Académique Documents

Professionnel Documents

Culture Documents

Ovation Io Overview

Transféré par

Naseer HydenCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ovation Io Overview

Transféré par

Naseer HydenDroits d'auteur :

Formats disponibles

Ovation™ I/O Overview

Data Sheet

Features

Modular, plug-in components support long-term

process reliability

Modules are installed and configured quickly

and easily with single-point DIN rail fastening

Built-in connectors eliminate power and

communications wiring

Electronic ID identifies module type, group,

serial number, and revision

Fewer module styles reduce spare parts

inventory costs

Redundant power supplies deliver system

reliability

“Hot swapping” streamlines system

maintenance

Standardized status indicators offer color-

coded diagnostic messages

Remote Ovation I/O provides a flexible, cost-

effective means to distribute I/O modules to

strategic locations throughout the plant

Emerson Process Management’s Ovation™

expert control technology is designed to support Ovation I/O Architecture

long-term process reliability and expandability.

With modular plug-in components, Ovation I/O The Base

delivers embedded advanced control

Ovation packaging reduces the system footprint

applications with built-in fault tolerance and

by using base units which attach to mounting

system diagnostics. With their inherent flexibility,

plates by DIN rail; these hold four independent

Ovation I/O modules convert input signals and

Ovation I/O modules of any style. This approach

create output signals, performing a multitude of

simplifies maintenance by making it easy to

functions. Specialized I/O modules are also

install, move, or replace individual base units.

available for loop interfacing, serial linking, and

Base unit features include:

pulse accumulating functions.

Field terminal blocks that accept two 14

AWG or a single 12 AWG

Simplified Maintenance

I/O bus communications built into the base

Standardized assembly style simplifies I/O modules automatically addressed by

maintenance and reduces spare parts inventory location

costs. Single-point DIN rail fastening makes I/O modules may reside in any location

installation and configuration quick and easy.

I/O module redundant power distribution

Built-in connectors eliminate power and

communications wiring. Because the modules I/O module auxiliary power distribution

are software configurable, no jumpers or thumb No interconnecting cables for I/O bases

wheels are necessary. Each module’s advanced Built-in spare fuse holders and strip gauge in

electronics also delivers low power consumption base

and HVAC costs.

© Emerson Process Management Power & Water Solutions, Inc. -1-

PWS_002864 [5]

™

Ovation I/O Overview

Data Sheet

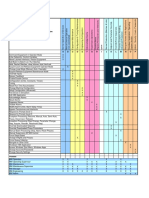

The base unit’s high-impact plastic housing Controller I/O Capabilities

protects the backplane, exposing only the Item Capability

connectors as modules are removed. Local Ovation I/O 2 sets of up to 8 independent

branches of 8 modules per

The I/O Module branch for a total of 128

modules.

The I/O module includes an electronic module

Remote Ovation Up to 8 nodes of 8 branches

and a personality module or cavity insert.

I/O* of 8 modules per branch for a

total of 64 modules per node

The I/O module converts field signals into data Local Q-Line I/O* 1 node of 48 Q Cards

and sends it to the controller. Electronic module Local Q-Line I/O* 1 additional node of 48 Q

styles include digital and analog input and output cards

modules, contact inputs, RTD inputs, pulse Remote Q-Line I/O* Up to 8 nodes of 48 cards

accumulator/counter, HART input and output Smart Device FOUNDATION fieldbus

modules, Foundation fieldbus, Profibus, Capability PROFIBUS

DeviceNet, Ethernet, and serial link controller DeviceNet

modules. Virtual I/O capability Allen-Bradley PLCs DF-1,

** (via Ethernet GE Mark V/VI GSM

I/O modules offer a number of protective TCP/IP and Modbus/TCP.

features. Signal conditioning, part of the surge- standard protocols)

withstand feature, dissipates voltage “spikes” to GE Genius I/O

protect the electronics. Fuses protect the circuit Toshiba Turbine Control

MHI Turbine Control

in case of a short in the field device line. External Ovation Network

Note:

Each module is “hot swappable,” allowing it to * Refer to the Ovation controller documentation for

be removed and replaced without interrupting valid combinations of the above listed hardware

system power or using mechanical tools. The interface capabilities since not all can be supported

standard Ovation system configuration allows for concurrently.

up to 128 I/O modules in local configuration. ** The valid combinations of software I/O interfaces

This modular approach simplifies maintenance depend upon the ports available and controller

by requiring less assembly and offering a device capability.

compact and uniform architecture.

Ovation Local I/O

Ovation I/O Architectures The Ovation Controller can directly support up to

16 independently driven branches of Ovation

The Ovation Controller supports multiple I/O

I/O.

capabilities in various combinations, including:

Hardware I/O interfaces to Ovation I/O

For local I/O, all modules reside in up to four

Q-Line I/O plus software I/O in the form of

standard cabinets, which are placed side by

Simulated I/O

side. All field wiring leads to these cabinets.

Virtual I/O generally communicated from

OEM models and systems.

Ovation Local I/O Specifications

Max branches per controller 16 branches

Ovation I/O has two methods of implementation:

Max I/O modules per branch 8 modules

locally within the controller and remotely away

Max I/O modules per controller 128

from the controller. Remote I/O provides a

means to distribute I/O throughout a plant. Max local I/O bus length 20m (60ft)

Ovation Redundant I/O

Redundant Ovation I/O modules are installed in

the same fashion as standard Ovation I/O

modules, but are associated in pairs located in

adjacent branches. The module pairs exchange

© Emerson Process Management Power & Water Solutions, Inc. -2-

PWS_002864 [5]

™

Ovation I/O Overview

Data Sheet

health, status, and I/O information via their

personality module interconnections. This Remote I/O Specifications

approach allows the user to take advantage of Max. remote nodes 8 nodes

I/O redundancy by wiring the field terminations Max. I/O modules per node

64 (8 branches with 8 modules

into a single terminal block on the primary I/O for each branch)

base, with no special control strategy Max. I/O modules per

512

controller

configuration required.

Remote I/O bus 10 BASE-FL Ethernet physical

configuration layer with a proprietary protocol

Redundancy is applied at I/O configuration time, Remote I/O cycle time

<100 microseconds (no

and during normal operation, the Ovation repeaters)

Standard remote

system automatically reads and compares the communications media

Fiber optic

I/O channels of both modules and determines 4 km. Distances of 6 km can be

which value to use. When a fault is detected the Maximum cable length for

achieved with repeaters (up to

850 nm fiber-optic media

system automatically switches to the backup two repeaters)

module thus increasing reliability and availability

of the process inputs or outputs. Q-Line I/O (Remote & Local)

The Ovation Controller additionally supports

Refer to the Ovation Redundant I/O Overview both local and remote Q-Line I/O, typically used

data sheet for complete details. in Emerson’s WDPF control system. This

interface capability provides the ability to reuse

Ovation Remote Ovation I/O the majority of your existing configurations.

Remote Ovation I/O places I/O modules close to

field devices, in contrast to local I/O modules. Simulated I/O

Remote I/O uses redundant fiber optic cables Another type of I/O supported by the Ovation

that stretch from the controller cabinet to up to Controller is simulated I/O, where the controller

4000 meters away — to a cabinet that houses can be directed to interface to I/O generated by

the I/O modules. By placing the I/O modules a software model accessible through the

closer to the transmitters and actuators, field Ovation Network.

cables can be made shorter. This significantly

reduces the amount of wiring required Virtual I/O

throughout the plant, delivering substantial cost The Ovation Controller supports a number of

savings significantly. Interfaces for both local standard 10/100 Ethernet based interface

and a remote I/O can reside the same controller. protocols. This capability allows OEM systems

Multiple remote I/O can be connected to the which support these same protocols as a

same controller. standard to intercommunicate with the Ovation

system. This ability provides remote operation,

The remote I/O system is easy to configure and monitoring, and control where appropriate.

requires no database modification. Again, I/O

selection type, whether local or remote, is made Summary

during configuration on the controller.

Ovation I/O significantly improves system

The remote I/O system offers a level of reliability performance, speed, and reliability. State-of-the-

unmatched in the industry through, redundant art electronics provides low power consumption

communications, periodic communication and heat dissipation. Remote I/O reduces costs

diagnostics, and error correction. When remote by placing modules closer to field devices,

I/O is implemented in a controller, the remote I/O thereby reducing field wiring. Streamlined design

subsystem provides a flexible, cost-effective standardizes inventory, requiring fewer spare

means to distribute I/O modules to strategic parts. Fast, effective, and reliable, simple pull-

locations throughout the plant. and-plug card swapping means the Ovation I/O

system is always online, available, and fully

functional.

© Emerson Process Management Power & Water Solutions, Inc. -3-

PWS_002864 [5]

Vous aimerez peut-être aussi

- Ovation v4.1 User ManualDocument244 pagesOvation v4.1 User Manualnex ammyPas encore d'évaluation

- Steam Turbine Control Solutions: FeaturesDocument4 pagesSteam Turbine Control Solutions: Featuresmsw123Pas encore d'évaluation

- Configuration & Maintenance AccessDocument1 pageConfiguration & Maintenance AccessMaricruz OlivarPas encore d'évaluation

- Ovation Engineer Workstation en 67354Document7 pagesOvation Engineer Workstation en 67354chandra prakashPas encore d'évaluation

- Ovation-OW352 R1100 PDFDocument597 pagesOvation-OW352 R1100 PDFHakan Bozkurt100% (2)

- Realtime Monitoring Software User ManualDocument70 pagesRealtime Monitoring Software User Manualsugeng wahyudiPas encore d'évaluation

- Swylite LST200 Instruction SheetDocument2 pagesSwylite LST200 Instruction Sheetgreen8019Pas encore d'évaluation

- Osc 003 PDFDocument319 pagesOsc 003 PDFEvbaruPas encore d'évaluation

- OvationDocument36 pagesOvationanandtvr100% (2)

- PWS 008289Document12 pagesPWS 008289Hanan KhanPas encore d'évaluation

- NW User ManualDocument51 pagesNW User Manualscribdhas2006Pas encore d'évaluation

- 3afe68237432 Ac800mDocument94 pages3afe68237432 Ac800mLeonardoAcevedoPas encore d'évaluation

- Function Block To Control Mm4 Via Profibus DP Docu v3 2 enDocument12 pagesFunction Block To Control Mm4 Via Profibus DP Docu v3 2 enxisamPas encore d'évaluation

- Ovation Q LineDocument678 pagesOvation Q LineCyrix.One100% (1)

- Managing Security For Ovation 3.6.0 OW360 - 40Document152 pagesManaging Security For Ovation 3.6.0 OW360 - 40kumarPas encore d'évaluation

- OVATION (Pws - 002856-2) PDFDocument12 pagesOVATION (Pws - 002856-2) PDFMaxmilianPas encore d'évaluation

- Production Software Within Manufacturing Reference ArchitecturesDocument13 pagesProduction Software Within Manufacturing Reference ArchitecturesNilesh ChavanPas encore d'évaluation

- System 57 5701 Control System ManualDocument213 pagesSystem 57 5701 Control System ManualRahul DevaPas encore d'évaluation

- 3BDD012501-111 A en Freelance Mounting and Installation AC 800F ControllerDocument379 pages3BDD012501-111 A en Freelance Mounting and Installation AC 800F ControllerMathias MollePas encore d'évaluation

- EntryDocument34 pagesEntryBAGLA001Pas encore d'évaluation

- HPM Parameter Reference DictionaryDocument336 pagesHPM Parameter Reference DictionaryAbdulaziz K AlbnyanPas encore d'évaluation

- Annexure 2 Technical CatalogueDocument26 pagesAnnexure 2 Technical Catalogue150819850Pas encore d'évaluation

- Io D PDFDocument56 pagesIo D PDFGarcia LeeAnnPas encore d'évaluation

- B0193ne FDocument88 pagesB0193ne FFrancis RodríguezPas encore d'évaluation

- S+ Engineering: Composer Harmony Batch 90 and UDF Programming Language 6.6Document211 pagesS+ Engineering: Composer Harmony Batch 90 and UDF Programming Language 6.6vodanhPas encore d'évaluation

- 5.3. - FTE Bridge ConfiguringDocument10 pages5.3. - FTE Bridge ConfiguringLuis LoretoPas encore d'évaluation

- Compact Controller (OCC100) User Guide For Ovation 3.6.0 and Feature Pack 4 OW360 - 50Document195 pagesCompact Controller (OCC100) User Guide For Ovation 3.6.0 and Feature Pack 4 OW360 - 50Adrian ReyesPas encore d'évaluation

- GUS Display Builder Users Guide EP-DSX786Document548 pagesGUS Display Builder Users Guide EP-DSX786Bouazza100% (1)

- Technical Product Guide Trident v3 Jun 2019Document64 pagesTechnical Product Guide Trident v3 Jun 2019Carlitos CastilloPas encore d'évaluation

- Using aaTrendControl in ArchestrADocument32 pagesUsing aaTrendControl in ArchestrAFolsom ChevPas encore d'évaluation

- SIS CHARMs Hardware InstallationDocument48 pagesSIS CHARMs Hardware InstallationSaad BroPas encore d'évaluation

- DeltaV Workstation and Server Hardware - Product Data Sheet - October 2021Document22 pagesDeltaV Workstation and Server Hardware - Product Data Sheet - October 2021Scribd AllPas encore d'évaluation

- As IEC 61131.2-2004 Programmable Controllers Equipment Requirements and TestsDocument14 pagesAs IEC 61131.2-2004 Programmable Controllers Equipment Requirements and TestsSAI Global - APACPas encore d'évaluation

- 3BSE020923-510 B en S800 I O Getting Started PDFDocument330 pages3BSE020923-510 B en S800 I O Getting Started PDFinelecstarPas encore d'évaluation

- Manual Book RTC EditorDocument384 pagesManual Book RTC Editorandi wardimanPas encore d'évaluation

- Ovation ProfibusDocument128 pagesOvation ProfibusthienPas encore d'évaluation

- B0750ap F PDFDocument328 pagesB0750ap F PDFAnonymous u0wETydFPas encore d'évaluation

- Emerson Ovation ConnectivityDocument3 pagesEmerson Ovation ConnectivitynpipariyaPas encore d'évaluation

- Ovation IntroductionDocument8 pagesOvation IntroductionMagoroku D. YudhoPas encore d'évaluation

- SICAM A8000 - HMI - ProfileDocument2 pagesSICAM A8000 - HMI - ProfileChristian Vasquez MedranoPas encore d'évaluation

- B0700ap ADocument76 pagesB0700ap ARodrigoCastilloAcostaPas encore d'évaluation

- 02 - Ov236-01-Sis HWDocument49 pages02 - Ov236-01-Sis HWSelva ManianPas encore d'évaluation

- Yokogawa DCS Tutorials - Configuration of Analog Input (Transmitter)Document16 pagesYokogawa DCS Tutorials - Configuration of Analog Input (Transmitter)Shumraiz MPas encore d'évaluation

- FDT DTMDocument6 pagesFDT DTMsathyabnPas encore d'évaluation

- Overview of Configuration Studio and Station: Superior, Flexible, and Efficient !!Document46 pagesOverview of Configuration Studio and Station: Superior, Flexible, and Efficient !!CorriePas encore d'évaluation

- Ti33j01j10-01en 004Document232 pagesTi33j01j10-01en 004Cappu CinoPas encore d'évaluation

- Product Manual 26518V3 (Revision C) : Micronet TMR 5009Ft Fault-Tolerant Steam Turbine ControlDocument240 pagesProduct Manual 26518V3 (Revision C) : Micronet TMR 5009Ft Fault-Tolerant Steam Turbine Controlkazmi81Pas encore d'évaluation

- s71200 System Manual en-US en-USDocument1 352 pagess71200 System Manual en-US en-USHoàng BửuPas encore d'évaluation

- Ow351 60 PDFDocument390 pagesOw351 60 PDFHashim BukhariPas encore d'évaluation

- S-Series Interface For PROVOX IODocument44 pagesS-Series Interface For PROVOX IOSaad BroPas encore d'évaluation

- ESD Ovation SystemDocument7 pagesESD Ovation SystemMuhammadIkhsanRestiadiPas encore d'évaluation

- GFK1533-VersaMax DeviceNet Communication ModulesDocument54 pagesGFK1533-VersaMax DeviceNet Communication ModulesSantosh GopalPas encore d'évaluation

- Et200sp Di 16x24vdc ST Manual en-US en-USDocument31 pagesEt200sp Di 16x24vdc ST Manual en-US en-USQuy HoangPas encore d'évaluation

- R3 - 1140 Ovation Record Types Reference PDFDocument342 pagesR3 - 1140 Ovation Record Types Reference PDFOleg SergeevPas encore d'évaluation

- 1.CENTUM VP Fundamentals For OperationDocument2 pages1.CENTUM VP Fundamentals For Operationabdel taibPas encore d'évaluation

- RSLOGIX5000 Programming A Clear and Concise ReferenceD'EverandRSLOGIX5000 Programming A Clear and Concise ReferencePas encore d'évaluation

- Process Control System A Complete Guide - 2020 EditionD'EverandProcess Control System A Complete Guide - 2020 EditionPas encore d'évaluation

- Ovation I/O: FeaturesDocument5 pagesOvation I/O: FeaturesNguyễn Quang HiệpPas encore d'évaluation

- Abb Iec 60947-2Document28 pagesAbb Iec 60947-2Dan100% (6)

- Model STR700 (DP, GP) Remote SealsDocument10 pagesModel STR700 (DP, GP) Remote SealsNaseer HydenPas encore d'évaluation

- R Series XP Operating InstructionsDocument11 pagesR Series XP Operating InstructionsNaseer HydenPas encore d'évaluation

- Spilt Range Main & Auxillary Air BlowerDocument1 pageSpilt Range Main & Auxillary Air BlowerNaseer HydenPas encore d'évaluation

- Reactive Power Compensation in 25kV 50Hz Contact NetworkDocument10 pagesReactive Power Compensation in 25kV 50Hz Contact NetworkNaseer HydenPas encore d'évaluation

- Electrical Calculation ExampleDocument15 pagesElectrical Calculation ExampleAbhoe StankPas encore d'évaluation

- 991 Thrust Transmitter Datasheet 141618h PDFDocument12 pages991 Thrust Transmitter Datasheet 141618h PDFNaseer HydenPas encore d'évaluation

- Product Catalogue: ConnectorDocument2 pagesProduct Catalogue: ConnectorNaseer HydenPas encore d'évaluation

- Protect Overcurrent Relay 7SJ62Document35 pagesProtect Overcurrent Relay 7SJ62Naseer HydenPas encore d'évaluation

- F80 Manual RevE PDFDocument17 pagesF80 Manual RevE PDFNaseer HydenPas encore d'évaluation

- Gas Analysis: Calomat 62Document144 pagesGas Analysis: Calomat 62Naseer HydenPas encore d'évaluation

- NFPA 70E Compliance GuideDocument1 pageNFPA 70E Compliance GuidejesusbarajasPas encore d'évaluation

- Pull Rope SwitchDocument3 pagesPull Rope SwitchNaseer HydenPas encore d'évaluation

- Service Window Installation InstructionsDocument4 pagesService Window Installation InstructionsNaseer HydenPas encore d'évaluation

- Parker Technical GuideDocument172 pagesParker Technical GuideWerner Schulz100% (1)

- Swagelok Hand Tube Bender ManualDocument32 pagesSwagelok Hand Tube Bender Manualharrywj100% (1)

- 1TNC911104M0205 MCUSetup User Guide (2016) - R5Document27 pages1TNC911104M0205 MCUSetup User Guide (2016) - R5Naseer HydenPas encore d'évaluation

- 02 - 2012 - Enus Drager Polytron 8100Document40 pages02 - 2012 - Enus Drager Polytron 8100Roberto de la CruzPas encore d'évaluation

- INTECONT® PLUS For Measuring Systems: % Compact Weighing Electronics ForDocument8 pagesINTECONT® PLUS For Measuring Systems: % Compact Weighing Electronics ForNaseer HydenPas encore d'évaluation

- MULTIBELT® Multi-Idler Belt WeighersDocument4 pagesMULTIBELT® Multi-Idler Belt WeighersDan Hidalgo QuintoPas encore d'évaluation

- Jamesbury® Support Literature 2012: DemosDocument1 pageJamesbury® Support Literature 2012: DemosNaseer HydenPas encore d'évaluation

- Motor ClasstyDocument128 pagesMotor Classtywatep_08Pas encore d'évaluation

- Asco Series 551 553 Direct Mount Inline Spool CatalogDocument4 pagesAsco Series 551 553 Direct Mount Inline Spool CatalogNaseer HydenPas encore d'évaluation

- Neldisc Metal Seated High Performance Triple Eccentric Disc ValveDocument36 pagesNeldisc Metal Seated High Performance Triple Eccentric Disc ValveNaseer HydenPas encore d'évaluation

- INTECONT® PLUS For Measuring Systems: % Compact Weighing Electronics ForDocument8 pagesINTECONT® PLUS For Measuring Systems: % Compact Weighing Electronics ForNaseer HydenPas encore d'évaluation

- Jamesbury® Wafer-Sphere® ValveDocument1 pageJamesbury® Wafer-Sphere® ValveNaseer HydenPas encore d'évaluation

- Pi - RSP254 - 255 - enDocument28 pagesPi - RSP254 - 255 - enNaseer HydenPas encore d'évaluation

- Motor ClasstyDocument128 pagesMotor Classtywatep_08Pas encore d'évaluation

- Parker Technical GuideDocument172 pagesParker Technical GuideWerner Schulz100% (1)

- How To Google Like A Pro-10 Tips For More Effective GooglingDocument10 pagesHow To Google Like A Pro-10 Tips For More Effective GooglingMinh Dang HoangPas encore d'évaluation

- Kooltherm PipeDocument8 pagesKooltherm Pipenaseema1Pas encore d'évaluation

- Katie Todd Week 4 spd-320Document4 pagesKatie Todd Week 4 spd-320api-392254752Pas encore d'évaluation

- JEdwards PaperDocument94 pagesJEdwards PaperHassan Hitch Adamu LafiaPas encore d'évaluation

- Sierra Wireless firmware versions for cellular modulesDocument20 pagesSierra Wireless firmware versions for cellular modulesjacobbowserPas encore d'évaluation

- Screenshot 2021-10-02 at 12.22.29 PMDocument1 pageScreenshot 2021-10-02 at 12.22.29 PMSimran SainiPas encore d'évaluation

- 028 Ptrs Modul Matematik t4 Sel-96-99Document4 pages028 Ptrs Modul Matematik t4 Sel-96-99mardhiah88Pas encore d'évaluation

- PNB V. Se, Et Al.: 18 April 1996 G.R. No. 119231 Hermosisima, JR., J.: Special Laws - Warehouse Receipts LawDocument3 pagesPNB V. Se, Et Al.: 18 April 1996 G.R. No. 119231 Hermosisima, JR., J.: Special Laws - Warehouse Receipts LawKelvin ZabatPas encore d'évaluation

- Journal of Petroleum Science and Engineering: Bin Yuan, David A. WoodDocument13 pagesJournal of Petroleum Science and Engineering: Bin Yuan, David A. Woodarash7495Pas encore d'évaluation

- MockupDocument1 pageMockupJonathan Parra100% (1)

- Examples 5 PDFDocument2 pagesExamples 5 PDFskaderbe1Pas encore d'évaluation

- Steps To Private Placement Programs (PPP) DeskDocument7 pagesSteps To Private Placement Programs (PPP) DeskPattasan U100% (1)

- LogDocument85 pagesLogJo NasPas encore d'évaluation

- Transmission Line ProtectionDocument111 pagesTransmission Line ProtectioneccabadPas encore d'évaluation

- Make $50 A Day Autopilot MethodDocument4 pagesMake $50 A Day Autopilot MethodJadon BoytonPas encore d'évaluation

- Cold Fear manual_englishDocument10 pagesCold Fear manual_englishHelmi IsmunandarPas encore d'évaluation

- Conflict of Laws (Summary Paper)Document13 pagesConflict of Laws (Summary Paper)Anonymous CWcXthhZgxPas encore d'évaluation

- Emiish Me: Answer BookDocument7 pagesEmiish Me: Answer BookNickPas encore d'évaluation

- Payment Solutions For Travel Platform: SabreDocument2 pagesPayment Solutions For Travel Platform: Sabrehell nahPas encore d'évaluation

- Danielle Smith: To Whom It May ConcernDocument2 pagesDanielle Smith: To Whom It May ConcernDanielle SmithPas encore d'évaluation

- Balanced Modulator and Demodulator ExperimentDocument6 pagesBalanced Modulator and Demodulator ExperimentShubham SharmaPas encore d'évaluation

- Potential Land Suitability For TeaDocument26 pagesPotential Land Suitability For TeaGautam NatrajanPas encore d'évaluation

- Family health assessment nursing problemsDocument8 pagesFamily health assessment nursing problemsMari MazPas encore d'évaluation

- Aegis SGR BrochureDocument2 pagesAegis SGR BrochureAmazonas ManutençãoPas encore d'évaluation

- Opening A New Company in Bangladesh (FAQ)Document12 pagesOpening A New Company in Bangladesh (FAQ)nomanpur100% (1)

- 6 Acop v. OmbudsmanDocument1 page6 Acop v. OmbudsmanChester Santos SoniegaPas encore d'évaluation

- Black Box Components and FunctionsDocument9 pagesBlack Box Components and FunctionsSaifPas encore d'évaluation

- Daftar Pustaka Marketing ResearchDocument2 pagesDaftar Pustaka Marketing ResearchRiyan SaputraPas encore d'évaluation

- Claim Form - Group Health InsuranceDocument5 pagesClaim Form - Group Health Insurancevizag mdindiaPas encore d'évaluation

- Rochester MN Unified Development Code (Draft)Document442 pagesRochester MN Unified Development Code (Draft)randyPas encore d'évaluation