full warranty also

Ambient-temperature sensor

The ”neutral zone” is adjusted by turning the brushes. worldwide!

Part # (1 piece) 4000395

Ambient-temperature

compensation for resistance test Type standard with booster for large sizes

Note: for testing, you require 2 four-wire test probes.

and insulation-resistance test Cable length 1.5 m 1.5 m SCHLEICH.Care | Europe Part # 403174

Part # 403102 403133 SCHLEICH.Care | Worldwide Part # 403175

Part # 403109

For our complete range of accessories, please check our website.

10 Further information: www.schleich.com/en/motoranalyzer1 11

Another word for “Made in Germany”: Service without limits.

SCHLEICH We are there for you – wherever you are.

First-class customer service is our top priority. From detailed

consulting during the planning phase to training and After-Sales-

Service – we support you during the entire process.

In training sessions adapted to your requirements, our technicians

will teach you the necessary know-how allowing you to avail

yourself of the functional variety of our testing devices to the full

extent. Should there be questions or technical problems, our

technical support team will assist you by phone, on-line or on-site

fast and reliably. Constant software updates and extensions make

sure that you can always work with state-of-the-art test software.

The periodic calibration of test equipment is an essential

precondition for quality assurance. We calibrate your test equipment

according to standards – on site or in our factory in Hemer. It goes

Extensive production facilities allow designing and manufacturing Modern high-end processors in our testers process the test tasks in without saying that we calibrate in accordance with national and

almost all tester components at our site in Hemer. a fast, precise and reliable manner. With our modern CNC-machines, international standards.

we also design and manufacture a great number of accessory

For example, our measuring and electronic PCBs are produced with components such as test covers, contacting units, workpiece Our Service Centers support you aroundthe world –

an ultra-modern in-line-SMD-placement system, which assures a carriers with DUT-holders or robot gripping tools as well as complete with dedication, competence and reliability.

stable quality of our products. automatic production lines.

Whatever you want to test… Sales and Service Centers

…SCHLEICH has the solution!

SCHLEICH is a leading system provider in the area of testing motors Every single one of our more than 120 employees works on

and windings. Our extensive range of products allows us to provide guaranteeing and optimizing the high quality standard of our testing

you with testers, test systems and complete production lines for devices each and every day. Our customers, our sales department,

almost every test task. our motivated engineers and manufacturing staff – with infinite

curiosity, new ideas and suggestions for improvement they are all

Decades of experience, listening to our customers and satisfying part of the innovation process.

their wishes – facing individual tasks with technical creativity and

realize them in a team of highly skilled engineers and designers –

this is what we do. This is SCHLEICH.

Production, Headquarters & Sales Center Germany

Sales and Service Centers

Sales Centers

MotorAnalyzer2 Surge tester MTC2 EncoderAnalyzer Dynamic-MotorAnalyzer

12 Further information: www.schleich.com/en/motoranalyzer1 13

Experts in tests and measurements.

Whatever you want to test, SCHLEICH has the solution! As a leading supplier of electric safety and function test systems as well as motor and

winding testers, we offer solutions for any task in this sector. Our owner-managed company, founded more than 50 years ago, is present in

over 40 markets all around the globe.

Testers for electric

electric motors

motorsand

andwindings

windings

Safety andsafety-

Electrical function

andtesters

function testers

Subject to technical modifications and errors. | 0917-EN

SCHLEICH GmbH Presented by:

An der Schleuse 11

58675 Hemer | Germany

Phone +49 (0) 2372 9498-9498

Fax +49 (0) 2372 9498-99

info@schleich.com

www.schleich.com

Expect more.

Certified Quality Management ISO 9001 www.abstrakt-werbung.de

Vous aimerez peut-être aussi

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaD'EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaPas encore d'évaluation

- Testers For Electric Motors and All Kinds of Windings: Product GuideDocument29 pagesTesters For Electric Motors and All Kinds of Windings: Product GuideMohamedPas encore d'évaluation

- Manual Mas345Document31 pagesManual Mas345Eibar016Pas encore d'évaluation

- Probador de Fase y Rotación de MotorDocument32 pagesProbador de Fase y Rotación de Motornatsumyortiz02Pas encore d'évaluation

- Brochure MotorAnalyzer2Document3 pagesBrochure MotorAnalyzer2Carlos Sanchez UstarezPas encore d'évaluation

- 2018 Vanguard Doble Condensed Catalog Rev. IDocument12 pages2018 Vanguard Doble Condensed Catalog Rev. ImanishPas encore d'évaluation

- Multi Amp 830280 TransformerDocument3 pagesMulti Amp 830280 TransformerJonathan LayedraPas encore d'évaluation

- Testing MotorsDocument5 pagesTesting Motors123peniscolaPas encore d'évaluation

- Asim4k0r True Rms 4000 Count Digital Multimeter ManualDocument18 pagesAsim4k0r True Rms 4000 Count Digital Multimeter Manualbalcar amilcarPas encore d'évaluation

- Electrical Test & Measurement Power Product Catalog: Next Generation of Testing TechnologyDocument19 pagesElectrical Test & Measurement Power Product Catalog: Next Generation of Testing TechnologyWilliam RaicoPas encore d'évaluation

- Scribed 4Document3 pagesScribed 4zayed shbanPas encore d'évaluation

- Scientech 2708Document40 pagesScientech 2708sarikapravinPas encore d'évaluation

- KT62 ManualDocument30 pagesKT62 ManualandyjwatsonPas encore d'évaluation

- MSG Catalogue Equipment 2023 EU WebDocument54 pagesMSG Catalogue Equipment 2023 EU WebSergio ZamoranoPas encore d'évaluation

- Manual Megger MJ159Document16 pagesManual Megger MJ159Patricia NaranjoPas encore d'évaluation

- Engine & Compressor Diagnostic ServicesDocument2 pagesEngine & Compressor Diagnostic ServicesJose RattiaPas encore d'évaluation

- Sotcher 568 Users ManualDocument12 pagesSotcher 568 Users ManualVadim RiabovPas encore d'évaluation

- MECH Lab RequirementDocument4 pagesMECH Lab RequirementJaishree ChauhanPas encore d'évaluation

- MU PHENIX LD60 Rev1Document17 pagesMU PHENIX LD60 Rev1soporte.widaggPas encore d'évaluation

- Danger Warning Caution: Safety InformationDocument7 pagesDanger Warning Caution: Safety InformationcombaheePas encore d'évaluation

- LC 103Document2 pagesLC 103serddsPas encore d'évaluation

- 02-Relay Operating PrinciplesDocument36 pages02-Relay Operating Principlesfdsfs2131Pas encore d'évaluation

- Factory Test Off Meduim VoltageDocument6 pagesFactory Test Off Meduim Voltagem khPas encore d'évaluation

- 670-675 enDocument32 pages670-675 enWalter EguizabalPas encore d'évaluation

- tkf13 Insobs v1 5 AngDocument9 pagestkf13 Insobs v1 5 AngplennyPas encore d'évaluation

- Testing Teccor Semiconductor Devices Using Curve TracersDocument20 pagesTesting Teccor Semiconductor Devices Using Curve TracersSajjad4434100% (1)

- Measuring Tools PresentationDocument10 pagesMeasuring Tools PresentationKATHLEEN CAMIGUINGPas encore d'évaluation

- Report Multimeter and OsiloskopDocument13 pagesReport Multimeter and OsiloskopFadly ShafiqPas encore d'évaluation

- Universal Test System: Model: L336iDocument4 pagesUniversal Test System: Model: L336iBaballPas encore d'évaluation

- Manual Telurometro Metrel 1Document50 pagesManual Telurometro Metrel 1jcramirezaPas encore d'évaluation

- All-Test Iv Pro: Motor Circuit AnalyzerDocument6 pagesAll-Test Iv Pro: Motor Circuit AnalyzerJorge Luis Torrico CalatayudPas encore d'évaluation

- General: Design Guidelines Technical Sections: All U-M Master Specifications: AllDocument7 pagesGeneral: Design Guidelines Technical Sections: All U-M Master Specifications: Allnadeem UddinPas encore d'évaluation

- Manual Ludlums 14CDocument38 pagesManual Ludlums 14CJhon Fredy Santos TovarPas encore d'évaluation

- OdlicnoDocument90 pagesOdlicnoJozo ĆurčićPas encore d'évaluation

- Agilent 4339B DatasheetDocument9 pagesAgilent 4339B Datasheetajaydce05Pas encore d'évaluation

- Lancol User Manual Micro 300Document4 pagesLancol User Manual Micro 300nery1automaticosPas encore d'évaluation

- Multimetro - FIX 7665 Bosch Manual PDFDocument104 pagesMultimetro - FIX 7665 Bosch Manual PDFAbraham Lozada67% (3)

- Rev A SmallDocument35 pagesRev A SmallMax TerlPas encore d'évaluation

- Diagnostic of Broken Bars by MCSA MethodDocument3 pagesDiagnostic of Broken Bars by MCSA MethodIvan GomezPas encore d'évaluation

- Anita Halliday - Workshop PresentationDocument11 pagesAnita Halliday - Workshop PresentationIsaac DanielPas encore d'évaluation

- EDOC-Transformer Diagnostics and Condition AssessmentDocument16 pagesEDOC-Transformer Diagnostics and Condition AssessmentEl Comedor Benedict100% (1)

- Baker ST112A-ST106A-ST103A DatasheetDocument2 pagesBaker ST112A-ST106A-ST103A DatasheetJose LiraPas encore d'évaluation

- 08 Generator Protection For TechniciansDocument38 pages08 Generator Protection For Techniciansmiremad kochakiPas encore d'évaluation

- Manual DMM PDFDocument13 pagesManual DMM PDFMujtabaAliPas encore d'évaluation

- KEP Catalog 2016 v1.0 enDocument32 pagesKEP Catalog 2016 v1.0 enXuân Tấn TrầnPas encore d'évaluation

- All Test Procedures (31121016-000-Gap-00023-000)Document155 pagesAll Test Procedures (31121016-000-Gap-00023-000)Zeeshan Hashmi100% (1)

- Spindle Motor Troubleshooting GuideDocument7 pagesSpindle Motor Troubleshooting GuideIsrael Martinez AlonsoPas encore d'évaluation

- Modern Testing On Motors 07.02.2018Document70 pagesModern Testing On Motors 07.02.2018Vivek Vous Aime100% (1)

- Low Resistance Ohmmeter: Ducter D007Document2 pagesLow Resistance Ohmmeter: Ducter D007Vikaas JainPas encore d'évaluation

- Yx 360 TRDocument14 pagesYx 360 TRNovian ArmaPas encore d'évaluation

- SOP ElectrocardiographsDocument7 pagesSOP ElectrocardiographsDodik E. PrasetyoPas encore d'évaluation

- Instruction Manual: NCTP9511 I-V Curve Tracer ProbeDocument10 pagesInstruction Manual: NCTP9511 I-V Curve Tracer ProbeVenera Segunda ManoPas encore d'évaluation

- Power Probe PP401AS User ManualDocument28 pagesPower Probe PP401AS User ManualJulio César LugoPas encore d'évaluation

- Agilent 4339B/4349B High Resistance Meters: Technical OverviewDocument8 pagesAgilent 4339B/4349B High Resistance Meters: Technical Overview彭以和Pas encore d'évaluation

- Common Rail Engine Diagnostic/Repair Kit: Tier Ii CompliantDocument14 pagesCommon Rail Engine Diagnostic/Repair Kit: Tier Ii CompliantYamil AguilarPas encore d'évaluation

- Manual Multi Amp1Document64 pagesManual Multi Amp1Argenis OrtizPas encore d'évaluation

- Tips 2plus InglesDocument11 pagesTips 2plus InglesGonçalo Casanova Costa PintoPas encore d'évaluation

- Sverker 900: Relay and Substation Test SystemDocument7 pagesSverker 900: Relay and Substation Test SystemchinnathambijPas encore d'évaluation

- Op Amps: Design, Application, and TroubleshootingD'EverandOp Amps: Design, Application, and TroubleshootingÉvaluation : 5 sur 5 étoiles5/5 (2)

- Overhead Set (OBC)Document19 pagesOverhead Set (OBC)MohamedPas encore d'évaluation

- Manual For Siemens PLC From HamitiDocument314 pagesManual For Siemens PLC From HamitiHAMIT91% (22)

- Linear Measuring Technology: Compact MWE21Document5 pagesLinear Measuring Technology: Compact MWE21MohamedPas encore d'évaluation

- Wave Washer: Material and HardnessDocument1 pageWave Washer: Material and HardnessMohamedPas encore d'évaluation

- Process Controllers: AC DCDocument5 pagesProcess Controllers: AC DCMohamedPas encore d'évaluation

- Draught Sensor DatasheetDocument4 pagesDraught Sensor DatasheetMohamedPas encore d'évaluation

- 252 Ai Hydraulic Gear Pump and Motor Failure Analysis Repair Guide 9-23-16Document32 pages252 Ai Hydraulic Gear Pump and Motor Failure Analysis Repair Guide 9-23-16Radha Raman YadavPas encore d'évaluation

- Huade CatalougeDocument632 pagesHuade CatalougeMohamedPas encore d'évaluation

- Digital Electronic Thermometer: IndexDocument8 pagesDigital Electronic Thermometer: IndexMohamedPas encore d'évaluation

- 26 - Moduflow Plus SeriesDocument16 pages26 - Moduflow Plus SeriesMohamedPas encore d'évaluation

- Industrial Training Template BasicsDocument65 pagesIndustrial Training Template BasicsFaiz IbrahimPas encore d'évaluation

- Features: Lead Free Finish, Rohs Compliant (Note 3)Document4 pagesFeatures: Lead Free Finish, Rohs Compliant (Note 3)MohamedPas encore d'évaluation

- CELmar3 2Document2 pagesCELmar3 2MohamedPas encore d'évaluation

- Vescor Tank Magnets Pay Off For YouDocument2 pagesVescor Tank Magnets Pay Off For YouMohamedPas encore d'évaluation

- Lube Filter Fuel Filter Water Filter Crankcase Ventilation Bypass Oil Filter Stage 1 Fuel Current Current Current Current CurrentDocument2 pagesLube Filter Fuel Filter Water Filter Crankcase Ventilation Bypass Oil Filter Stage 1 Fuel Current Current Current Current CurrentMohamedPas encore d'évaluation

- Industrial Training Template BasicsDocument65 pagesIndustrial Training Template BasicsFaiz IbrahimPas encore d'évaluation

- Vescor Tank Magnets Pay Off For YouDocument2 pagesVescor Tank Magnets Pay Off For YouMohamedPas encore d'évaluation

- Fleetguard Technical Information Catalog Fuel Filtration PDFDocument116 pagesFleetguard Technical Information Catalog Fuel Filtration PDFabelmonte_geotecniaPas encore d'évaluation

- DS STG 16-30-40 3090-4090 Actuator With Gear eDocument2 pagesDS STG 16-30-40 3090-4090 Actuator With Gear eBenArdan100% (1)

- DS LA-25!30!35 Linear-Actuators eDocument2 pagesDS LA-25!30!35 Linear-Actuators eMohamedPas encore d'évaluation

- Damen Cutter Suction DredgersDocument21 pagesDamen Cutter Suction DredgersMohamedPas encore d'évaluation

- Electric Cutter Suction DredgerDocument2 pagesElectric Cutter Suction DredgerMohamed ElsayedPas encore d'évaluation

- Diode IN5408 Data SheetDocument4 pagesDiode IN5408 Data SheetSuresh Kumar100% (1)

- DS LA-25!30!35 Linear-Actuators eDocument2 pagesDS LA-25!30!35 Linear-Actuators eMohamedPas encore d'évaluation

- 225 Series: Electrical ActuatorDocument7 pages225 Series: Electrical ActuatorMohamedPas encore d'évaluation

- Damen Cutter Suction DredgersDocument21 pagesDamen Cutter Suction DredgersMohamedPas encore d'évaluation

- FOLIO 07580: Damen Cutter Suction Dredger 450 - NewDocument3 pagesFOLIO 07580: Damen Cutter Suction Dredger 450 - NewMohamedPas encore d'évaluation

- True RMS 3-Phase Voltage and Frequency Monitoring Relay: BenefitsDocument11 pagesTrue RMS 3-Phase Voltage and Frequency Monitoring Relay: BenefitsMohamedPas encore d'évaluation

- Celmar 2-3: VHF Marine AntennaDocument1 pageCelmar 2-3: VHF Marine AntennaMohamedPas encore d'évaluation

- DPC02DM44: True RMS 3-Phase Voltage and Frequency Monitoring RelayDocument10 pagesDPC02DM44: True RMS 3-Phase Voltage and Frequency Monitoring RelayMohamedPas encore d'évaluation

- Any Questions?: Bibita Nicolae 1 Brecon Way High WycombeDocument4 pagesAny Questions?: Bibita Nicolae 1 Brecon Way High WycombeKalo LnxPas encore d'évaluation

- Solve The Five Most Common FCC ProblemsDocument21 pagesSolve The Five Most Common FCC ProblemsOMID464Pas encore d'évaluation

- 2023 Q4 Industrial Houston Report ColliersDocument6 pages2023 Q4 Industrial Houston Report ColliersKevin ParkerPas encore d'évaluation

- Tata Power HistoryDocument14 pagesTata Power Historyvinit2801Pas encore d'évaluation

- Problems and SolutionsDocument14 pagesProblems and SolutionsAsif Iqbal DawarPas encore d'évaluation

- ESPC GuideDocument223 pagesESPC GuidejoechengshPas encore d'évaluation

- Cutler Hammer Dry Type TransformerDocument220 pagesCutler Hammer Dry Type TransformernprajanPas encore d'évaluation

- MotorisedValves DS 27100 ENDocument2 pagesMotorisedValves DS 27100 ENsledgehammerPas encore d'évaluation

- Twin LoopDocument5 pagesTwin LoopBalbalaManiuk100% (1)

- 1410080-5 HP Floating AeratorDocument12 pages1410080-5 HP Floating AeratorAbhinav SrivastavaPas encore d'évaluation

- Adani Group PresentationDocument21 pagesAdani Group PresentationMayank Ranjan0% (1)

- Poster 'I Want To Be ' - Rev0Document4 pagesPoster 'I Want To Be ' - Rev0hafizahmad84Pas encore d'évaluation

- Rpvi Slide 180319Document6 pagesRpvi Slide 180319Siti Dhamirah 'IzzatiPas encore d'évaluation

- Global Beta CoeffitientsDocument4 pagesGlobal Beta CoeffitientsAnonymous xv5fUs4AvPas encore d'évaluation

- LithiumBattery EnglishDocument7 pagesLithiumBattery EnglishgojarooPas encore d'évaluation

- Res 18 S 2005 PDFDocument2 pagesRes 18 S 2005 PDFJopan SJPas encore d'évaluation

- Power Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Document46 pagesPower Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Kimeli KiptanuiPas encore d'évaluation

- Stirlings Fittings CatalogueDocument108 pagesStirlings Fittings CatalogueJúlio HenriquesPas encore d'évaluation

- Presentation-Crude Oil Pricing PakistanDocument7 pagesPresentation-Crude Oil Pricing PakistanMuhammad NaeemPas encore d'évaluation

- Comparison of Calculation Standards of NGL and LPGDocument22 pagesComparison of Calculation Standards of NGL and LPGmotaleby100% (1)

- Smart (R) Electronic Watt-Hour MetersDocument12 pagesSmart (R) Electronic Watt-Hour MetersmdaveryPas encore d'évaluation

- Presentation FINAL - ReadyDocument40 pagesPresentation FINAL - ReadyAsim RiazPas encore d'évaluation

- Annual Report 2022Document90 pagesAnnual Report 2022Kevin ParkerPas encore d'évaluation

- Lecture 4 Pumps Pumping SystemsDocument42 pagesLecture 4 Pumps Pumping SystemsKeith Tanaka MagakaPas encore d'évaluation

- Hyosung PlanetDocument8 pagesHyosung PlanetErcan BAYRAKCIPas encore d'évaluation

- Smart Grid and Energy Management PDFDocument19 pagesSmart Grid and Energy Management PDFEng_Mennat_AllahPas encore d'évaluation

- Gilian Operating ManualDocument37 pagesGilian Operating ManualMatthew KingPas encore d'évaluation

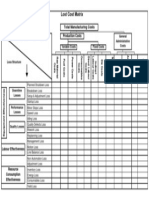

- Lost Cost Matrix: Total Manufacturing CostsDocument1 pageLost Cost Matrix: Total Manufacturing CostsMadhan KumarPas encore d'évaluation

- Hyd Actua Device070110 1Document6 pagesHyd Actua Device070110 1Ashish SinglaPas encore d'évaluation

- Turnover More Then 10 Crores1Document8 pagesTurnover More Then 10 Crores1tejasPas encore d'évaluation