Académique Documents

Professionnel Documents

Culture Documents

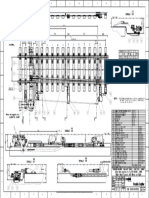

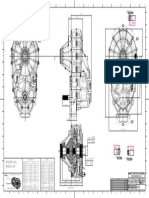

02070-FCK-PRV-DRW-C204 Comentarios CPT PDF

Transféré par

johnnyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

02070-FCK-PRV-DRW-C204 Comentarios CPT PDF

Transféré par

johnnyDroits d'auteur :

Formats disponibles

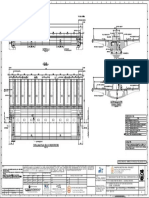

A B C D E F G H I J K L M

115 115 DESIGN DATA

114 DESIGN CODE: ASME SECT. VIII DIV.1 Ed. 2013

113 ASME (U) STAMP YES

NO INSULATION 112 INTERNAL PRESSURE Kg/cm² (g) 24,7

111 TEMPERATURE FOR INTERNAL PRESSURE 270

DESIGN

110 110 PRESSURE DROP Kg/cm² (g) -

CONDITIONS

109 AT TOP EXTERNAL PRESSURE Kg/cm² (a) F.V.

"B" "C" "D" TEMPERATURE FOR EXTERNAL PRESSURE 150

108

48100 (T.L. TO T.L.) 4800

107 MIN. DESIGN METAL TEMP. 12,8

106 INTERNAL PRESSURE Kg/cm² (g) 21,1

OPERATING

CONDITIONS INTERNAL TEMPERATURE TOP/BOTTOM 42 / 196

105 105

17255 (NO INSULATION) 30845 (HEAT CONSERVATION) 3240 x 28 THK. 60

104 STEAM-OUT PRESSURE Kg/cm² (g) 3,5 / F.V.

(SA-285 Gr.C)

CONDITION TEMPERATURE 180 / 150

650x34 THK. 103

102 NATURE -- SOUR COKER GAS / UNSTABILIZED NAPHTA

11980 x 24 THK. 2505 x 30 THK. 27615 x 30 THK. 1345 3505 x 44 THK. 1500 x 28 THK. 750

FLUID

L.

x 49 THK. (SA-516 Gr.70N) 101 SPECIFIC GRAVITY --

W.

L.

L.

L.

W.

W.

(SEE STD. SA- 2044)

EARTH ATTACH.

500 x 44 THK.

W.

100 100 SPECIAL WET H2S SERVICE (CATEGORY 2)

09/05/16 915 2440 915 4880 915 4270 2920 1265 3660 2290 1220 3840 4880 3860 4880 2692 2258 1900 99 SERVICES -

"A" 6 SPACES 8 SPACES

4 SPACES 8 SPACES 7 SPACES 1000 560 2 SPACES 450 8 SPACES

@ 610 98 POSTWELD HEAT TREATMENT YES

BUTOR

@ 610 @ 610 @ 610 FOR 2CN @ 610 @ 610 @ 610

)

DOW NCOM ER BARS (TYP.

1305

(SEE NOTE 30)

2CN

L "G"

2CN 2CN 2CN 2CN 2CN

BUTOR

SHEETS- 15& 16/33 AND SEE NOTE 29)

(SEE STD. SA- 2019)

V

6N 97 RADIOGRAPHY

R TYPE I

(SEE 02070- FCK- PRO- DTS- C204

17N

STRI

A B C D E F

L 200x200x25 THK.

NGEM ENT BAFFLE (SEE DETAI

3605

N 02070- FCK- PRO- DTS- C204

L 200x220x25 THK.

JOINT EFFICIENCY SHELL/HEAD & CONE 1 / 1

-

)

50

4957

96

(SEE NOTE 30)

2.

STRI

NG (TYP.

RETURN DI

1CN 1CN 3CN 1CN 1CN 1CN 4CN 2CN 2CN

50 S.F.

mm

SHEETS- 6& 7/33)

A SHELL AND HEADS (INT.) 6

RT CHAI

LER RETURN DI

95 A B D E F B G H 13N 95

NG EL.

S.F. 10N 12N

D. x 28 THK.

- VORTEX BAFFLE

NTERNAL VENDOR

NG EL.

1100

PER GP 05- 02- 01

- VORTEX BAFFLE

NTERNAL VENDOR

11N

PER GP 05- 02- 01

PE SLEEVE

4CN 1CN B B 1CN 1CN 300 94 SKIRT (INT./EXT.) mm 1,5/1,5

1N 2N

EL. 21150

EL. 21600

5M 9N

PES

16N

EL. 2445

EL. 350

C

80

A G H

M NEY TRAY

SKI

80x18 THK.

ANCHOR BOLTS mm 3 (DIA.)

PP. RI

&

93

L.

L.

VENT PI

FF. RI

6" SCH.

(BY OTHERS)

EL. 24850

EL. 13280

EL. 10735

EL. 24900

EL. 24340

EL. 20550

FF. RI

CORROSION

EL. 13500

L.W .

L. T.

T

250

EL. 18775

NTERCOOLER DRAW

EL. 11195

EL. 47840

TOP DAVI

EL. 44125

55

EL. 32000

COLUM N

mm

EL. 25260

(SS) 0,5 ON EACH FACE

EL. 12500

EL. 32135

EL. 31000

92 ALLOWANCE

60x18 THK.

EL. 21265

EL. 11395

REBOI

T.

400 REMOVABLE

D.

.

W.

500 I

TRAY SI

mm

PI

(CS)

STI

91 INTERNALS 3 ON EACH FACE

STI

2450 I

-

D.

8.

14N

CHI

ANTI

mm

.

BY I

WELDED (CS) 6 ON EACH FACE

BOTTOM

90 90

1700 I

ANTI

M PI

BY I

B

A. ANCHOR BOLTS)

NG

3

RT

I

mm 80 / HC (DENSITY 100 Kg/m min.)

ON RI

89 INSULATION THICKNESS/TYPE

310

D. 4056 SKI

&

I

NG

1200 88 FIREPROOFING INSIDE/OUTSIDE mm 50 / 50

D. 3700 BASE RI

COM PRESSI

L.

A.

L.

NS. DI

HORIZONTAL Kg/cm² (g) SEE SPEC. GP-05-03-01

1610

D. 4200

87

L.

460

HYDROTEST SHOP

L. EL.

L. EL.

VERTICAL Kg/cm² (g) SEE SPEC. GP-05-03-01

(32 HOLES FOR 1 7/8" DI

86

#45

PRESSURE

4000 I

5N

#41

#31

#49

#46

#39

#36

#29

#50

#48

#47

#43

#42

#40

#38

#37

#35

#33

#32

#30

#44

#34

FIELD Kg/cm² (g) SEE NOTE 21

)

85 85

D. 4350 BASE &

(TYP.

O.

L.

C.

L.

#21

#11

#1

#26

#19

#16

#9

#6

#28

#27

#25

#23

#22

#20

#18

#17

#15

#13

#12

#10

#8

#7

#5

#3

#2

#24

#14

#4

90° L.R.

L.

15N

H.

110

B.

14

84 WIND CODE AS PER PERUVIAN STANDARD E.020: "CARGAS",

ELBOW

BOTTOM

450

CONDITIONS SPEED (EL. 10 m) 22 m/s

83

WIND &

.

I

(SEE STD. SA- 2021)

N 02070- FCK- PRO- DTS- C204 SHEET- 4/33)

N 02070- FCK- PRO- DTS- C204

(SEE STD. SA- 2013)

82 SEISMIC CODE AS PER ASCE 7-10: I=1, R=3, S =2,642, S1 =0,667

33712

M NEY TRAYS

LADDER RUNGS

L 150x200x13 THK.

EARTHQUAKE

- VORTEX BAFFLE

NTERNAL VENDOR

33050

S

EL. 47475

EL. 44250

EL. 38450

L "A"

GN BY VENDOR)

L 150x150x13 THK.

O.

PER GP 05- 02- 01

FACTORS SITE CLASS: D

02070- FCK- PRO- DTS- C204 SHEET- 3/33

06

02070- FCK- PRO- DTS- C204 SHEETS- 6& 7/33

EL. 18775

81

(SEE GP 05- 02- 01)

EL. 7490

EL. 6270

EL. 5050

EL. 32165

EL. 30610

N

EL. 31350

EL. 21750

EL. 20910

EL. 13280

L "B" I

EL. 25570

EL. 11500

EL. 11095

N

EL. 9930

EL. 23730

EL. 20700

L "C" I

13& 14/33 AND SEE NOTE 29)

L "F" I

EL. 24850

EL. 24240

T

ONS

)

)

NLET DEFLECTOR BAFFLE (SEE DETAI

DAVI

(TYP.

(TYP.

VORTEX BREAKER

NG EL.

NG

NG

SHEETS- 8& 9/33 AND SEE NOTE 29)

(SEE STD. SA- 2019)

BUTOR &

NG EL.

80 80

SPECIFICATIONS

EL. 4510

BUTOR

BUTOR

EL. 40767

RCULAR ACCESS OPENI

ELD RI

EL. 750

TRUNNI

REPROOF. SUPPORTS

EL. 300

(SEE STD. SA- 2029)

EL. 2700

(SEE STD. SA- 2023)

GEM ENT BAFFLE (SEE DETAI

NAM EPLATE EL. 1650

EL. 1900

GN BY VENDOR)

(SEE DETAI

(SEE DETAI

02070- FCK- PRO- DTS- C204

79

AND SEE NOTE 29)

GP 03-16-01: FLANGED JOINTS, GASKETS AND BOLTING GP 19-01-01: PAINT AND PROTECTIVE COATINGS

STRI

STRI

CHI

EL. 4600

STRI

FF. RI

AND SEE NOTE 29)

N SHI

78

FF. RI

LER RETURN DI

GP 05-01-01: PRESSURE VESSELS GP 19-03-01: GUNITE FOR LINING AND FIREPROOF COATING

NTERCOOLER RETURN DI

NG LUG

NLET DI

ANTI

BY I

77

1M 2M 3M GP 05-01-02: ADDIT. REQUIR. FOR SPECIAL CRITERIAL PRESS. VESSELS GP 20-01-01: INSPECTION OF EQUIPMENT AND MATERIALS

-

RAI

(DESI

2.

7N

STI

5CN 5CN 10N 12N 5CN 5CN 5CN

NGEM ENT BAFFLE

NGEM ENT BAFFLE

STI

8N 4N 6M 7M 76

L "D" I

NAPHTHA I

A/B A B A A C D E 14N GP 05-02-01: INTERNALS FOR TOWERS AND DRUMS -

LI

8M 9M

A

TAI

75 3N 75

4M 5CN GP 05-03-01: PRESSURE TESTING OF UNIFIRED PRESSURE VESSELS GP 20-01-03: QUALITY PROGRAMS

FI

V- BAFFLE (SEE DETAI

D REBOI

(DESI

SHEETS- 12,

F 1CN 1CN 74

CI

3CN GP 14-01-01: EXTERNAL INSULATION 02070-GEN-ENG-SPE-002: INSULATION FOR HOT SERVICE

M PI

B I J

INLET DEFLECTOR BAFFLE (SEE DETAIL "D" IN 73

M PI

I

M PI

GP 14-03-01: FIREPROOFING 02070-GEN-MET-SPE-001: PROYECT SPECIF. WET H2S SERVICE

MI

900

I

I

2CN 2CN

02070-FCK-PRO-DTS-C204 SHEETS-8&9/33)

I

I

I

72

I J GP 18-07-01: WELDING PROCEDURES 02070-GEN-PNG-SPE-003: JOB SPEC. FOR DESIGN STRESS ANALYSIS

&

150

&

1600 SEE HOT BOX 71

GP 18-10-01: ADDITIONAL REQUIREMENTS FOR MATERIALS

"A" FOR 2CN DETAIL

70 70

GP 18-12-01: POSITIVE MATERIAL IDENTIFICATION

INSULATION SUPPORTS (SEE STD. SA-2023)

69

68

MATERIAL SPECIFICATION

ALLY,

"B" "C" "D" SHELL SA-516 Gr.70N (HIC)

67

HEAD SA-516 Gr.70N (HIC)

66

#17 TO #11

TRAY #22

RCUM STANCES BE TOTALLY OR PARTI

FLANGE SA-105N

N

TTEN CONSENT, FOR ANY PURPOSE AND I

65 65

NECK PIPES SA-333 Gr.6

N 64

NECK PLATES SA-516 Gr.70N (HIC)

63

#19

FITTINGS SA-420 Gr.WPL6

M NEY BELOW

WELD. L. 62

DOW NCOM ER TRAYS #20 &

TRAY #1

1CN 5CN 1CN

TRAY #10 &

4.5 Thk. SPIRAL WOUND GRAPHITE FILLER WITH SS 316 WINDING, CS

DOW NCOM ER EVEN TRAYS

61 OUTSIDE

F B E

SOLID CENTER RING AND SS 316 INNER RING.

DOW NCOM ER ODD TRAYS

10N 06 TANG. L. GASKETS

60 2CN A 60

#18 TO #10

INSIDE KLINGERSIL C-4430

DOW NCOM ER TRAYS

B 6N

59

GHT OF USE.

7N

SEAL PAN BELOW

INSULATION

DOW NCOM ER CHI

#8 TO #2

TAILING LUG SKIRT SA-516 Gr.70N / SA-285 Gr.C

#9 TO #1

2CN A

16N AIR SPACE 58

A VESSEL

SEAL PAN BELOW

8N BASE RING AND CHAIR SA-516 Gr.70N

57 SUPPORT

1CN 2CN 8.- VENT PIPES

ANCHOR BOLTS & NUTS

#21 TO #19 &

CONTINUOUS RING A-F1554 Gr.105 (BY OTHERS)

2N 06 B E 3 (EQUISPACED) 56

)

725 2CN 6

n.

11 (WELDED OR BOLTED OUTSIDE BOLTS AND NUTS SA-193 Gr.B7 / SA-194 Gr.2H

(m i

55 D 55

DOWNCOMER ODD TRAYS 1CN 2CN 2CN CONSTRUCTION)

2.- TRUNNIONS TAILING LUG 3

155 C 6 REINFORCING PLATES SA-516 Gr.70N

#49 TO #29 A F 11 54

450m m

DE THE EXTENT OF THE AGREED UPON RI

TOP DAVIT INSULATION INSULATION SUPPORTS SA-516 Gr.70N / SA-36

1CN 1CN 53

1400

1150

INLET DEFLECTOR BAFFLE C D 14N STIFFENING RING SA-516 Gr.70N

12N 52

620 620

530 530

A A

CLIPS OUTSIDE SA-516 Gr.70N

3CN 4CN 51

1N 5N 9N 3N 4N 11N 13N 17N

A A EARTH ATTACH SS. 304

50 12N 50

DAVIT 14N

DAS AND SHALL NOT, UNDER ANY CI

B NAMEPLATE SS. 304

B 49

2CN 2CN

15N 2CN DAVIT 2CN BOLTING SA-193 Gr.B6 / SA-194 Gr.6

G I 48

DOWNCOMER EVEN TRAYS 1CN H J RAIN SHIELD

5M TRAY SUPPORTS SA-516 Gr.70N (HIC)

G RING

OR W RI

DOWNCOMER EVEN TRAYS #28 TO #22 1CN 47

DAVITS 1475 1CN

DAVITS #50 TO #30 H 8M 3CN GUNITE PER TRAYS SA-240 TP.410S (BY OTHERS)

DAVIT SEAL PAN DOWNCOMER ODD TRAYS I 46

4CN 06 1CN

#27 TO #23 B GP 14-03-01

1M BELOW #22 J PIPES SA-333 Gr.6 / SA-312 TP.304L

DAVIT B 16.

875°

45 4M 11. GUNITE PER 45

DOWNCOMER CHIMNEY 7M 25 INTERNAL

2M 5CN ° 2.-ACCESS OPENING SUPPORT SKIRT SA-516 Gr.70N (HIC) / SA-240 TP.410S

BELOW TRAY #29 EQUISPACED GP 14-03-01 PLATES

TS PRI

44 ELEMENTS

3M C

5CN 5CN 32.- ANCHOR BOLTS FLANGES SA-105N / SA-182 F304L

5CN 43

A E DAVIT

6M D HOT BOX (DETAIL) ELBOWS/TEES -

7N 42

5CN

1800 (DESIGN BY VENDOR) V-BAFFLE 4N SA-516 Gr.70N (HIC)

THOUT I

B F 41

10N VORTEX BREAKER SS304L

40 40

B 9M

EQUIPMENT: (ABOVE CHIMNEY TRAY EL.30845)

39

- CODE 2Zep or 2Uuu ACC. TO GP 19-01-01 / RAL 9003

38

SCLOSED OR USED W I

EQUIPMENT: (BELOW CHIMNEY TRAY EL.30845)

VIEW "A-A" VIEW "B-B" VIEW "C-C" VIEW "D-D" CARBON STEEL SURFACES

37 - CODE 2nn or 2m ACC. TO GP 19-01-01 / (RAL 9006)

PAINTING

ORIENTATION ORIENTATION ORIENTATION ORIENTATION 36 SYSTEM

EQUIPMENT: (BELOW TRAY #2) CODE 2Z ACC. TO GP 19-01-01 / RAL 9006

SHED OR OUTSI

SUPPORT: CODE 3nn ACC. TO GP 19-01-01 / (RAL 9006)

35 35

WET H2S SERVICE (CATEGORY 2) EMRE

34 STAINLESS STEEL SURFACES -

CAS REUNI

33

8/9M 2 24" 2375 MANHOLE W/BLIND FLANGE & DAVIT CL300 W.N. R.F. 24 mm 1050 44

DESCRIPTION SUPPLIED BY ASSEMBLY REQUISITION R.F.P. 32 LOCATION TYPE MINIMUM THICKNESS AFTER FORMING (mm)

7M 1 24" 1550 MANHOLE W/BLIND FLANGE & DAVIT CL300 W.N. R.F. 24 mm 1050 30

20.- ALL THE PROCESS NOZZLES SHALL BE DESIGNED TO WITHSTAND THE EXTERNAL GENERAL VESSEL FAB. SHOP 31 HEAD TOP ELLIPTICAL 2:1 24

5/6M 2 24" 1550 MANHOLE W/BLIND FLANGE & DAVIT CL300 W.N. R.F. 24 mm 980/1050 30

30

4M 1 1500 MANHOLE W/BLIND FLANGE & DAVIT CL300 W.N. R.F. 24 mm 1050 30

LOADS AS PER SECTION 8.7 OF PROJECT SPECIFIC. 02070-GEN-PNG-SPE-003. BLIND FLANGES 30 DETAILS BOTTOM ELLIPTICAL 2:1 44

24"

19.- MATERIAL TO BE WELDED TO THE EQUIPMENT SHALL BE SAME MATERIAL AS SHELL. EXT.BOLTS VESSEL FAB. SHOP

29

CALLY FURNI

- - -

S THE PROPERTY OF TECNI

2-3M 2 24" 1150 MANHOLE W/BLIND FLANGE & DAVIT CL300 W.N. R.F. 24 mm 1000 22 AND GASKETS

ED, DI

020700343/K119

18.- MARK WITH WATER-PROOF WHITE PAINT A CIRCUMFERENTIAL BAND 100 WIDE

1M 1 1150 MANHOLE W/BLIND FLANGE & DAVIT CL300 W.N. R.F. 24 mm 1000 22 AT THE CENTER OF GRAVITY OF THE TOWER (IN SHIPPING COND.) THE BAND 28

24"

TRAYS AND OTHER MOMENTS AND FORCES WEIGHT AND CAPACITY

SHALL BE IDENTIFIED WITH THE TEXT "CENTER OF GRAVITY" IN LETTERS 200 HIGH. VESSEL FAB. SHOP

5CN A-E/F 6 2" 1450 TI (NOTE 32) CL300 L.W.N. R.F. - 190/- 12/- INTERNAL SUPPORTS 27 (AT BASE PLATE) (ESTIMATED) (SEE NOTE 22)

020700343

17.- DIMENSIONS OF TRAY SUPPORT RING AND DOWNCOMER BOLTING SHALL BE

4CN A/B 06 32.- PI & PDI NOZZLES (3CN A/B & 4CN A/B) SHALL BE ARRANGED IN VAPOUR SPACE.

RECTLY, TRANSFERRED, REPRODUCED, COPI

2 2" 1450 PI (NOTE 32) CL300 L.W.N. R.F. - 190 12 IN ACCORDANCE WITH TRAY VENDOR DRAWINGS. SUPPORT CLIPS 26 FABRICATION WEIGHT 142.800 Kg.

31.- TI NOZZLES (5CN A, C, D, E & F) SHALL BE ARRANGED IN LIQUID PHASE.

3CN A/B 2 2" 1450/1675 PDI (NOTE 32) CL300 L.W.N. R.F. - 190/265 12 FOR PIPING, PLAT VESSEL FAB. SHOP 06

25 FOR 5CN B REFER TO DETAIL "E" INCLUDED IN PROCCES DATA SHEET. 25 EARTH. BENDING MOMENT 1.066.399 Kgm ERECTION WEIGHT 188.030 Kg.

200 HIGH APPROXIMATELY 500 ABOVE THE BASE. AND LADDERS

2CN I-J 2 2" 2225 LG CL300 L.W.N. R.F. - 205 22 30.- TRAY SUPPORTS RING AND DOWNCOMER BARS DESIGN BY INTERNALS VENDOR AND

15.- FLANGES FACES SHALL BE SMOOTH FINISH FROM 125 TO 250 AARH. INSULATION AND 24 WIND BENDING MOMENT 06 249.536 Kgm SHUT-DOWN WEIGHT 200.930 Kg.

FI

2CN A-H 8 2" 1450 LG CL300 L.W.N. R.F. - 190 12 SUPPLY BY COLUMN VENDOR.

14.- FLANGES LARGER THAN 24 INCH SHALL BE SPECIFIED IN ACCORDANCE FIREPROTECTION VESSEL FAB. SHOP 23 31.032 Kg. 244.180 Kg.

S SPECI

29.- PIPE DISTRIBUTOR IN NOZZLES "2N", "8N", "12N A/B", "14N A/B" AND V-BAFFLE 4N EARTHQUAKE SHEAR OPERATING WEIGHT

1CN I-J 2 2" 2225 LI/LC CL300 L.W.N. R.F. - 205 22 WITH ASME B16.47 SERIES B. SUPPORTS

SUPPLY BY COLUMN VENDOR AND DESIGN BY INTERNAL VENDOR. 22 8.143

FLANGES 24 INCH AND SMALLER SHALL BE SPECIFIED IN ACCORDANCE FIELD WIND SHEAR Kg. HYDROTEST WEIGHT 433.100 Kg.

1CN A-H 8 2" 1450 LI/LC CL300 L.W.N. R.F. 190 12 SPARE PARTS VESSEL FAB.

28.- MARK WITH WATER-PROOF WHITE PAINT IN LETTER 200 mm HIGH: "TRATADO

WITH ASME B16.5. 21 3

TERMICAMENTE - NO SOLDAR / HEAT TREATED - DO NOT WELD" PAINTING VESSEL FAB. CAPACITY 232,24 m

17N 1 3" 2250 STEAM OUT CL300 W.N. R.F. XXS 210 30 SHOP

13.- NOZZLE BOLT HOLES SHALL STRADDLE THE N-S AND E-W AXIS

20 27.- DELETED 20

16N 1 3" SEE DWG DRAIN CL300 W.N. R.F. XXS - - FOR VERTICAL NOZZLES FOR HORIZONTAL NOZZLES, BOLT HOLES SHALL TEMPLATE VESSEL FAB. FIELD

T I

STRADDLE THE VERTICAL AND HORIZONTAL AXIS. 26.- WET H2S SERVICE: MATERIAL SELECTION TO BE IN ACCORDANCE 06 01/04/16 FOR CONSTRUCTION (REVISED AS INDICATED

06 ) AGM JJV/VEJ RIJ/EGG

15N 1 SEE DWG VENT W/BLIND FLANGE CL300 W.N. R.F. 160 280 12 19

6" VORTEX BREAKER VESSEL FAB. SHOP

WITH PROJECT SPECIFICATION 02070-GEN-MET-SPE-001 AND GP 18-10-01. 05 07/08/15 FOR CONSTRUCTION WITH HOLD (REVISED AS INDICATED ) RPS DAS/FRR RIJ/JMMA

05

CH I

12.- PROJECTION "L" IS FROM VESSEL CENTERLINE TO FLANGE FACE.

14N A/B 2 10" SEE DWG BOTTOM REBOILER RETURN CL300 W.N. R.F. 100 560 49 25.- FLANGES FOR INTERNAL PIPE DISTRIBUTOR SHALL BE SLIP ON CLASS 150 PER ASME B 16.5. PIPE DISTRIBUTORS 18

11.- UNLESS PROJECTIONS ARE SPECIFIED, NOZZLES, MANWAYS AND HAND- VESSEL FAB. SHOP 04 07/11/14 FOR PURCHASE (REVISED AS INDICATED ) DAA VRF/FRR RIJ/JMMA

04

NG I

13N 1 16" 2350 BOTTOM REBOILER DRAW CL300 W.N. R.F. 16 mm 720 44 HOLES SHALL BE CUT OFF FLUSH WITH THE INSIDE OF THE SHELL OR 24.- NOZZLE REINF.(CONSIDERING EXTERNAL LOADS AS PER PROJECT SPEC. 02070-GEN-PNG-SPE-003) 17

V-BAFFLE FOR 4N VESSEL FAB. SHOP 03 11/07/14 FOR PURCHASE (REVISED AS INDICATED03 ) DAA VRF/FRR AAT/JMMA

ANY W AY OTHER THAN THAT FOR W HI

HEAD OF PRESSURE VESSEL. AND CONE-TO-CYLINDER JUNCTION REINF. SHALL NOT LIMIT THE VESSEL MAWP.

12N A/B 2 8" SEE DWG MID REBOILER RETURN CL300 W.N. R.F. 120 460 22 16 02 30/06/14 FOR INQUIRY (REVISED AS INDICATED ) DAA VRF/FRR AAT/JMMA

02

10.- ALL REMOVABLE INTERNALS SHALL PASS THROUGH VESSEL MANHOLES. 23.- ANCHOR BOLT DESIGN SHOWN IN THIS DRAWING IS BASED ON 1400 Kg/cm² FOR

THE PRESENT DOCUM ENT OR DRAW I

11N 1 12" 1525 MID REBOILER DRAW CL300 W.N. R.F. 100 510 30 01 12/02/14 FOR INQUIRY (REVISED AS INDICATED

01 ) DAA VRF/FRR AAT/JMMA

15 9.- ELEVATION OF SUPPORTS FOR TRAYS, DEMISTERS, INSULATION,..ETC. IS A-307 AND 3000 Kg/cm² FOR A-F1554 Gr.105 ALLOWABLE TENSILE STRESS AND 15

ANCHOR BOLTS OTHERS FIELD -

-

10N A/B 2 10" 1525 WATER SETTLER RETURN CL300 W.N. R.F. 100 480 22 REFERRED TO THE TOP OF SUPPORT. CONCRETE RESISTANCE f'c=350 Kg/cm². 00 18/10/13 FOR INQUIRY DAA VRF/FRR AAT/JMMA

14

8.- NOZZLE LOCATION SHOWN ON GENERAL VESSEL OUTLINE IS SCHEMATIC. INSULATION Rev. Fecha Descripción Diseñado Comprob. Aprobado

9N 1 12" 1525 WATER SETTLER DRAW CL300 W.N. R.F. 100 510 30 02070-FCK-PRO- ABSORBER DEETHANIZER COLUMN 22.- WEIGHTS: & OTHERS FIELD - Rev. Date Description Dwg. by Chkd.by Appd. by

FOR NOZZLE ORIENTATIONS SEE ORIENTATION PLAN OR VIEWS. 13

8N 2 6" SEE DWG INTERCOOLER RETURN CL300 W.N. R.F. 160 390 22 DTS-C204 PROCESS DATA SHEET (REV. TR3) FIREPROOFING

7.- WELDING SEAMS SHALL NOT INTERFERE WITH NOZZLES, NOZZLE REINFORCEMENT PADS, · FABRICATION WEIGHT INCLUDES: SHELL, HEADS, NOZZLES, VESSEL SUPPORT, INTERNALS

12

7N A/B 2 8" 1500 INTERCOOLER DRAW CL300 W.N. R.F. 120 375 22 VESSEL SUPPORTS, ETC., OR WITH WELDS FOR INTERNAL FIXTURES. WELDED ELEMENT (SUPPORT RING FOR INTERNALS, BAFFLES, ETC.) AND EXTERNAL TRAYS OTHERS FIELD - PROYECTO DE MODERNIZACION

PETROPER

6.- WELDING SEAMS OF HEADS IF MADE OF TWO OR MORE PLATES SHALL BE WELDED ELEMENT (SUPPORT CLIPS FOR PLATFORM AND LADDERS, STIFFENING RINGS, 11 REFINERIA TALARA (PERU)

6N 1 12" 2650 BOTTOMS LIQUID CL300 W.N. R.F. 100 575 30 SA-2049 STANDARD OF CLIPS FOR VERTICAL VESSELS COLUMN TOP DAVIT OTHERS FIELD -

FULLY RADIOGRAPHED. SUPPORT CLIPS FOR PIPING, INSULATION SUPPORT AND FIREPROTECTION SUPPORT, ETC

10 5N 1 SEE DWG VAPOR OUTLET CL300 W.N. R.F. 120 325 12 SA-2044 EARTH ATTACHMENT FOR VESSELS 10

8" 5.- PLATE WELDING SEAMS SHALL BE BUTT WELDING AND FULL PENETRATION. CHIMNEY TRAYS OTHERS FIELD -

· ERECTION WEIGHT INCLUDES: FABRICATION WEIGHT, LADDERS AND PLATFORMS.

4N 1 10" 1500 VAPOR INLET CL300 W.N. R.F. 100 440 30 SA-2029 VESSEL NAMEPLATE & SUPPORT BRACKET 4.- ALL WELDINGS SHALL BE CONTINUOUS UNLESS OTHERWISE SPECIFIED. · SHUT-DOWN WEIGHT INCLUDES: ERECTION WEIGHT, OTHERS INTERNAL (CATALYST, 9

INLET DEFLECTOR BAFFLE OTHERS FIELD -

3.- ALL THICKNESSES SHOWN ARE MINIMUN AFTER FORMING. IT IS MANUFAC- ALUMINA BALLS, RANDOM PACKING, ETC.), FIREPROOFING, PIPING TRAYS, STRUCTURED

3N 1 3" 1450 NAPHTHA INLET (CENTER) CL300 W.N. R.F. XXS 210 22 SA-2023 HOT INSULATION. MK-III INS. SUP. FOR VESSELS 8

TURER'S RESPONSIBILITY TO CHECK THAT ALL THICKNESSES OF ALL PARTS IMPINGEMENT BAFFLE OTHERS FIELD - UNIT-11 FLEXICOKING

NDI

PACKING, DEMISTER AND INSULATION.

2N 1 3" SEE DWG NAPHTHA INLET (TOP) CL300 W.N. R.F. XXS 200 12 SA-2021 MISCELLANEOUS DETAILS FOR VESSEL OF THE COLUMN ARE ADEQUATE AND THAT SATISFY ALL THE REQUIREMENTS 7

· OPERATING WEIGHT INCLUDES: SHUT-DOWN WEIGHT AND MAXIMUM LIQUID LEVEL FOR

OF THE CORRESPONDING CODE AND SPECIFICATIONS. MUST ALSO ASSURE

ABSORBER DEETHANIZER COLUMN

RECTLY OR I

1N 1 6" 1125 LEAN OIL INLET CL300 W.N. R.F. 160 300 12 SA-2019 BASE RING AND CHAIRS DETAILS OPERATION.

THE STABILITY OF THE EQUIPMENT UNDER ALL LOADS INCLUDING WIND & EARTHQUAKE. 6

MARK NOM. PROJ."L" SA-2013 MANHOLE COVER DETAILS (ASME) 2.- FITTINGS SUCH AS ELBOWS, TEES, ETC., SHALL BE OF THE SAME SIZE & · HYDROTEST WEIGHT INCLUDES: SHUT-DOWN WEIGHT, LIQUID WEIGHT (VESSEL FULL OF

5 QUANT. CLASS TYPE FACE SCH./THK DIA. THK 5

DIA (NOTE 12) SA-2003 WALL THICKNESSES FOR NOZZLES WITH FLANGES THICKNESS AS THE ATTACHED PIPES. WATER) MINUS REMOVABLE INTERNALS (CATALYST, ALUMINA BALLS, RANDOM PACKING)

PROYECTO Nª

ITEM: FCK-C-204

DESCRIPTION 4 T-02070

1.- ALL DIMENSIONS ARE IN MILLIMETRES (mm). UNLESS OTHERWISE SPECIFIED. 21.- PROVISION FOR FUTURE FIELD HYDROSTATIC TEST IN OPERATION AND CORRODED

NOZZLES FLANGES (NOTES 14 & 15) NECK REINFOR NUMBER NAME

PROJECT Nr.

ALL NOZZLES, FITTINGS & PIPING ARE IN INCHES (in). CONDITION SHALL BE CONSIDERED IN ACCORDANCE WITH GP 05-01-01.

3

ESCALA

SCALE

REV.

NOZZLE SCHEDULE 2 PLANO Nº

REFERENCE DRAWINGS GENERAL NOTES BILL OF MATERIAL 02070-FCK-PRV-DRW-C204

DWG Nr.

1 1

06

DI

A B C D E F G H I J K L M --

Vous aimerez peut-être aussi

- International Certificate in WealthDocument388 pagesInternational Certificate in Wealthabhishek210585100% (2)

- Top Malls in Chennai CityDocument8 pagesTop Malls in Chennai CityNavin ChandarPas encore d'évaluation

- Philippine Coastal Management Guidebook Series No. 8Document182 pagesPhilippine Coastal Management Guidebook Series No. 8Carl100% (1)

- MRD Upright VW120CUP CNC VKBA 757Document1 pageMRD Upright VW120CUP CNC VKBA 757Olivia WeiPas encore d'évaluation

- HIBAY CS16838 - Victoria-IP-W 20190408 - MechanicalDrawingDocument1 pageHIBAY CS16838 - Victoria-IP-W 20190408 - MechanicalDrawing金山 刘Pas encore d'évaluation

- Diagrama Unifilar SEINDocument1 pageDiagrama Unifilar SEINMARCAVILLACA CONDORI ANTONY CLEMENTPas encore d'évaluation

- Diagrama Unifilar SEINDocument1 pageDiagrama Unifilar SEINFranklin Jesus Simeon PucuhuaylaPas encore d'évaluation

- Standards: ISO 128 TOL: ISO 2768-mk Not For ScalingDocument1 pageStandards: ISO 128 TOL: ISO 2768-mk Not For ScalingmajidhaghpanahfbcPas encore d'évaluation

- Document summary L-2194Document1 pageDocument summary L-2194Franklin Jesus Simeon PucuhuaylaPas encore d'évaluation

- 2040-000-1050 WipDocument1 page2040-000-1050 WipMina AlbertPas encore d'évaluation

- 01) 5333-107-B - General Arrangement Drawing CN8202 ElevatorDocument1 page01) 5333-107-B - General Arrangement Drawing CN8202 ElevatorRicardo Diaz AristaPas encore d'évaluation

- Screenshot 2023-11-11 at 2.51.42 PMDocument4 pagesScreenshot 2023-11-11 at 2.51.42 PMxbgv6282y9Pas encore d'évaluation

- Piping and Instrumentation Diagram Symbols GuideDocument1 pagePiping and Instrumentation Diagram Symbols GuideIslam SahafayatPas encore d'évaluation

- Standards: ISO 128 TOL: ISO 2768-mk Not For ScalingDocument1 pageStandards: ISO 128 TOL: ISO 2768-mk Not For ScalingmajidhaghpanahfbcPas encore d'évaluation

- Flange ø1 1/2Document4 pagesFlange ø1 1/2dhiaa mohammedPas encore d'évaluation

- 1077mmx1087 5mmx50mmDocument1 page1077mmx1087 5mmx50mmmajidhaghpanahfbcPas encore d'évaluation

- Standards: ISO 128 TOL: ISO 2768-mk Not For ScalingDocument1 pageStandards: ISO 128 TOL: ISO 2768-mk Not For ScalingmajidhaghpanahfbcPas encore d'évaluation

- 84.0-U03001 Schematic Air System (Pneumatic) MC CarDocument2 pages84.0-U03001 Schematic Air System (Pneumatic) MC Carhamzah faisPas encore d'évaluation

- 06) 5333-106-D - General Arrangement Drawing CN7065 Screw ConveyorDocument1 page06) 5333-106-D - General Arrangement Drawing CN7065 Screw ConveyorluisleojossewPas encore d'évaluation

- Espe Mep SQ SD R.sump.r2-4Document1 pageEspe Mep SQ SD R.sump.r2-4Tri SafrilPas encore d'évaluation

- Unauthorized use of engineering documentDocument1 pageUnauthorized use of engineering documentOptima EnergijaPas encore d'évaluation

- Diagrama Unifilar Sein (Osinergmin)Document1 pageDiagrama Unifilar Sein (Osinergmin)cuenta secundariaPas encore d'évaluation

- Diagrama Unifilar SEINDocument1 pageDiagrama Unifilar SEINVictor JimenezPas encore d'évaluation

- 03-Proposed WS SystemDocument1 page03-Proposed WS SystemKhalid YousafPas encore d'évaluation

- Power Distribution Box R115-4017 A 01Document1 pagePower Distribution Box R115-4017 A 01brallanPas encore d'évaluation

- PONMLKJIHGFEDCBA - Side Support Rod and Front Wheel Shaft Engineering DrawingsDocument1 pagePONMLKJIHGFEDCBA - Side Support Rod and Front Wheel Shaft Engineering Drawingspravin1112Pas encore d'évaluation

- Planta Alta 1Document1 pagePlanta Alta 1Evelyn HerreraPas encore d'évaluation

- All of me-Trombone_3Document1 pageAll of me-Trombone_3uriupsPas encore d'évaluation

- Mswil - Path - WD - Ar-340 - Ground Floor Canteen Preparation Area Details - r0Document1 pageMswil - Path - WD - Ar-340 - Ground Floor Canteen Preparation Area Details - r0Bharat BaliyanPas encore d'évaluation

- Denah RafterDocument1 pageDenah RafterYusuf KhoirPas encore d'évaluation

- Puntoapunto MP1600Document3 pagesPuntoapunto MP1600Juan Carlos Pino CamposPas encore d'évaluation

- B262/B284/B288/B292 (GW) POINT TO POINT DIAGRAM: Power Pack-BCT (PCB11) Key Card (Option)Document2 pagesB262/B284/B288/B292 (GW) POINT TO POINT DIAGRAM: Power Pack-BCT (PCB11) Key Card (Option)Mahmoud RabiehPas encore d'évaluation

- Mounting Instructions: VFW 465 PartsDocument2 pagesMounting Instructions: VFW 465 PartsYawar NoshahiPas encore d'évaluation

- Title: Ledmatrixclock: File: Matrix1.sch SheetDocument1 pageTitle: Ledmatrixclock: File: Matrix1.sch SheetPau Costa FerrerPas encore d'évaluation

- Mswil Path WD Ar-335 Ground Canteen Layout r0Document1 pageMswil Path WD Ar-335 Ground Canteen Layout r0Bharat BaliyanPas encore d'évaluation

- Duhailgym Flooring Screed DetailsDocument3 pagesDuhailgym Flooring Screed DetailsAvdija HamzićPas encore d'évaluation

- Project MSWIL Pathredi General NotesDocument1 pageProject MSWIL Pathredi General NotesBharat BaliyanPas encore d'évaluation

- MSWIL PATHREDI PROJECT:- GENERAL NOTESDocument1 pageMSWIL PATHREDI PROJECT:- GENERAL NOTESBharat BaliyanPas encore d'évaluation

- Assembly drawing of mechanical part with multiple viewsDocument1 pageAssembly drawing of mechanical part with multiple viewsFatih BahşiPas encore d'évaluation

- 1077mmx1087 5mmx50mmDocument1 page1077mmx1087 5mmx50mmmajidhaghpanahfbcPas encore d'évaluation

- To Be Revised: N Brown Fint Ube France SaDocument4 pagesTo Be Revised: N Brown Fint Ube France Sadhiaa mohammedPas encore d'évaluation

- Majestic: Rob Romeyn (ASCAP)Document1 pageMajestic: Rob Romeyn (ASCAP)David Carrasco BarrenaPas encore d'évaluation

- Fixed Point Side View Looking Toward South Front View Looking Toward EastDocument1 pageFixed Point Side View Looking Toward South Front View Looking Toward EastDima Fon NmskPas encore d'évaluation

- Michigan Rail 430289 7Document1 pageMichigan Rail 430289 7mike_mckeown_3Pas encore d'évaluation

- All of me-Trombone_2Document1 pageAll of me-Trombone_2uriupsPas encore d'évaluation

- Ddf102-r0-Mks-typical Road Signs - Warning SignsDocument1 pageDdf102-r0-Mks-typical Road Signs - Warning Signsrohith eticalaPas encore d'évaluation

- Ddf104-r0-Mks-typical Details of Road Marking - 1Document1 pageDdf104-r0-Mks-typical Details of Road Marking - 1rohith eticalaPas encore d'évaluation

- Ddf105-r0-Mks-typical Details of Road Marking - 2Document1 pageDdf105-r0-Mks-typical Details of Road Marking - 2rohith eticalaPas encore d'évaluation

- Fabricacion Cañería: ASTM-A106 GR.B ASTM-A234 GR - WPB ASTM-A105 S A 5 1 6 - 7 0Document1 pageFabricacion Cañería: ASTM-A106 GR.B ASTM-A234 GR - WPB ASTM-A105 S A 5 1 6 - 7 0Javier ReyesPas encore d'évaluation

- Panel Power KardusDocument1 pagePanel Power Karduskristanto eko santosoPas encore d'évaluation

- Design of 4L 31.25m SpanDocument1 pageDesign of 4L 31.25m Spanarif_rubinPas encore d'évaluation

- Nagpur Metro Rail Project: Systra-Aecom-Egis-RitesDocument1 pageNagpur Metro Rail Project: Systra-Aecom-Egis-Ritesarif_rubinPas encore d'évaluation

- Superstructure design drawing of a 4 lane flyoverDocument1 pageSuperstructure design drawing of a 4 lane flyoverarif_rubinPas encore d'évaluation

- HS2 Map West Midlands wm15103Document1 pageHS2 Map West Midlands wm15103HighSpeedRailPas encore d'évaluation

- P Q R S: View - MY Cases: 10 (G+Wacc+0.8S)Document1 pageP Q R S: View - MY Cases: 10 (G+Wacc+0.8S)ymitevPas encore d'évaluation

- Skematik Diagram Panel Sump-Pit-08 Lantai 1: South QuayDocument1 pageSkematik Diagram Panel Sump-Pit-08 Lantai 1: South QuayTri SafrilPas encore d'évaluation

- A-1 Ground Floor PlanDocument1 pageA-1 Ground Floor PlanarjayymerlePas encore d'évaluation

- Terrace Beam & Slab DetailsDocument1 pageTerrace Beam & Slab DetailsRaghul ShangarthiyanPas encore d'évaluation

- Terrace Beam & Slab Details PDFDocument1 pageTerrace Beam & Slab Details PDFRaghul ShangarthiyanPas encore d'évaluation

- Desen Tehnic Ambreiaj 1-Stanciu Razvan PDFDocument1 pageDesen Tehnic Ambreiaj 1-Stanciu Razvan PDFRazvan StanciuPas encore d'évaluation

- Joanne Sophia - Teachers Training Institute and Icse SchoolDocument28 pagesJoanne Sophia - Teachers Training Institute and Icse SchoolGayathri KathiravanPas encore d'évaluation

- PRGi KDocument46 pagesPRGi KjohnnyPas encore d'évaluation

- Free-Piston Stirling CoolersDocument11 pagesFree-Piston Stirling CoolersjohnnyPas encore d'évaluation

- NozzlePRO PDFDocument185 pagesNozzlePRO PDFIan CarrPas encore d'évaluation

- Guest Speaker - Keolian - For PostingDocument30 pagesGuest Speaker - Keolian - For PostingjohnnyPas encore d'évaluation

- Thermoacoustic Refrigeration For Ice Cream Sales: NtroductionDocument8 pagesThermoacoustic Refrigeration For Ice Cream Sales: NtroductionDharani PathyPas encore d'évaluation

- Design Thermo RefrigeratorDocument9 pagesDesign Thermo RefrigeratorSigitPamungkasPas encore d'évaluation

- Tijani MEH. Loudspeaker-Driven Thermo-Acoustic RefrigerationDocument177 pagesTijani MEH. Loudspeaker-Driven Thermo-Acoustic RefrigerationjohnnyPas encore d'évaluation

- Review of Flow-Through Design in Thermoacoustic RefrigerationDocument5 pagesReview of Flow-Through Design in Thermoacoustic RefrigerationjohnnyPas encore d'évaluation

- Low-cost thermoacoustic refrigerator designDocument7 pagesLow-cost thermoacoustic refrigerator designjohnnyPas encore d'évaluation

- Manual Dream Weaver Cs5 SpanishDocument707 pagesManual Dream Weaver Cs5 SpanishHarol DíazPas encore d'évaluation

- CAS-GEC04 Module11 Food-SecurityDocument6 pagesCAS-GEC04 Module11 Food-SecurityPermalino Borja Rose AnnePas encore d'évaluation

- Attributes and DialogsDocument29 pagesAttributes and DialogsErdenegombo MunkhbaatarPas encore d'évaluation

- Reg FeeDocument1 pageReg FeeSikder MizanPas encore d'évaluation

- DIN Flange Dimensions PDFDocument1 pageDIN Flange Dimensions PDFrasel.sheikh5000158Pas encore d'évaluation

- Chapter 3 of David CrystalDocument3 pagesChapter 3 of David CrystalKritika RamchurnPas encore d'évaluation

- AFNOR IPTDS BrochureDocument1 pageAFNOR IPTDS Brochurebdiaconu20048672Pas encore d'évaluation

- 1.2 - Venn Diagram and Complement of A SetDocument6 pages1.2 - Venn Diagram and Complement of A SetKaden YeoPas encore d'évaluation

- Orc & Goblins VII - 2000pts - New ABDocument1 pageOrc & Goblins VII - 2000pts - New ABDave KnattPas encore d'évaluation

- KSEB Liable to Pay Compensation for Son's Electrocution: Kerala HC CaseDocument18 pagesKSEB Liable to Pay Compensation for Son's Electrocution: Kerala HC CaseAkhila.EPas encore d'évaluation

- 3ccc PDFDocument20 pages3ccc PDFKaka KunPas encore d'évaluation

- Java development user guide eclipse tutorialDocument322 pagesJava development user guide eclipse tutorialVivek ParmarPas encore d'évaluation

- Account Statement From 30 Jul 2018 To 30 Jan 2019Document8 pagesAccount Statement From 30 Jul 2018 To 30 Jan 2019Bojpuri OfficialPas encore d'évaluation

- Prenatal and Post Natal Growth of MandibleDocument5 pagesPrenatal and Post Natal Growth of MandiblehabeebPas encore d'évaluation

- Wi FiDocument22 pagesWi FiDaljeet Singh MottonPas encore d'évaluation

- Android software download guideDocument60 pagesAndroid software download guideRizky PradaniPas encore d'évaluation

- April 26, 2019 Strathmore TimesDocument16 pagesApril 26, 2019 Strathmore TimesStrathmore Times100% (1)

- C6030 BrochureDocument2 pagesC6030 Brochureibraheem aboyadakPas encore d'évaluation

- Rubber Chemical Resistance Chart V001MAR17Document27 pagesRubber Chemical Resistance Chart V001MAR17Deepak patilPas encore d'évaluation

- Good Ethics Is Good BusinessDocument9 pagesGood Ethics Is Good BusinesssumeetpatnaikPas encore d'évaluation

- Unit 1 TQM NotesDocument26 pagesUnit 1 TQM NotesHarishPas encore d'évaluation

- DELcraFT Works CleanEra ProjectDocument31 pagesDELcraFT Works CleanEra Projectenrico_britaiPas encore d'évaluation

- 4 Wheel ThunderDocument9 pages4 Wheel ThunderOlga Lucia Zapata SavaressePas encore d'évaluation

- BIBLIO Eric SwyngedowDocument34 pagesBIBLIO Eric Swyngedowadriank1975291Pas encore d'évaluation

- Pre Job Hazard Analysis (PJHADocument2 pagesPre Job Hazard Analysis (PJHAjumaliPas encore d'évaluation

- Mission Ac Saad Test - 01 QP FinalDocument12 pagesMission Ac Saad Test - 01 QP FinalarunPas encore d'évaluation

- Surgery Lecture - 01 Asepsis, Antisepsis & OperationDocument60 pagesSurgery Lecture - 01 Asepsis, Antisepsis & OperationChris QueiklinPas encore d'évaluation