Académique Documents

Professionnel Documents

Culture Documents

Stanadyne de Pump Timing Instructions

Transféré par

konstantin chekanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Stanadyne de Pump Timing Instructions

Transféré par

konstantin chekanDroits d'auteur :

Formats disponibles

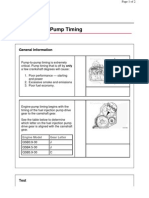

Pump / Engine Timing Kit

P/N 40572

IMPORTANT: Complete installation instructions including requirements for safety, cleanliness

and environmental awareness are contained in the John Deere Technical Manual for 4.5L & 6.5L

PowerTech® Engines with DE Electronic Fuel Injection (John Deere P/N CTM331).

Timing Kit Contents: Torque Values:

40610 DE Pump Timing Pin Injection Pump Mounting Stud Nut 19 lb-ft (25 N•m)

40571 Engine Timing Pin Injection Pump Drive Gear Nut 145 lb-ft (195 N•m)

13324 1/4” Hex Key Wrench Injection Pump Timing Pin Plug 7.5 lb-ft (9.5 N•m)

Pump Installation:

1. Position the engine crankshaft so number one Flywheel Timing Flywheel

Pin Hole Housing

cylinder is at TDC on the compression stroke.

Insert the Engine Timing Pin (P/N 40571) thru the Engine Timing Pin

hole in the flywheel housing and engage the pin (P/N 40571)

in the flywheel (Figure 1).

Figure 1 Engine Block

2. Using the included 1/4” Hex Key Wrench (P/N

13324), remove the timing hole plug on the top of

the fuel injection pump (Figure 2).

Timing Hole Plug

3. Insert the Pump Timing Pin (P/N 40610) into the 75-100 lbf.-in. (8-11 N•m) Top of Pump

hole (Figure 3a) and rotate the pump’s drive shaft

until the pin indexes in the internal drive shaft Use 1/4” Hex Key Wrench

slot. Leave the pump timing pin in the pump until (P/N 13324)

installation is complete. NOTE: A small punch

Figure 2

may be temporarily inserted into the small hole in

the drive shaft taper to facilitate shaft rotation

(Figure 3b).

Pump Timing Pin

3. Ensure the pump’s flange seal is in place and (P/N 40610)

that the drive shaft and mating surfaces are clean

and dry. Carefully insert the injection pump drive Pump Mounting Nuts (3)

shaft into the drive gear and guide the housing 19 lbf.-ft. (25 N•m)

flange onto the three mounting studs. Install

washers and nuts then tighten the nuts evenly to Figure 3a

19 lbf-ft. (25 N•m).

4. Install the drive gear retaining nut and washer Use a Small Punch in

(Figure 4). Do not tighten the nut at this time. this Hole to Rotate

Drive Shaft

5. Rotate the crankshaft counterclockwise (as

viewed from the front of the engine) to remove

Figure 3b

gear backlash*. Tighten the gear retaining nut to

145 lbf-ft (195 N•m).

*IMPORTANT: Gear backlash can cause the

injection timing to be off by as much as several Injection Pump

Drive Gear Access Hole

degrees resulting in poor engine performance.

Retaining Nut

6. Install the injection pump drive gear access 145 lbf.-ft. (195 N•m)

cover. Remove the engine timing pin (P/N 40571)

from the flywheel and remove the pump timing Injection Pump

pin (P/N 40610) from the pump. Install the timing Drive Gear

hole plug (Figure 2) and tighten to 75-100 lbf.-in. Figure 4

(8-11 N•m).

99864 Printed in U.S.A. www.stanadyne.com Rev. 11/09

Vous aimerez peut-être aussi

- John Deere Fuel Injection Pump Repair & InstallationDocument8 pagesJohn Deere Fuel Injection Pump Repair & Installationjohncouey67% (6)

- Stanadyne de Pump Timing InstructionsDocument1 pageStanadyne de Pump Timing InstructionsPiotr Kowal100% (5)

- PDFDocument60 pagesPDFAdolfo Moscoso100% (1)

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Anderson BombistaPas encore d'évaluation

- 2011-03-13 134535 New Opendocument TextDocument5 pages2011-03-13 134535 New Opendocument TextUriel MFPas encore d'évaluation

- Rebuild StanadyneDocument4 pagesRebuild StanadyneKevin TtitoPas encore d'évaluation

- Delphi E1 Diesel Electronic Unit Injector: BenefitsDocument2 pagesDelphi E1 Diesel Electronic Unit Injector: BenefitsRicardo Urio100% (1)

- Part 1 StanadyneDocument168 pagesPart 1 Stanadynemike leveck80% (5)

- DYNA102 Stanadyne PumpDocument4 pagesDYNA102 Stanadyne Pumpanurag_pai_1100% (3)

- Workshoo Stanadyne 05872Document4 pagesWorkshoo Stanadyne 05872Kevin TtitoPas encore d'évaluation

- Stanadyne Service Tool ManualDocument19 pagesStanadyne Service Tool ManualAnderson BombistaPas encore d'évaluation

- Fuel Injection Pump Data SCANIA DC9Document2 pagesFuel Injection Pump Data SCANIA DC9Mateen Younas100% (1)

- Gov Mec - WSM - 0001158 - 01Document36 pagesGov Mec - WSM - 0001158 - 01ARY TOGINHO100% (7)

- Yanmar 3Document2 327 pagesYanmar 3LUIS SAENZ100% (1)

- Simens VDO K16 Pump Reman Line Preliminary Plan v1.0Document8 pagesSimens VDO K16 Pump Reman Line Preliminary Plan v1.0安靖Pas encore d'évaluation

- CAT 3306B InstructionsDocument2 pagesCAT 3306B Instructionsdoriam140575% (4)

- John Deere Fuel Injection Pump Repair & Installation PDFDocument8 pagesJohn Deere Fuel Injection Pump Repair & Installation PDFscheisshandy33% (3)

- Mot 3412 HeuiDocument28 pagesMot 3412 HeuiMamadou DiaPas encore d'évaluation

- Plano de Teste DB 2435-5686 John Deere 5425Document4 pagesPlano de Teste DB 2435-5686 John Deere 5425GiovaniBalzani100% (1)

- Dpa Pump Delphi PDFDocument127 pagesDpa Pump Delphi PDFasadiqbalansari100% (8)

- Bomba Stanadyne John DeereDocument60 pagesBomba Stanadyne John Deereyamilmr100% (16)

- EU/5/2360 Test PlanDocument2 pagesEU/5/2360 Test PlanOseasJuniorPas encore d'évaluation

- Delphi Katalog Duesen PDFDocument373 pagesDelphi Katalog Duesen PDFDavid Lincoln83% (6)

- New Scroll - IntroducciónDocument9 pagesNew Scroll - IntroducciónNicole SmithPas encore d'évaluation

- Inj - Pump Calibration Data: DaewooDocument1 pageInj - Pump Calibration Data: DaewooЕвгений АбрамовPas encore d'évaluation

- Instalacion Bomba Delphi DP210Document3 pagesInstalacion Bomba Delphi DP210Martina FambPas encore d'évaluation

- Caterpillar Parts CatalogueDocument20 pagesCaterpillar Parts CataloguejosePas encore d'évaluation

- Link - Delphi Dp210 ManualDocument5 pagesLink - Delphi Dp210 Manualexpert mecha50% (2)

- Delphi DP210 Fuel Injection Pump CatDocument3 pagesDelphi DP210 Fuel Injection Pump CatSilas F Pimenta89% (19)

- Cat Injector and Pump Product ListDocument10 pagesCat Injector and Pump Product Listhklocker100% (3)

- lt1000d6 PDFDocument3 pageslt1000d6 PDFJo Ferry0% (1)

- Delphi TrimCodePresentation PDFDocument27 pagesDelphi TrimCodePresentation PDFEdivaldoVeronesePas encore d'évaluation

- db4429 5514Document4 pagesdb4429 5514WillianPachecoPas encore d'évaluation

- CAT C7 C9 HEUI CatalogueDocument24 pagesCAT C7 C9 HEUI CatalogueDodik Cahyono100% (2)

- Engine Number Guide: Engines 2 Litre/cylinderDocument6 pagesEngine Number Guide: Engines 2 Litre/cylinderHeri PurnadiPas encore d'évaluation

- Catalog 2019 Jyhy DieselDocument10 pagesCatalog 2019 Jyhy DieselAndre vatar andrePas encore d'évaluation

- Herramientas Bombas Rotativas 2016 PDFDocument48 pagesHerramientas Bombas Rotativas 2016 PDFMynor Witt100% (1)

- Injection Pump Removal Installation Timing AdjustmentDocument5 pagesInjection Pump Removal Installation Timing AdjustmentMimmo LeonePas encore d'évaluation

- 001-05a Merlin Equipment and Accessories Catalogue 0810 - WEB 0311Document173 pages001-05a Merlin Equipment and Accessories Catalogue 0810 - WEB 0311Aspro Brazil Se IglesiasPas encore d'évaluation

- Injetor HR 28229873 IiDocument65 pagesInjetor HR 28229873 IiLider Com.Manutenção em bombas Injetoras Ltda100% (1)

- Alliant Power HEUI Injector Application GuideDocument4 pagesAlliant Power HEUI Injector Application GuideUliAlejandroRodriguezCorianga100% (1)

- Jcb444 SD SF Oct10Document31 pagesJcb444 SD SF Oct10MACHINERY101GEAR100% (2)

- All Injector Pump List PDFDocument13 pagesAll Injector Pump List PDFLakbirPas encore d'évaluation

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Kevin TtitoPas encore d'évaluation

- 216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 15 UBA PDFDocument6 pages216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 15 UBA PDFubaldo caraballoPas encore d'évaluation

- PRD Spec 2 5Document6 pagesPRD Spec 2 5Cesar Orlando Laura AlipazPas encore d'évaluation

- Zexel Calib PDFDocument11 pagesZexel Calib PDFduongbk24 luu quang duong100% (1)

- Electronic Unit Injector - Install: C6.6 Industrial EngineDocument13 pagesElectronic Unit Injector - Install: C6.6 Industrial EngineBassiePas encore d'évaluation

- Fuel Injection Pump Concerns Gen207E1Document2 pagesFuel Injection Pump Concerns Gen207E1Md ShPas encore d'évaluation

- Timig VP30 44 BoschDocument2 pagesTimig VP30 44 BoschGilberto Nunes Dualdo Junior100% (5)

- RepairStats NEF67 MechEngines Mar05 PDFDocument20 pagesRepairStats NEF67 MechEngines Mar05 PDFpckey100% (1)

- 001-04 Merlin Equipment and Accessories Catalogue 0810 - On Web 0211Document173 pages001-04 Merlin Equipment and Accessories Catalogue 0810 - On Web 0211kampeePas encore d'évaluation

- HX Service Data Sheet, TurboDocument17 pagesHX Service Data Sheet, TurboghostrpgPas encore d'évaluation

- Stanadyne de Pump Timing Instructions PDFDocument1 pageStanadyne de Pump Timing Instructions PDFSMITIPas encore d'évaluation

- Dokumen - Tips - John Deere Powertech 68l Diesel Engines Mechanical Fuel Systems Component Service Repair Technical Manual ctm207Document15 pagesDokumen - Tips - John Deere Powertech 68l Diesel Engines Mechanical Fuel Systems Component Service Repair Technical Manual ctm207Valeriy Valkovets100% (1)

- Install Fuel Injection Pump Housing StepsDocument4 pagesInstall Fuel Injection Pump Housing StepsLeonardo Alca QuispePas encore d'évaluation

- 3208 Pump Install Timing InstructionsDocument4 pages3208 Pump Install Timing Instructionsshinichie100% (3)

- Seal Kit Assembly Instructions For Coolant Pumps: U4814, U4816, U4817 and U4851Document2 pagesSeal Kit Assembly Instructions For Coolant Pumps: U4814, U4816, U4817 and U4851andrzejPas encore d'évaluation

- Fuel Injection Pump Timing - AdjustDocument6 pagesFuel Injection Pump Timing - AdjustRonald Yucra Cadena100% (2)

- Fuel Injection Pump Install DelphiDocument5 pagesFuel Injection Pump Install DelphiKhalid El SabroutyPas encore d'évaluation

- Piezo Injector For Common-Rail Systems: Low Fuel ConsumptionDocument1 pagePiezo Injector For Common-Rail Systems: Low Fuel Consumptionalmia tronicsPas encore d'évaluation

- Mahindra New Price List 22.2.2014Document113 pagesMahindra New Price List 22.2.2014Satya Magoo100% (3)

- Wartsila InglesDocument448 pagesWartsila InglesMendez Francisco83% (6)

- Ford Transit 2.4 Tdci Engine Specifications & ProblemsDocument4 pagesFord Transit 2.4 Tdci Engine Specifications & ProblemsCallum Smith43% (14)

- Admin Uploads Documentos Catalogo Cb110 1317759355Document103 pagesAdmin Uploads Documentos Catalogo Cb110 1317759355Olivia White100% (1)

- What is a Piston? The Moving Component in Engines and PumpsDocument1 pageWhat is a Piston? The Moving Component in Engines and PumpsJomariBobadillaPas encore d'évaluation

- Nissan M9R: ManufacturerDocument79 pagesNissan M9R: ManufacturerJAHID HOSSAINPas encore d'évaluation

- New Beetle 2.5L 2010Document116 pagesNew Beetle 2.5L 2010Luis Ramon Arguello RealPas encore d'évaluation

- Bme NotesDocument44 pagesBme Notestempoterrace2306Pas encore d'évaluation

- TM0080 PDFDocument1 pageTM0080 PDFKo NgelayPas encore d'évaluation

- ECM Daewoo NubiraDocument5 pagesECM Daewoo Nubirawnsd90% (10)

- 570T Parts CatalogDocument690 pages570T Parts CatalogMOTOR POOLPas encore d'évaluation

- 3 AVANZA Starting System ComponentsDocument1 page3 AVANZA Starting System Componentsaritw541214Pas encore d'évaluation

- Ub125nmm3 (Mb8ea11dhn) Ub125nmum3 (Mb8ea11dhn)Document100 pagesUb125nmm3 (Mb8ea11dhn) Ub125nmum3 (Mb8ea11dhn)surojit karmakarPas encore d'évaluation

- Cylinder Head Overhaul ReportDocument2 pagesCylinder Head Overhaul ReporttomiPas encore d'évaluation

- Cummins C-Series Engine Torque SpecificationsDocument4 pagesCummins C-Series Engine Torque Specificationsheni50% (2)

- Pai Industries, Inc Inframe Kit n14Document1 pagePai Industries, Inc Inframe Kit n14Eduardo SantanaPas encore d'évaluation

- Katalog 150AET-175AET-200AET-L150AET-L200AET 08Document75 pagesKatalog 150AET-175AET-200AET-L150AET-L200AET 08JONI JONIPas encore d'évaluation

- 2 0 Tdi SSPDocument90 pages2 0 Tdi SSPmicol53100% (1)

- Gasoline Engine Management SystemsDocument1 pageGasoline Engine Management SystemsJustas PetkeviciusPas encore d'évaluation

- Cummins Spare PartsDocument17 pagesCummins Spare PartsAHMED TAHAPas encore d'évaluation

- D20 25 30 33 35NX (M) - Sb1284eDocument563 pagesD20 25 30 33 35NX (M) - Sb1284eYuda Pratama100% (1)

- Train SLK r171 IntroDocument98 pagesTrain SLK r171 IntroIvo AlmeidaPas encore d'évaluation

- Business Portal Online Print 27-10-2020Document139 pagesBusiness Portal Online Print 27-10-2020sxturboPas encore d'évaluation

- WSM M5071N, M5091N, M5101N EngDocument962 pagesWSM M5071N, M5091N, M5101N EngGabriel GrazielaPas encore d'évaluation

- 2.engine Fuel SystemDocument16 pages2.engine Fuel SystemSoeAyePas encore d'évaluation

- CDS PB 840, 844D #6800253Document324 pagesCDS PB 840, 844D #6800253Hai Van100% (1)

- X354 With 42" Accel Deep™ Deck: Maintenance Reminder SheetDocument1 pageX354 With 42" Accel Deep™ Deck: Maintenance Reminder SheetFlorin TomaPas encore d'évaluation

- STMG1672-SLD, 3408e, 3412e HeuiDocument138 pagesSTMG1672-SLD, 3408e, 3412e HeuiDavid Mercado100% (2)

- Siglas de Sensores de VehiculosDocument15 pagesSiglas de Sensores de VehiculosByron RiveraPas encore d'évaluation